DIY Ford 8.8 into V1 Build thread

#181

TECH Fanatic

iTrader: (6)

The car has pretty much everything.. Only thing that comes to mind is I'm running 20's with nt05's. before the 8.8 I had a gen4 rear with gforce axles. Had no hop but kept braking inner cv's.

I built the entire car, motor included. Set the rear up with an iron case,3.55 and all new carbon clutches. No whine what so ever! Everything has been double checked. So I'm at a loss

I built the entire car, motor included. Set the rear up with an iron case,3.55 and all new carbon clutches. No whine what so ever! Everything has been double checked. So I'm at a loss

#182

The car has pretty much everything.. Only thing that comes to mind is I'm running 20's with nt05's. before the 8.8 I had a gen4 rear with gforce axles. Had no hop but kept braking inner cv's.

I built the entire car, motor included. Set the rear up with an iron case,3.55 and all new carbon clutches. No whine what so ever! Everything has been double checked. So I'm at a loss

I built the entire car, motor included. Set the rear up with an iron case,3.55 and all new carbon clutches. No whine what so ever! Everything has been double checked. So I'm at a loss

Has the car been rearended?

How many miles on it when you got it?

I am wondering if the diff may be the culprit.

What bushings are you running in everything?

What trailing arms?

Can you get a picture of the pinion angle?

#187

TECH Resident

iTrader: (10)

Join Date: Oct 2005

Location: Cincinnati, Ohio

Posts: 948

Likes: 0

Received 0 Likes

on

0 Posts

As far as pinion angle how does GM do the Cadillac? Is the pinion itlted up and down or is is offset to the sie like a Ford. The 8.8 rears are typically offset to one side like a 9 inch. I know on the older stuff like my Chevelle if you change the pinion angle slightly you can do everything from have it hook harder/eliminate wheel hop to having it vibrate like your diff is about to fall out. Also since we have a carrier bearing would only the rear be offset? I know without any offset the u-joints won't turn.

#188

As far as pinion angle how does GM do the Cadillac? Is the pinion itlted up and down or is is offset to the sie like a Ford. The 8.8 rears are typically offset to one side like a 9 inch. I know on the older stuff like my Chevelle if you change the pinion angle slightly you can do everything from have it hook harder/eliminate wheel hop to having it vibrate like your diff is about to fall out. Also since we have a carrier bearing would only the rear be offset? I know without any offset the u-joints won't turn.

When you are saying pinion offset, that is in the DIFFERENTIAL itself, not the placement on the vehicle.

Take a look at a Ford Dana 60 front diff vs. a Chevy Dana 60 front diff.

One is passenger side offset and the other is drivers. The "offset" is built into the differential. Now this is horizontal offset.

There are also vertical offset pinions, known as High output pinions/differentials.

I believe there is a Dana 44 that has a pinion that is mounted higher in the differential giving more ground clearance and less of a u-joint angles.

The concern in most pinions, in most u-joint applications, is dealing with the angle on the horizontal, looking from the side of the vehicle, and not any of the "offset".

You are also comparing a solid rear axle u-joint setup vs. an IRS with CV joints.

Totally different ball game.

The CVs allow the driveshaft to move more in different directions. Much more forgiving. There are 40 degree CV joints out there. And double CV joints.

In our IRS, the differential/pumpkin/rearend is semi-solidly mounted and so adjusting the pinion angle, in theory, is not needed and difficult to do.

The pinion angle is set when designing/building the brackets.

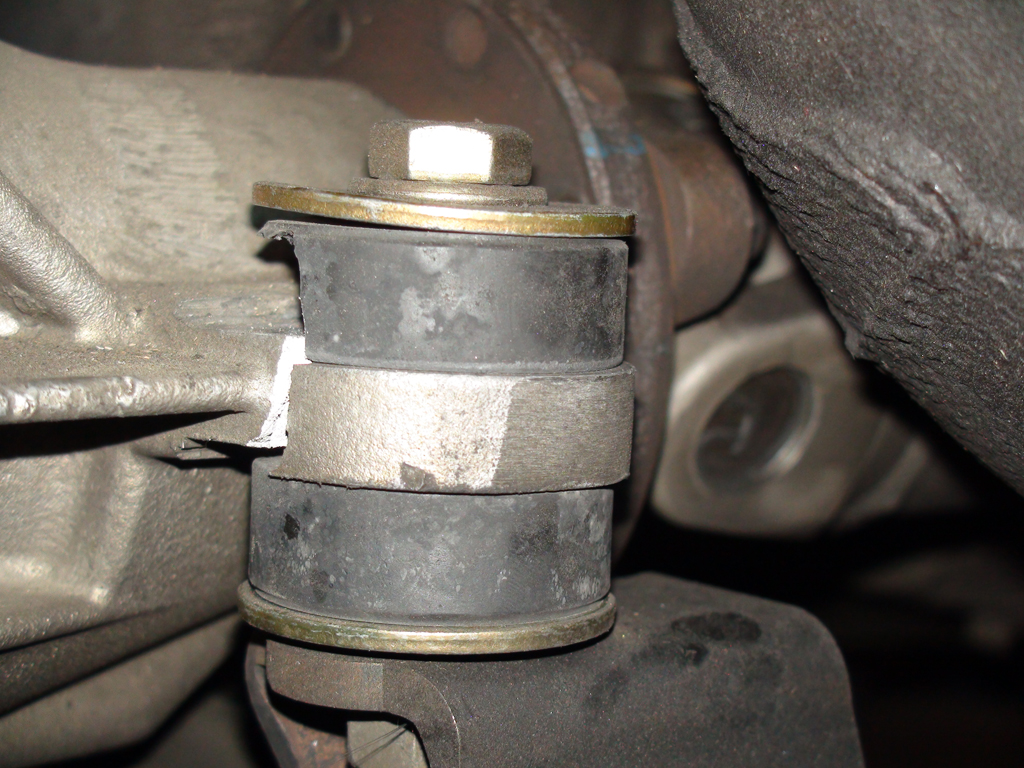

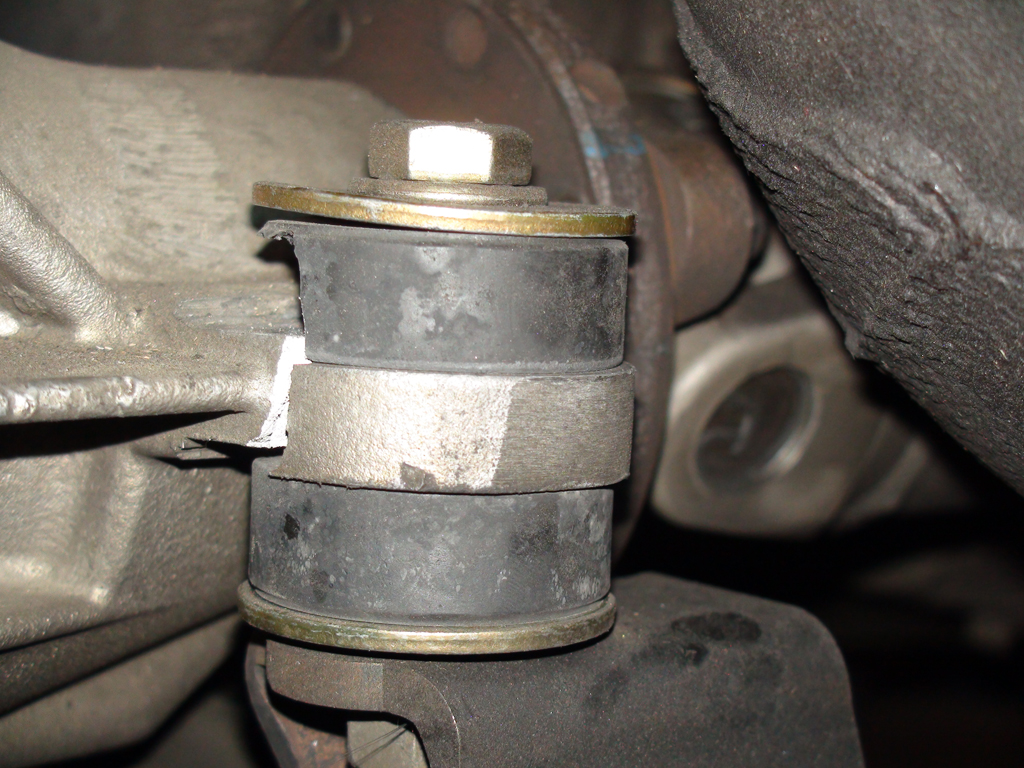

I have toyed with the idea of removing the rear cradle bushings(the ones that the two ears of the perimeter bracket bolt to) and seeing if Revshift, hint hint, could build some bushings to replace the factory ones.

My thought is that you are mounting the front of the 8.8 in poly, but leaving the back in GM rubber thus creating an unwanted torsional load on the case similar to the one that breaks the Getrag.

Just like motor mounts and transmission mounts(just an example, not the totality of this theory); when you are mounting a piece all mounts should be made up of the same material so it is firmly mounted and 1-2 mounts are not flexing more than others.

Make sense?

I am confused on your offset, the ujoint won't turn comment, but I have rambled enough. lol

#189

TECH Resident

iTrader: (10)

Join Date: Oct 2005

Location: Cincinnati, Ohio

Posts: 948

Likes: 0

Received 0 Likes

on

0 Posts

What i meant is that without some kind of angle the needle bearings in the u-joint won't turn and can fail or so i was told. Gm pinion angle is up and down and ford is left and right to my understanding.

#190

TECH Regular

iTrader: (14)

Join Date: Jan 2009

Location: Cypress TX

Posts: 422

Likes: 0

Received 0 Likes

on

0 Posts

Just ordered axle stubs from DSS, not cheap at $250 each, but they are the only vendor I could find that makes a stub for 31 spline cobra carriers, and a 930 cv joint flange on the outside.

The Porsche 930 CV has been used for ages in the dune buggy scene, and is what most of the performance axle builders use for their "1000hp axles". There is a lot of aftermarket support for the 930, unlike the stock tripod type joint used in cobra axle shafts. If I break a CV I can find stock replacements for $50, or upgraded hardened/chromoly pieces for around $100-$150.

Picture of the stubs I found on the internet for reference, this is from a 8.8 swap into a BMW.

Porsche 930 CV's

The Porsche 930 CV has been used for ages in the dune buggy scene, and is what most of the performance axle builders use for their "1000hp axles". There is a lot of aftermarket support for the 930, unlike the stock tripod type joint used in cobra axle shafts. If I break a CV I can find stock replacements for $50, or upgraded hardened/chromoly pieces for around $100-$150.

Picture of the stubs I found on the internet for reference, this is from a 8.8 swap into a BMW.

Porsche 930 CV's

#191

TECH Fanatic

iTrader: (6)

thats the same stub and cv that come in the CS kit. since your making your own brackets you might just wanna see what DSS would do on the already made axles.. since your brackets are pretty much putting the diff in the same place as CS.

i know guys wanna save money and try to reuse stock axles and the such but there isnt much room here. thats why CS offered the kit to adapt the stock outers. i opted to just be done with the rear and got the full axles.

only thing i can see being made available is a coupler for the stock DS to the 8.8 thats actually reasonable like your brackets are gonna be. wish i woulda waited or made my own but atlast i have no shop at the moment and winter sucks. keep up the good work

i know guys wanna save money and try to reuse stock axles and the such but there isnt much room here. thats why CS offered the kit to adapt the stock outers. i opted to just be done with the rear and got the full axles.

only thing i can see being made available is a coupler for the stock DS to the 8.8 thats actually reasonable like your brackets are gonna be. wish i woulda waited or made my own but atlast i have no shop at the moment and winter sucks. keep up the good work

#192

TECH Regular

iTrader: (14)

Join Date: Jan 2009

Location: Cypress TX

Posts: 422

Likes: 0

Received 0 Likes

on

0 Posts

Quick question, do you know if the stock outers are 28 spline same as the 930 CV? I have stock axles, just haven't torn them apart yet.

#193

TECH Fanatic

iTrader: (6)

i can tell you what the stock axles are when i get home as i have 3 broken ones with good outers.. i cant however tell u what the actual spline count is on the DSS axle itself because im not taking them apart.. but both cv's on the DSS axles are 930's thats for sure.

31 spline on the inner and 28 spline on the outer to adapt to the hub using 930 style cv's on both ends. quality pieces for sure!

31 spline on the inner and 28 spline on the outer to adapt to the hub using 930 style cv's on both ends. quality pieces for sure!

#194

TECH Fanatic

iTrader: (6)

oh and just an fyi as people have done this method to remove the stock cv's. do not put them in a vise or beat em with a hammer...smh

pull the boot back and use a snap ring plyer on the retaining ring..the cv slides right off the axle. ive read 10 threads where guys are beating on the cv for an hr trying to get it off..lol

pull the boot back and use a snap ring plyer on the retaining ring..the cv slides right off the axle. ive read 10 threads where guys are beating on the cv for an hr trying to get it off..lol

#195

Make sense?

Just ordered axle stubs from DSS, not cheap at $250 each, but they are the only vendor I could find that makes a stub for 31 spline cobra carriers, and a 930 cv joint flange on the outside.

The Porsche 930 CV has been used for ages in the dune buggy scene, and is what most of the performance axle builders use for their "1000hp axles". There is a lot of aftermarket support for the 930, unlike the stock tripod type joint used in cobra axle shafts. If I break a CV I can find stock replacements for $50, or upgraded hardened/chromoly pieces for around $100-$150.

The Porsche 930 CV has been used for ages in the dune buggy scene, and is what most of the performance axle builders use for their "1000hp axles". There is a lot of aftermarket support for the 930, unlike the stock tripod type joint used in cobra axle shafts. If I break a CV I can find stock replacements for $50, or upgraded hardened/chromoly pieces for around $100-$150.

i can tell you what the stock axles are when i get home as i have 3 broken ones with good outers.. i cant however tell u what the actual spline count is on the DSS axle itself because im not taking them apart.. but both cv's on the DSS axles are 930's thats for sure.

31 spline on the inner and 28 spline on the outer to adapt to the hub using 930 style cv's on both ends. quality pieces for sure!

31 spline on the inner and 28 spline on the outer to adapt to the hub using 930 style cv's on both ends. quality pieces for sure!

oh and just an fyi as people have done this method to remove the stock cv's. do not put them in a vise or beat em with a hammer...smh

pull the boot back and use a snap ring plyer on the retaining ring..the cv slides right off the axle. ive read 10 threads where guys are beating on the cv for an hr trying to get it off..lol

pull the boot back and use a snap ring plyer on the retaining ring..the cv slides right off the axle. ive read 10 threads where guys are beating on the cv for an hr trying to get it off..lol

This is being added to post #1.

Thanks!

#197

I went with an Iron housing after seeing this thread back in march.. apparent the front diff mount ears snap off. the weight was a non issue for me. plus its cheaper

http://www.norotors.com/index.php?topic=4344.0

makes perfect sense. I have the prothane bushings in the front diff bushings.. Im in for a urathane set for the rear aswell

http://www.norotors.com/index.php?topic=4344.0

I have toyed with the idea of removing the rear cradle bushings(the ones that the two ears of the perimeter bracket bolt to) and seeing if Revshift, hint hint, could build some bushings to replace the factory ones.

My thought is that you are mounting the front of the 8.8 in poly, but leaving the back in GM rubber thus creating an unwanted torsional load on the case similar to the one that breaks the Getrag.

Make sense?

My thought is that you are mounting the front of the 8.8 in poly, but leaving the back in GM rubber thus creating an unwanted torsional load on the case similar to the one that breaks the Getrag.

Make sense?

#198

TECH Regular

iTrader: (14)

Join Date: Jan 2009

Location: Cypress TX

Posts: 422

Likes: 0

Received 0 Likes

on

0 Posts

I'll knock out the rear bushings in the junk subframe and take measurements for Revshift. I'm sure it would be easy for them to build a set. You will most likely need to remove the whole subframe to install the new bushing, there isn't enough clearance to remove the stock rear diff bolts with the subframe bolted to the car. Guess it's not a big deal if you already have the subframe down to replace the subframe bushings.

#199

TECH Apprentice

iTrader: (2)

Join Date: Nov 2007

Location: fairfax, VA

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

is there any way to support those front ears to prevent them from snapping off?

apparently that was after 30ish 1.4 60 foot's...If we can get our V's in that range...we are in pretty good shape haha

apparently that was after 30ish 1.4 60 foot's...If we can get our V's in that range...we are in pretty good shape haha

#200

TECH Enthusiast

iTrader: (8)

oh and just an fyi as people have done this method to remove the stock cv's. do not put them in a vise or beat em with a hammer...smh

pull the boot back and use a snap ring plyer on the retaining ring..the cv slides right off the axle. ive read 10 threads where guys are beating on the cv for an hr trying to get it off..lol

pull the boot back and use a snap ring plyer on the retaining ring..the cv slides right off the axle. ive read 10 threads where guys are beating on the cv for an hr trying to get it off..lol