8.8 rear end vibration

#201

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,407

Received 107 Likes

on

89 Posts

AFAIK the driveshaft is as I received it. I don't think I have any good pics of the rear CV, but this pic seems to show the same thing as what I've got now. I don't see anything covering the rear of the CV - seems to be the same grey colored part that I see now. What is supposed to be there?

#202

TECH Resident

iTrader: (3)

It's right.. Now that I look with full screen brightness, I was mistaken. Sorry. Youre definitely gonna not be straight with using stacks of washers like that. Best way is what was said. Keep disc in place and bolt to same holes as transmission output. That will show your alignment.

#204

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,407

Received 107 Likes

on

89 Posts

Yesterday I swapped out the driveshaft with a used stocker that I picked up from bigti99a last weekend. Before removing the existing driveshaft, I rotated the flex disk and bolted the driveshaft to the tranny output through the flex disk. With the rear CV still fully bolted to the diff, I unbolted the carrier bearing and then spun a rear wheel to get the driveshaft to spin. Definitely still movement of the carrier bearing in a circular motion.

I elected to drop the cradle a bit to facilitate getting the driveshaft out and putting the "new" one back in. Much better that way, didn't have to force it past the adapter. Of course, messing with the rear cradle had to introduce a new wrinkle

After swapping the driveshafts I did the same carrier bearing movement check with the new driveshaft. Still some movement of the carrier, but not as pronounced. And whatever oscillation remains is apparently within the capacity of the flex disk and the stock rubber carrier bearing surround to absorb.

On the road the vibrations in the 42-47mph range are gone. (Which is very good, because much of daily commute is on 35 & 45mph roads, so with traffic and stop lights I spend a lot of the commute doing speeds around there.) I haven't gotten on the highway yet to test higher speeds, but I think I'll be good to go.

I also took some measurements to compare the pinion flange position for the stock Getrag diff vs the 8.8" diff with driveshaft adapter. (I have my stock diff sitting in my basement.)

Stock: 3-9/16"

8.8" w/adapter: 4-1/8"

So those of using the stock driveshaft with the 8.8" adapter have lost roughly 1/2" of fore-aft play in the CVs.

My plan at this point is to take the "old" driveshaft (which has the Voodoochikin poly carrier bearing surround) to a driveshaft shop and see if they can confirm whether or not there's some run-out at the input flange. I'll also ask about the possibility of chopping ~1/2" out of the rear portion of the shaft and re-balancing it.

#205

When I installed my driveshaft I needed to leave the front bolt for the 8.8 bracket out to dip down the pinion flange just a hair so I could get the driveshaft in. (To clear that bump on the rear CV I'm sure you've noticed) But once I lined up the driveshaft and diff and put the bolt back in, there was no pressure on the CV and it didn't need to be extended to mate up with the adapter.

#206

If you guys want a hard aluminum coupler to help measure runout off the stock driveshaft, I still have a 6-shooter made by Revshift. It's been collecting dust in my spare parts closet for years because it was too rigid to tolerate the stock driveline misalignment angles. If you pay shipping, it's yours.

Last edited by FuzzyLog1c; 04-28-2016 at 03:53 PM.

#207

TECH Addict

iTrader: (2)

On the road the vibrations in the 42-47mph range are gone. (Which is very good, because much of daily commute is on 35 & 45mph roads, so with traffic and stop lights I spend a lot of the commute doing speeds around there.) I haven't gotten on the highway yet to test higher speeds, but I think I'll be good to go.

I also took some measurements to compare the pinion flange position for the stock Getrag diff vs the 8.8" diff with driveshaft adapter. (I have my stock diff sitting in my basement.)

Stock: 3-9/16"

8.8" w/adapter: 4-1/8"

So those of using the stock driveshaft with the 8.8" adapter have lost roughly 1/2" of fore-aft play in the CVs.

My plan at this point is to take the "old" driveshaft (which has the Voodoochikin poly carrier bearing surround) to a driveshaft shop and see if they can confirm whether or not there's some run-out at the input flange. I'll also ask about the possibility of chopping ~1/2" out of the rear portion of the shaft and re-balancing it.

I also took some measurements to compare the pinion flange position for the stock Getrag diff vs the 8.8" diff with driveshaft adapter. (I have my stock diff sitting in my basement.)

Stock: 3-9/16"

8.8" w/adapter: 4-1/8"

So those of using the stock driveshaft with the 8.8" adapter have lost roughly 1/2" of fore-aft play in the CVs.

My plan at this point is to take the "old" driveshaft (which has the Voodoochikin poly carrier bearing surround) to a driveshaft shop and see if they can confirm whether or not there's some run-out at the input flange. I'll also ask about the possibility of chopping ~1/2" out of the rear portion of the shaft and re-balancing it.

At this point, I guess you may not be able to machine a 1/2" out of the rear adapter because there wouldn't be enough threads left to bolt the CV too?

Too bad voodoo can't offer a balancing service for the factory 2 piece. You'd think you could balance it pretty easily in 2 separate pieces while he's got the shaft apart for servicing.

#209

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,407

Received 107 Likes

on

89 Posts

Well, I guess that's progress...how clunky sounding is the stock driveshaft on the 8.8 versus the voodoo driveshaft?

At this point, I guess you may not be able to machine a 1/2" out of the rear adapter because there wouldn't be enough threads left to bolt the CV too?

Too bad voodoo can't offer a balancing service for the factory 2 piece. You'd think you could balance it pretty easily in 2 separate pieces while he's got the shaft apart for servicing.

At this point, I guess you may not be able to machine a 1/2" out of the rear adapter because there wouldn't be enough threads left to bolt the CV too?

Too bad voodoo can't offer a balancing service for the factory 2 piece. You'd think you could balance it pretty easily in 2 separate pieces while he's got the shaft apart for servicing.

I think the CS adapter is cut down as much as they're comfortable doing. I don't know how tight the clearance is now, but at some point as you shave the adapter down you'll end up with the rear face of the CV bottoming out on the pinion shaft and pinion nut protruding from the pinion flange. I imagine that's the limiting factor on how thin you can make the adapter.

As for balancing, I honestly don't think that's a problem. It seems to be very uncommon for anyone on this forum or CF to report a driveshaft out of balance. The only reason I mentioned rebalancing is that I figured it would necessary if one were to cut the shaft apart to shorten it. I could be wrong.

I have the short one, which I'm assuming is all CS is selling at this point.

Last edited by AAIIIC; 04-29-2016 at 03:42 PM.

#210

TECH Addict

iTrader: (2)

Ok so there isn't much you're going to be able to do with size of the adapter to accommodate the driveshaft...that blows but is typical hot rod stuff it seems. I really can't remember anyone being able to balance a 2 piece fully assembled but then again, I've never tried to have one done either.

My 8.8 with a one piece is fairly clunk free although it seems to be setup on the loose side.

Have you had a chance to get it out on the highway?

My 8.8 with a one piece is fairly clunk free although it seems to be setup on the loose side.

Have you had a chance to get it out on the highway?

#211

TECH Resident

iTrader: (3)

Been a long time on inactivity on this thread and wanted to bring it back to life. Was curious if you ever took that shaft to a shop to check the runout on the flange? i read back over the whole thread and it really does look as if there is some runout on that flange.

Also if we had a shaft balancer within 60 miles, we could have that option of balancing however in the last few years only one person has had to get a factory shaft balanced and that was because it had been taken apart previously by a different owner. most likely not indexed.

Also if we had a shaft balancer within 60 miles, we could have that option of balancing however in the last few years only one person has had to get a factory shaft balanced and that was because it had been taken apart previously by a different owner. most likely not indexed.

#212

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,407

Received 107 Likes

on

89 Posts

My plan at this point is to take the "old" driveshaft (which has the Voodoochikin poly carrier bearing surround) to a driveshaft shop and see if they can confirm whether or not there's some run-out at the input flange. I'll also ask about the possibility of chopping ~1/2" out of the rear portion of the shaft and re-balancing it.

The shop took 1/2" out of the rear half of the driveshaft.

I confirmed a week or so ago that that 1/2" change makes install substantially easier, so that's nice. Unfortunately, the vibration issue hasn't magically fixed itself.

I reinstalled the shortened driveshaft with the VDC poly carrier bearing surround because I think the carrier bearing and/or the CVs on the stock driveshaft I had installed were in bad shape. I've got a pretty bad cyclic/rhythmic, speed-related drivetrain noise, and I thought maybe it was a bad driveshaft CV because I had found signs they had been puking out grease. There was grease splattered around the carrier bearing area; I don't know if came out of the carrier bearing or out of the CV.

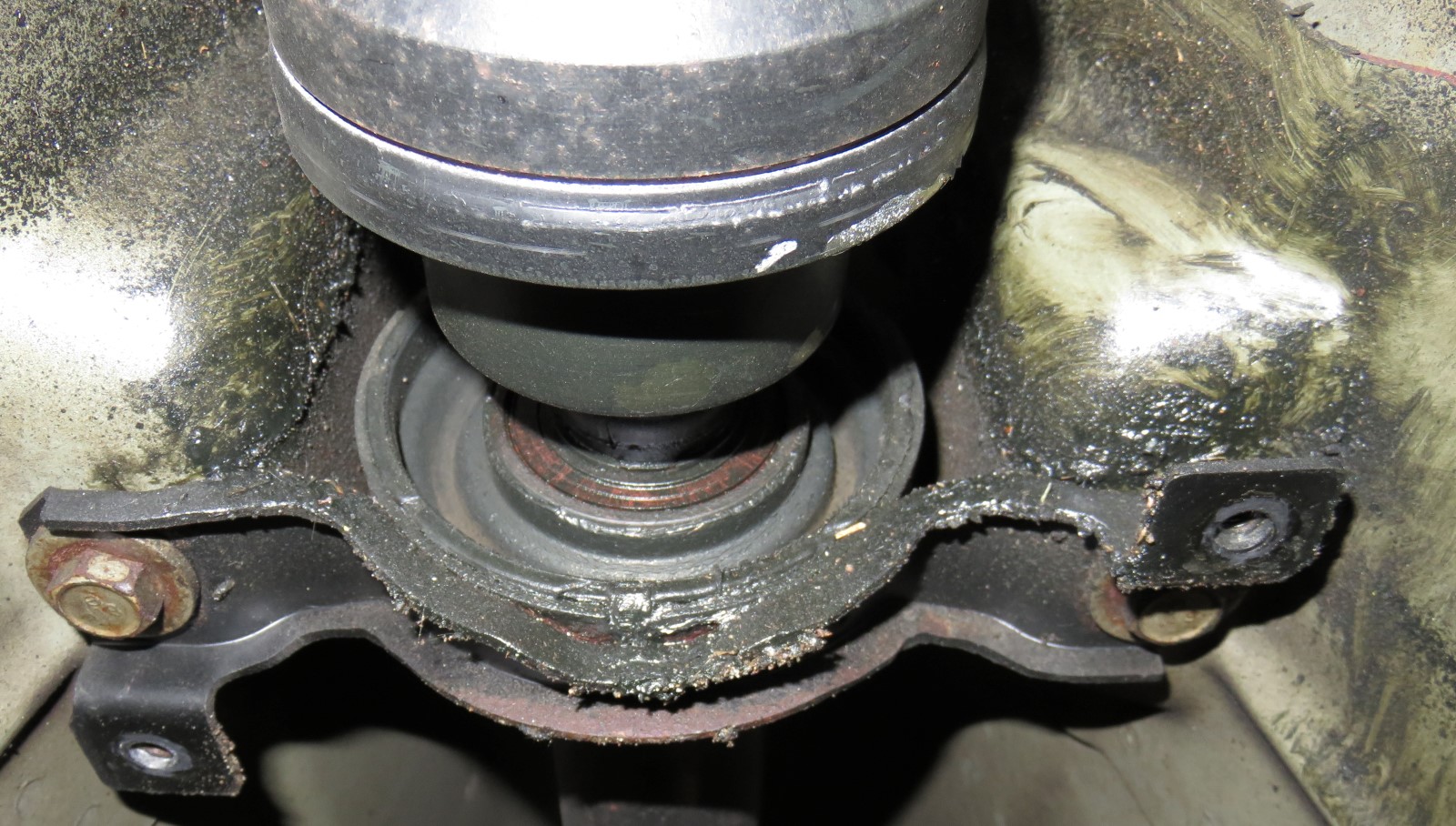

There was also grease around the rear CV area:

(Compare that shot to the similar pic in this post 8 months ago, at which point everything was nice and clean.)

Unfortunately, while I do think the driveshaft CVs aren't healthy, swapping out the driveshaft did not alleviate the noise. Turns out that's due to the inner CV on the driver side axle:

#213

TECH Resident

iTrader: (3)

Damn, you can't escape.... That's definitely CV grease. Front from a torn boot and rear due to bad seals, or the 6 bolts loosened up.. idk man, from that video you posted it looks like the flange on driveshaft is bent slightly, especially since a different shaft spun more straight.

#214

TECH Addict

iTrader: (2)

So in the year or so since getting mine vibe free at 90, where the vibes were pretty violent, I've had a chance to break 130 a time or two and have found that shimming the cradle just moved the vibes up the mph scale, not fully eliminated them. The vibes start coming in around 120 and while they aren't as bad as they were, it's not what I'm hoping for if I'm going to keep this car.

while shimming the front cradle bushings did change the pinion angle, I'm also thinking it affectively lengthened the driveshaft just slightly which unloaded the cvs a tiny bit, allowing them to work more affectively.

Like AAIIC, my driveshaft is a very tight fit and I've come to the conclusion that the shaft needs to bolt into the car in a relaxed state to work like it supposed to, not with the cvs compressed as it is now. After thinking back, I can honestly say I've never installed a cv shaft that wasn't fairly relaxed when I put it in and I've done my share.

will shortening the driveshaft help me out here? I have no clue but since DSS is close by, it's the easiest thing for me to try next so that's where I'm headed.

while shimming the front cradle bushings did change the pinion angle, I'm also thinking it affectively lengthened the driveshaft just slightly which unloaded the cvs a tiny bit, allowing them to work more affectively.

Like AAIIC, my driveshaft is a very tight fit and I've come to the conclusion that the shaft needs to bolt into the car in a relaxed state to work like it supposed to, not with the cvs compressed as it is now. After thinking back, I can honestly say I've never installed a cv shaft that wasn't fairly relaxed when I put it in and I've done my share.

will shortening the driveshaft help me out here? I have no clue but since DSS is close by, it's the easiest thing for me to try next so that's where I'm headed.

#215

TECH Resident

iTrader: (3)

If the CV joint is too far compressed it will bind and cause vibes for sure. Same issue with running too much angle. The rear CV joint has like 10* of operating angle or so.. might even be less. With that low angle and being compressed I don't believe yours can operate how they should. But I'm not an expert.

#216

TECH Addict

iTrader: (2)

If the CV joint is too far compressed it will bind and cause vibes for sure. Same issue with running too much angle. The rear CV joint has like 10* of operating angle or so.. might even be less. With that low angle and being compressed I don't believe yours can operate how they should. But I'm not an expert.

#217

TECH Addict

iTrader: (15)

Whaddaya think?

#218

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,407

Received 107 Likes

on

89 Posts

It seems like the easier route would be to take some thickness out of the 8.8 adapter. I am not looking at mine right now so I could be wrong but it seems like there was some meat that could be machined away. Also a very portable part and more easily sourced if messed up. That's what I would try if I were looking to "decompress" the shaft a bit.

Whaddaya think?

Whaddaya think?

I think the CS adapter is cut down as much as they're comfortable doing. I don't know how tight the clearance is now, but at some point as you shave the adapter down you'll end up with the rear face of the CV bottoming out on the pinion shaft and pinion nut protruding from the pinion flange. I imagine that's the limiting factor on how thin you can make the adapter.

Last edited by AAIIIC; 01-10-2017 at 09:00 AM.

#219

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,407

Received 107 Likes

on

89 Posts

The driveshaft I just reinstalled (the shortened one with the VDC poly carrier bearing surround) had some grease in the bolt holes at the rear CV. Is that a sign of impending doom, or is that just a sign that the rear cover wasn't tightly held in place so some grease leaked out? (It's been in a box in my garage for months, and I didn't zip-tie the rear cover in place while it was sitting there.)

#220

TECH Addict

iTrader: (2)

It seems like the easier route would be to take some thickness out of the 8.8 adapter. I am not looking at mine right now so I could be wrong but it seems like there was some meat that could be machined away. Also a very portable part and more easily sourced if messed up. That's what I would try if I were looking to "decompress" the shaft a bit.

Whaddaya think?

Whaddaya think?

yea, if there's enough bolt engagement and pinion clearance then it would make sense to mill the adapters. But there's yet another question to answer that I'm sure I wont get an answer too....why did DSS make the adapters that thick?

I'm on my second driveshaft from these guys and while the performance of their product has been a disappointment their customer service hasn't been. I might be able to talk them into doing whatever needs to be done to shorten this POS for free.

in other words, the driveshafts coming out of the car so it's going to DSS one way or another so I may just let them figure out how they want to shorten it.