Yet another New Edge Mustang, Turbo LQ9, T56

#1

Launching!

Thread Starter

This swap is already done and has been running for a while, but I thought I'd document it for the sake of anyone who wants to attempt something similar.I've owned this car since it was new. It started life as a 3.8L V6, and then went through several incarnations, including a 4.2L turbo V6. I got bored with the V6 setup (and worried about its longevity--the 3.8/4.2 wasn't really designed to make 450 whp like I was) and decided to go to the dark side. It's mostly just a silly street car that I like tinkering with; I don't have any intention of racing it.The current specs include:

LQ4/LQ9-based iron block engine built by Texas Speed

* Forged pistons

* Forged H-beam rods

* Stock crank

* ARP head and main studs

* PRC 225cc (as cast) cathedral port heads

* 228/232* (@ .050"), 114* LSA + 3*, .600" lift camshaft

* Stock rocker arms with trunion upgrade

* LS6 intake manifold

* CTS-V oil pan

* LS Brackets alternator relocation bracket (using "truck" accessory spacing)

* Slightly modified urethane 4.6L engine mounts so I can use my Maximum Motorsports K-member

Fuel and engine control

* Stock GM P59 ECU, 2-bar speed density OS with RTT, sensors based on '05 GMC Yukon

* Custom wiring harness by Speartech (DBW, cruise, no provision for MAF, EV6/USCAR injector connections)

* Injector Dynamics ID725 fuel injectors

* Dual Walbro GSS342 fuel pumps in an '03 Cobra tank (has additional baffle/sump compared to normal SN95 tank)

* Full return fuel system with boost-referenced Aeromotive regulator

Turbo system and exhaust

* Built by Doug Chase (www.chaserace.com) who is conveniently a block away from where I live

* LS3 Camaro exhaust manifolds, flipped side-to-side

* Turbonetics T-series 7875 turbocharger, T4, .96 A/R

* 3.5" downpipe into dual 3" catalysts, DynoMax Ultraflo mufflers, side-exit (necessary due to rear suspension choice)

* Treadstone TRV25-series intercooler

* Synapse BPV

* Precision Turbo wastegate (think it's a 46mm) with "6 psi" spring

* Turbosmart E-Boost Street electronic boost controller

Drivetrain

* Quicktime steel bellhousing, custom ordered by Modern Driveline, GM Gen 3/4 to Ford T56 w/cable release fork

* Some full-face Kevlar single-disk clutch spec'd by Modern Driveline

* Ford-style T56 Magnum, wide ratio (.50 6th gear)

* Custom ordered driveshaft from Inland Empire Driveline

* Ford 8.8 rear axle with 28-spline Torsen T2, currently using a 4.10 axle ratio (Clearly not effective as a drag car!)

Suspension/Brakes/Chassis

* Maximum Motorsports K-member, A-arms, coilovers, CC plates, etc.

* Subframe connectors, jacking rails, and matrix braces

* Steeda 5-link rear suspension (forces me to use side exit exhaust)

* MM Sport Bilstein dampers, 350 lb/in standard location rear springs, 375 lb/in coilover front springs

* 4th gen F-body/C5 Corvette front calipers, 13" rotors

* 17" x 9" wheels with 275-width Falken RT-615Ks all around

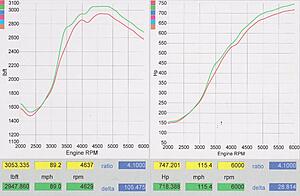

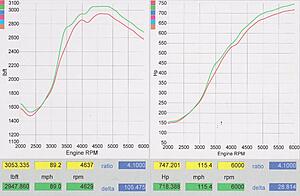

In its current incarnation, it made a best of 747 hp and 744 lb-ft on a pair of Dynapacks, at ~13 psi on 92-octane pump gas, at an 11.5:1 AFR, with about 15* of timing advance. Since it made peak HP right at 6000 RPM, it probably had another 10-15 hp if I'd wound it out to 6500. It makes about 550 whp at "spring" pressure (~ 7 psi).

First, some pics of the "finished" product:

LQ4/LQ9-based iron block engine built by Texas Speed

* Forged pistons

* Forged H-beam rods

* Stock crank

* ARP head and main studs

* PRC 225cc (as cast) cathedral port heads

* 228/232* (@ .050"), 114* LSA + 3*, .600" lift camshaft

* Stock rocker arms with trunion upgrade

* LS6 intake manifold

* CTS-V oil pan

* LS Brackets alternator relocation bracket (using "truck" accessory spacing)

* Slightly modified urethane 4.6L engine mounts so I can use my Maximum Motorsports K-member

Fuel and engine control

* Stock GM P59 ECU, 2-bar speed density OS with RTT, sensors based on '05 GMC Yukon

* Custom wiring harness by Speartech (DBW, cruise, no provision for MAF, EV6/USCAR injector connections)

* Injector Dynamics ID725 fuel injectors

* Dual Walbro GSS342 fuel pumps in an '03 Cobra tank (has additional baffle/sump compared to normal SN95 tank)

* Full return fuel system with boost-referenced Aeromotive regulator

Turbo system and exhaust

* Built by Doug Chase (www.chaserace.com) who is conveniently a block away from where I live

* LS3 Camaro exhaust manifolds, flipped side-to-side

* Turbonetics T-series 7875 turbocharger, T4, .96 A/R

* 3.5" downpipe into dual 3" catalysts, DynoMax Ultraflo mufflers, side-exit (necessary due to rear suspension choice)

* Treadstone TRV25-series intercooler

* Synapse BPV

* Precision Turbo wastegate (think it's a 46mm) with "6 psi" spring

* Turbosmart E-Boost Street electronic boost controller

Drivetrain

* Quicktime steel bellhousing, custom ordered by Modern Driveline, GM Gen 3/4 to Ford T56 w/cable release fork

* Some full-face Kevlar single-disk clutch spec'd by Modern Driveline

* Ford-style T56 Magnum, wide ratio (.50 6th gear)

* Custom ordered driveshaft from Inland Empire Driveline

* Ford 8.8 rear axle with 28-spline Torsen T2, currently using a 4.10 axle ratio (Clearly not effective as a drag car!)

Suspension/Brakes/Chassis

* Maximum Motorsports K-member, A-arms, coilovers, CC plates, etc.

* Subframe connectors, jacking rails, and matrix braces

* Steeda 5-link rear suspension (forces me to use side exit exhaust)

* MM Sport Bilstein dampers, 350 lb/in standard location rear springs, 375 lb/in coilover front springs

* 4th gen F-body/C5 Corvette front calipers, 13" rotors

* 17" x 9" wheels with 275-width Falken RT-615Ks all around

In its current incarnation, it made a best of 747 hp and 744 lb-ft on a pair of Dynapacks, at ~13 psi on 92-octane pump gas, at an 11.5:1 AFR, with about 15* of timing advance. Since it made peak HP right at 6000 RPM, it probably had another 10-15 hp if I'd wound it out to 6500. It makes about 550 whp at "spring" pressure (~ 7 psi).

First, some pics of the "finished" product:

Last edited by lemming104; 05-08-2018 at 01:19 PM.

#3

Launching!

Thread Starter

I think I've got more in-progress pics around somewhere; I'll dig when I get the chance. Some interesting things I noticed along the way:

1. If anyone wants to go with a cable clutch setup, it can be made to work, but the custom bellhousing doesn't come cheap. When my QuickTime bellhousing arrived, I needed to grind a small chunk out of the lower lip--the CTS-V pan drains from the rear, and they clearly didn't have that in mind when they built the bellhousing. Another important point is that, if you have the clutch fork in the SN95 7 o'clock position, the cable is a pretty tight fit to the oil filter housing. Just something to keep in mind. Oh, yeah, you also need one of those funky pilot bearing adapters to make this work--the input shaft isn't long enough to use the (smaller, further forward) pilot bushing.

2. I'm not a huge fan of those adapter plates that allow you to stick SN95 motor mounts on an LS. They make the engine sit a bit higher than it needs to. I ended up just ordering a set of SN95 motor mounts, cutting the rearward facing ears off, and fabricating new mounting ears to fit the 4-bolt pattern on the truck block. It's worth noting that, at least with the MM K-member, the engine is really tight to the firewall.

3. The LS Brackets accessory drive adapter kit isn't bad, but they put the idler pulley right next to the crank pulley and that doesn't seem very helpful. I removed that one and put an idler pulley in between the alternator and the PS pump, improving the wrap on both.

4. As I'm sure everyone is well aware by now, the truck intake manifold is tough to fit into one of these cars, and the truck accessory drive puts the alternator up too high to clear the stock hood.

5. The CTS-V pan is a great fit, and looks like it was meant to be there.

6. I don't think I have any good pictures of this, but we retrofitted one of the truck DBW pedals with a steel arm into this car. We basically cut and drilled the bracket so it'd fit on the same studs as the stock Mustang pedal, then cut and re-welded the pedal arm so the whole thing would follow a similar path to the factory Mustang pedal.

7. If I had to start all over again, I think I'd have used factory LS3 heads and a matching intake rather than using aftermarket heads. This block obviously doesn't have a provision for the 6-bolt stuff on the PRC heads, and I actually had to cut those off because the Camaro manifolds wouldn't fit with them in place.

1. If anyone wants to go with a cable clutch setup, it can be made to work, but the custom bellhousing doesn't come cheap. When my QuickTime bellhousing arrived, I needed to grind a small chunk out of the lower lip--the CTS-V pan drains from the rear, and they clearly didn't have that in mind when they built the bellhousing. Another important point is that, if you have the clutch fork in the SN95 7 o'clock position, the cable is a pretty tight fit to the oil filter housing. Just something to keep in mind. Oh, yeah, you also need one of those funky pilot bearing adapters to make this work--the input shaft isn't long enough to use the (smaller, further forward) pilot bushing.

2. I'm not a huge fan of those adapter plates that allow you to stick SN95 motor mounts on an LS. They make the engine sit a bit higher than it needs to. I ended up just ordering a set of SN95 motor mounts, cutting the rearward facing ears off, and fabricating new mounting ears to fit the 4-bolt pattern on the truck block. It's worth noting that, at least with the MM K-member, the engine is really tight to the firewall.

3. The LS Brackets accessory drive adapter kit isn't bad, but they put the idler pulley right next to the crank pulley and that doesn't seem very helpful. I removed that one and put an idler pulley in between the alternator and the PS pump, improving the wrap on both.

4. As I'm sure everyone is well aware by now, the truck intake manifold is tough to fit into one of these cars, and the truck accessory drive puts the alternator up too high to clear the stock hood.

5. The CTS-V pan is a great fit, and looks like it was meant to be there.

6. I don't think I have any good pictures of this, but we retrofitted one of the truck DBW pedals with a steel arm into this car. We basically cut and drilled the bracket so it'd fit on the same studs as the stock Mustang pedal, then cut and re-welded the pedal arm so the whole thing would follow a similar path to the factory Mustang pedal.

7. If I had to start all over again, I think I'd have used factory LS3 heads and a matching intake rather than using aftermarket heads. This block obviously doesn't have a provision for the 6-bolt stuff on the PRC heads, and I actually had to cut those off because the Camaro manifolds wouldn't fit with them in place.

#5

Launching!

Thread Starter

Obligatory empty engine compartment shot:

The old 4.2L and T5. Made ~450 whp with a GT35R. Fun setup.

The block plate that came with the bellhousing.

The bellhousing, mounted to the transmission.

A junkyard LQ4 I used for mockup.

With intake manifold.

It stuck up pretty far past the fender line of the car. There's no way this would have cleared the hood, even with the noticeable bulge/cowl the stock New Edge hoods have.

The old 4.2L and T5. Made ~450 whp with a GT35R. Fun setup.

The block plate that came with the bellhousing.

The bellhousing, mounted to the transmission.

A junkyard LQ4 I used for mockup.

With intake manifold.

It stuck up pretty far past the fender line of the car. There's no way this would have cleared the hood, even with the noticeable bulge/cowl the stock New Edge hoods have.

#6

Launching!

Thread Starter

I had a local LS-oriented guy (Speed Secrets of Monroe, WA) do the initial tuning. I'm getting more comfortable with HP Tuners and have reworked a bunch of stuff since then, and I've been doing all the work the last couple of times it was on the dyno. My initial setup had too restrictive an exhaust setup and it wasn't hitting anywhere near my boost target, so I needed to revise it and retune. I don't think I like tuning speed density stuff quite as much as the MAF setup on the Fords I've tuned, but it's not that bad and I like HP Tuners' realtime features.

Now that I know what kinds of things need to be changed in the tune, and I have some existing stuff for reference, I'd probably tackle the next one myself.

#7

Launching!

Thread Starter

Even with the "truck" accessory drive spacing, there is a good bit of space left in the nose of an SN95 with an LS-based engine. I measured the distance between the alternator pulley and the back side of the radiator at ten inches.

So much room for activities!

The guy who did my turbo fabrication did, however, elect to take a big chunk out of my strut tower so we could run a 3.5" downpipe with plenty of room around it, and not crowd the coils or plug wires. He boxed it back in. I don't mind.

So much room for activities!

The guy who did my turbo fabrication did, however, elect to take a big chunk out of my strut tower so we could run a 3.5" downpipe with plenty of room around it, and not crowd the coils or plug wires. He boxed it back in. I don't mind.

Trending Topics

#9

Launching!

Thread Starter

As you might guess from the dyno plot (I started the pull at 2000 RPM), it doesn't really want to spool until after 3000 RPM. After about 4000 RPM, regardless of whether the engine is initially loaded or not, it's pretty snappy, and it claws its way back to full boost pretty quickly on shifts. I'm used to manual transmission turbo cars, and this is pretty normal for those.

As far as traction goes, yeah. The last time I had it on the dyno was actually because I put in a softer wastegate spring and added an electronic boost controller. That way, I can toggle between 6-7 psi and 13 psi on the fly. The latter is really fun in fourth gear, but mostly just burns tires in the lower gears.

The last time I had it on the dyno was actually because I put in a softer wastegate spring and added an electronic boost controller. That way, I can toggle between 6-7 psi and 13 psi on the fly. The latter is really fun in fourth gear, but mostly just burns tires in the lower gears.

As far as traction goes, yeah.

The last time I had it on the dyno was actually because I put in a softer wastegate spring and added an electronic boost controller. That way, I can toggle between 6-7 psi and 13 psi on the fly. The latter is really fun in fourth gear, but mostly just burns tires in the lower gears.

The last time I had it on the dyno was actually because I put in a softer wastegate spring and added an electronic boost controller. That way, I can toggle between 6-7 psi and 13 psi on the fly. The latter is really fun in fourth gear, but mostly just burns tires in the lower gears.

#11

Launching!

Thread Starter

At one point, I was using a stock V6 radiator, yes. It was fine for street use; no obvious overheating issues. I did learn that it's not such a great idea to use one of those thermostat necks that is designed for an old-style SBC thermostat--without the little divider flap that the LS-style thermostats have, it recirculates too much coolant through the engine rather than pulling from the radiator, even when the thermostat is open, and it makes the engine run too hot. With the correct style of thermostat, it seems to stay under 200*F consistently, and around 180*F when the car is moving. Just make sure you've got decent fans for when it's not; the stock Mustang hoods don't exactly have vents or anything.

In the current incarnation, I'm using a three-pass Fluidyne radiator for a '94-95 5.0L Mustang, but that's mainly just because it contains more fluid and thus should buffer against large temperature spikes if I start beating on it. It's probably overkill.

In the current incarnation, I'm using a three-pass Fluidyne radiator for a '94-95 5.0L Mustang, but that's mainly just because it contains more fluid and thus should buffer against large temperature spikes if I start beating on it. It's probably overkill.

#13

You gonna sell the PRC 225's? What springs are in the head and chamber cc's? I would stay with the cathedral head myself. I have a S475/96 and a 480/96 on my bench, there are T-6 stuff. Would like to run one as a single, but the procharger/vortech super is easier to tune for. I'm gonna build an iron 408 engine and use my cnc gm LS3 head. Your running about the same cam as I want to run, or might go with a LFE cam as they seem to idle better. Awesome build, congrats.

Last edited by MikeHolmen; 05-09-2018 at 10:36 PM.

#14

Launching!

Thread Starter

Nope, I'm staying with the PRC heads. It's all together and working, has been for nearly a year at this point. Looks like I'm using the 68cc chambers and some PAC dual spring setup. -11cc pistons. I think I estimated the compression ratio at something like 9.5:1?

My comments about starting over were mainly just thoughts about what I'd do if something catastrophic happened--I'd probably build an engine with forged pistons and rods again, but I'd keep the rest of the build super mild to maximize streetability, drop the compression down into the 8s, and try to make power by boosting the bejeezus out of it. I've also gone through a bunch of turbo Subarus, so I'm sort of used to the "total dog when out of boost, but it scoots OK once it hits 21 psi" thing.

One of the things I like about this Turbonetics turbo is how easy it is to package. The hotside is T4-flanged, and it uses a T04S style compressor cover (4" inlet, 2.5" slip fit outlet), so it's a lot smaller than something like an S475 with the standard compressor cover. One of the major downsides in sizing single turbos for these engines is that we're kind of at that tipping point where most of the manufacturers start going to 4" V-bands on the hot side, T6 flanges, and huge compressor housings. It starts getting unwieldy.

At this point, I've worked through all of the major bugs in the setup and am just working on nitpicky stuff like cleaning up the rest of the unused factory wiring, getting the cruise control working again, etc. Just little things, which probably means it's time to go find some other idiotic project to start.

My comments about starting over were mainly just thoughts about what I'd do if something catastrophic happened--I'd probably build an engine with forged pistons and rods again, but I'd keep the rest of the build super mild to maximize streetability, drop the compression down into the 8s, and try to make power by boosting the bejeezus out of it. I've also gone through a bunch of turbo Subarus, so I'm sort of used to the "total dog when out of boost, but it scoots OK once it hits 21 psi" thing.

One of the things I like about this Turbonetics turbo is how easy it is to package. The hotside is T4-flanged, and it uses a T04S style compressor cover (4" inlet, 2.5" slip fit outlet), so it's a lot smaller than something like an S475 with the standard compressor cover. One of the major downsides in sizing single turbos for these engines is that we're kind of at that tipping point where most of the manufacturers start going to 4" V-bands on the hot side, T6 flanges, and huge compressor housings. It starts getting unwieldy.

At this point, I've worked through all of the major bugs in the setup and am just working on nitpicky stuff like cleaning up the rest of the unused factory wiring, getting the cruise control working again, etc. Just little things, which probably means it's time to go find some other idiotic project to start.

#16

Launching!

Thread Starter

What's to update? The thread is effectively in reverse order since the build was basically finished when I posted it.  The first two posts are of a completed, running setup; the rest are the in-progress pictures of how I got there.

The first two posts are of a completed, running setup; the rest are the in-progress pictures of how I got there.

I'm still messing around with little stuff here and there:

1. I went to a larger alternator pulley to avoid overdriving the truck alternator.

2. I'm going to back off to a slightly smaller cam so I can have it sound sleepier at idle. Will probably start on that this weekend.

3. I've noticed that the front cylinders run a bit richer than the rear cylinders (just from looking at the plugs); might try a different intake manifold to see if it's any different.

Other than that, I don't have much to complain about and it basically works. 750ish WHP on a narrow-tired street car is more than enough for me, so it's all down to making it a more livable daily driver at this point.

edit: Of course, if you have questions about this setup or want additional pictures of some aspect of it, let me know.

The first two posts are of a completed, running setup; the rest are the in-progress pictures of how I got there.

The first two posts are of a completed, running setup; the rest are the in-progress pictures of how I got there.I'm still messing around with little stuff here and there:

1. I went to a larger alternator pulley to avoid overdriving the truck alternator.

2. I'm going to back off to a slightly smaller cam so I can have it sound sleepier at idle. Will probably start on that this weekend.

3. I've noticed that the front cylinders run a bit richer than the rear cylinders (just from looking at the plugs); might try a different intake manifold to see if it's any different.

Other than that, I don't have much to complain about and it basically works. 750ish WHP on a narrow-tired street car is more than enough for me, so it's all down to making it a more livable daily driver at this point.

edit: Of course, if you have questions about this setup or want additional pictures of some aspect of it, let me know.

Last edited by lemming104; 08-31-2018 at 11:11 AM.

#17

Launching!

Thread Starter

I've continued to play around with this car, changing little bits of stuff here and there. Most recently, I have switched from the Steeda 5-link rear suspension I was using to an '03-04 Cobra rear suspension. I know these are the rear axle setup everyone loves to hate, but I wanted to see how well it worked with every single bushing replaced with Delrin or solid aluminum and a decent spring/damper combination. I've actually been pleased with the results. The 5-link handled well for a solid axle, but it could get upset by bumps and potholes to a much greater degree than the IRS. As this is just a "fun" weekend and daily-when-I-feel-like-it car, I don't care about the loss of drag racing potential; since I have a fondness for manual transmissions and torque-biasing differentials, it's not like the car is well suited to that anyway.

I've switched to a milder cam. I realize the 228/232 setup I was using is not one that most people would even consider "large", but I'm only using a T4 7875 turbo (albeit a "name brand" one), so I figured I wasn't losing much. I think I'm currently running a 219/223 cam, which has virtually no overlap. I also got silly and put a Shearer Fab "Surge" split plenum intake on there just for laughs.

I finally broke down and bought a small welder, so I've gone back and rebuilt some hacked-together bracketry for stuff like the radiator overflow bottle and a small support I built to keep the coolant hoses out of the coil packs. I'm not good at welding by any means, but it's nice to be able to make things.

Overall, the car has been pretty good. My biggest remaining concerns stem from oil consumption. The car burns through a little under a quart every 1000 miles, which seems excessive to me. So far, I've played around with PCV routing, but that hasn't helped much. I've also re-sealed the intake rocker bolts (which, since these are cathedral-port aftermarket heads, thread straight into the intake port roofs) with a few different products to see what works best, but none of that has had any real impact. This entire engine was bought as a finished long block from TSP, so I doubt it's valve seals, since I don't think the engine even has even 10K on it yet. I did a leakdown test a few weeks ago, and it was about 5-8% and pretty consistent across all cylinders, which didn't seem too bad to me, considering that it has forged pistons and I was forced to do the leakdown test cold because getting at the passenger's side spark plugs on this thing is a nightmare. I'm kind of puzzled at this point. It could be the turbo, I suppose, but there isn't an appreciable amount of leakage into the compressor side--I am not finding oil in my intercooler piping.

I've switched to a milder cam. I realize the 228/232 setup I was using is not one that most people would even consider "large", but I'm only using a T4 7875 turbo (albeit a "name brand" one), so I figured I wasn't losing much. I think I'm currently running a 219/223 cam, which has virtually no overlap. I also got silly and put a Shearer Fab "Surge" split plenum intake on there just for laughs.

I finally broke down and bought a small welder, so I've gone back and rebuilt some hacked-together bracketry for stuff like the radiator overflow bottle and a small support I built to keep the coolant hoses out of the coil packs. I'm not good at welding by any means, but it's nice to be able to make things.

Overall, the car has been pretty good. My biggest remaining concerns stem from oil consumption. The car burns through a little under a quart every 1000 miles, which seems excessive to me. So far, I've played around with PCV routing, but that hasn't helped much. I've also re-sealed the intake rocker bolts (which, since these are cathedral-port aftermarket heads, thread straight into the intake port roofs) with a few different products to see what works best, but none of that has had any real impact. This entire engine was bought as a finished long block from TSP, so I doubt it's valve seals, since I don't think the engine even has even 10K on it yet. I did a leakdown test a few weeks ago, and it was about 5-8% and pretty consistent across all cylinders, which didn't seem too bad to me, considering that it has forged pistons and I was forced to do the leakdown test cold because getting at the passenger's side spark plugs on this thing is a nightmare. I'm kind of puzzled at this point. It could be the turbo, I suppose, but there isn't an appreciable amount of leakage into the compressor side--I am not finding oil in my intercooler piping.

#18

Launching!

Thread Starter

A few more updates on this, since I just can't stop finding new things to mess with.

I replaced the Turbonetics 7875 I was using with a Precision 7675 CEA Gen 2. Similar size, but the PTE unit seems to be more responsive.

I most recently switched from the HPTuners-reflashed P59 ECU to a Holley Terminator X Max and a 7" digital dash. This allowed me to get rid of a lot of extra nonsense, including:

1. The X-Link I was using to make the newer gold blade throttle body (which I added when I put the Shearer intake on) work with the older ECU and pedal.

2. Boost gauge (now using the MAP input)

3. Boost controller

4. Hobbs switch I was using to run the second fuel pump

All that stuff is handled by the ECU now, and this allowed me to simplify the wiring and vacuum plumbing a bit.

Might as well include some updated pictures.

I replaced the Turbonetics 7875 I was using with a Precision 7675 CEA Gen 2. Similar size, but the PTE unit seems to be more responsive.

I most recently switched from the HPTuners-reflashed P59 ECU to a Holley Terminator X Max and a 7" digital dash. This allowed me to get rid of a lot of extra nonsense, including:

1. The X-Link I was using to make the newer gold blade throttle body (which I added when I put the Shearer intake on) work with the older ECU and pedal.

2. Boost gauge (now using the MAP input)

3. Boost controller

4. Hobbs switch I was using to run the second fuel pump

All that stuff is handled by the ECU now, and this allowed me to simplify the wiring and vacuum plumbing a bit.

Might as well include some updated pictures.

#19

I have somehow missed this thread completely and I really enjoyed reading it while dissecting your every word and studying the pics. This is a badass pile of tin brother! I really, really like it! You have great tastes! Top notch stuff here, thank you for sharing! I wanted to get it on the front page to make someone else's day!!