Torque Converter Installations

#61

Personally in your case I would not worry about it because the converter you are using has already been run. It has had some oil in it to lube all components. I would make sure to dump 4-5 qts in the trans before starting it up. After you start your vehicle start dumping the rest of the oil in as quick as possible. Another way is to fill the trans with 4-5 qts and start it for a short time. Meaning like 20-30 seconds and then shut it down. Refill trans and continue until full. Hope this helps. Vince

#64

#65

Teching In

iTrader: (2)

Join Date: Apr 2008

Location: Hooksett,NH

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

Excuse me of my lack of knowledge in this area but I have a question. When do you have to shim? Is this only with a aftermarket flex and converter? Or just an aftermarket converter? Could non using shims end up with this issue?

https://ls1tech.com/forums/automatic...l#post14086377

https://ls1tech.com/forums/automatic...l#post14086377

#66

Customizing Director

iTrader: (12)

Excuse me of my lack of knowledge in this area but I have a question. When do you have to shim? Is this only with a aftermarket flex and converter? Or just an aftermarket converter? Could non using shims end up with this issue?

https://ls1tech.com/forums/automatic...l#post14086377

https://ls1tech.com/forums/automatic...l#post14086377

#67

Restricted User

iTrader: (12)

Join Date: Feb 2010

Location: kansas

Posts: 1,786

Likes: 0

Received 0 Likes

on

0 Posts

Ok so when you tighten ur bolts to the converter it will pull the converter flat into the flex-plate right? And the info here is to make sure you don't have to much room between your converter mounting pads and the flex-plate, so you don't pull the converter to far out of the transmission and damage things. Correct on all that?

#69

Hello all,

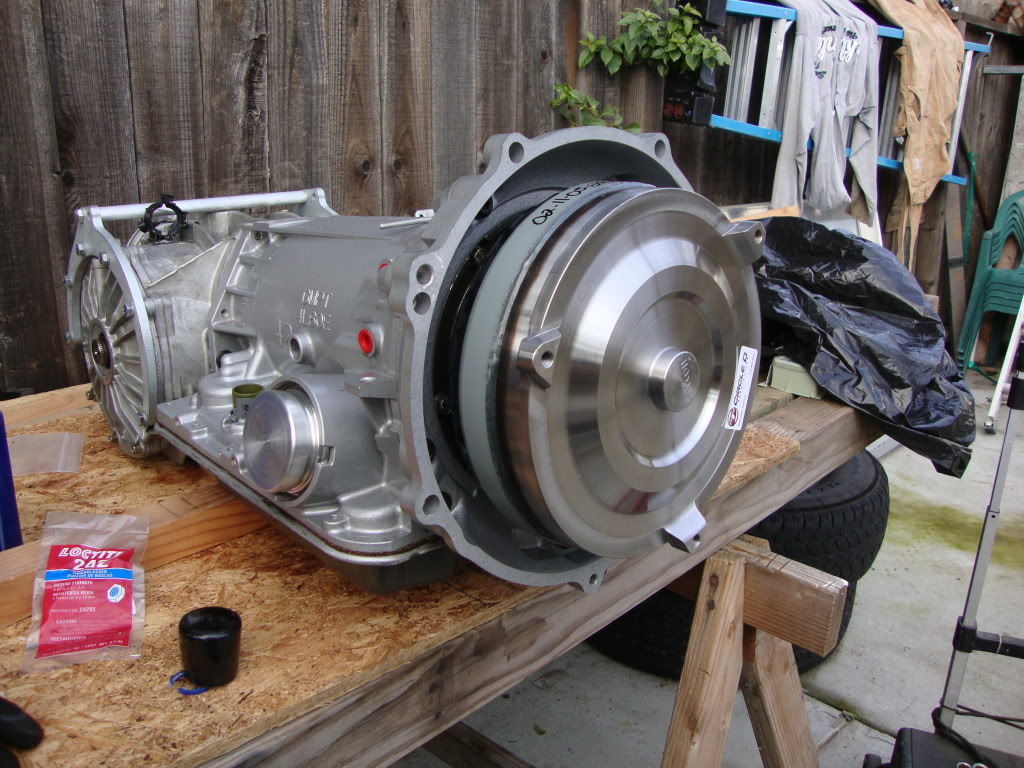

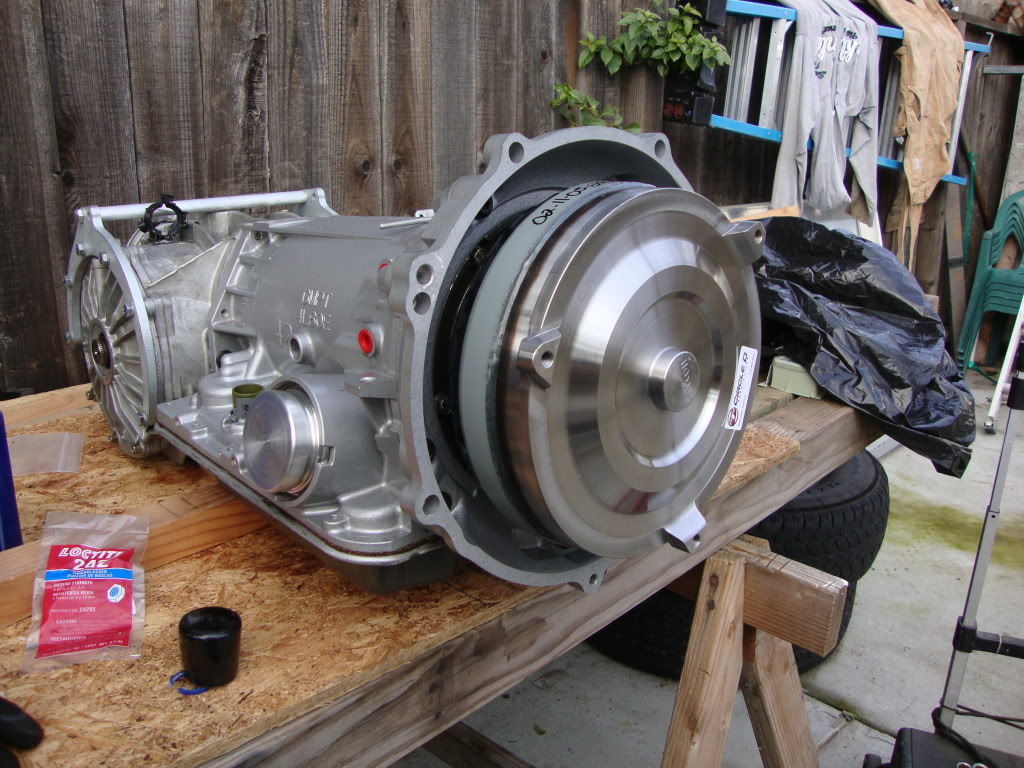

im still confused on the measurements from the TC to the flexplate. so here is what i did:

1- Filled the TC with 1 quart of Trans fluid

2- Gently mounted it to the trans. i only heard 2 clunks but i spun the TC about 20 times gently pushing and tugging it in till it went no more

3. bolted the TT to the trans but not torqued yet. (bolts are hand tight) TT went in with zero issues.

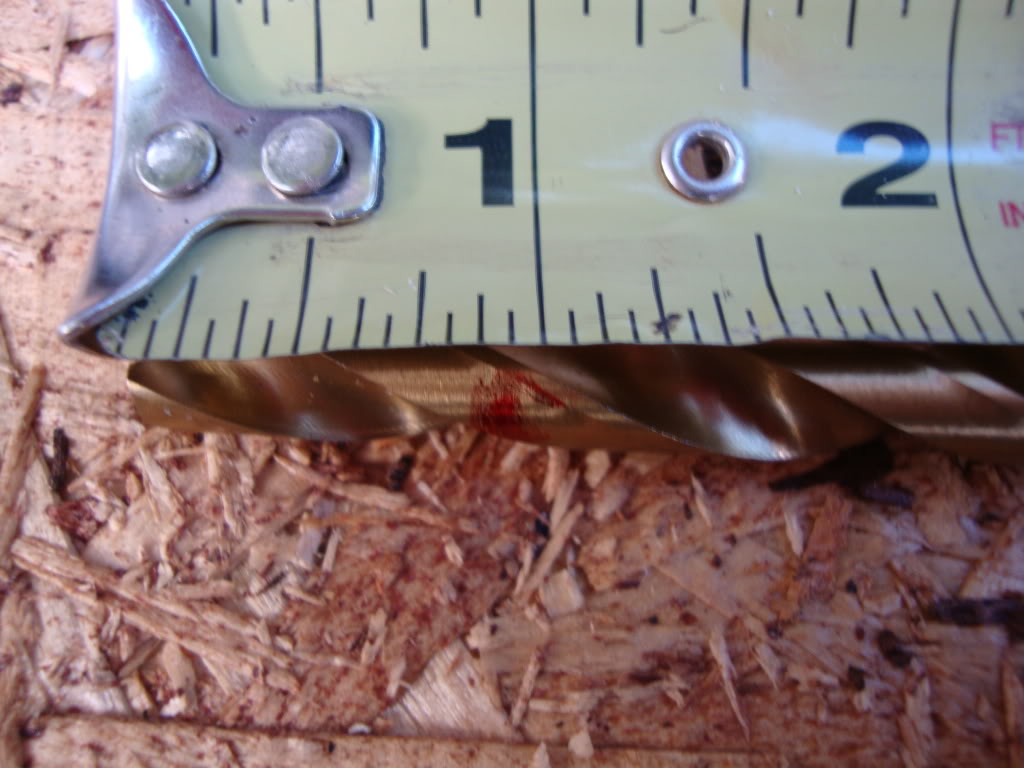

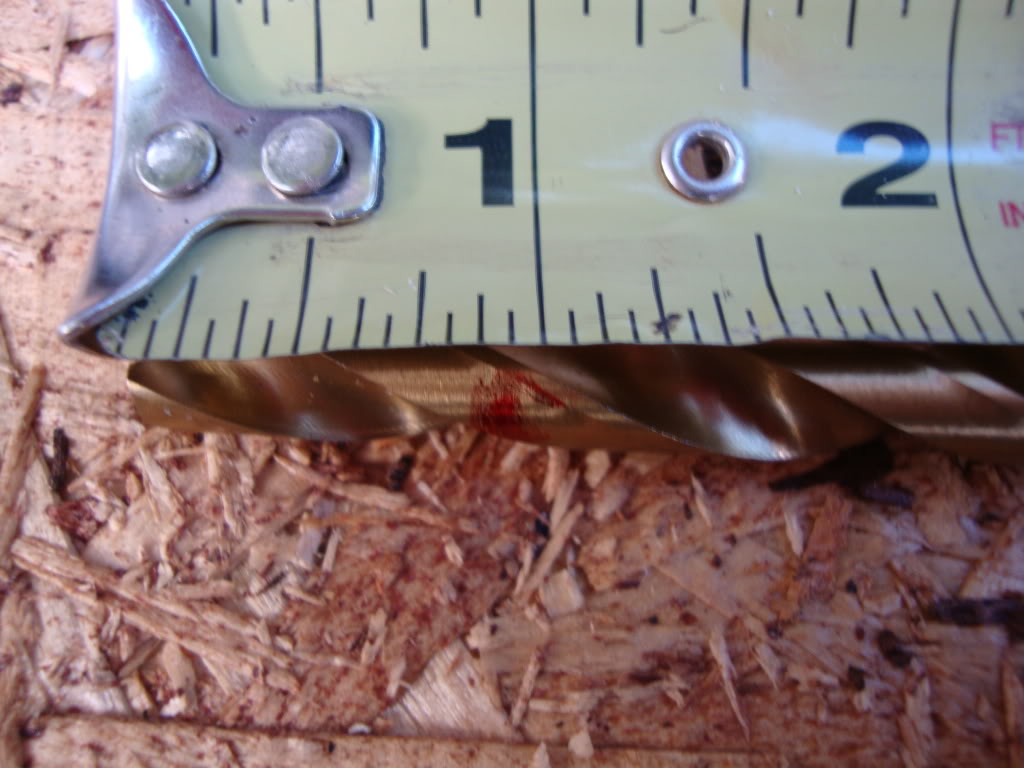

so here is where im stuck. im trying to measure the distance from the TC to the flexplate using the drill bit method but im not sure if im doing it right. i placed the bit all the way in and marked it with a sharpie. it measured 7/8". then i did it measuring the "tail end" of the bit which measured 4" (drill bit measures 4 7/8"). so its safe to say my first measurement is right. i did it for all three holes and they measuring the same. so is this a safe distance or do i need to shim it? here are some pics to help clarify what im trying to get at

im still confused on the measurements from the TC to the flexplate. so here is what i did:

1- Filled the TC with 1 quart of Trans fluid

2- Gently mounted it to the trans. i only heard 2 clunks but i spun the TC about 20 times gently pushing and tugging it in till it went no more

3. bolted the TT to the trans but not torqued yet. (bolts are hand tight) TT went in with zero issues.

so here is where im stuck. im trying to measure the distance from the TC to the flexplate using the drill bit method but im not sure if im doing it right. i placed the bit all the way in and marked it with a sharpie. it measured 7/8". then i did it measuring the "tail end" of the bit which measured 4" (drill bit measures 4 7/8"). so its safe to say my first measurement is right. i did it for all three holes and they measuring the same. so is this a safe distance or do i need to shim it? here are some pics to help clarify what im trying to get at

#70

11 Second Club

iTrader: (8)

Join Date: Jan 2002

Location: SILSBEE TX

Posts: 1,782

Likes: 0

Received 0 Likes

on

0 Posts

Using a drill bit as a reference. I find that most people own a set or can get their hands on a set of drill bits. Use the part that you would chuck in the drill as a feeler gauge so to speak. Just have to find a place to be able to access the converter pad to flexplate distance and go from there.

and IF I understand correctly you should ROLL the drill bit BETWEEN the flex plate and the mounting pad on the converter NOT try to stick in in long ways, also you should hear 3 clicks not just 2 , please reread several of the other post as how to messure from the face of the trans to the front of converter ( about 1" I think) before stabing trans to moter

I hope that I am not confused.

Johnny

Last edited by SS SLP2; 01-03-2011 at 08:29 PM.

#71

Restricted User

iTrader: (12)

Join Date: Feb 2010

Location: kansas

Posts: 1,786

Likes: 0

Received 0 Likes

on

0 Posts

Im pretty sure you are saposed to find a 3/16 drill bit. And use the end to stick between the flexplate and converter mounting pad and if it fits or if there is more room than the 3/16 bit, than you need to put a shim in there so it doesn't pull ur converter out to far from the tranny and ruin ur pump and converter

#72

TECH Senior Member

iTrader: (96)

Join Date: Aug 2007

Location: Turnin' Wrenches Infractions: 005

Posts: 24,240

Likes: 0

Received 79 Likes

on

70 Posts

You bolt the trans to the engine, go through the starter hole and see how big of a drill bit will fit in-between the feet of the converter and the flexplate (with the converter completely seated in the trans). With mine, I could fit a 1/4 bit (.25) but could not fit a 5/16th (.31). So I estimated my clearance at about .28. Shooting for 3/16ths or .18, I shimmed it .10 to get an estimated .18 or so.

If you are trying to seat the converter, try moving the shift lever. I found that by selecting different gears I could get the converter to go in easier.

If you are trying to seat the converter, try moving the shift lever. I found that by selecting different gears I could get the converter to go in easier.

#73

Restricted User

iTrader: (12)

Join Date: Feb 2010

Location: kansas

Posts: 1,786

Likes: 0

Received 0 Likes

on

0 Posts

You bolt the trans to the engine, go through the starter hole and see how big of a drill bit will fit in-between the feet of the converter and the flexplate (with the converter completely seated in the trans). With mine, I could fit a 1/4 bit (.25) but could not fit a 5/16th (.31). So I estimated my clearance at about .28. Shooting for 3/16ths or .18, I shimmed it .10 to get an estimated .18 or so.

If you are trying to seat the converter, try moving the shift lever. I found that by selecting different gears I could get the converter to go in easier.

If you are trying to seat the converter, try moving the shift lever. I found that by selecting different gears I could get the converter to go in easier.

#79

Moderator

iTrader: (1)

Join Date: Sep 2005

Location: Bloomingdale Illinois

Posts: 8,633

Likes: 0

Received 0 Likes

on

0 Posts

Mickey it looks good from here. Another thing to mention on C5 cars. I believe that the shaft that runs through the torque tube on those cars is adjustable. This adjustment is near the engine side of the tube. I hope this helps for others that have C5 bodied cars. Vince Bielanski

#80

Thanks vince

Mickey it looks good from here. Another thing to mention on C5 cars. I believe that the shaft that runs through the torque tube on those cars is adjustable. This adjustment is near the engine side of the tube. I hope this helps for others that have C5 bodied cars. Vince Bielanski