Anyone ever make their harness from scratch?

#21

TECH Addict

iTrader: (36)

Join Date: Apr 2002

Location: Murphy, Tx

Posts: 2,526

Likes: 0

Received 0 Likes

on

0 Posts

Good luck. If its not new or you modding their personal harness, most wont touch it

Not really. The important bits like the connector side and the PCM terminal are still there and clearly labeled. When using different connectors, wire colors change anyways so unless you build it yourself 100% to stock diagrams, itll never be that way. Let you in on a little secret too: OEM diagrams dont follow OEM circuits all the time. Wire colors, number in the commons, even fuse assignments arent always correct to the schematics

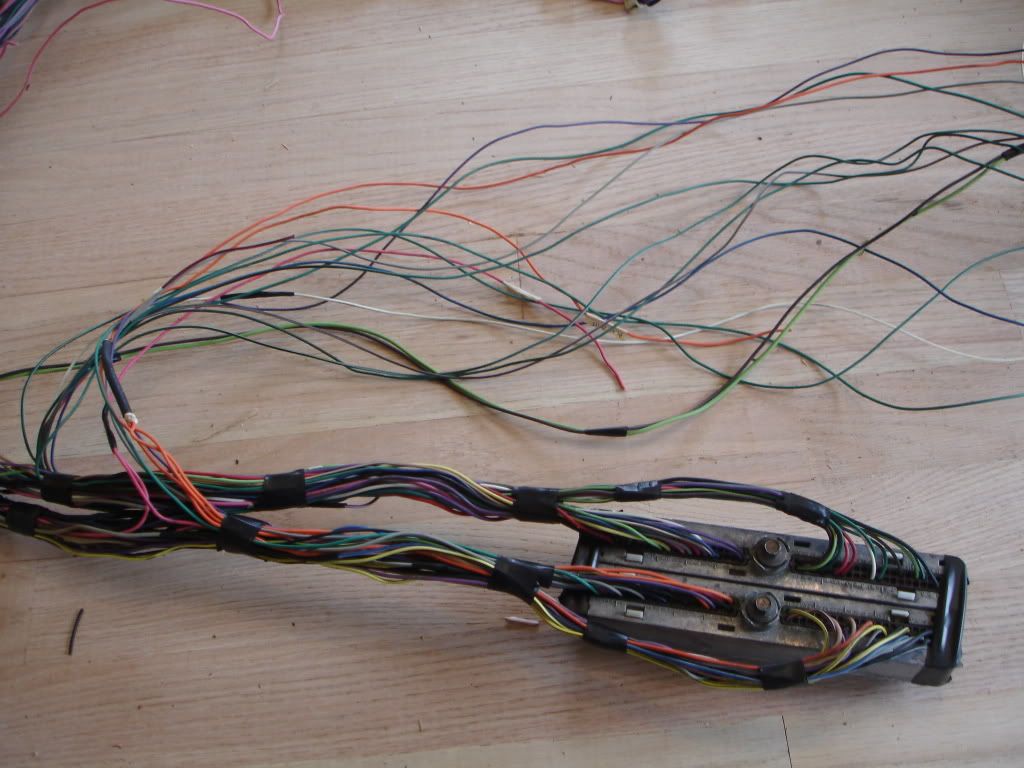

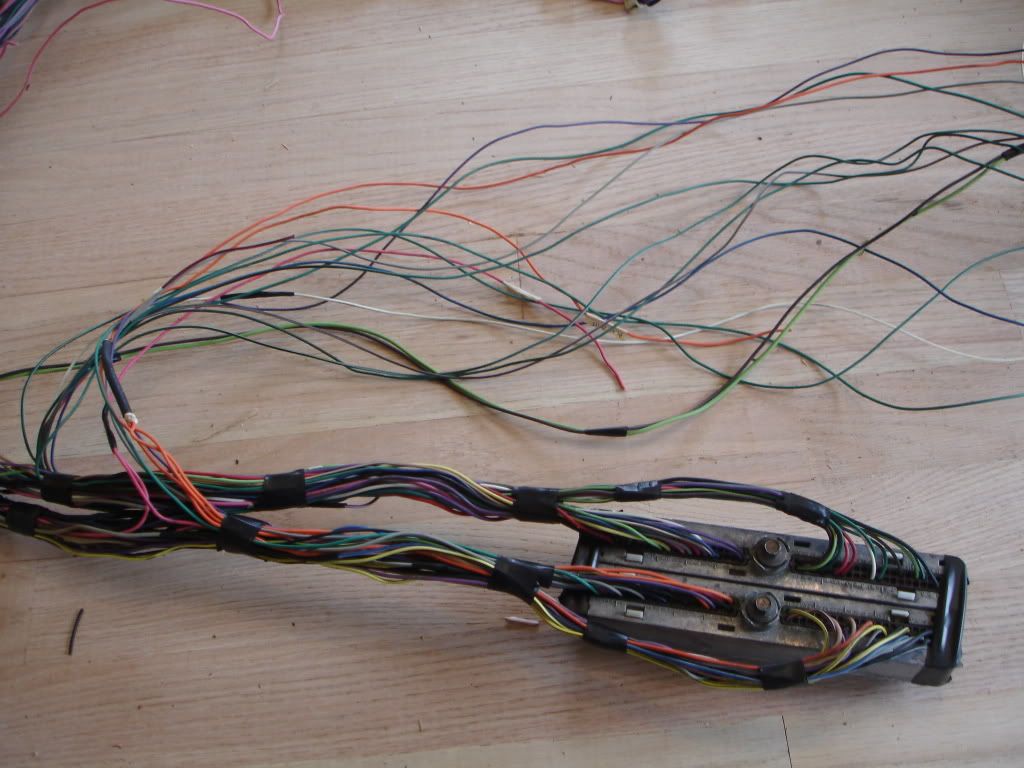

Most of the harnesses I build go through the firewall so only 30-50 wires need a few inches added. The rest get shortened. Truck harnesses are massively long though and even PCM extensions like the pic above can be done with minimal lengths added. IIRC that harness above was set with the PCM 7 feet from the middle of the intake. It is not typical for most swaps

Most look like this

Not really. The important bits like the connector side and the PCM terminal are still there and clearly labeled. When using different connectors, wire colors change anyways so unless you build it yourself 100% to stock diagrams, itll never be that way. Let you in on a little secret too: OEM diagrams dont follow OEM circuits all the time. Wire colors, number in the commons, even fuse assignments arent always correct to the schematics

Most of the harnesses I build go through the firewall so only 30-50 wires need a few inches added. The rest get shortened. Truck harnesses are massively long though and even PCM extensions like the pic above can be done with minimal lengths added. IIRC that harness above was set with the PCM 7 feet from the middle of the intake. It is not typical for most swaps

Most look like this

I wish my harness looked that clean when I did it. Mine looked like a rats nest. U did a really good job.

#26

I've been working on my LR4 harness. I was doing a crappy job till I read a couple of threads on here and another site and got serious. It started coming together for me when I removed all the sheathing and black tape. I found that I could remove about half of the bulk of the wires and fuse box. Loosely speaking the harness connects the PCM to the transmission and to the gages (through a coupl of connectors). Then you send power to it, constant and keyed (orange and pink). Mine is not done yet but it is looking so much better after I cut out about half of it. If I decided to remove unneeded wires to the PCM I could remove more. It was intimidating until I took off the coverings and could easily trace the wires.

Brian

Brian