1991 Z/28 6.0L/T56 Swap

#82

update time....

burned in the subframe connectors and i have started on my 8.8 hybrid build. should have it done in a few weeks. hope to have the car on the rollers by early may.

burned in the subframe connectors and i have started on my 8.8 hybrid build. should have it done in a few weeks. hope to have the car on the rollers by early may.

#84

started a build thread on the 8.8 in the gear section

https://ls1tech.com/forums/gears-axl...l#post17307710

https://ls1tech.com/forums/gears-axl...l#post17307710

#85

8.8 build is finished, on to the dyno on friday for the tune.

will need to do some detail work to center the axle at a later date, didn't do my due diligence and now my rear is 7/8" too far back. going to drive as-is this summer and enjoy before #4 gets here. this winter i'll pull it back apart and get the ds chopped down and move the torque arm mount if i have to.

8.8 held some 2800 rpm dumps, and with the jegster ta and lcarbs/boxed lca's it bites hard.

will need to do some detail work to center the axle at a later date, didn't do my due diligence and now my rear is 7/8" too far back. going to drive as-is this summer and enjoy before #4 gets here. this winter i'll pull it back apart and get the ds chopped down and move the torque arm mount if i have to.

8.8 held some 2800 rpm dumps, and with the jegster ta and lcarbs/boxed lca's it bites hard.

#86

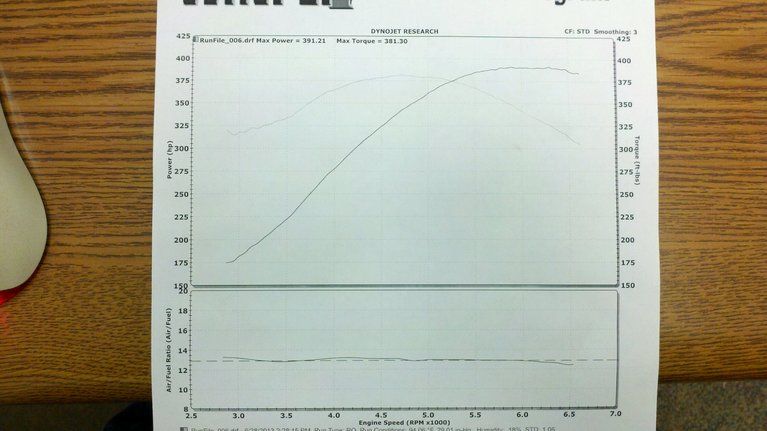

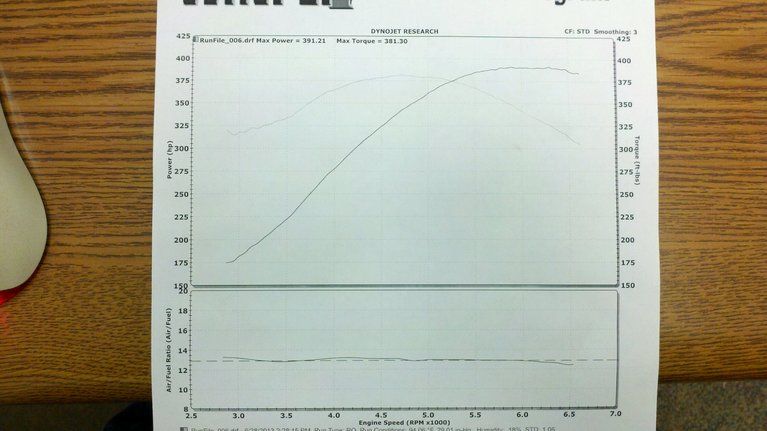

dyno numbers are in...

391hp/381tq

didn't hit the 400# that i was looking for, but i'm still very pleased. justin said more cam and more compression, but i explained to him it was not a track car or a racecar. the car does what i want it too and we'll see what the track numbers say. he went and did the street tune and when he came back it put down 371/366. he worked his way up from there.

i think their is some more left in it, my pinion angle has been giving me fits, and i think it was binding a little during the dyno session.

the cutout added 10hp/10tq when opened, so i'll definitely be going to a 3.5" single exhaust. it idles better and drives better, so i'm happy with the end result.

trying to get the pinion angle dialed in has been a headache, the car was smooth all the way up to 130mph plus before. now has a vibration after 70. so that is my new mission.

391hp/381tq

didn't hit the 400# that i was looking for, but i'm still very pleased. justin said more cam and more compression, but i explained to him it was not a track car or a racecar. the car does what i want it too and we'll see what the track numbers say. he went and did the street tune and when he came back it put down 371/366. he worked his way up from there.

i think their is some more left in it, my pinion angle has been giving me fits, and i think it was binding a little during the dyno session.

the cutout added 10hp/10tq when opened, so i'll definitely be going to a 3.5" single exhaust. it idles better and drives better, so i'm happy with the end result.

trying to get the pinion angle dialed in has been a headache, the car was smooth all the way up to 130mph plus before. now has a vibration after 70. so that is my new mission.

#88

then i can eliminate my cutout....possibly. tired of hearing it rattle.

#90

made some slow progress over the last 2 weeks. getting the car "ready" for this spring. needed to clean up some things that were left over from last year.

first, i was able to get my intake finished up. i cut a small chunk of aluminum tube that i had laying around and drilled a hole for the IAT sensor. everything else went together without much mofication.

this weekend i had a short blast on the rear end project. pulled the rear out, ground the welds down on the LCARBs and took the air chisel to bust them loose. i cut down the nose on the torque arm to give me the 7/8" clearance i will need. put the new LCA's together, decided to try the 3 piece poly joints, mounted them on the car, and put the new LCARBs on the axle.

i still need to hook up the axle and do some measuring before i weld the LCARBs on. then all i have to do is measure for the drive shaft recut and i should have this project wrapped up.

then it's on to new head lights and secondary harness with relays to make them brighter.

first, i was able to get my intake finished up. i cut a small chunk of aluminum tube that i had laying around and drilled a hole for the IAT sensor. everything else went together without much mofication.

this weekend i had a short blast on the rear end project. pulled the rear out, ground the welds down on the LCARBs and took the air chisel to bust them loose. i cut down the nose on the torque arm to give me the 7/8" clearance i will need. put the new LCA's together, decided to try the 3 piece poly joints, mounted them on the car, and put the new LCARBs on the axle.

i still need to hook up the axle and do some measuring before i weld the LCARBs on. then all i have to do is measure for the drive shaft recut and i should have this project wrapped up.

then it's on to new head lights and secondary harness with relays to make them brighter.

#93