control arm bushings

#41

Look at the video posted recently in that thread. I basically got my a$$ handed to me on the poly in F-bodies and some others..which i am good with--always like to learn. But the video talking about the IRS with poly has me thinking we may run into a little of the same with our trailing arms. Maybe not. Need to get a break from work and get mine back on the lift and try it out. And put the engine in. And the trans, diff, axles. And everything else.

#43

TECH Regular

iTrader: (1)

Join Date: Oct 2003

Location: Tampa FL

Posts: 474

Likes: 0

Received 0 Likes

on

0 Posts

Yep! And he sold lots of suspension parts for F-bodies too, since that's what he drove to win the AutoX Nationals. I never knew a fat Camaro could move like that.

Once I upgraded to his custom valved shocks, sway bars and springs, there was a definite improvement in my times.

Once I upgraded to his custom valved shocks, sway bars and springs, there was a definite improvement in my times.

#44

TECH Regular

iTrader: (1)

Join Date: Oct 2003

Location: Tampa FL

Posts: 474

Likes: 0

Received 0 Likes

on

0 Posts

Definitely. As the solid rear axle articulates during cornering, due to body roll, the control arm joint needs to twist. The poly bushings (in part due to stiffness, but mostly due to design) would bind and cause unpredictable snaps, which almost always resulted in unintentional over steer. Not exactly the type of behavior you want for daily driving, much less AutoX or road racing.

#45

TECH Fanatic

iTrader: (1)

Yep! And he sold lots of suspension parts for F-bodies too, since that's what he drove to win the AutoX Nationals. I never knew a fat Camaro could move like that.

Once I upgraded to his custom valved shocks, sway bars and springs, there was a definite improvement in my times.

Once I upgraded to his custom valved shocks, sway bars and springs, there was a definite improvement in my times.

#47

TECH Addict

iTrader: (13)

Strano's bars and either of his shock packages were **** for f-bodies. I WISH he would come out with a simple Bilstein kit for our cars. I'd buy right now. Heck, I'd buy a Koni kit too, but I always loved the Bilsteins on stock springs with sways. I actually put that arrangement on my old suburban. You'd be shocked how well it handles and still rides nice.

#48

TECH Junkie

iTrader: (3)

Fuzzy, what's your take on the lower rear control arm bushing (inner to the subframe)?

I've looked and it appears this bushing isn't offered but the smaller outer bushing is (OEM). I haven't removed that control arm, but looking down the side with it in place I believe I see rubber. Am I mistaken?

I've looked and it appears this bushing isn't offered but the smaller outer bushing is (OEM). I haven't removed that control arm, but looking down the side with it in place I believe I see rubber. Am I mistaken?

#49

Mercier and Bud, I read both of your questions but need more time to answer them. To answer Mercier's question, I have to **** on the F-body polyurethane bushing vendors as well as Creative Steel's imitations of the Revshift designs. Diagrams will be involved.

To answer Bud's question, I need to finish refurbishing some spare rear V1 LCAs (a previously low priority task) and take some pictures of the process. Both bushings are available, but pressing them out is extremely hard. I almost broke my 10 ton arbor press trying to get the rusted originals out. I need a bigger press.

A while back, Creative Steel offered pictures of adjustable "rear spring perch delete" lower control arms, but for one reason or another they never became real products. The idea was sound; the only real problem is that most people don't want to delete the perch. What we really need is a narrower, adjustable length spring perch. The camber adjustment slots on the rear subframe are basically unusable since they're tucked up under the bumper.

To answer Bud's question, I need to finish refurbishing some spare rear V1 LCAs (a previously low priority task) and take some pictures of the process. Both bushings are available, but pressing them out is extremely hard. I almost broke my 10 ton arbor press trying to get the rusted originals out. I need a bigger press.

A while back, Creative Steel offered pictures of adjustable "rear spring perch delete" lower control arms, but for one reason or another they never became real products. The idea was sound; the only real problem is that most people don't want to delete the perch. What we really need is a narrower, adjustable length spring perch. The camber adjustment slots on the rear subframe are basically unusable since they're tucked up under the bumper.

Last edited by FuzzyLog1c; 01-13-2017 at 01:09 PM.

#50

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,405

Received 107 Likes

on

89 Posts

I have a poly bushing in the knuckle where the trailing arm attaches, and I have the old MAP trailing arms, which have a Delrin (or Delrin-like) front bushing/joint. I have GMPP UCAs, which (apparently) have firmer rubber bushings. With what I've got thus far I think it would be inviting significant bushing bind to go all poly in the LCA; maybe one end or the other, but not both ends.

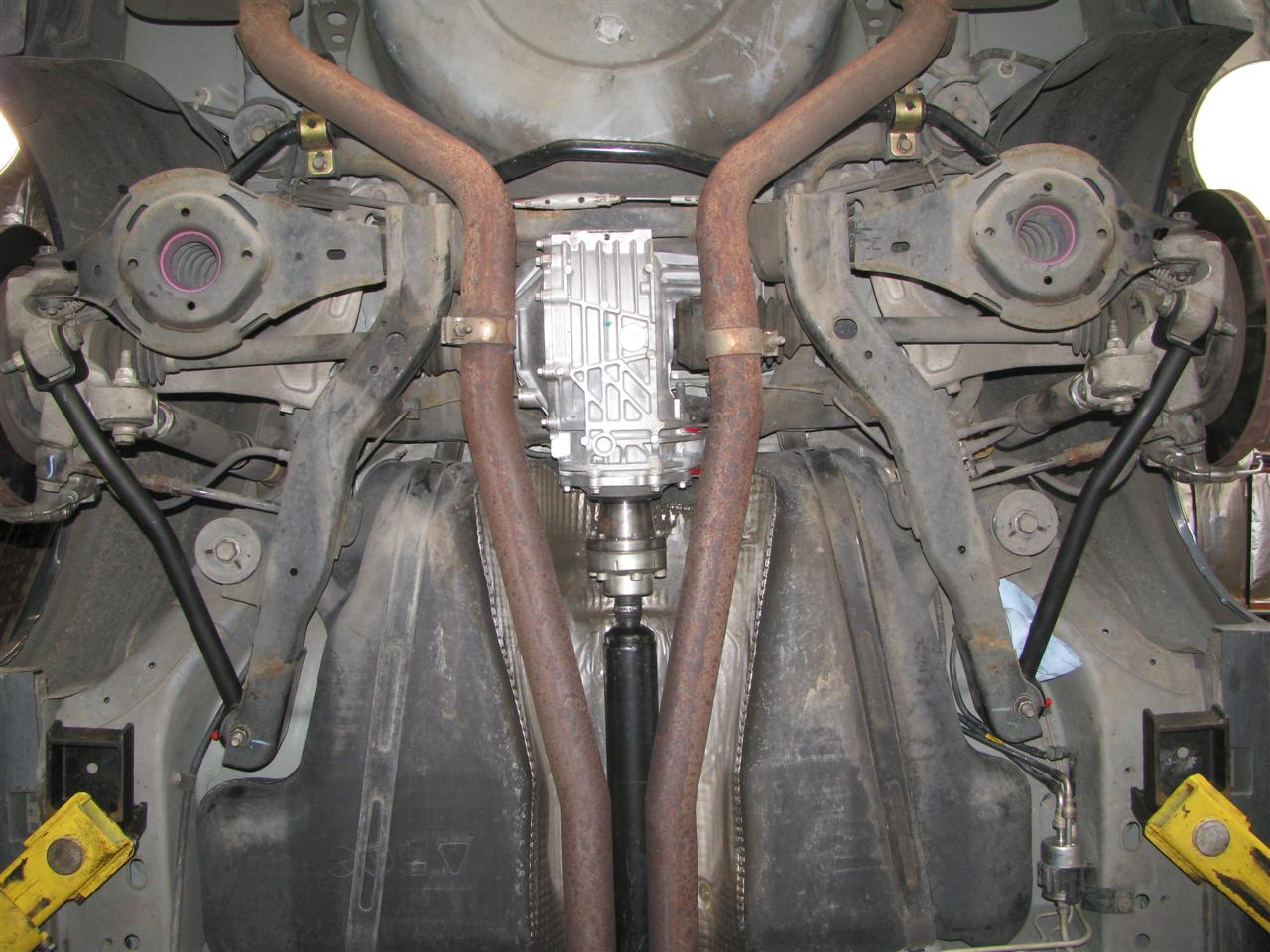

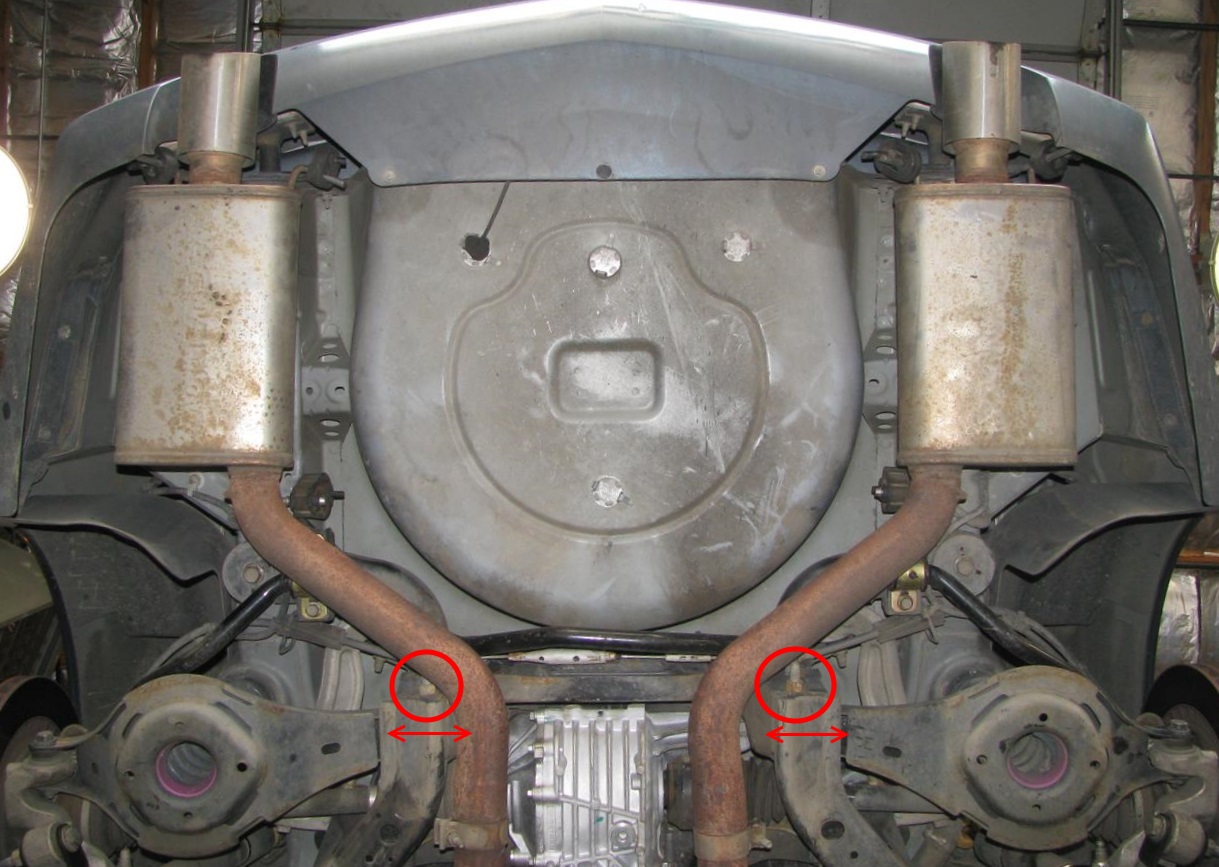

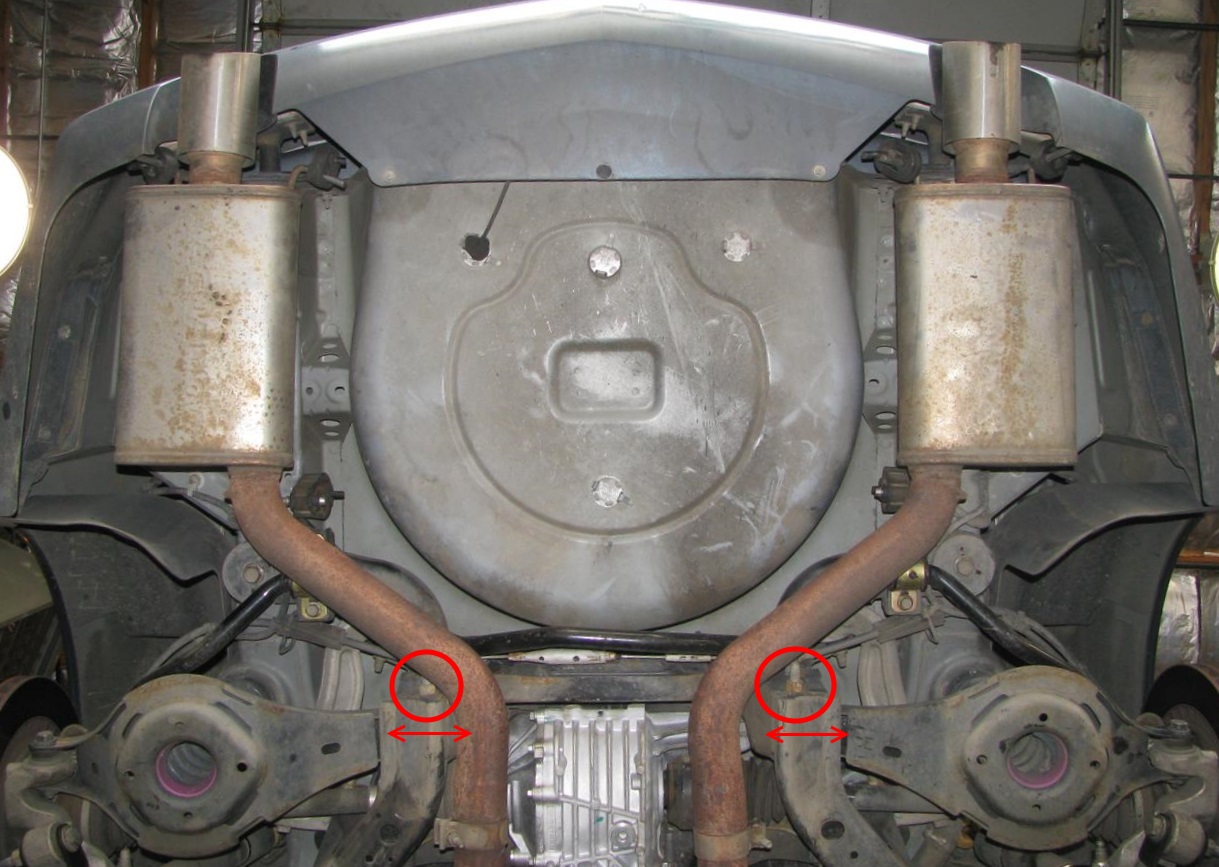

Seriously, I think the rear camber adjustments are easily accessible. Yes, the exhaust pipes are there, but that's not much of an impediment.

#52

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,405

Received 107 Likes

on

89 Posts

In that last pic you can see the bolts with nuts on them sticking out the back of the end of the subframe. Those are the LCA mounting bolts. Camber adjustment is done by loosening those and sliding the LCA in or out.

#53

On The Tree

iTrader: (1)

Join Date: Dec 2012

Location: GA

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I believe I was the one that talked to you, and I appreciate the input. We are redesigning the grease channels on the flanges of all our bushings and redesigning the molds to retain grease and flow it to where it needs to be.

And yes, having a greaseable bolt is a lifesaver!

And yes, having a greaseable bolt is a lifesaver!

My opinion is that the inside of the bushings is completely open (no flange), so all the grease just runs out that end. You can also see the gap between the non-flanged side and the inner metal sleeve opens up at least an 1/8" if you turn the wheels back and forth while it's on the rack.

If someone can tell me how to keep the grease in these, I'm all about it, but at this point I'm ready to plop in the revshifts and see if they are better. They don't have a wide open path for water to wash out the grease, so I'm hoping that will help. I'm a fan of all the other CS products I have, but these LCA bushings are really p!ssing me off.

#54

TECH Junkie

iTrader: (3)

I can't say I'm having the same problem. Do you have any photos of the 1/8th inch gap? I'm having trouble picturing where you'd be seeing that. Popping would indicate some sort of excessive wear as opposed to a lack of lube which squeaks, wouldn't it?

As far as the revshifts, there are no grease provisions from what I see. Dropping a control arm to grease them annually to semi annually sounds like a pain, especially considering an alignment may be necessary.

As far as the revshifts, there are no grease provisions from what I see. Dropping a control arm to grease them annually to semi annually sounds like a pain, especially considering an alignment may be necessary.

#55

TECH Addict

iTrader: (19)

Join Date: Aug 2007

Location: Where the Navy tells me to go

Posts: 2,405

Received 107 Likes

on

89 Posts

I'm having a hard time visualizing the 1/8" gap, too.

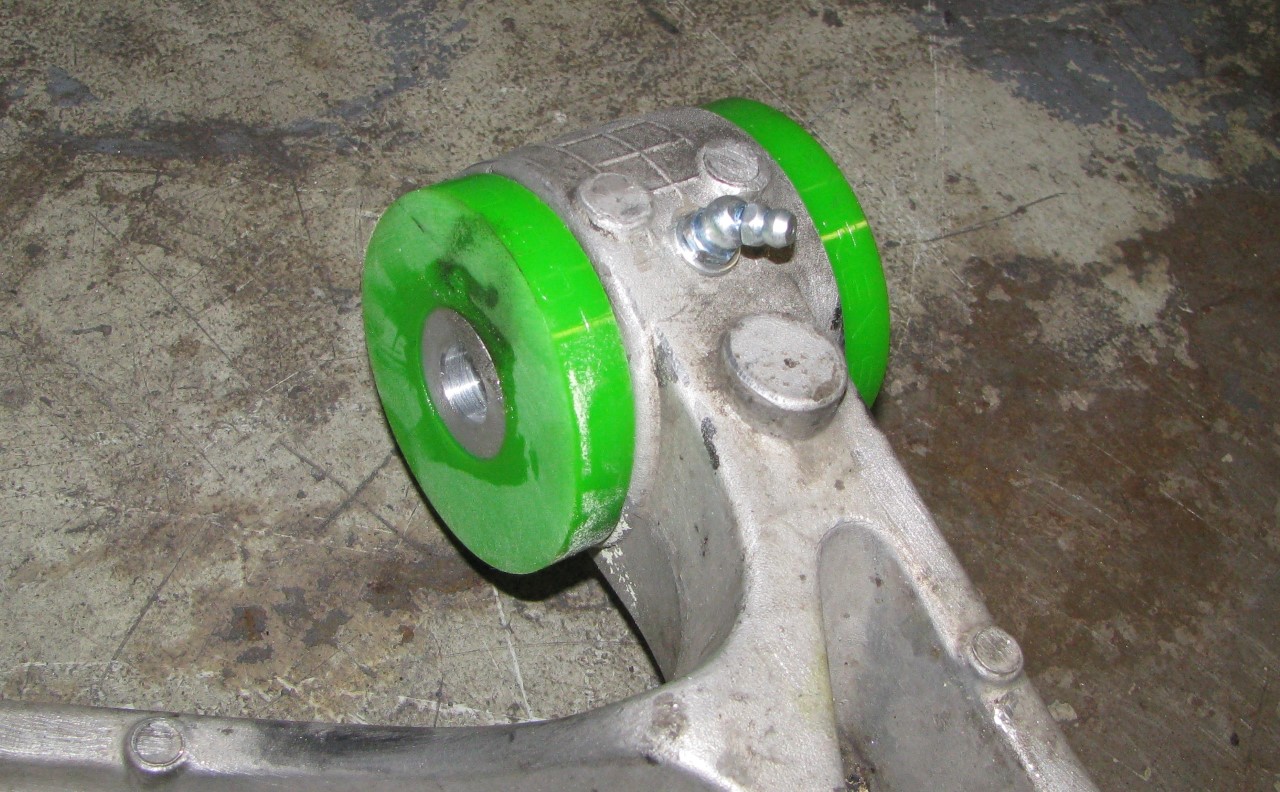

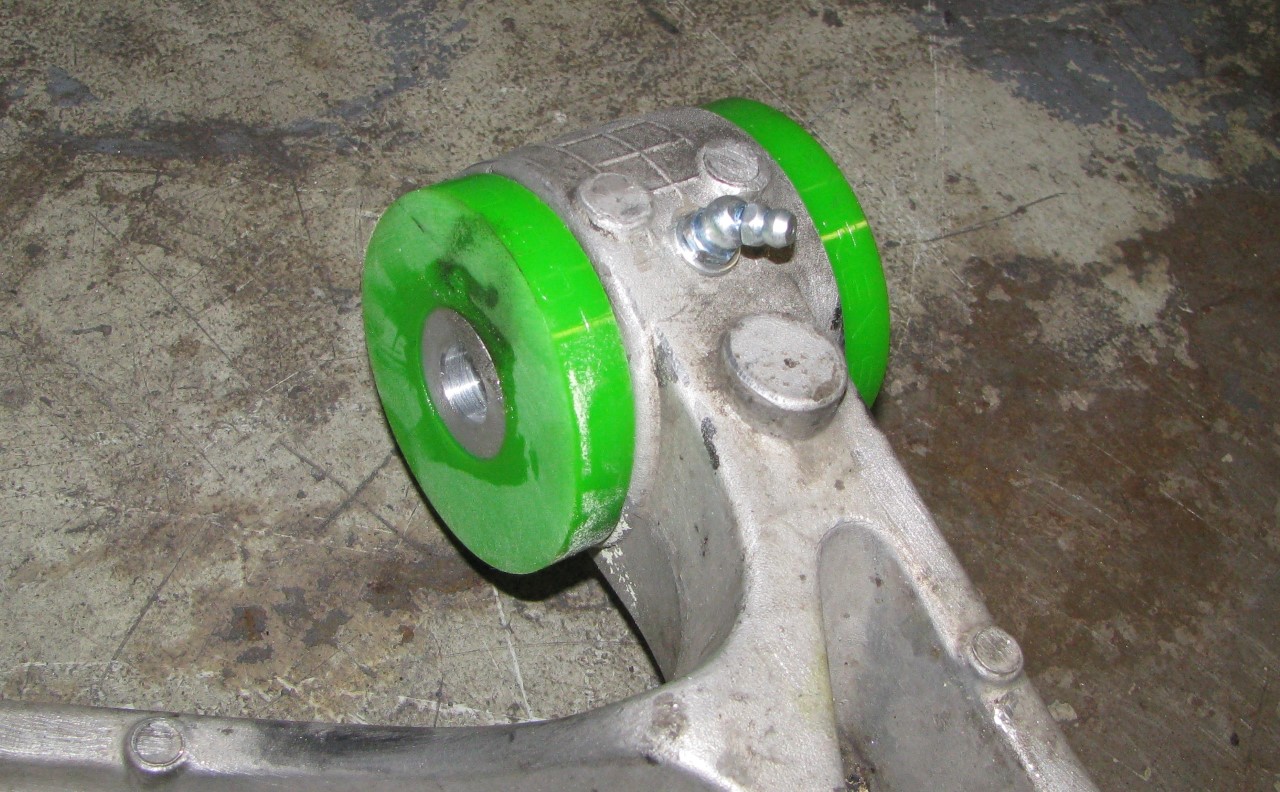

As for greasing the Revshift ones, I drilled my control arms for zerks:

I also used a belt sander and palm sander to reduce the thickness of the Revshift bushing flanges. They were too thick, so they would've generated all sorts of unnecessary binding against the mounts.

As for greasing the Revshift ones, I drilled my control arms for zerks:

I also used a belt sander and palm sander to reduce the thickness of the Revshift bushing flanges. They were too thick, so they would've generated all sorts of unnecessary binding against the mounts.

#56

On The Tree

iTrader: (1)

Join Date: Dec 2012

Location: GA

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

I can't say I'm having the same problem. Do you have any photos of the 1/8th inch gap? I'm having trouble picturing where you'd be seeing that. Popping would indicate some sort of excessive wear as opposed to a lack of lube which squeaks, wouldn't it?

As far as the revshifts, there are no grease provisions from what I see. Dropping a control arm to grease them annually to semi annually sounds like a pain, especially considering an alignment may be necessary.

As far as the revshifts, there are no grease provisions from what I see. Dropping a control arm to grease them annually to semi annually sounds like a pain, especially considering an alignment may be necessary.

The popping is more like a stick/slip in the bushing. It's not wear- the bushings were installed in September and it started doing it within a few weeks. I thought it was steering/tie-rods/etc., but two different shops diagnosed it as the bushings. I didn't bias them- I just said I have a popping noise while steering, please take a look. They both called me out to take a look and you can tell the popping is coming from the bushings. You can feel it if you put your hand on the LCA by the bushing, too.

It also goes away every time it rains, because the water gets in there and acts as a lube. Once the roads dry up, popping returns. I can't even get it to hold grease- it just takes the path of least resistance, i.e., straight out the end with no flange. You can see in the photo where it comes straight out. I figure at least the revshifts will have the other flange to provide some protection from water ingress and also some pressure resistance to force the grease to fill the gaps instead of running straight out.