turbine supercharger.

#22

skunk, are centrifugals more efficient than axials these days?? im not really upto date on jet engines, but i thought the centi. jet engines died a death?

just thinking about altitude and how it effects engines. toying with some ideas really.

is there any sites or stuff you could point me towards???

thanks Chris.

just thinking about altitude and how it effects engines. toying with some ideas really.

is there any sites or stuff you could point me towards???

thanks Chris.

#23

TECH Resident

Join Date: Dec 2004

Location: Baltimore, MD.

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

All of the production jets I know of are axials. Centrifugals for jet duty did go out of style quite a while ago. Someone posted earlier that in the bigger sizes the axials have an advantage, which is probably correct (given that big jets are axial and turbochargers are still centrifugal). Question would be where the two cross over (axial take the lead) and what factors determine that efficiency crossover, and how to design small efficient axial units that are reasonably affordable.

I would think that doing a compound setup with an axial and some other device would be unnecessary. Typically, an axial compressor has multiple stages, so building additional boost would be as "simple" as adding additional stages.

Might also be easy to regulate boost by allowing the air to bypass a certain number of stages. Say for example you build a 6 stage setup to make 20 psi (which may or may not be practical). If you want to run lower boost (say 12psi), you might be able to set up your compressor so that you can efficiently bypass the last 2 stages. Not sure what the fluid mechanics / thermodynamics would be of trying to "idle" a couple stages, nor the mechanics of bypassing them.

Interesting set of thoughts. Hadn't ever even thought about an axial setup for a gasoline / piston engine. Guess I'll have to pick the brain of my aerospace engineering sister (who's busy testing a FA-18 Super Hornet engine upgrade package) next time I see her.

This reminds me of some of the last radial piston aircraft (before being superceded by jets). Engines on the Constellations (Connies or Super Connies) were multi-row radials (28 cylinders, 4 rows of 7) with compounding, 2 stage centrifugal superchargers (I think they may have been 2 speed too), with I believe 3 exhaust turbines that were geared to the output shaft. Not sure if the turbines were axial or centrifugal. Take Off Power was something around 3500hp, IIRC.

'JustDreamin'

I would think that doing a compound setup with an axial and some other device would be unnecessary. Typically, an axial compressor has multiple stages, so building additional boost would be as "simple" as adding additional stages.

Might also be easy to regulate boost by allowing the air to bypass a certain number of stages. Say for example you build a 6 stage setup to make 20 psi (which may or may not be practical). If you want to run lower boost (say 12psi), you might be able to set up your compressor so that you can efficiently bypass the last 2 stages. Not sure what the fluid mechanics / thermodynamics would be of trying to "idle" a couple stages, nor the mechanics of bypassing them.

Interesting set of thoughts. Hadn't ever even thought about an axial setup for a gasoline / piston engine. Guess I'll have to pick the brain of my aerospace engineering sister (who's busy testing a FA-18 Super Hornet engine upgrade package) next time I see her.

This reminds me of some of the last radial piston aircraft (before being superceded by jets). Engines on the Constellations (Connies or Super Connies) were multi-row radials (28 cylinders, 4 rows of 7) with compounding, 2 stage centrifugal superchargers (I think they may have been 2 speed too), with I believe 3 exhaust turbines that were geared to the output shaft. Not sure if the turbines were axial or centrifugal. Take Off Power was something around 3500hp, IIRC.

'JustDreamin'

Last edited by 'JustDreamin'; 04-18-2007 at 04:37 PM.

#25

Originally Posted by JustDreamin

All of the production jets I know of are axials. Centrifugals for jet duty did go out of style quite a while ago.

Someone posted earlier that in the bigger sizes the axials have an advantage, which is probably correct (given that big jets are axial and turbochargers are still centrifugal).

Someone posted earlier that in the bigger sizes the axials have an advantage, which is probably correct (given that big jets are axial and turbochargers are still centrifugal).

http://www.rolls-royce.com/education...y02/flash.html

#26

TECH Junkie

iTrader: (7)

Join Date: Aug 2004

Location: Prairie de Femme, LA

Posts: 3,809

Likes: 0

Received 0 Likes

on

0 Posts

seems like size would be one of the biggest limiting factors in an automotive application as far as a supercharger/turbocharger, primarily in length.

another completely different idea, although idk how efficient they are, is a rotary supercharger. the rotary engine supposively developed out of a rotary supercharger.

another completely different idea, although idk how efficient they are, is a rotary supercharger. the rotary engine supposively developed out of a rotary supercharger.

#27

TECH Regular

iTrader: (3)

Join Date: Jan 2005

Location: Magnolia, Texas

Posts: 464

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Phoenix 5.7

another completely different idea, although idk how efficient they are, is a rotary supercharger. the rotary engine supposively developed out of a rotary supercharger.

http://www.mazda.com/mazdaspirit/rotary/story/

Vernon

#28

JustDreamin,

Yes most current jet engines use purely axial compressors with some notable exceptions. First would be Williams and PW Canada, they use centrifugal as last stage before combustion chamber. Size is the key here as these engines are typically under 5000 lb of thrust. I canít remember exact pressure ratio of centrifugal but feel fairly comfortable saying ~ 4:1, this cuts down on manufacturing cost as these engines are designed to be cost effective. The Williams engine is a result of a NASA funded program that sought to bring jet engine cost down to a reasonable or attainable level. The PW Canada engine uses tube diffuser that they have Patent on, so information is sparse, but looks like it may have some benefits in channeling air to combustion chamber. If you want I may be able to dig up some cutaways and post later or PM with email address and Iíll pass it on.

Again Iím not saying centrifugal is the end all but when talking about automotive type mass flows, axial does have some limitations. As an example target running clearance is 1% of inlet blade height, so with a blade that is less then 0.5Ē (closer to 0.4Ē) in height that creates some manufacturing headaches, also with larger running clearance efficiency and surge margins suffer. Then with such a small and fragile blade, surge becomes very large concern. Surge in a axial is much worse then a centrifugal and propensity to vibrate is much higher. I cant think of any modern commercial jet engine that uses aluminum alloys for compressor stages, titanium is the norm (cost being key).

As far as bypassing a stage or two, I thought about that a few years ago. Doable yes but turning losses add up, then never mind cost. On paper theoretical boost curve is appealing.

Oddly a few years ago I spent allot of time looking at 2-stage highly loaded axial flow compressor but the scale concerned me. Blades had to be steel or titanium to get decent efficiency and retain structural integrity. Then as mentioned earlier blades where small and aerodynamically complex resulting in an investment casting from hell. Then look at compressor maps for axial and centrifugal stages, note tip speeds at x pressure ratio.

I have since moved onto a different concept, but with some penalties that being high tip speeds by comparison to centrifugal at same pressure ratio.

Oh, I have spoken to Richard current owner of Latham superchargers and he has yet to get under 4-stage design for say 10-12 psi of boost.

Midnight F-117A,

Axial compressors are actually more susceptible to FOD damage then centrifugals.

chuntington101,

Send me a PM with your email address and Iíll send some turbomachinery books in PDF format your way.

Mike

Yes most current jet engines use purely axial compressors with some notable exceptions. First would be Williams and PW Canada, they use centrifugal as last stage before combustion chamber. Size is the key here as these engines are typically under 5000 lb of thrust. I canít remember exact pressure ratio of centrifugal but feel fairly comfortable saying ~ 4:1, this cuts down on manufacturing cost as these engines are designed to be cost effective. The Williams engine is a result of a NASA funded program that sought to bring jet engine cost down to a reasonable or attainable level. The PW Canada engine uses tube diffuser that they have Patent on, so information is sparse, but looks like it may have some benefits in channeling air to combustion chamber. If you want I may be able to dig up some cutaways and post later or PM with email address and Iíll pass it on.

Again Iím not saying centrifugal is the end all but when talking about automotive type mass flows, axial does have some limitations. As an example target running clearance is 1% of inlet blade height, so with a blade that is less then 0.5Ē (closer to 0.4Ē) in height that creates some manufacturing headaches, also with larger running clearance efficiency and surge margins suffer. Then with such a small and fragile blade, surge becomes very large concern. Surge in a axial is much worse then a centrifugal and propensity to vibrate is much higher. I cant think of any modern commercial jet engine that uses aluminum alloys for compressor stages, titanium is the norm (cost being key).

As far as bypassing a stage or two, I thought about that a few years ago. Doable yes but turning losses add up, then never mind cost. On paper theoretical boost curve is appealing.

Oddly a few years ago I spent allot of time looking at 2-stage highly loaded axial flow compressor but the scale concerned me. Blades had to be steel or titanium to get decent efficiency and retain structural integrity. Then as mentioned earlier blades where small and aerodynamically complex resulting in an investment casting from hell. Then look at compressor maps for axial and centrifugal stages, note tip speeds at x pressure ratio.

I have since moved onto a different concept, but with some penalties that being high tip speeds by comparison to centrifugal at same pressure ratio.

Oh, I have spoken to Richard current owner of Latham superchargers and he has yet to get under 4-stage design for say 10-12 psi of boost.

Midnight F-117A,

Axial compressors are actually more susceptible to FOD damage then centrifugals.

chuntington101,

Send me a PM with your email address and Iíll send some turbomachinery books in PDF format your way.

Mike

#29

Originally Posted by Skunkworks

Midnight F-117A,

Axial compressors are actually more susceptible to FOD damage then centrifugals.

#30

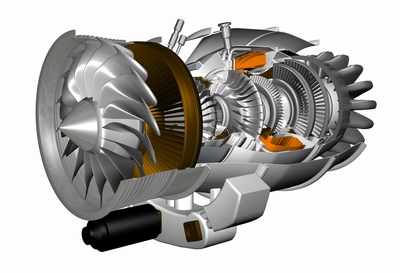

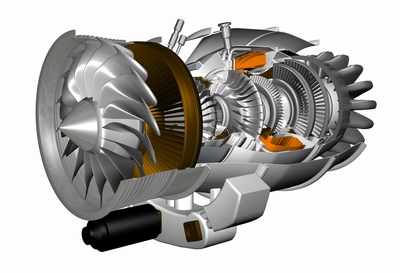

Here are some pics...

All engines pictured below except F119 use centrifugal as last compressor stage to reduce component count thus cost. Engines are new in design actually some of the newest engines introduced.

FJ33-1

PW610F low res

PW625F high res *** Note tube difusers can be seen ***

Military F119 cutaway

Mike

All engines pictured below except F119 use centrifugal as last compressor stage to reduce component count thus cost. Engines are new in design actually some of the newest engines introduced.

FJ33-1

PW610F low res

PW625F high res *** Note tube difusers can be seen ***

Military F119 cutaway

Mike

#31

http://www.rcturbine.com/

Not shure what kind of cfm somthing like this would flow, but it is small(4.37") and will handle 128000 rpm(no thats not a typo)

Prolly not real reliable at that rpm but that may be whats needed for such a small unit.

Not shure what kind of cfm somthing like this would flow, but it is small(4.37") and will handle 128000 rpm(no thats not a typo)

Prolly not real reliable at that rpm but that may be whats needed for such a small unit.

#32

People don't give the WWII era aircraft engine manufacturers enough credit for all the advances they pioneered. This drawing of a Napier Nomad is extracted from "A History of Aircraft Piston Engines" by Herschel Smith.

Note the axial compressor, axial turbine, shaft drive, CVT and jet thrust.

Note the axial compressor, axial turbine, shaft drive, CVT and jet thrust.

#33

thanks for all the info guys. its really helped out.

i did come across one site that made MASSIVE marine turbos for 2stroke diesels. the used a axial-turbine on the turbine side. could these be used for cars??? or are the centrifugal turbines better suited???

thanks Chris.

i did come across one site that made MASSIVE marine turbos for 2stroke diesels. the used a axial-turbine on the turbine side. could these be used for cars??? or are the centrifugal turbines better suited???

thanks Chris.