4l60e question

#1

Staging Lane

Thread Starter

Join Date: Jan 2019

Location: florida

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

hello i am new to the forum and have been working on a 4l60e out of a 2003 suburban it had burnt 3/4 clutches rebuilt the trans and installed the better clutches and did a full rebuild with all clutches and steels and torque converter and replaced the formed pistons also had to replace the spacer plate cause a couple of the valve body ***** were about to get stuck or go through and installed the trans and had reverse and first and second but no 3rd or 4th but if you unplug the electrical connector on the trans it would default to third and you could get 50 mph at 2500 rpm so i pulled the valve body off and checked all valves and solenoids and replaced all solenoids and harness and pressure manifold and reinstalled valve body and still no 3rd or 4th but this time it would goto 3rd and just free spin like when the clutches were bad so i got a air pressure plate and tested and sounded like it was leaking so i pulled the trans back out and tore it down and all clutches and o-rings are good i did find a piece of the old green o-ring under the new piston for 3/4 but the new o-ring was still good but one thing i can not find anything on is the input clutch housing orificed cup plug you can see the ball down inside the drum and its stationary and does not move if you look on the turbine shaft side it looks like its a stacked tube like the ball should move just wanting to see if anybody has had this issue or knows about that orifice

#2

TECH Enthusiast

iTrader: (1)

Hi, welcome to ls1tech. It's a little difficult to read your paragraph. Could you tweak it a bit to make sure we understand what you're telling us and can give you the best responses? Lots of experienced people here, including pro-builders, and I'm sure we'll be able to help you.

#4

TECH Junkie

Did you disassemble valve body?

#6

TECH Junkie

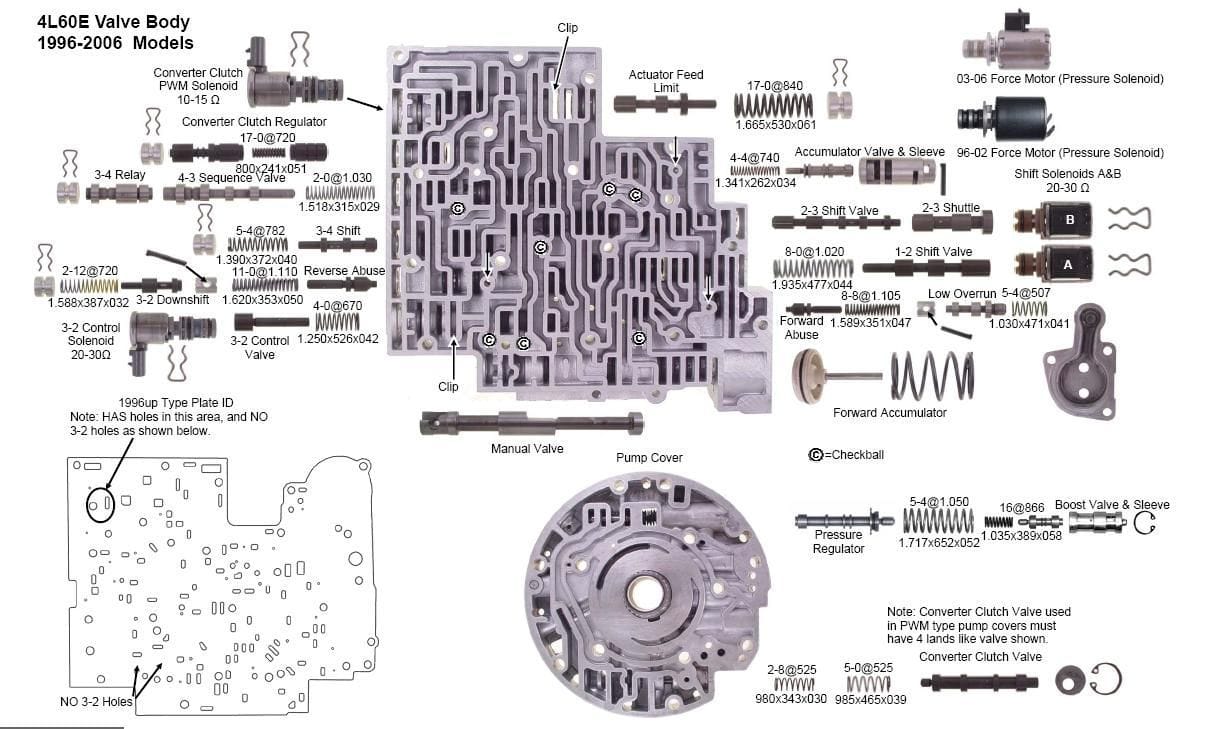

I'm betting you have misplaced a valve in the valve body. Disassemble again and make sure they are all oriented properly.

Also...re-write your paragraph like cory said and try to have it more clear and concise so you can get better help

Also...re-write your paragraph like cory said and try to have it more clear and concise so you can get better help

Trending Topics

#9

Staging Lane

Thread Starter

Join Date: Jan 2019

Location: florida

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

all valves are showing to be correct i did a conversion on the converter clutch valve that is just turning the cup and spring around and reinstalling it

#11

Staging Lane

Thread Starter

Join Date: Jan 2019

Location: florida

Posts: 57

Likes: 0

Received 0 Likes

on

0 Posts

i do have the trans back out and apart if there is anything i should check to make sure of before reassembly i pulled it out and apart cause i used a air test plate a freind had and it showed to be leaking

but did not find anything cut or broken to looking at everything

but did not find anything cut or broken to looking at everything

#12

TECH Enthusiast

Air test the Input drum on the bench with 40psi air. Fill the area where the bearing rides with a little fluid. Check for leaks at the well in the drum where the input shaft presses into the drum itself. Then test it on the stator of the pump and make sure all the clutches apply.

These Sonnax sure cure kit instruction sheets will help with the air test

https://d2q1ebiag300ih.cloudfront.ne...f?v=1532981927

This article may help understand the circuit better.

https://www.sonnax.com/tech_resource...ith-confidence

These Sonnax sure cure kit instruction sheets will help with the air test

https://d2q1ebiag300ih.cloudfront.ne...f?v=1532981927

This article may help understand the circuit better.

https://www.sonnax.com/tech_resource...ith-confidence

Last edited by Tranzman; 01-28-2019 at 09:26 PM. Reason: add content

#15

TECH Enthusiast

I know I'm a newbie on here and To each their own style. I build 50 or so of these a year and 40 psi works for me. The only clutch that doesn't work at 40 psi is the reverse input drum. That is only if I don't add the fitzall orifice plug or the TransGo dual orifice cup plugs. I air test a total of four times. The input drum alone the reverse input drum alone. The two assembled on the completely assembled pump and then again with an air test plate through the case. I made my own plate and added the hole for the third release circuit. That require two sources of air to make sure it works. 1st to apply the band and the 2nd to release it. I rigged up a weighted slip yoke that falls if the band releases. It's tuff to work by yourself on that without 3 hands. 😆

Last edited by Tranzman; 01-29-2019 at 09:26 AM. Reason: grammar

#16

TECH Addict

Air test the Input drum on the bench with 40psi air. Fill the area where the bearing rides with a little fluid. Check for leaks at the well in the drum where the input shaft presses into the drum itself. Then test it on the stator of the pump and make sure all the clutches apply.

These Sonnax sure cure kit instruction sheets will help with the air test

https://d2q1ebiag300ih.cloudfront.ne...f?v=1532981927

This article may help understand the circuit better.

https://www.sonnax.com/tech_resource...ith-confidence

These Sonnax sure cure kit instruction sheets will help with the air test

https://d2q1ebiag300ih.cloudfront.ne...f?v=1532981927

This article may help understand the circuit better.

https://www.sonnax.com/tech_resource...ith-confidence

#18

TECH Enthusiast

There are 2 squeeze/lock tabs on the side of the shifter cable. You should be able to use a small set of channel lock pliers or maybe regular pliers and squeeze the tabs and presto the cable will slide through the bracket

Last edited by Tranzman; 01-29-2019 at 10:28 AM.

#20

TECH Junkie

Start your own thread don't hijack this random thread.

I'll answer your question...but after this you need to start your own thread.

The 60e bracket unbolts with two bolts from above (sometimes normal hex somtimes torx)

The 60 (non e) pan and shifter shaft are the same as the 60e...so just use the bracket and cable from the 60. That way it will have the proper spacing and be easy to adjust. You may have to swap the shifter arm but that's it.

I'll answer your question...but after this you need to start your own thread.

The 60e bracket unbolts with two bolts from above (sometimes normal hex somtimes torx)

The 60 (non e) pan and shifter shaft are the same as the 60e...so just use the bracket and cable from the 60. That way it will have the proper spacing and be easy to adjust. You may have to swap the shifter arm but that's it.