LQ4 with LS3 heads/4l80e in a 1968 camaro - Ryan's Official Build thread.

#1

So I've been doing a build thread on camaros.net, but no one there is really as interested.

I'm going to repost the thread's pictures and brief story here, and post here as well. This thread is where I got

I live in a condo in downtown Miami. Here is the view:

I am fortunate enough to have a 1968 Camaro. I purchased the camaro for $2000 in the summer of 2001, when I was in college. It had a blown engine and a powerglide transmission. The upholstery was shot. It had a nice krylon paint job.

I put in a 383 and a TH 350 a couple years back. Also got the car painted. It was equipped with the pro-topline heads, and a 222/232 custom ground cam with .447 lift. I ran it with a rebuild holley carb on an air-gap intake. It had ceramic coated headers and a flow master exahust. I installed the Mark 8 fan and an aluminum 4 core radiator. The car never was really something I could drive every day. The car would stall on hard braking, backfire, stall at idle, and otherwise drive like crap. I'd put a timing light to get it to run well and set the idle speed, and then drive it out for a weekend, but then next time I'd drive it the weather or humidity would be different and it would drive like crap again.

Here is the car as it sits today:

It has dings and a few dents, has a bit of bondo, but I don't want to do a frame off right now, just to have a good looking car that drives great. 5 years from now I'll take it off the frame.

As you can imagine, you can't exactly work on a Camaro in downtown Miami. So the car is located in the warehouse district waaaaay down south, where I can get a smallish warehouse for very, very cheap. Each weekend I drive about a half hour to get to the car where I work on it. I've become sick of having such a fun car but having it be so tempermental. I understand I could proobably tune it and put on a choke and fiddle with it to get it running perfectly, but let's face it: carbs do not even compare with EFI for drivability. I wanted the car to be like my 99 trans am. Turn the key, go. Change oil every 3000 miles and that's about it. Furthermore, the old technology, including different valve angles and hydraulic rollers makes the modern GM V8 pretty much the best engine out there that will pretty much bolt up to a 68 camaro.

So in January I bought this:

[img]https://img.photobucket.com/albums/v654/killmrryan/IMG_20110122_113414.jpg

[/img]

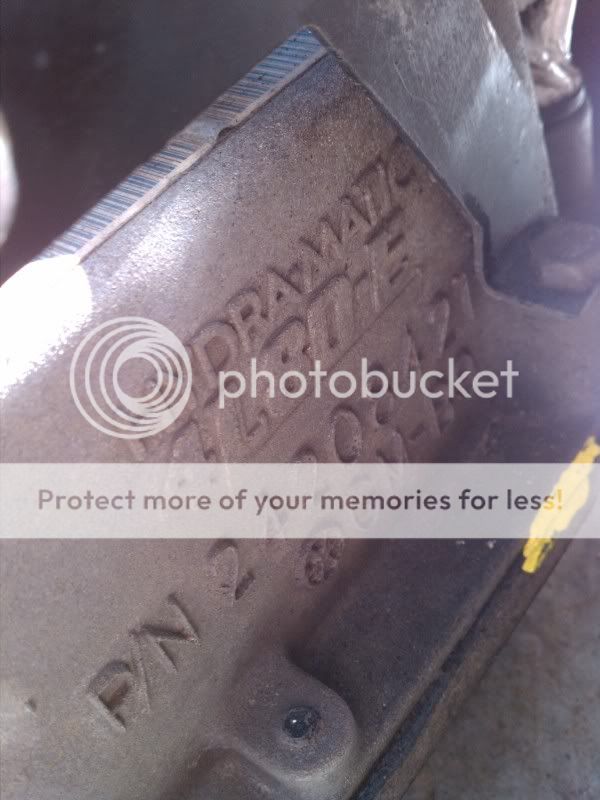

It is an Lq4 6.0L truck engine from a 2006 Chevrolet Silverado. You can get these shortblocks for $800. This one was $1500 as it came with all accessories, ECU, and harness. I've shipped the ecu to Brenden at lt1swap.com, who is programming it for me. He charges only $75.

Here is the old engine:

I had patrick G here design me a cam. It's a .222/.230 with .570" of lift (remember, DAILY DRIVER)

Here are some of the parts I bought:

Edelbrock 90 mm TB:

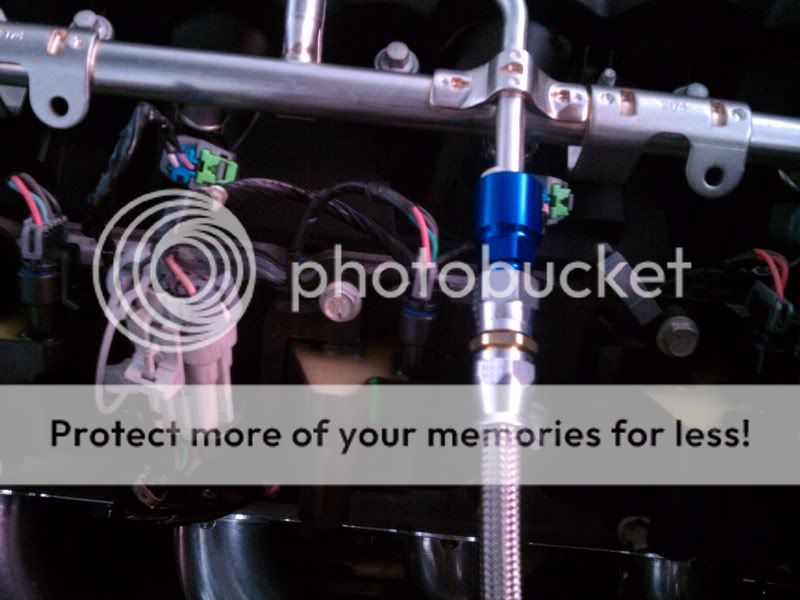

An LS3 intake, complete with injectors and rails:

LS3 heads:

Me putting together the wiring harness on my living room floor (I'm sure glad I don't have a wife to bitch about these sorts of things!)

Used 4l80e transmission:

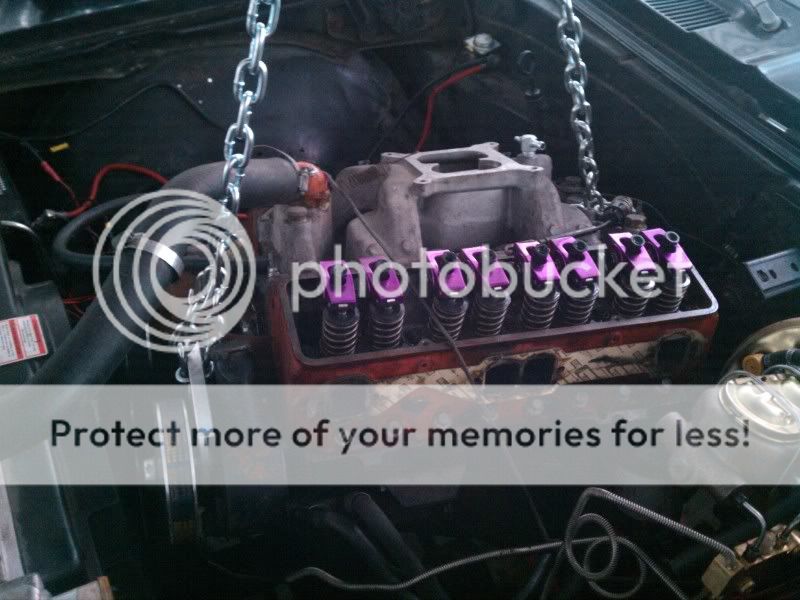

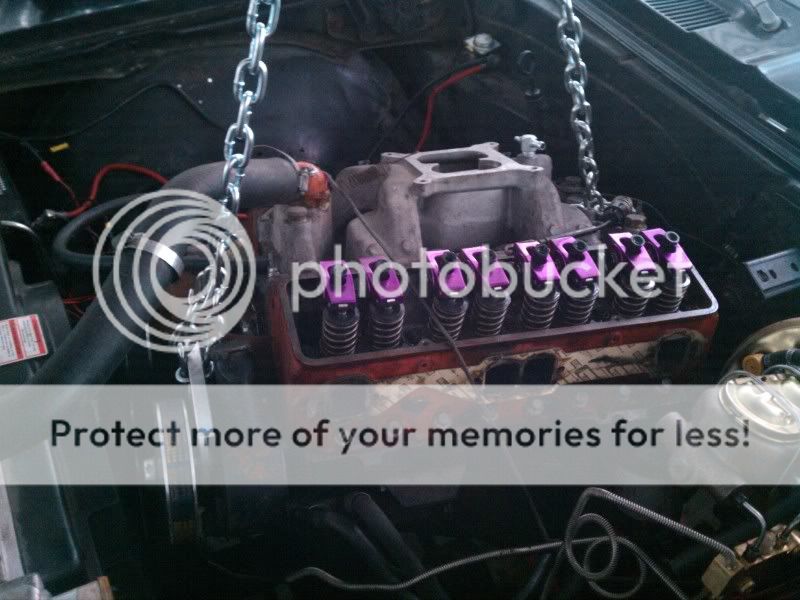

Putting the engine in - April 2, 2011:

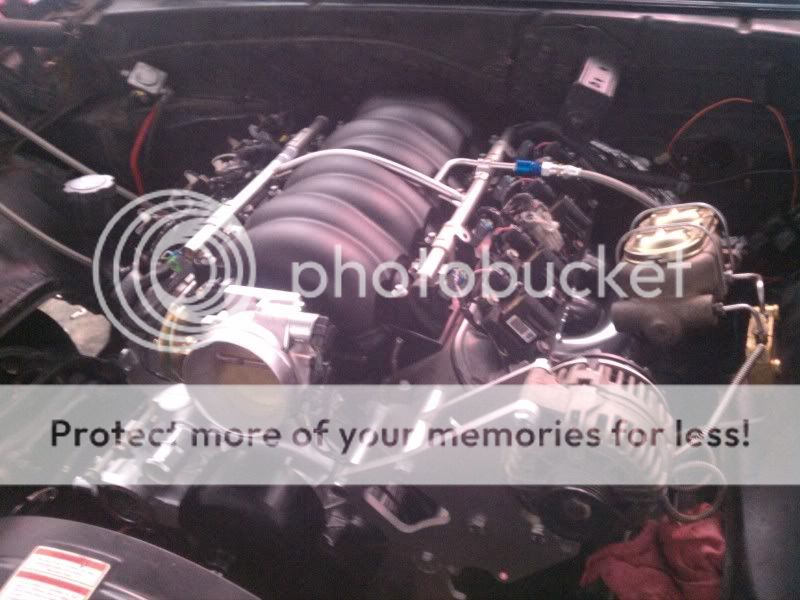

Few more updates:

As you can see I went with Kwik brackets.

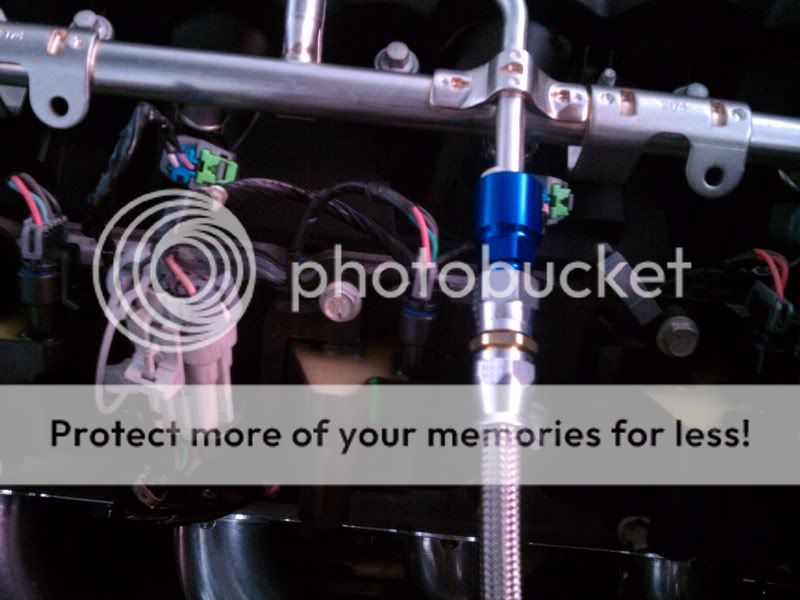

I hope this connector doesn't spray fuel anywhere - this is hooked up to a Spetra tank:

Some gauges I ordered:

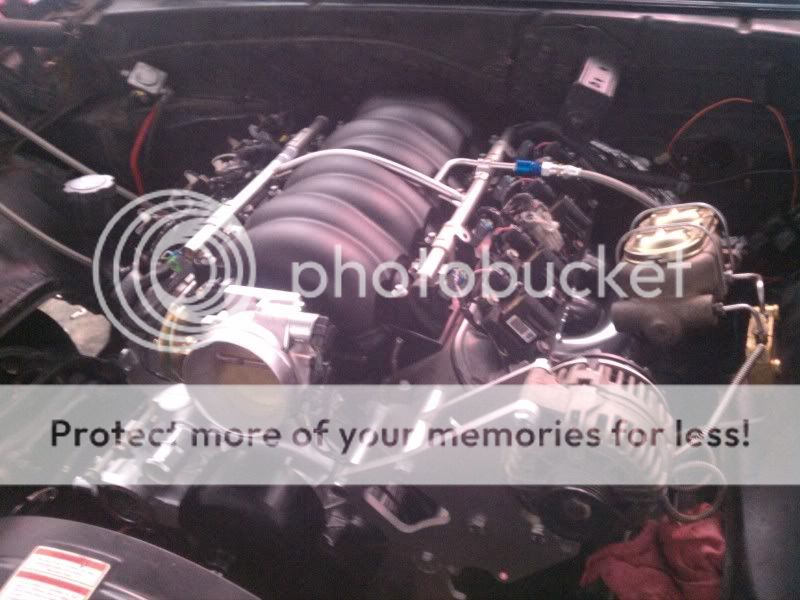

Coming together:

Had to squeeze the caps together for the Denny's driveshaft. My rear is a 9.5" 14 bolt welded to fit a 68 camaro done by a guy named Jim at JD Race.

Installed subframe body mounts (GW- solid): Didn't break anything!

Interor isn't bad - there's the OBDII input!

I'm going to repost the thread's pictures and brief story here, and post here as well. This thread is where I got

I live in a condo in downtown Miami. Here is the view:

I am fortunate enough to have a 1968 Camaro. I purchased the camaro for $2000 in the summer of 2001, when I was in college. It had a blown engine and a powerglide transmission. The upholstery was shot. It had a nice krylon paint job.

I put in a 383 and a TH 350 a couple years back. Also got the car painted. It was equipped with the pro-topline heads, and a 222/232 custom ground cam with .447 lift. I ran it with a rebuild holley carb on an air-gap intake. It had ceramic coated headers and a flow master exahust. I installed the Mark 8 fan and an aluminum 4 core radiator. The car never was really something I could drive every day. The car would stall on hard braking, backfire, stall at idle, and otherwise drive like crap. I'd put a timing light to get it to run well and set the idle speed, and then drive it out for a weekend, but then next time I'd drive it the weather or humidity would be different and it would drive like crap again.

Here is the car as it sits today:

It has dings and a few dents, has a bit of bondo, but I don't want to do a frame off right now, just to have a good looking car that drives great. 5 years from now I'll take it off the frame.

As you can imagine, you can't exactly work on a Camaro in downtown Miami. So the car is located in the warehouse district waaaaay down south, where I can get a smallish warehouse for very, very cheap. Each weekend I drive about a half hour to get to the car where I work on it. I've become sick of having such a fun car but having it be so tempermental. I understand I could proobably tune it and put on a choke and fiddle with it to get it running perfectly, but let's face it: carbs do not even compare with EFI for drivability. I wanted the car to be like my 99 trans am. Turn the key, go. Change oil every 3000 miles and that's about it. Furthermore, the old technology, including different valve angles and hydraulic rollers makes the modern GM V8 pretty much the best engine out there that will pretty much bolt up to a 68 camaro.

So in January I bought this:

[img]https://img.photobucket.com/albums/v654/killmrryan/IMG_20110122_113414.jpg

[/img]

It is an Lq4 6.0L truck engine from a 2006 Chevrolet Silverado. You can get these shortblocks for $800. This one was $1500 as it came with all accessories, ECU, and harness. I've shipped the ecu to Brenden at lt1swap.com, who is programming it for me. He charges only $75.

Here is the old engine:

I had patrick G here design me a cam. It's a .222/.230 with .570" of lift (remember, DAILY DRIVER)

Here are some of the parts I bought:

Edelbrock 90 mm TB:

An LS3 intake, complete with injectors and rails:

LS3 heads:

Me putting together the wiring harness on my living room floor (I'm sure glad I don't have a wife to bitch about these sorts of things!)

Used 4l80e transmission:

Putting the engine in - April 2, 2011:

Few more updates:

As you can see I went with Kwik brackets.

I hope this connector doesn't spray fuel anywhere - this is hooked up to a Spetra tank:

Some gauges I ordered:

Coming together:

Had to squeeze the caps together for the Denny's driveshaft. My rear is a 9.5" 14 bolt welded to fit a 68 camaro done by a guy named Jim at JD Race.

Installed subframe body mounts (GW- solid): Didn't break anything!

Interor isn't bad - there's the OBDII input!

#2

Here is the post from last weekend:

On Worked again all day on the car. The morning started like this:

http://www.youtube.com/watch?v=zqaCUHz3MjQ

http://www.youtube.com/watch?v=FzwOBAi3eQw

It is awesome when your ECU turns on your fan. (skip ahead to 30 seconds in).

http://www.youtube.com/watch?v=UGq3P6fsAjA

It turns on at 195 degrees.

And then. Kaput. Kept turning over but wouldn't start. Timing light showed no spark. Checked codes, it said there was a problem with the MAF in the intake piping. Tuns out this was the problem:

.

.

The MAF wire got caught in the belt. The ground and the +12 got crossed. I fixed it. But still it didn't turn over. I checked the fuses with my multimeter and it said they were fine. Most of my wiring is hidden behind the manifold. I actually routed a the front sensors underneath the manifold. (you can do it on an LS engine). After a great deal of troubleshooting, turns out it really was a fuse:

Car started right up once I replaced it.

Actually got it down from the jackstands, and for the first time since January, it rolled under its own power!

Tranny works! Rear is good!

I killed it a few feet out of the garage. When I tried to fire it up again, it would fire up and die immediately. I played with a couple of wires and it fired up, but there are some codes the car is throwing. Specifically, MAF, MAP, and TPS are not working. It is probably a short. But that will have to wait until next weekend because I literally spent all day there both days. We'll see if next weekend I can get the exhaust installed.

On Worked again all day on the car. The morning started like this:

http://www.youtube.com/watch?v=zqaCUHz3MjQ

http://www.youtube.com/watch?v=FzwOBAi3eQw

It is awesome when your ECU turns on your fan. (skip ahead to 30 seconds in).

http://www.youtube.com/watch?v=UGq3P6fsAjA

It turns on at 195 degrees.

And then. Kaput. Kept turning over but wouldn't start. Timing light showed no spark. Checked codes, it said there was a problem with the MAF in the intake piping. Tuns out this was the problem:

.

.The MAF wire got caught in the belt. The ground and the +12 got crossed. I fixed it. But still it didn't turn over. I checked the fuses with my multimeter and it said they were fine. Most of my wiring is hidden behind the manifold. I actually routed a the front sensors underneath the manifold. (you can do it on an LS engine). After a great deal of troubleshooting, turns out it really was a fuse:

Car started right up once I replaced it.

Actually got it down from the jackstands, and for the first time since January, it rolled under its own power!

Tranny works! Rear is good!

I killed it a few feet out of the garage. When I tried to fire it up again, it would fire up and die immediately. I played with a couple of wires and it fired up, but there are some codes the car is throwing. Specifically, MAF, MAP, and TPS are not working. It is probably a short. But that will have to wait until next weekend because I literally spent all day there both days. We'll see if next weekend I can get the exhaust installed.

Trending Topics

#9

TECH Senior Member

iTrader: (12)

Hey.. great start to your build. Yeah. this new engine well be great once you get it all of the bugs out. The EFI well handle them climate changes for your with out any tuning.

But it looks like you got a few bugs more to find and fix.. I'd check over the wiring again.. makes sure you don't have any cold joints or crossed wires.

But it looks like you got a few bugs more to find and fix.. I'd check over the wiring again.. makes sure you don't have any cold joints or crossed wires.

#10

Got the exhaust welded up.

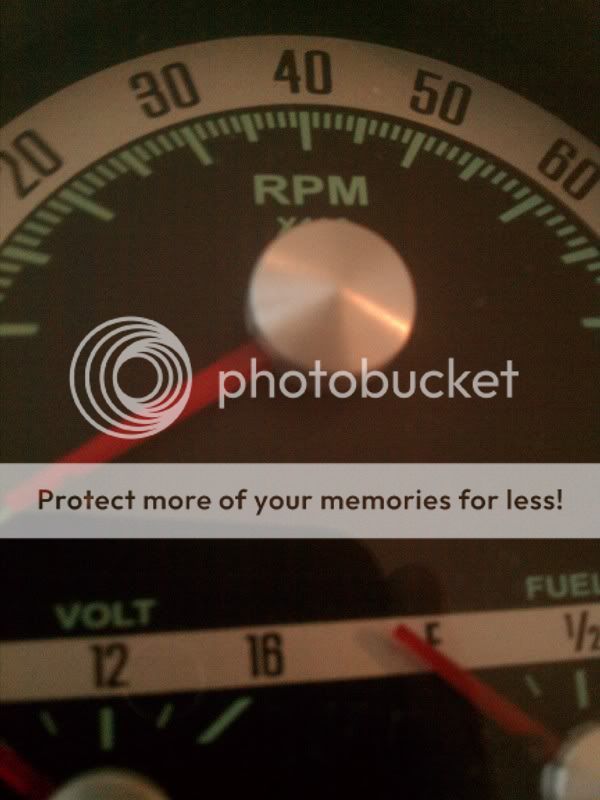

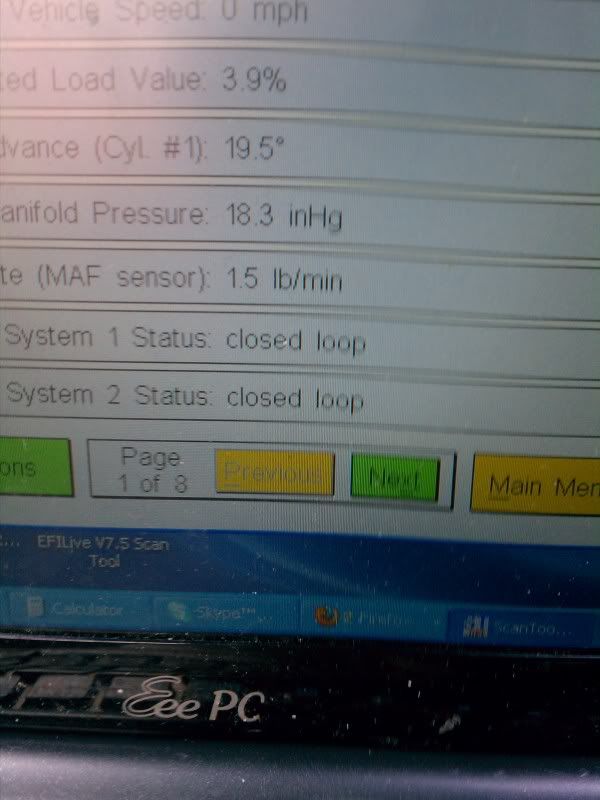

I was pleased to see this:

Closed loop!

Here's the exhaust.

http://www.youtube.com/watch?v=qPg1RwDZZOI

I have to isolate the whistle at 1:10. I think it is either the PCV hooked up wrong or the exhaust

http://www.youtube.com/watch?v=GZ9_ZvXhUI8

As you can see here, hot idle is low - it looks like between 10-15 psi - but gets up 10 PSI per 1k rpm at least. I am dead certain I put in that O-ring properly (red). The Bearings have 90k miles on them - probably should have replaced them, but they looked good. I didn't want to tear apart the entire bottom end. I think the oil level is low, it had a leak (from the bolts not being tight on the oil filter adaptor, which I fixed). Plus when I got home I realized that I misread somewhere that the oil pan holds only 4 quarts, so that's all I put in. Maybe with the full 5 1/2 it should have, it won't be a problem. I've read GM doesn't consider an engine requiring service until 6 psi at idle or less anyway. Maybe it's the gauge as well. I've got 5-30 in it now, going to put 10-40 and just run it until it knocks. It doesn't have any noises in it now, and there was no oil or junk in the old pan/oil, so I feel fine running it. I'm not tearing it apart or taking it out of the car until it knocks. If and when it does, well, I'll just use that as an excuse to get a 408 stroker crank with all forged internals.

The gauges. I love them. New Vintage USA. 68 series. They are amazing. I didn't want 12 different gauges installed in various places, and these have all you need - oil pressure, temp, volts, fuel level, tach, speedo. Best looking gauges you can find, and they fit right in the old bezel. I think they were around $700.00. But when you're doing your own labor, you can spend more on parts. Worth every single penny.

As I said in my other post, the car has a whistle. It may be the rear main seal from an improper PCV setup, a leak, pulley, etc. I'm troubleshooting that next weekend.

The wiring harness I built works great so far. I did blow a fuse catching the MAF cable in the belts, which crossed +12 and ground, and had a bad MAP. Other than that it works great.

I was pleased to see this:

Closed loop!

Here's the exhaust.

http://www.youtube.com/watch?v=qPg1RwDZZOI

I have to isolate the whistle at 1:10. I think it is either the PCV hooked up wrong or the exhaust

http://www.youtube.com/watch?v=GZ9_ZvXhUI8

As you can see here, hot idle is low - it looks like between 10-15 psi - but gets up 10 PSI per 1k rpm at least. I am dead certain I put in that O-ring properly (red). The Bearings have 90k miles on them - probably should have replaced them, but they looked good. I didn't want to tear apart the entire bottom end. I think the oil level is low, it had a leak (from the bolts not being tight on the oil filter adaptor, which I fixed). Plus when I got home I realized that I misread somewhere that the oil pan holds only 4 quarts, so that's all I put in. Maybe with the full 5 1/2 it should have, it won't be a problem. I've read GM doesn't consider an engine requiring service until 6 psi at idle or less anyway. Maybe it's the gauge as well. I've got 5-30 in it now, going to put 10-40 and just run it until it knocks. It doesn't have any noises in it now, and there was no oil or junk in the old pan/oil, so I feel fine running it. I'm not tearing it apart or taking it out of the car until it knocks. If and when it does, well, I'll just use that as an excuse to get a 408 stroker crank with all forged internals.

The gauges. I love them. New Vintage USA. 68 series. They are amazing. I didn't want 12 different gauges installed in various places, and these have all you need - oil pressure, temp, volts, fuel level, tach, speedo. Best looking gauges you can find, and they fit right in the old bezel. I think they were around $700.00. But when you're doing your own labor, you can spend more on parts. Worth every single penny.

As I said in my other post, the car has a whistle. It may be the rear main seal from an improper PCV setup, a leak, pulley, etc. I'm troubleshooting that next weekend.

The wiring harness I built works great so far. I did blow a fuse catching the MAF cable in the belts, which crossed +12 and ground, and had a bad MAP. Other than that it works great.

Last edited by rp0029; 10-17-2011 at 08:34 PM.

#13

TECH Senior Member

iTrader: (12)

Glad to hear your working out them bugs and your in closed loop..

I would consider looking at the O-Ring or making sure the pickup is seated fully.. cause it really looks like your loosing pressure at idle. I've never seen my oil pressure below 45-50psi really HOT... usually 65psi hot at idle.

I would consider looking at the O-Ring or making sure the pickup is seated fully.. cause it really looks like your loosing pressure at idle. I've never seen my oil pressure below 45-50psi really HOT... usually 65psi hot at idle.

#15

Also, consider my sending gauge. The oil cooler delete wasn't an option due to header clearance, so I did this:

Perhaps the pressure isn't getting up the tube. Or maybe my sending wire is just getting electrical interference. Who knows?

Glad to hear your working out them bugs and your in closed loop..

I would consider looking at the O-Ring or making sure the pickup is seated fully.. cause it really looks like your loosing pressure at idle. I've never seen my oil pressure below 45-50psi really HOT... usually 65psi hot at idle.

I would consider looking at the O-Ring or making sure the pickup is seated fully.. cause it really looks like your loosing pressure at idle. I've never seen my oil pressure below 45-50psi really HOT... usually 65psi hot at idle.

I guess I'll hook up a mechanical gauge to it this weekend.

However, if this engine comes out of the car, even to check the damn oil ring, then I will tear it all down and have the block re-done and put in a stroker kit. I really don't want to take the engine out, and if I do, there had better be a damn good reason.

#16

TECH Senior Member

iTrader: (12)

Looking at your oil sender setup. I recall that Teflon tape can cause problems with one wire senders.. as they must get their grounds from the threads of the sender and the block (grounding circuit). Could be one reason for your various oil pressure readings.?

Some say it should not be used (don't flame me guys, its just what I have been told and read, and yes, many use it successfully) on them one wire senders. Other sealants should be used (Permatex ?). Some state that Teflon and oil are not to be used together also (?).

You can research on the internet searches and find both pro and cons on using teflon.

BC

Some say it should not be used (don't flame me guys, its just what I have been told and read, and yes, many use it successfully) on them one wire senders. Other sealants should be used (Permatex ?). Some state that Teflon and oil are not to be used together also (?).

You can research on the internet searches and find both pro and cons on using teflon.

BC

#17

11 Second Club

iTrader: (18)

Well if the pressure was there for a good bit of run time, i dont see it being the oring in the oil pump. You definitely might want to try to get a little more breathing space, exhaust temps could definitely be doing some damage to good oil. I'm not sure about the ground thing for the threads, but you could always try to ground the body of the sender. Also, the long tube wouldn't affect a pressure reading enough to be noticable.

I've got my fingers crossed for you on the oil change, hopefully that will bring it back up and you will just have to make some room.

Good luck!

Craig

I've got my fingers crossed for you on the oil change, hopefully that will bring it back up and you will just have to make some room.

Good luck!

Craig