Line pressures

#1

I'm doing some r&d work on a trans controller and looking at pressures that are default settings. What I'm looking for is the psi of a gm controlled 60E? I know how to ck and what max psi should be. Also what is your opinions as minimum psi that a 60E should be ran at? Thanks for any input

#2

Moderator

You are obviously interested in the technical details of how the transmission works. The best reference for this is the GM Hydramatic 4L60-E Technicians Guide. Here is an online version of the guide:

http://www.grail-ss.com/GRAIL%20Webs...ETechGuide.pdf

Page 28 described how the pressure is regulated.

First you need to know that the valve body has a regulated pressure line called the AFL. It has a max pressure of about 115psi, but for tuning purposes it is considered 96 psi. The EPC (pressure control solenoid) then controls how much of this 96 psi pressure is applied to the boost valve; this "torque signal" can be anywhere from 0 to 96.

At the max 96 psi pressure, the boost valve is pressed against a spring and pressure regulator valve which then increases the line pressure to the max, typically in the 180 psi range. A bigger boost valve will press harder and increase the pressure further, typically to 230 psi. With a torque signal of 0, line pressure drops to the minimum, typically around 60 psi. Larger boost valves usually come with a spring to increase the minimum pressure a bit, typically 75psi.

Tuning the line and shift pressure is done by putting values between 0 and 96 (the torque signal) into various tables. Assuming you have a bigger boost valve, the values 0-96 therefore correspond to a line pressure of 75-230psi, and I think it is fairly linear.

I have monitored my line pressure with a gauge while driving and it varies from 75 to 230 psi depending upon throttle position.

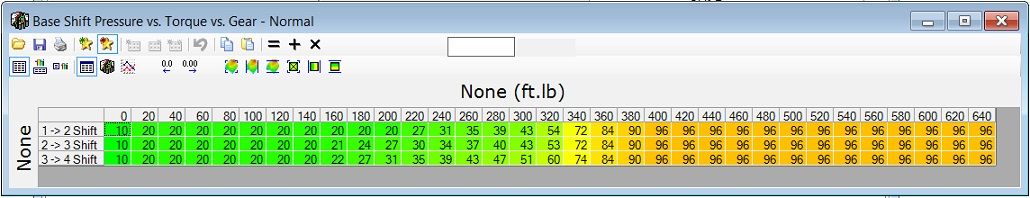

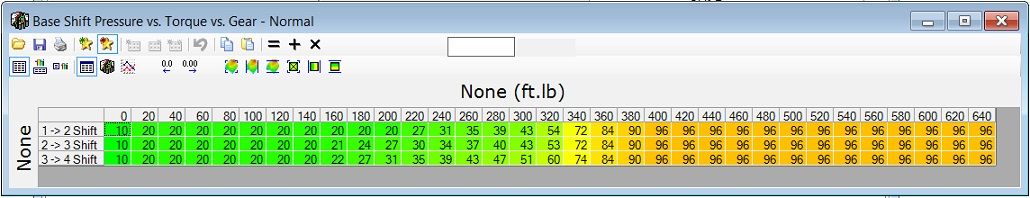

Here is the tuning table I use for shifts:

I won't claim that my description is exactly correct, but it is close.

http://www.grail-ss.com/GRAIL%20Webs...ETechGuide.pdf

Page 28 described how the pressure is regulated.

First you need to know that the valve body has a regulated pressure line called the AFL. It has a max pressure of about 115psi, but for tuning purposes it is considered 96 psi. The EPC (pressure control solenoid) then controls how much of this 96 psi pressure is applied to the boost valve; this "torque signal" can be anywhere from 0 to 96.

At the max 96 psi pressure, the boost valve is pressed against a spring and pressure regulator valve which then increases the line pressure to the max, typically in the 180 psi range. A bigger boost valve will press harder and increase the pressure further, typically to 230 psi. With a torque signal of 0, line pressure drops to the minimum, typically around 60 psi. Larger boost valves usually come with a spring to increase the minimum pressure a bit, typically 75psi.

Tuning the line and shift pressure is done by putting values between 0 and 96 (the torque signal) into various tables. Assuming you have a bigger boost valve, the values 0-96 therefore correspond to a line pressure of 75-230psi, and I think it is fairly linear.

I have monitored my line pressure with a gauge while driving and it varies from 75 to 230 psi depending upon throttle position.

Here is the tuning table I use for shifts:

I won't claim that my description is exactly correct, but it is close.

#3

Thanks for the link, I will look into that. We have a trans controller that will run a 60e or 80e now. After installing a transducer I seen that our default settings have a starting point around 60 or so psi. Of course you can raise these pressures up if you want. I'm basically just comparing pressures between trans to see if we need to recalibrate our default settings so they will be at a higher psi.