CAD Project Ideas

#21

Staging Lane

Join Date: Apr 2011

Location: Metro Deroit

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

probably gonna get some bashing for this but i would like to see an IRS kit for 98-02 camaro or trans am. ie: rear frame, brakets, axles, diff, springs shocks and everyting. and as bolt in as possible.

#23

#24

#26

Teching In

Join Date: Jan 2012

Location: Fort Wayne Indiana

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

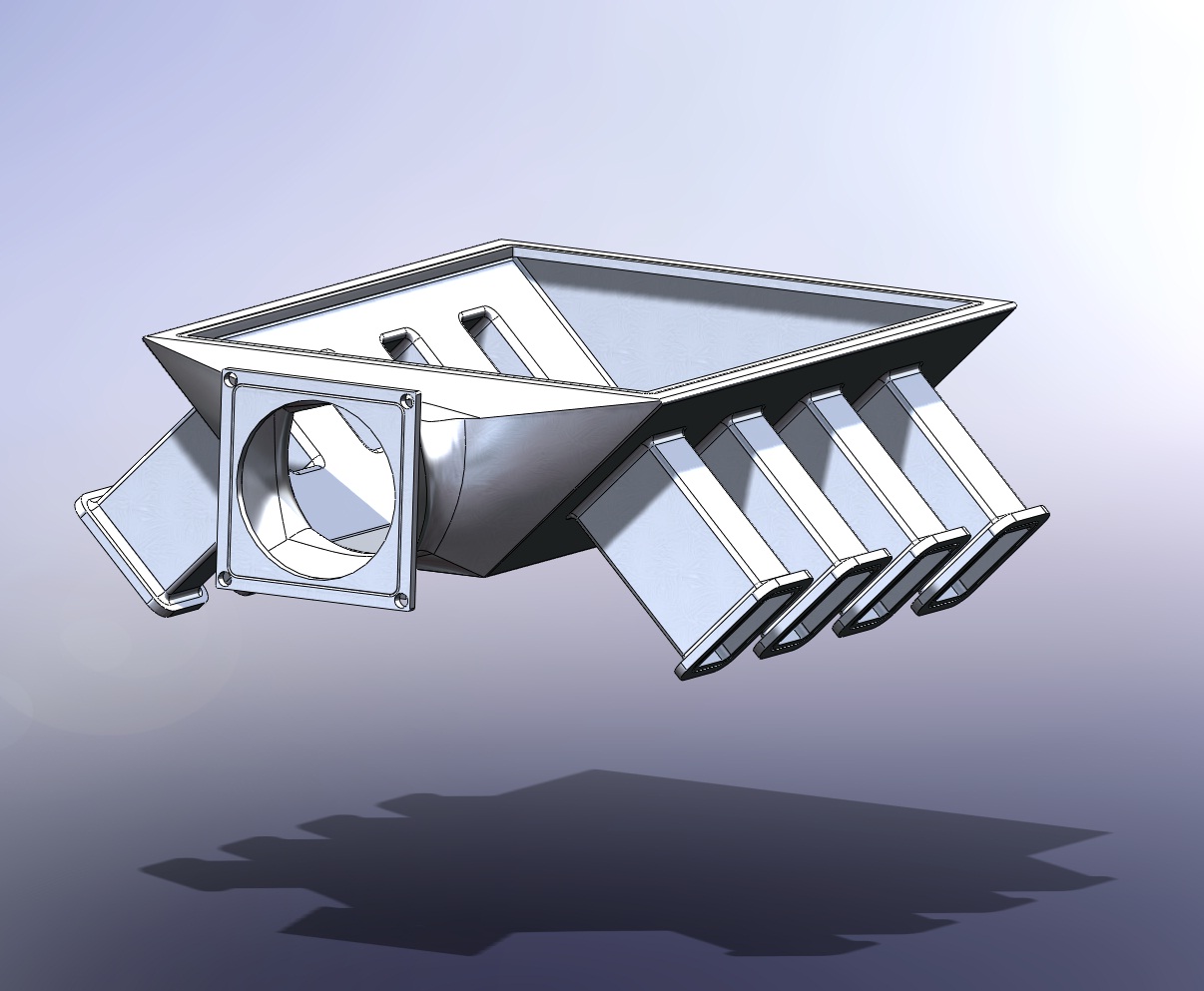

why not do what most professionals do. Send it out have a 3D scan done and alter the model from there. That is how we start on a lot of projects here at work. This will save a very large chunk of time when it comes to getting the 3D solid model done. How about a redesign of a FAST 102 intake where the MAP will not hit on the fire wall.

#27

A piston and rod would take me an hour and a half. This has to be something that will take me the entire semester. And also and assembly. I'm using Solidworks.

The twin turbo kit would be a great project. Maybe do a mirror image turbo kit for a car that doesn't have one specifically made for it yet.

The twin turbo kit would be a great project. Maybe do a mirror image turbo kit for a car that doesn't have one specifically made for it yet.

http://www.youtube.com/watch?v=b8ezQMdtyW4

#28

I love the independent rear suspension bolt on project also, that will keep you occupied for an extended period, especially if you want to do any engineering on it to back it up.

Quick word of advice to help you learn: whenever you are modeling a part, always think about how you would make it. Ask yourself, can I machine this feature? How can I get a mill in there? Would this be easier cast or as a weldment instead? Can I make more features round so I can make it all on a lathe? Do I need this fillet / chamfer or is it just for looks?

From experience, it sucks finishing a really cool design for a part and then realizing you can't make it .

.

Quick word of advice to help you learn: whenever you are modeling a part, always think about how you would make it. Ask yourself, can I machine this feature? How can I get a mill in there? Would this be easier cast or as a weldment instead? Can I make more features round so I can make it all on a lathe? Do I need this fillet / chamfer or is it just for looks?

From experience, it sucks finishing a really cool design for a part and then realizing you can't make it

.

.

#29

Launching!

iTrader: (20)

I love the independent rear suspension bolt on project also, that will keep you occupied for an extended period, especially if you want to do any engineering on it to back it up.

Quick word of advice to help you learn: whenever you are modeling a part, always think about how you would make it. Ask yourself, can I machine this feature? How can I get a mill in there? Would this be easier cast or as a weldment instead? Can I make more features round so I can make it all on a lathe? Do I need this fillet / chamfer or is it just for looks?

From experience, it sucks finishing a really cool design for a part and then realizing you can't make it .

.

Quick word of advice to help you learn: whenever you are modeling a part, always think about how you would make it. Ask yourself, can I machine this feature? How can I get a mill in there? Would this be easier cast or as a weldment instead? Can I make more features round so I can make it all on a lathe? Do I need this fillet / chamfer or is it just for looks?

From experience, it sucks finishing a really cool design for a part and then realizing you can't make it

.

.

#30

Launching!

Join Date: Jan 2012

Location: Davisburg, MI

Posts: 205

Likes: 0

Received 0 Likes

on

0 Posts

#31

On The Tree

Join Date: May 2012

Location: Keller, TX

Posts: 101

Likes: 0

Received 0 Likes

on

0 Posts

Might start off with something a little simpler and go from there.

A header is a pretty good start as it will teach you sweeps, shelling and the like. Or, build the whole thing from surfaces.

A header is a pretty good start as it will teach you sweeps, shelling and the like. Or, build the whole thing from surfaces.

#33

On The Tree

Join Date: May 2012

Location: Keller, TX

Posts: 101

Likes: 0

Received 0 Likes

on

0 Posts

lt1detroit,

Very nice project. Are all the line-up dimensions accurate? Any way you could show a cut-away??

I'm working on something similar for a siamese port configuration.

Very nice project. Are all the line-up dimensions accurate? Any way you could show a cut-away??

I'm working on something similar for a siamese port configuration.

#35

wow this is a good thread, ive been trying to learn some solidworks for a few months now. those headers and intakes look amazing, yall need to do a solidworks tutorial lol.

#36

TECH Senior Member

iTrader: (59)

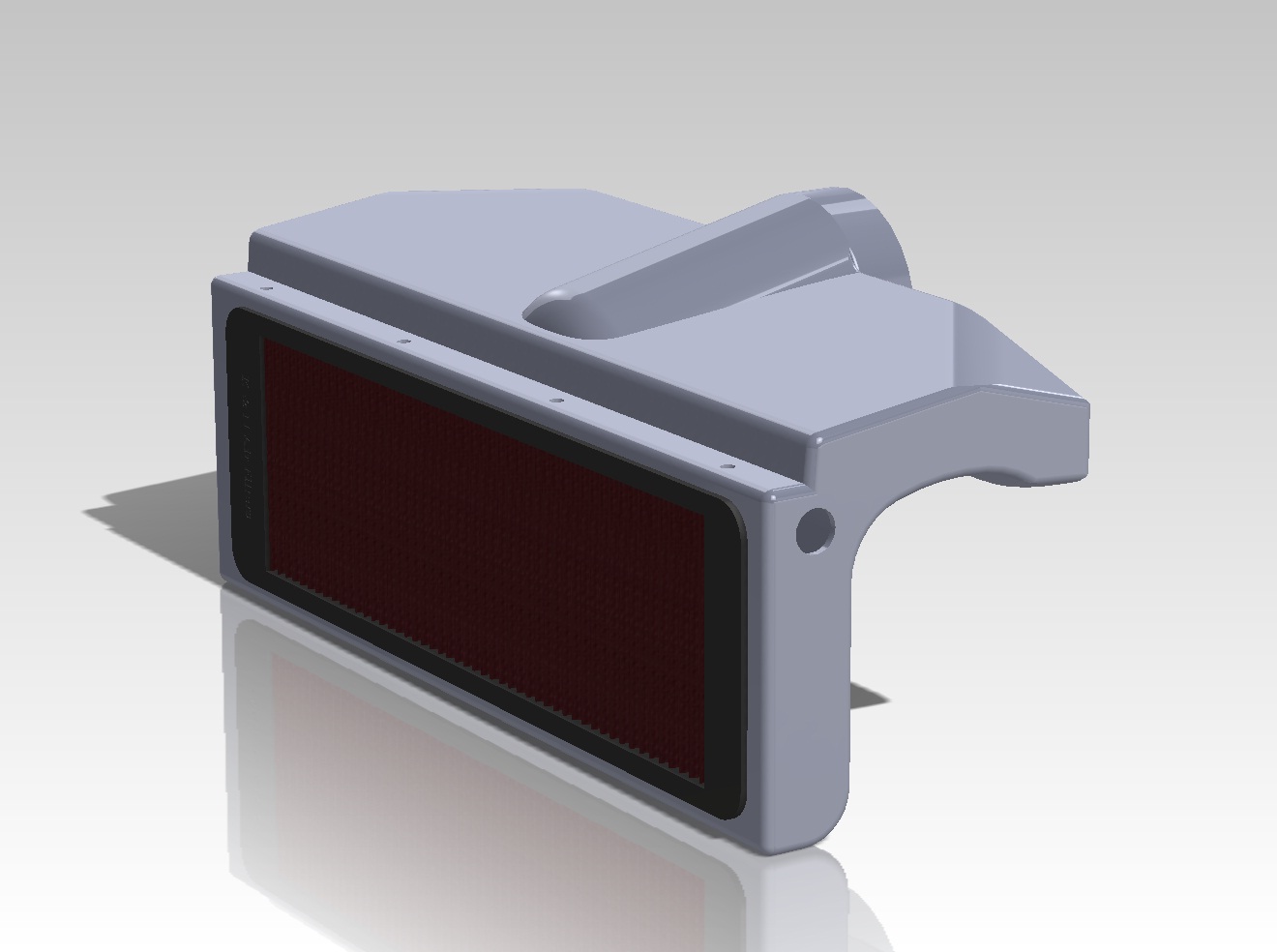

ive made a few things for my car and other peoples for ideas:

https://picasaweb.google.com/1144453...CMW5g6m9r-3JMg

my personal fav is probably the intercooler i designed and made

https://picasaweb.google.com/1144453...CMW5g6m9r-3JMg

my personal fav is probably the intercooler i designed and made

#37

On The Tree

Join Date: May 2012

Location: Keller, TX

Posts: 101

Likes: 0

Received 0 Likes

on

0 Posts

FWIW, the header was built and rendered in Catia, SW's big brother. The truck was my first real attempt at pushing SW's surfacing capabilities. It can be a bit of a challenge to surface with where continuity is important but overall a great package.

#38

I've always liked designing wheels with SolidWorks. But they only take less than an hour each haha.

I think you could try to tackle a complete LS1 engine. Wouldn't be easy, but would definitely be cool, especially if you could do a rapid prototype of the piece for your desk.

How many CAD designers does Tech have? I finished my 2nd year towards my bachelors in CAD product design.

I think you could try to tackle a complete LS1 engine. Wouldn't be easy, but would definitely be cool, especially if you could do a rapid prototype of the piece for your desk.

How many CAD designers does Tech have? I finished my 2nd year towards my bachelors in CAD product design.

#39

Launching!

iTrader: (20)

I've always liked designing wheels with SolidWorks. But they only take less than an hour each haha.

I think you could try to tackle a complete LS1 engine. Wouldn't be easy, but would definitely be cool, especially if you could do a rapid prototype of the piece for your desk.

How many CAD designers does Tech have? I finished my 2nd year towards my bachelors in CAD product design.

I think you could try to tackle a complete LS1 engine. Wouldn't be easy, but would definitely be cool, especially if you could do a rapid prototype of the piece for your desk.

How many CAD designers does Tech have? I finished my 2nd year towards my bachelors in CAD product design.

#40

Launching!

Join Date: Jan 2012

Location: Davisburg, MI

Posts: 205

Likes: 0

Received 0 Likes

on

0 Posts

Graphite, flow pens & aluminum stylus

Applicon Bravo

PDGS

Aries

SDRC I-Deas

UG

CATIA

Those are just the design softwares.

Last edited by ACCLR8N; 05-19-2012 at 11:19 AM. Reason: Okay, that was definately braggy