Rant about wiring, please read

#41

The biggest issue I have is that Matt B comes on and tries to belittle the DIY guy for atleast trying to do the job themselves. Matt, I am sure you in fact do quality, show winning work, but, were the first few cars you did perfect, first place, worldclass class jobs, I doubt it. Everyone needs to start someplace. Some never get better and that's all they can do, others may end up like you and turn this into a profession. Coming on a forum and slamming every person who wants to try to build their car because they take pride in doing themselves, don't have the money to pay you $2-3000 for a harness is not right.

I for one would at the very least like to see some of your work so you can lead by example, that way us little people can learn from your experience.

I for one would at the very least like to see some of your work so you can lead by example, that way us little people can learn from your experience.

#42

On The Tree

Join Date: Jul 2004

Location: Stockholm, Sweden

Posts: 166

Likes: 0

Received 0 Likes

on

0 Posts

To illustrate what Matt says, here is a shot of my setup with the harness pulled through the firewall and the PCM on the floor. As you can see there is a lot of harness that can be routed almost anywhere onthe passengerside firewall.

Jan

Jan

#43

dude you did exactly what Im talking about!! I hope that a few guys read this if they still havent wired their cars cause between what Ive wrote and pics you have it should totally make sense to anyone.

#44

TECH Resident

iTrader: (2)

I understand what matty is saying. But, I have a truck that doesn't call for anything cleaner looking than the way it came from GM. I don't show off my truck to anyone, anytime. I could care less. My engine compartment is neat & tidy to my satisfaction for serviceability & cleanliness. If & when I put together a street rod, everything will all be concealed differently. I know all about the show end of things. I have built & wired, cost is no object, big dollar offshore powerboats for 25+ years. To each there own.

#45

RESURRECT:

I actually found this post in the midst of searching for the answers to questions 1, 2 and 3. Some good opinion and insight here.

This post is exactly what I am trying to do with my build. I like good clean wiring and really am looking at how I am installing the factory harness in my 94 T/A. I want that nice clean look with everything nice, neat, and routed appropriately. I do have a couple of questions, that are for most intense purposes, general.

1) Painting a computer. Acceptable or not?

2) What vendor sells that braided wire wrap stuff? It's like plastic strands and looks dynamite on new cars. Should I get something different? Cable covers and electrical tape is a bit aged in my opinion.

3) What is the best way to affix parts of the harness to the motor and body? I know that in my 94 LT1, there are these circular holders that plug into random holes on the body and motor. Is there something a bit more aesthetic, that I can use that either screws, bolts or somehow otherwise secures its self to the body and motor?

4) What is the best way to shield wires from heat? I've seen that silvery wrap. Is it truly effective? Is there something that performs better?

I actually found this post in the midst of searching for the answers to questions 1, 2 and 3. Some good opinion and insight here.

This post is exactly what I am trying to do with my build. I like good clean wiring and really am looking at how I am installing the factory harness in my 94 T/A. I want that nice clean look with everything nice, neat, and routed appropriately. I do have a couple of questions, that are for most intense purposes, general.

1) Painting a computer. Acceptable or not?

2) What vendor sells that braided wire wrap stuff? It's like plastic strands and looks dynamite on new cars. Should I get something different? Cable covers and electrical tape is a bit aged in my opinion.

3) What is the best way to affix parts of the harness to the motor and body? I know that in my 94 LT1, there are these circular holders that plug into random holes on the body and motor. Is there something a bit more aesthetic, that I can use that either screws, bolts or somehow otherwise secures its self to the body and motor?

4) What is the best way to shield wires from heat? I've seen that silvery wrap. Is it truly effective? Is there something that performs better?

#47

2) What vendor sells that braided wire wrap stuff? It's like plastic strands and looks dynamite on new cars. Should I get something different? Cable covers and electrical tape is a bit aged in my opinion.

McMaster Carr, Summit, Jegs and about everyone else sell the braided nylon loom. I like the split loom stuff to simplify future mods. I also use Velcro cable ties instead of zip ties for the same reason. Plus it blends in with the nylon braid better. Tape is probably the worst thing for maintenance and I don't like the look of the nylon convoluted tubing. But unlike the OP to each his own.

3) What is the best way to affix parts of the harness to the motor and body? I know that in my 94 LT1, there are these circular holders that plug into random holes on the body and motor. Is there something a bit more aesthetic, that I can use that either screws, bolts or somehow otherwise secures its self to the body and motor?

Lots of options. For sheet metal nutserts are the most professional. A 30 second way to put a threaded bolt hole anywhere you want. You can also pick up plastic clips that mount with double sided tape. That works well under the dash. for a more permanent solution pull off the tape and JB weld them in place. I have used brake line/fuel line clamps in places also. Reusing factory harness straps always looks the most factory.

4) What is the best way to shield wires from heat? I've seen that silvery wrap. Is it truly effective? Is there something that performs better?

IMO the best way is to not run them near anything hot in the first place. Second choice would be a sheet metal shield. Third choice would be the insulated wire sheaths, again available from McMaster Carr.

What ever you do, make it so the thing is easy to work on. IMO that looks better than wiring hidden inside a frame rail somewhere, or electronic boxes buried up under the dash. If I had a rant it is people putting coil packs behind the firewall then running bundles of plug wires through sheet metal grommets. It may look better, but damn the engineering of that is just asking for cross fires and poor performance. But like I said, to each his own.

McMaster Carr, Summit, Jegs and about everyone else sell the braided nylon loom. I like the split loom stuff to simplify future mods. I also use Velcro cable ties instead of zip ties for the same reason. Plus it blends in with the nylon braid better. Tape is probably the worst thing for maintenance and I don't like the look of the nylon convoluted tubing. But unlike the OP to each his own.

3) What is the best way to affix parts of the harness to the motor and body? I know that in my 94 LT1, there are these circular holders that plug into random holes on the body and motor. Is there something a bit more aesthetic, that I can use that either screws, bolts or somehow otherwise secures its self to the body and motor?

Lots of options. For sheet metal nutserts are the most professional. A 30 second way to put a threaded bolt hole anywhere you want. You can also pick up plastic clips that mount with double sided tape. That works well under the dash. for a more permanent solution pull off the tape and JB weld them in place. I have used brake line/fuel line clamps in places also. Reusing factory harness straps always looks the most factory.

4) What is the best way to shield wires from heat? I've seen that silvery wrap. Is it truly effective? Is there something that performs better?

IMO the best way is to not run them near anything hot in the first place. Second choice would be a sheet metal shield. Third choice would be the insulated wire sheaths, again available from McMaster Carr.

What ever you do, make it so the thing is easy to work on. IMO that looks better than wiring hidden inside a frame rail somewhere, or electronic boxes buried up under the dash. If I had a rant it is people putting coil packs behind the firewall then running bundles of plug wires through sheet metal grommets. It may look better, but damn the engineering of that is just asking for cross fires and poor performance. But like I said, to each his own.

#48

TECH Addict

iTrader: (10)

http://www.skycraftsurplus.com/hight...uretubing.aspx

Here's the manufacturer's website with specs:

http://www.varflex.com/varf-spec_sili_rubr.html

The shiny stuff is mainly for radiant heat. If you do get one of the shiny (reflective) products, make sure it has some insulation behind it.

#49

Some great answers here. One concern i have with varflex and other sheath-type products is how do you install it? Do you wire tie it on? Does it shrink on? Do you have to split it down the middle to wrap it over the wires? I dont want to have to cut my wires to install this stuff.

#50

TECH Regular

Just because you like a clean engine bay, does not mean you have to move the ECM inside the car. I currently have 3 LS powered cars and none of them have visible computers, and none of them are inside the car. I build Corvettes, and they are pretty tight inside, especially when you add A/C, so I hide them up front where they are not visible, but very accessible. Obviously, the old style computer is more of a challenge than the newer ones, just because of the sheer size, but it can be done. All of my cars have the computer mounted back under the fender.

I fabricate a bracket that allows the ECM and TCM to be mounted out of sight under the fender, but allows quick access to it. I also run all of my body wiring completely out of sight except for the wiper wiring, and it disappears through the firewall in just a few inches. I route all wiring wherever possible, between the inner fender and the outer fender where it can't be seen. I just hate a cluttered engine compartment! I was going to post a couple of links from my photo hosting site, but Villagephotos is down again!

Since I put A/C on all my cars, I always fill in the old fuse block hole in the firewall that the original body harness exited from, and come out through the cowl vent area where it is completely hidden from sight, and build a blocker plate at the outside air floor vent in the kickpanels. It is some work, but it is worth it.

Regards, John McGraw

I fabricate a bracket that allows the ECM and TCM to be mounted out of sight under the fender, but allows quick access to it. I also run all of my body wiring completely out of sight except for the wiper wiring, and it disappears through the firewall in just a few inches. I route all wiring wherever possible, between the inner fender and the outer fender where it can't be seen. I just hate a cluttered engine compartment! I was going to post a couple of links from my photo hosting site, but Villagephotos is down again!

Since I put A/C on all my cars, I always fill in the old fuse block hole in the firewall that the original body harness exited from, and come out through the cowl vent area where it is completely hidden from sight, and build a blocker plate at the outside air floor vent in the kickpanels. It is some work, but it is worth it.

Regards, John McGraw

#51

On The Tree

Join Date: Apr 2011

Location: Mobile Alabama

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

Does anyone have the part numbers for the ECM pins for Gen 3s?

As to the braided wrap I have looked around a lot on it and the best place I found for the non-heat shield type is delcity.net You have to buy it in 100 or 200ft sections depending on size but the price is still much better than the other stuff even if the upfront cost is higher.

A friend and I went in on it and it was 150 total for spools of 4 different sizes and a decent amount of double walled 3:1 heat shrink.

As to the braided wrap I have looked around a lot on it and the best place I found for the non-heat shield type is delcity.net You have to buy it in 100 or 200ft sections depending on size but the price is still much better than the other stuff even if the upfront cost is higher.

A friend and I went in on it and it was 150 total for spools of 4 different sizes and a decent amount of double walled 3:1 heat shrink.

#52

Does anyone know where to find the wrap depicted here? I looked at the stuff that some of you mentioned and the fiberglass braid stuff is freakin expensive. Not sure if I am willing to dish $30 - $90 for just a few feet. Should I make the leap or is this stock wrap acceptable?

#53

On The Tree

Join Date: Apr 2011

Location: Mobile Alabama

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

#54

On The Tree

Join Date: Apr 2011

Location: Mobile Alabama

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

For short sections of the fiberglass heat shield loom also check amazon

http://www.amazon.com/Techflex-Satur...=1Z5S1FIPCNX9T

http://www.amazon.com/Techflex-Satur...=1Z5S1FIPCNX9T

#55

TECH Enthusiast

I am finishing an install and have the complete 4th gen wiring harness in the car. The harnes was stripped of noessential items but I also kept everything I could use. This makes my harness not 70 wires but over 120 at the pcm. I was going to put the PCM just above the glove compartment but the wires were short by a few inches. This was after I wasted 2 weekends making a mount and the pcm fit just above the glove compartment hoping I would not have to lengthen the harness. Other than that I have no room inside the dash except for right under the center where the speaker hole is due to all the crap already there like the vintage air, bcm, stereo, console and other factory stuff. I am not fond of taking apart a dash for any reason especially if I need a new pcm and I am going between a 04GTO and a 02Camaro pcm setup. It will go in the fenderwell behind the battery. The drivers side has no room what so ever. I guess if this makes my build crappy so be it but most professionals would not even have the time or patience to redo a factory harness from the front of the car to the back keeping all the systems like a factory car. The harness was probably at least 50% of my entire time spent on the conversion. What did I get for that? Well how about cruise control, fog lights, factory alarm with remote, door locks, VATS, electric trunk latch, automatic headlights, courtesy lights, map lights, wiper motor with delay, electric seat, etc. Nothing against a Foose type car but they are so predictable it isn't even funny. Yea you can make them look pretty but get to really looking the underlying build and a lot of these guys are just show and go for about $25k a pop.

#56

Have any of you used the Summit Heat Tape before? Any good?

UPDATE: Ended up buying this stuff... http://cableorganizer.com/thermo-shield-tape/

UPDATE: Ended up buying this stuff... http://cableorganizer.com/thermo-shield-tape/

Last edited by LT1FirebirdSLP; 10-27-2011 at 10:11 AM.

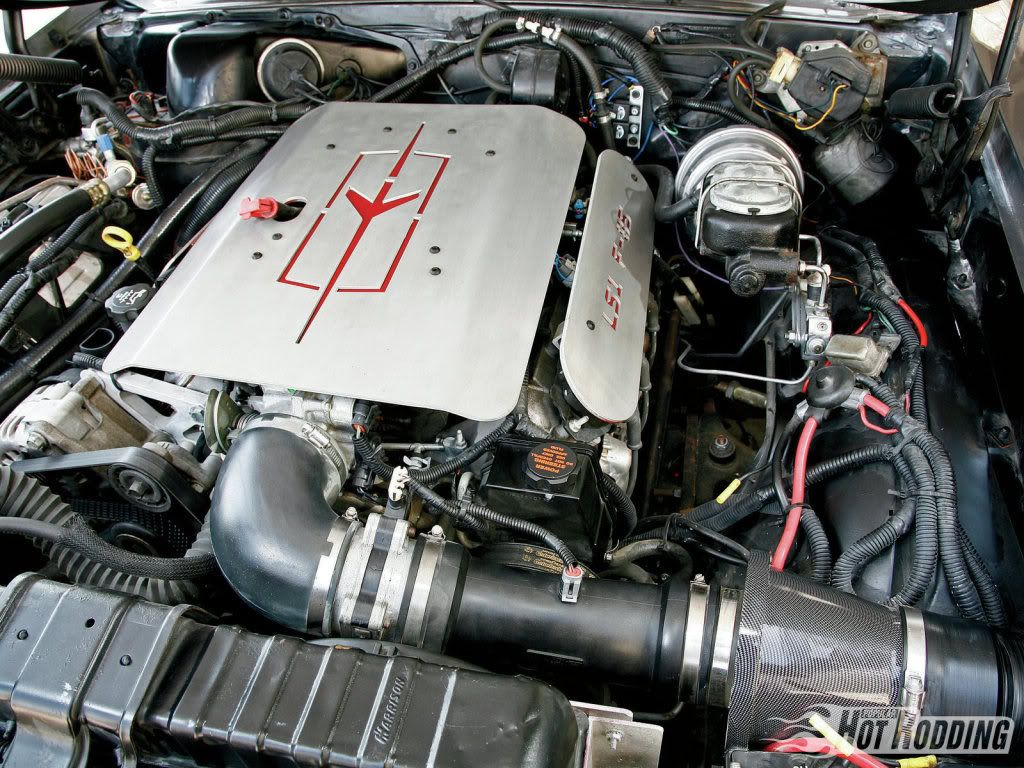

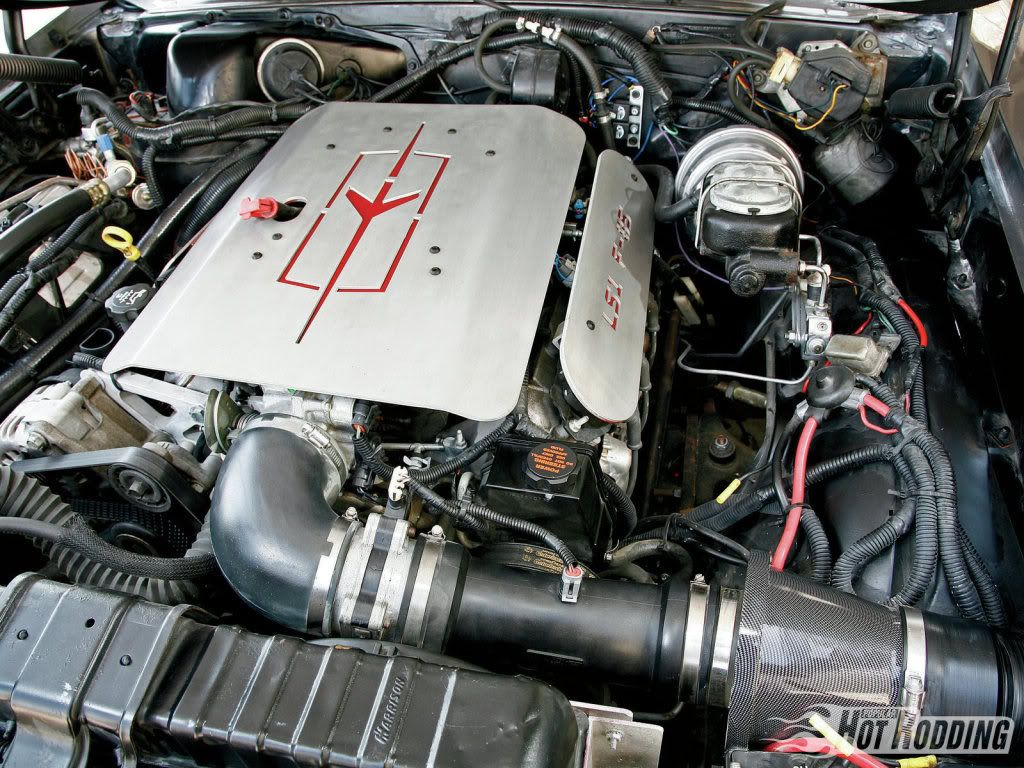

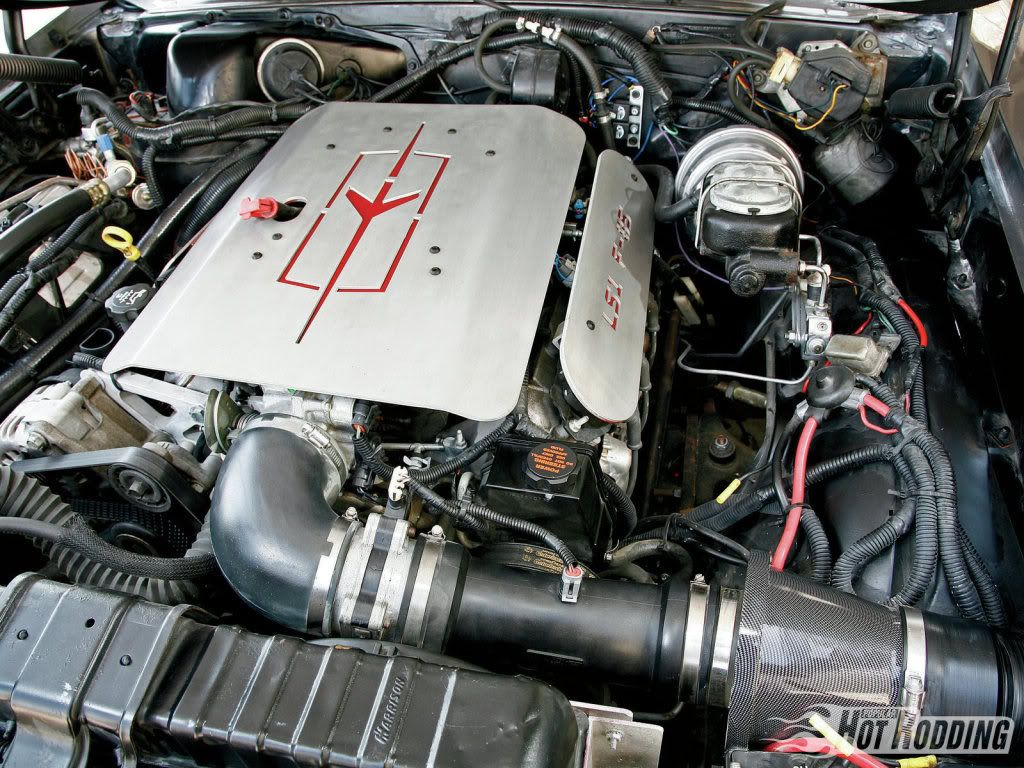

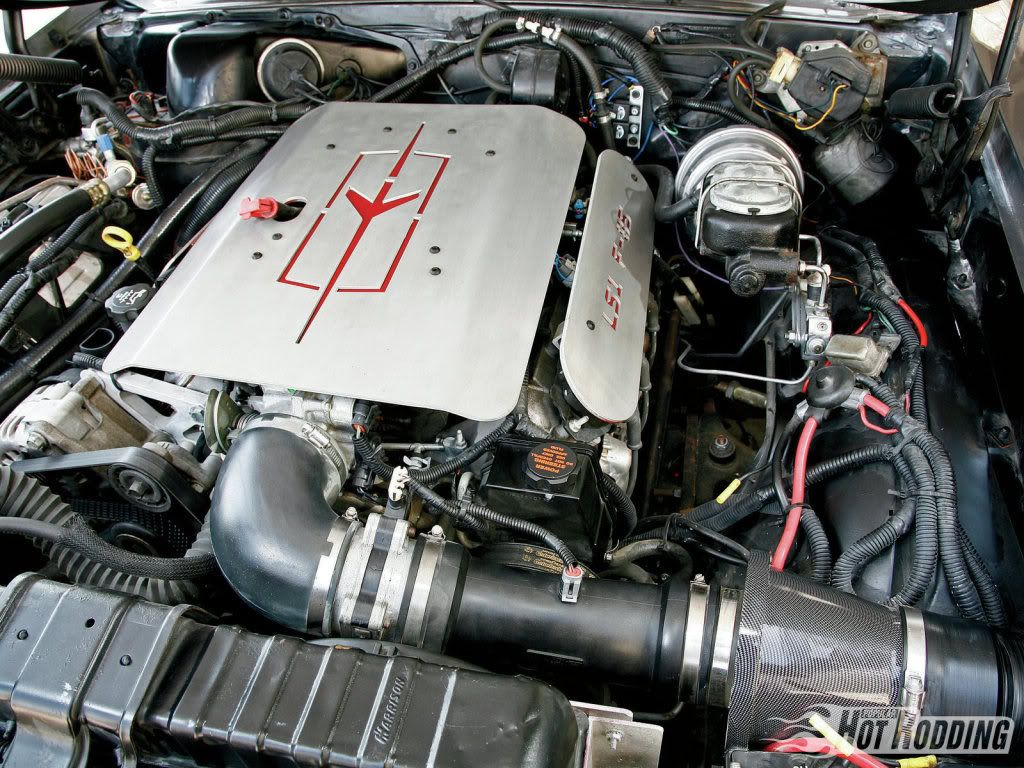

#57

This is a fine example of a well done swap good enough to make a feature in a magazine.  How you like that Matt? By the way 99% of those ugly wires and hoses that offend you were done that way in 1965 from the factory and have nothing to do with the LS1 swap.

How you like that Matt? By the way 99% of those ugly wires and hoses that offend you were done that way in 1965 from the factory and have nothing to do with the LS1 swap.

The fact that I put a LS1 (CHEBY motor) in an olds offends most folks so once they see that they never even notice all the ugly wires and hoses. They turn their head in discuss and walk away.

The fact that I put a LS1 (CHEBY motor) in an olds offends most folks so once they see that they never even notice all the ugly wires and hoses. They turn their head in discuss and walk away.

#58

This is a fine example of a well done swap good enough to make a feature in a magazine.  How you like that Matt? By the way 99% of those ugly wires and hoses that offend you were done that way in 1965 from the factory and have nothing to do with the LS1 swap.

How you like that Matt? By the way 99% of those ugly wires and hoses that offend you were done that way in 1965 from the factory and have nothing to do with the LS1 swap.

The fact that I put a LS1 (CHEBY motor) in an olds offends most folks so once they see that they never even notice all the ugly wires and hoses. They turn their head in discuss and walk away.

The fact that I put a LS1 (CHEBY motor) in an olds offends most folks so once they see that they never even notice all the ugly wires and hoses. They turn their head in discuss and walk away.

#59

TECH Addict

iTrader: (22)

Looks like a nightmare to troubleshoot

Say you had a 12v dead short somewhere. Where would you start?

Saying the factory sold it as a mess doesnt mean you have to swap it in as a mess too

Factory mess

Cleaned up and sorted with the swap. Notice there are quite a few less lines and the ones present are neat and tidy

Same applies to future mods. Heres a SC bolted on the same car and keeping the wiring/hoses tidy is still top priority. Granted I did spend about 25 hours on just the wiring and used probably 2x the amount of hose to get the routing how I like it

All this is done without a huge cover to hide 90% of the engine. Your car being in a magazine is cool, but doesnt excuse the downright mess it is

To the questions posted before. Theres nothing stopping you from mounting the PCM under the battery tray or behind the fender. Mine is mounted under the dash before it was easy to access and the stock ECM holder made a perfect place for it. Insulating the firewall is pretty simple. A short length of PCV/fuel line split long ways covers the jagged edge. For the fiberglass reflective stuff, a well thought out harness shouldnt need it, but if theres no getting around it, it does work quite well. Keep in mind OEM high quality split loom is rated to withstand sustained temps of +600* F, so anything not directly on a glowing header will be just fine protected just by the loom. You can tell the good stuff because it cannot be flattened by two fingers

EFI connection and mouser have better deals on the terminals than buying from GM. Keep in mind there are two types, 18ga and 20 ga

Say you had a 12v dead short somewhere. Where would you start?

Saying the factory sold it as a mess doesnt mean you have to swap it in as a mess too

Factory mess

Cleaned up and sorted with the swap. Notice there are quite a few less lines and the ones present are neat and tidy

Same applies to future mods. Heres a SC bolted on the same car and keeping the wiring/hoses tidy is still top priority. Granted I did spend about 25 hours on just the wiring and used probably 2x the amount of hose to get the routing how I like it

All this is done without a huge cover to hide 90% of the engine. Your car being in a magazine is cool, but doesnt excuse the downright mess it is

To the questions posted before. Theres nothing stopping you from mounting the PCM under the battery tray or behind the fender. Mine is mounted under the dash before it was easy to access and the stock ECM holder made a perfect place for it. Insulating the firewall is pretty simple. A short length of PCV/fuel line split long ways covers the jagged edge. For the fiberglass reflective stuff, a well thought out harness shouldnt need it, but if theres no getting around it, it does work quite well. Keep in mind OEM high quality split loom is rated to withstand sustained temps of +600* F, so anything not directly on a glowing header will be just fine protected just by the loom. You can tell the good stuff because it cannot be flattened by two fingers

EFI connection and mouser have better deals on the terminals than buying from GM. Keep in mind there are two types, 18ga and 20 ga

#60

TECH Addict

iTrader: (10)

To use this product properly, you run the wires through the sleeve. I don't know how it would hold up if you sliced it down the middle.

There's been a lot of talk on the thread about putting the PCM in the cabin, which would require sending the 100+ wire bundle through the firewall. I would deal with that the same way I would deal with the Varflex: Take the PCM wiring connectors apart and send each PCM wire through the Varflex and the firewall (with a grommet) one by one. It would be really easy to do if you had an extra set of PCM connectors, so you could plug each wire into it's respective spot immediately after unplugging it and running it through the hole. I did not do this with my PCM, but I did do it with my DBW pedal-to-TAC bundle and it worked great.

BTW, I have removed and added terminals from/to the PCM connector. It's not hard once you get the hang of it.

There's been a lot of talk on the thread about putting the PCM in the cabin, which would require sending the 100+ wire bundle through the firewall. I would deal with that the same way I would deal with the Varflex: Take the PCM wiring connectors apart and send each PCM wire through the Varflex and the firewall (with a grommet) one by one. It would be really easy to do if you had an extra set of PCM connectors, so you could plug each wire into it's respective spot immediately after unplugging it and running it through the hole. I did not do this with my PCM, but I did do it with my DBW pedal-to-TAC bundle and it worked great.

BTW, I have removed and added terminals from/to the PCM connector. It's not hard once you get the hang of it.

Some great answers here. One concern i have with varflex and other sheath-type products is how do you install it? Do you wire tie it on? Does it shrink on? Do you have to split it down the middle to wrap it over the wires? I dont want to have to cut my wires to install this stuff.