Anyone running a TCI ULTIMATE Street Fighter??

#41

TECH Fanatic

iTrader: (1)

Join Date: Jul 2006

Location: MPLS MN

Posts: 1,215

Likes: 0

Received 0 Likes

on

0 Posts

i cant find a photo of the tci's internals for the exact converter the OP is talking about but this one is the closest i could find http://www.tciauto.com/tc/727-ultima...ing-platehtml/ which looks decent. i was thinking $500 tci. and fyi for jake here is where im seeing photos of parts http://www.protorque.com/torque-conv...ons-parts.html

Last edited by DANOZ28; 02-04-2014 at 01:13 PM.

#42

TECH Fanatic

iTrader: (45)

Your original post asked for me to expand on why a non-billet cover converter would 60' harder than a billet cover.

I was offline most of the day yesterday enjoying the Super Bowl and resting since I typically work 7 days a week, 12+ hrs a day. Responding to your question wasn't high on my priority list.

Then today was busy helping customers, taking orders, and building transmissions. You know, actually doing what an expert in this field does. Not an internet like yourself.

like yourself.

So yes I am an ******* but I would prefer to be that than a whiny bitch like you who gets upset because the big bad transmission guy hurt your little feelings by not answering your question.

I was offline most of the day yesterday enjoying the Super Bowl and resting since I typically work 7 days a week, 12+ hrs a day. Responding to your question wasn't high on my priority list.

Then today was busy helping customers, taking orders, and building transmissions. You know, actually doing what an expert in this field does. Not an internet

like yourself.

like yourself.So yes I am an ******* but I would prefer to be that than a whiny bitch like you who gets upset because the big bad transmission guy hurt your little feelings by not answering your question.

#43

TECH Fanatic

iTrader: (1)

Join Date: Jul 2006

Location: MPLS MN

Posts: 1,215

Likes: 0

Received 0 Likes

on

0 Posts

what really bothers me is the average joe hot rodder cant go to the different websites that sell torque converters and view a list of internal componants along with reasons why i should buy their product. why is that? are torque converter builders really a secret society? i searched & searched until i found a product that specified several parts after which i called & emailed the manufacturer with questions. finally satisfied i made a purchase.

#44

what really bothers me is the average joe hot rodder cant go to the different websites that sell torque converters and view a list of internal componants along with reasons why i should buy their product. why is that? are torque converter builders really a secret society? i searched & searched until i found a product that specified several parts after which i called & emailed the manufacturer with questions. finally satisfied i made a purchase.

Pump, stator, turbine, cover, and clutch if applicable.

That's pretty much the point I've been trying to make as that there isn't a significant difference in the internal components used no matter where the converter comes from. There may be NO difference.

You start out with a basic core, using a pump and stator to make the stall speed, possibly modifying these parts.

You can change the stator from a roller clutch to a mechanical diode, actual sprag, or to a solid stator (spragless) with commonly available parts or kits.

Many of the kits also include new bearings, upgraded bearings, or end caps to upgrade from thrust washers to bearings.

You can use a ring to adapt the stock cover, or a billet cover.

An impeller hub (usually flanged) and heat treated turbine hub are standard in the kits because they must be changed anyway as part of the converter build to mate up to a RWD trans and engine. So this isn't even a "selling point" to me because without it, the converter wouldn't fit your application.

And there isn't much difference visually to the untrained eye inside a converter. So that is why many likely don't show what they do.

#45

TECH Fanatic

iTrader: (1)

Join Date: Jul 2006

Location: MPLS MN

Posts: 1,215

Likes: 0

Received 0 Likes

on

0 Posts

hey jake , how about this question. if you had a buddy & you werent in the business what suggestions / items / features would you tell him to have the converter builder use / add? (for a 400/500 rwhp street - strip converter). thx.

Last edited by DANOZ28; 02-05-2014 at 10:55 AM.

#46

For what type of transmission?

#47

FormerVendor

iTrader: (21)

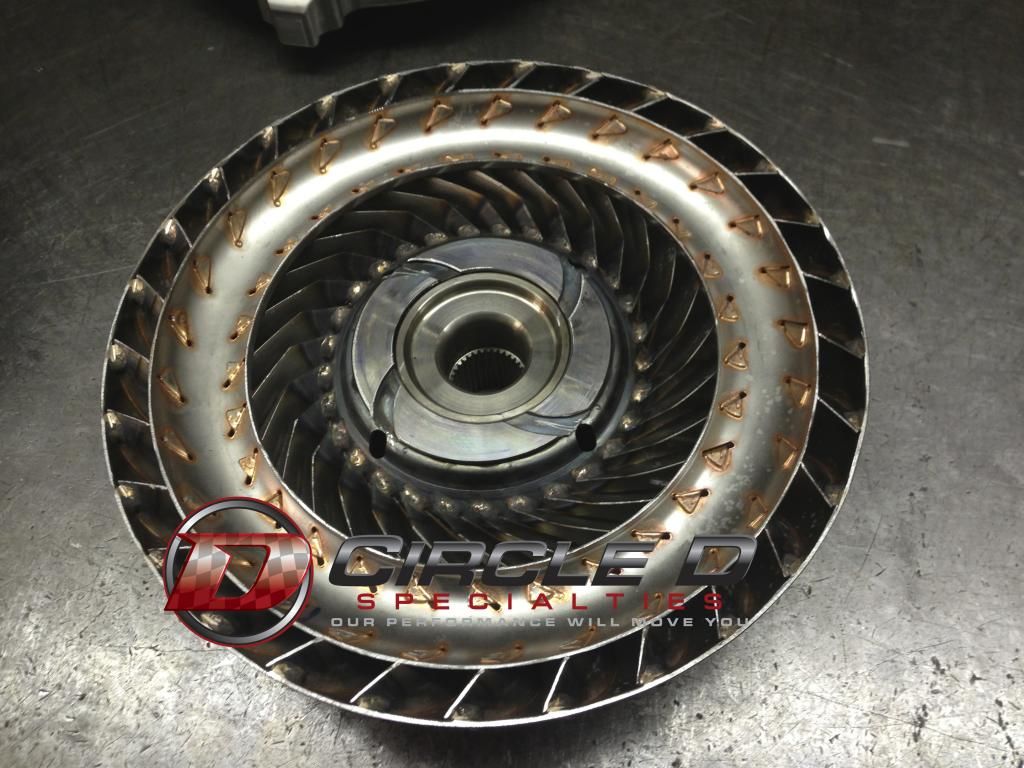

Thought I would chime in here to clear up some things, at least about what Circle D offers. First we will touch on our billet parts. We design and manufacturer all our single disk and multi disk billet parts in house, we do not buy them from the suppliers Jake is referring to. We start off with a 60 pound forging that is produced in the USA, very proud of that, that gets machined in house down to ~12 pounds depending on the transmission type and single or multi disk. We have continually improved and offer several advantages over the conventional industry billet front. Some of which are, a better pad design that moves the load to the side of the converter, deeper threads for better thread engagement, better curves to prevent flexing under high RPM and power. We add a deep groove ball bering on the turbine hub for extreme efficiency and it removes the load from the stator support bushing at high RPM. Our multi disk clutch pack has heat treated steels to prevent any wear on the clutch teeth eliminating the rattle commonly associated with a multi disk. We also incorporate slots in out clutch pack to help prevent drag when foot breaking, great for turbo setups. Our one piece apply piston on our multi disk eliminates the possibility of a weld failure and allows for better flow through the clutch pack when unlocked. I could go on but you get the idea, we have invested a lot of time and R&D to make what we feel is the best billet front in the industry.

Next we will talk about the rest of the converter. Jake is right here, we use the same core options that anybody else does, 245mm, 258mm or 265mm. These 3 diameters along with multiple stator choices let us build a converter to handle just about any vehicle or power level. There are a lot of in house secrets we have learned over the years to achieve different results, stator choice, pump fin angle, stator position, internal clearances just to name a few. As far as the furnace brazing and TIG welding, all our billet converters get a furnace brazed pump and turbine. The 245mm and 265mm have TIG welded blades as well, GM did a great job on the 258mm and they are factory furnace brazed very well and do not require TIG welding till you get into big power.

Cliffs notes - We make our own billet parts in house and build a very nice converter.

Chris

Next we will talk about the rest of the converter. Jake is right here, we use the same core options that anybody else does, 245mm, 258mm or 265mm. These 3 diameters along with multiple stator choices let us build a converter to handle just about any vehicle or power level. There are a lot of in house secrets we have learned over the years to achieve different results, stator choice, pump fin angle, stator position, internal clearances just to name a few. As far as the furnace brazing and TIG welding, all our billet converters get a furnace brazed pump and turbine. The 245mm and 265mm have TIG welded blades as well, GM did a great job on the 258mm and they are factory furnace brazed very well and do not require TIG welding till you get into big power.

Cliffs notes - We make our own billet parts in house and build a very nice converter.

Chris

Last edited by Circle-D; 02-05-2014 at 11:12 AM.

#49

TECH Fanatic

iTrader: (1)

Join Date: Jul 2006

Location: MPLS MN

Posts: 1,215

Likes: 0

Received 0 Likes

on

0 Posts

since i drive a 99 w 4l60e thats my preference. great input circle D , but im a little confused why converters cost so much if the cores & basic parts are all common. cheers everybody! ps when does a car need a multi disk? your photo looks like a work of art.

#50

FormerVendor

iTrader: (21)

Chris

#51

Moderator

iTrader: (11)

Join Date: Mar 2002

Location: East Central Florida

Posts: 12,604

Likes: 0

Received 6 Likes

on

6 Posts

TCI makes a range of converters. The big sellers are the

cheap Streetfighter series. They have wimpy clutches,

but I had no complaints about the fluidic portion of

mine. Where this "Ultimate" falls, relative to the known

wimpy standard Streetfighter versions, you probably ought

to be asking TCI to prove.

cheap Streetfighter series. They have wimpy clutches,

but I had no complaints about the fluidic portion of

mine. Where this "Ultimate" falls, relative to the known

wimpy standard Streetfighter versions, you probably ought

to be asking TCI to prove.

#52

TECH Senior Member

I'm late to this party, but here's opinion:

the pics in post #2 show poor brazing...

the usual (correct) manner of brazing fins is to braze each and every fin tab (the bent over tabs you see in the pics) completely around each tab's edge and also along the fin's edges where possible/accessible (see the Cirle-D pic of the turbine in post #48 for excellent example)...

the pics in post #2 show a large blob of braze filler deposited at one or two places on each fin of the turbine... so the fins can still rattle/shake and if fins move sufficiently fluid can cross leak... and there are blobs in the path of the fluid; and the impeller/pump looks like it has no brazing at all;

brazing can be done by hand (very tedious, each fin tab has to be done by hand) or by furnace brazing (brazing paste is applied to all the fins/tabs, and then the piece is baked in a suitable oven) which is quicker and cost effective;

what you see in the pics in post #2 is very poor and does not look what TCI does, see this (look closely, all fins/tabs brazed on turbine and pump)(expanded pic from url in post #41):

the pics in post #2 show poor brazing...

the usual (correct) manner of brazing fins is to braze each and every fin tab (the bent over tabs you see in the pics) completely around each tab's edge and also along the fin's edges where possible/accessible (see the Cirle-D pic of the turbine in post #48 for excellent example)...

the pics in post #2 show a large blob of braze filler deposited at one or two places on each fin of the turbine... so the fins can still rattle/shake and if fins move sufficiently fluid can cross leak... and there are blobs in the path of the fluid; and the impeller/pump looks like it has no brazing at all;

brazing can be done by hand (very tedious, each fin tab has to be done by hand) or by furnace brazing (brazing paste is applied to all the fins/tabs, and then the piece is baked in a suitable oven) which is quicker and cost effective;

what you see in the pics in post #2 is very poor and does not look what TCI does, see this (look closely, all fins/tabs brazed on turbine and pump)(expanded pic from url in post #41):

Last edited by joecar; 02-19-2014 at 10:59 PM.

#53

TECH Senior Member

The Pro Torque site shows pics of good brazing (expanded pic from website from url in post #41):

Maybe TC makers should post pics of their internals on their websites (they should be proud of their workmanship, there is nothing to hide)

Maybe TC makers should post pics of their internals on their websites (they should be proud of their workmanship, there is nothing to hide)