86 Monte SS. 5.3, Single turbo, Megasquirt II. Lots of pics

#81

Man, I hate to do this to you, but can I make a recommendation? If the motor were just a regular NA build it would probably be fine, but the way you have the fuel system routed may not be sufficient for a FI application. There was a guy on here recently that had his routed the same and it took out the entire driver's side bank of cylinders. Were it me, I would do it like this (same way I did mine):

Fuel pump->

-Y fitting->

-one line to each rail->

-one line out of each rail equal length into each input on the regulator->

-return line back to tank.

This is the way I did it on my personal car and every car I have built. I feel it gives more equal distribution of fuel. There is some debate as to when it is necessary to route it in parallel like this vs in series, but it makes me sleep better at night and I have never had issues running it the way I described above. I have however seen one side of a couple forced induction cars get starved from running it in series as the pump starts approaching its limit. Sure it is a couple extra bucks in fittings, but it may save the motor later.

Fuel pump->

-Y fitting->

-one line to each rail->

-one line out of each rail equal length into each input on the regulator->

-return line back to tank.

This is the way I did it on my personal car and every car I have built. I feel it gives more equal distribution of fuel. There is some debate as to when it is necessary to route it in parallel like this vs in series, but it makes me sleep better at night and I have never had issues running it the way I described above. I have however seen one side of a couple forced induction cars get starved from running it in series as the pump starts approaching its limit. Sure it is a couple extra bucks in fittings, but it may save the motor later.

#85

Looks good so far.... just a few areas I feel need to be visited.

Fuel system routing needs to be addressed to avoid previously mentioned issues.

I personally like this routing... And yes that is my engine. The inlet connection is a T fitting in the rear stainless lines that feeds both rails.

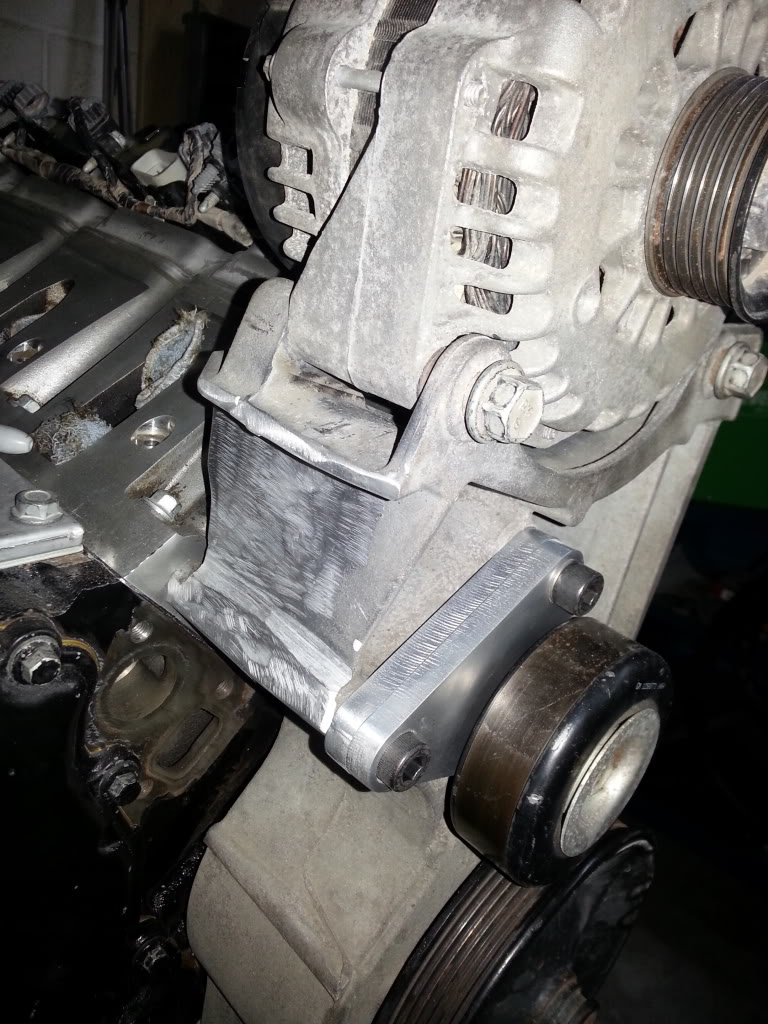

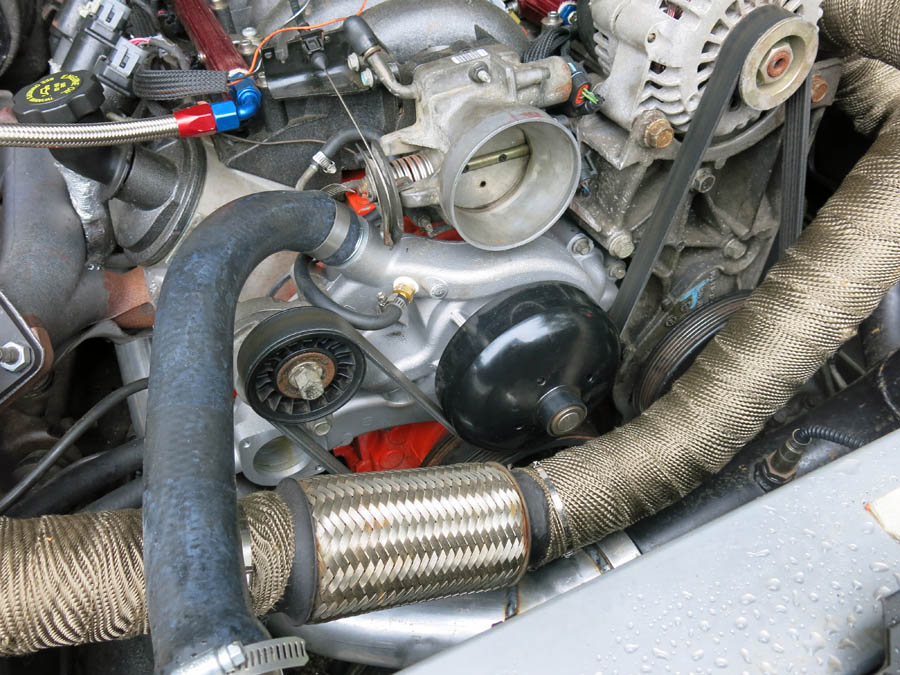

The belt routing will not work... period. seen many try it and all failed. Dirty Dingo makes a bolt on solution found here http://dirtydingo.com/store/product_...oducts_id=1371

-or-

As mentioned above a stationary idler right below the alternator with a longer bolt and a stand off.

The truck injectors..... if they are the normal 5.3L injectors you are going to be wayyyy over 100% duty cycle when that Turbo is working. I would look at the marine 8.1L injectors at minimum.

Keep going~!

Fuel system routing needs to be addressed to avoid previously mentioned issues.

I personally like this routing... And yes that is my engine. The inlet connection is a T fitting in the rear stainless lines that feeds both rails.

The belt routing will not work... period. seen many try it and all failed. Dirty Dingo makes a bolt on solution found here http://dirtydingo.com/store/product_...oducts_id=1371

-or-

As mentioned above a stationary idler right below the alternator with a longer bolt and a stand off.

The truck injectors..... if they are the normal 5.3L injectors you are going to be wayyyy over 100% duty cycle when that Turbo is working. I would look at the marine 8.1L injectors at minimum.

Keep going~!

#88

Thanks to everyone for the advice.

The fuel rails are going to stay plumbed the way they are. I can see fuel starvation from a small pump. The Bosch 044 is NOT a small pump and will be able to provide enough volume to keep this motor happy to the power levels I am looking to reach. If I smoke the motor I will come back and say I was wrong. Considering I can pick up a boneyard 5.3 for less than the cost of replumbing this setup I am more than willing to take the risk. As far as injectors go, well the stockers won't get me far but at the very least I can run 5 PSI of boost on them. When I actually start turning up the wick I will be picking up something bigger.

The merge came from Columbia River Mandrel Bending and was $27.00. For the money it was pretty hard to beat. Much easier than doing it myself. It is part number CL2-2530-MS

I have made a pretty good bit of progress.

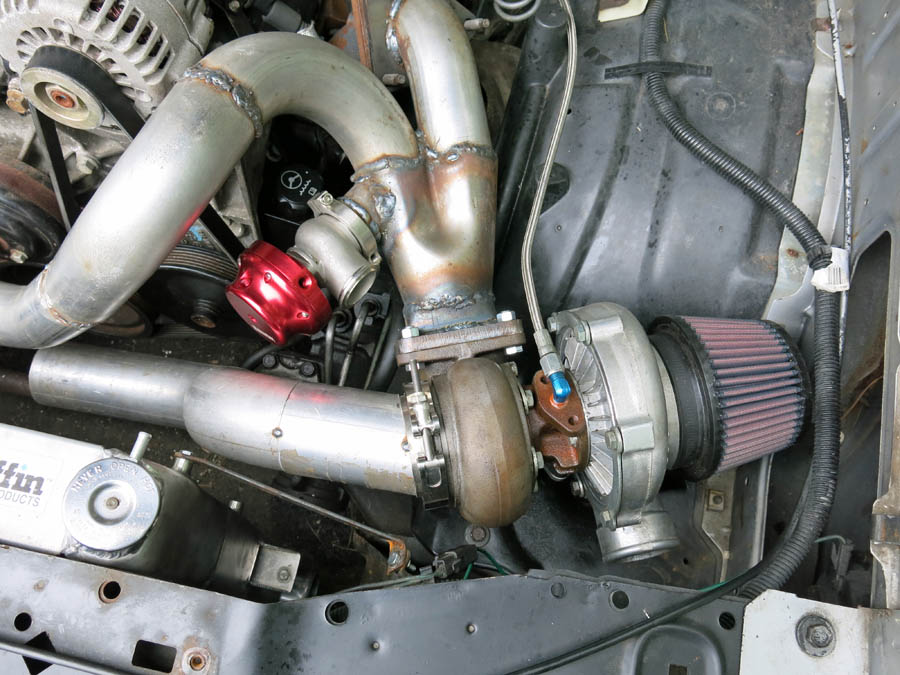

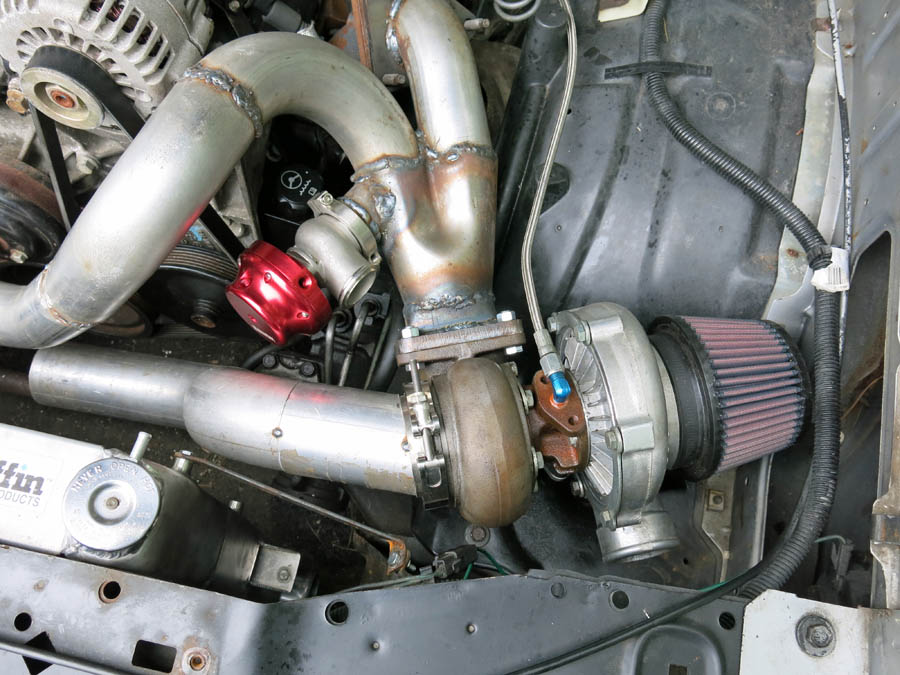

I reformed the hotside a bit to give some more hood clearance so I wouldn't have to worry about burning the paint off my hood. Then I finish welded the whole assembly. I think it came out nice. Here it is mocked into place with the turbo hanging on the end of it all.

Then I mocked up a downpipe to come off the turbine discharge.

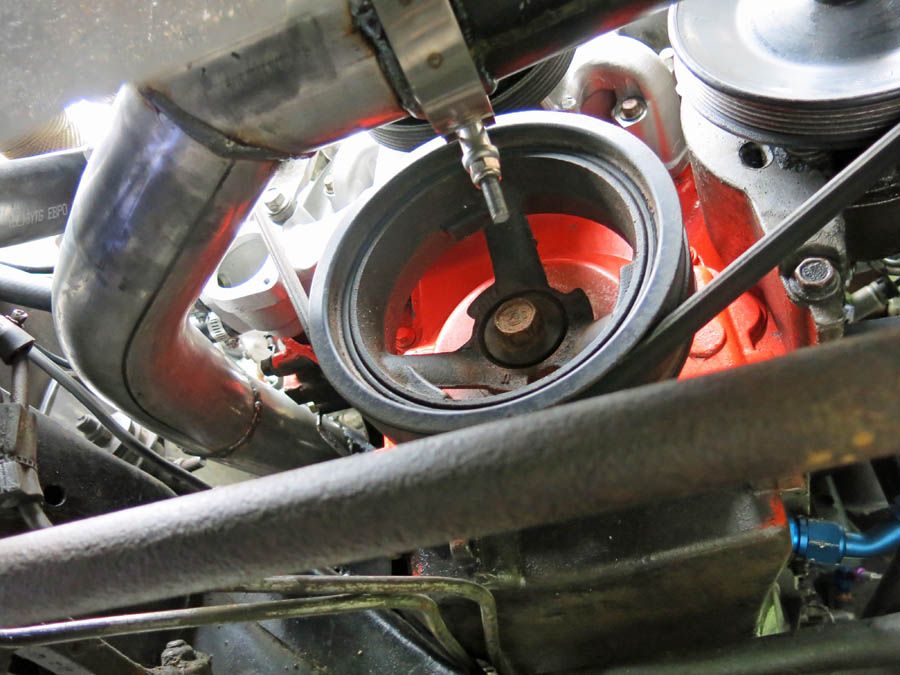

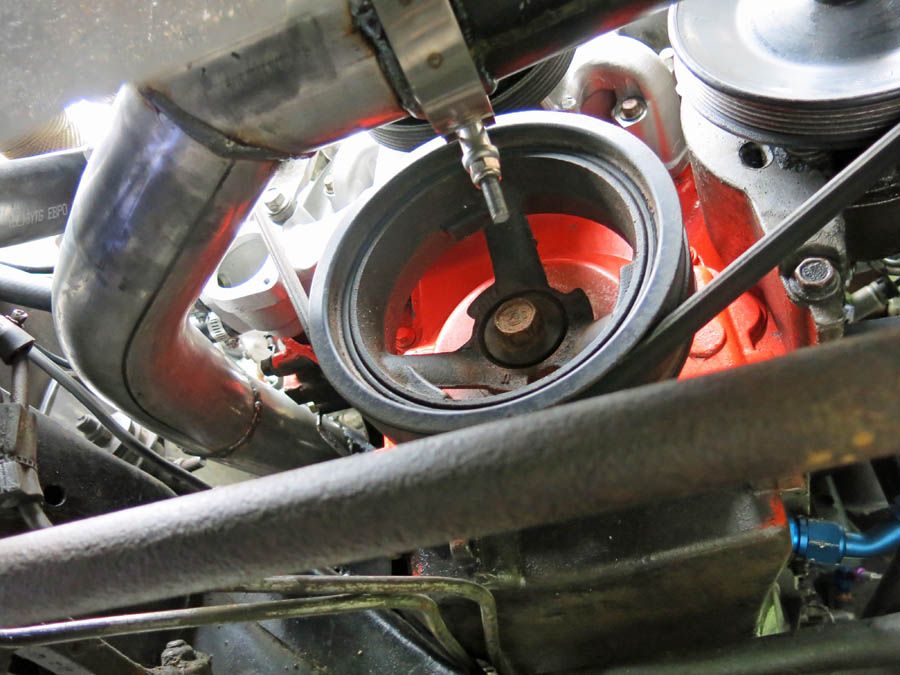

I then started getting the wastegate figured out.

Then I finish welded the downpipe and painted everything in high temp flat black. This is one of my favorite pictures from this whole build. It is really starting to look like something.

Then I dry fitted everything together and began wrapping the hotside.

Wrapped up and bolted into the car. Looking good to me at this point.

I had to make my own exhaust gaskets to go from the manifolds to the flanges on the crossover pipe I made. I used some universal exhaust gasket material from Summit made by Mr. Gasket. The stuff is awesome!

I ended up changing the location of the bung for the wideband O2 sensor. I was worried that the wastegate dump coming in after the sensor would give false readings to the computer. So I plugged the original and put in a new one.

The wideband O2 gauge and vac/boost gauge are installed, shown here on the A pillar.

My wife took this pic as a surprise. She came out with the camera and told me to smile. I actually like it, I think it is cool.

A quick video that has some delicious turbo whistle in it.

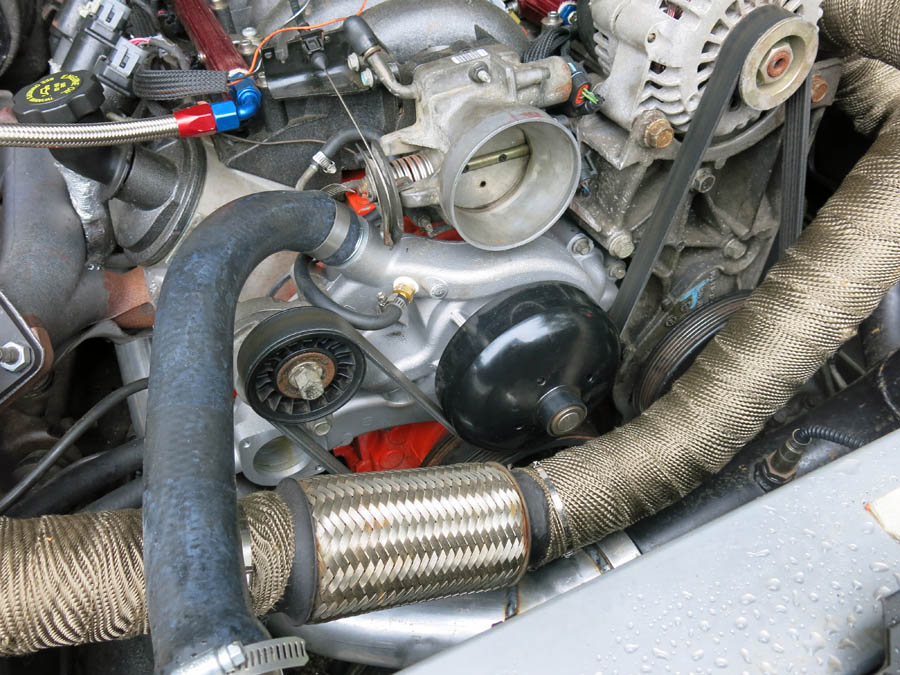

I ended up swapping out the older style water pump for the newer style one. It made more sense to do the radiator hose outlet this way. I put a new steam vent line in. It was a bit nerve wracking drilling into my new $150 water pump but it came out alright.

I built up a pipe to go from the turbo downpipe to underneath the car. I will freely admit that this thing is NOT pretty. But it does manage to get the exhaust as far as underneath the heater box and it doesn't hit anything! 3 Inch exhaust pipe is fairly difficult to fit through tight spots and this was very difficult to make work.

Here it is installed. Not a very good pic but if you look closely you can see that it is indeed a tight fit under there. This pipe is now back out so I can paint it and then wrap it to help keep it from melting anything. Of interest in this picture is the -10 AN line running into the drivers side of the oil pan. It looks like it is running at a serious uphill angle, it's not.

I'm about to hit the road now. The last of the silicone pieces are here to put the coldside together. So hopefully I will have video of the old girl roasting the tires off shortly!

The fuel rails are going to stay plumbed the way they are. I can see fuel starvation from a small pump. The Bosch 044 is NOT a small pump and will be able to provide enough volume to keep this motor happy to the power levels I am looking to reach. If I smoke the motor I will come back and say I was wrong. Considering I can pick up a boneyard 5.3 for less than the cost of replumbing this setup I am more than willing to take the risk. As far as injectors go, well the stockers won't get me far but at the very least I can run 5 PSI of boost on them. When I actually start turning up the wick I will be picking up something bigger.

I have made a pretty good bit of progress.

I reformed the hotside a bit to give some more hood clearance so I wouldn't have to worry about burning the paint off my hood. Then I finish welded the whole assembly. I think it came out nice. Here it is mocked into place with the turbo hanging on the end of it all.

Then I mocked up a downpipe to come off the turbine discharge.

I then started getting the wastegate figured out.

Then I finish welded the downpipe and painted everything in high temp flat black. This is one of my favorite pictures from this whole build. It is really starting to look like something.

Then I dry fitted everything together and began wrapping the hotside.

Wrapped up and bolted into the car. Looking good to me at this point.

I had to make my own exhaust gaskets to go from the manifolds to the flanges on the crossover pipe I made. I used some universal exhaust gasket material from Summit made by Mr. Gasket. The stuff is awesome!

I ended up changing the location of the bung for the wideband O2 sensor. I was worried that the wastegate dump coming in after the sensor would give false readings to the computer. So I plugged the original and put in a new one.

The wideband O2 gauge and vac/boost gauge are installed, shown here on the A pillar.

My wife took this pic as a surprise. She came out with the camera and told me to smile. I actually like it, I think it is cool.

A quick video that has some delicious turbo whistle in it.

I ended up swapping out the older style water pump for the newer style one. It made more sense to do the radiator hose outlet this way. I put a new steam vent line in. It was a bit nerve wracking drilling into my new $150 water pump but it came out alright.

I built up a pipe to go from the turbo downpipe to underneath the car. I will freely admit that this thing is NOT pretty. But it does manage to get the exhaust as far as underneath the heater box and it doesn't hit anything! 3 Inch exhaust pipe is fairly difficult to fit through tight spots and this was very difficult to make work.

Here it is installed. Not a very good pic but if you look closely you can see that it is indeed a tight fit under there. This pipe is now back out so I can paint it and then wrap it to help keep it from melting anything. Of interest in this picture is the -10 AN line running into the drivers side of the oil pan. It looks like it is running at a serious uphill angle, it's not.

I'm about to hit the road now. The last of the silicone pieces are here to put the coldside together. So hopefully I will have video of the old girl roasting the tires off shortly!

#89

just saying.. U may have issues with the placement of your wastegate it doesn't really give both banks of cylinders good venting, may have problems with controlling boost,an what is the hotside a/r on your turbo? in a earlier post it looks to be a .68?

#91

[QUOTE=TurboMonte;16994172]Well I'm getting there bit by bit!

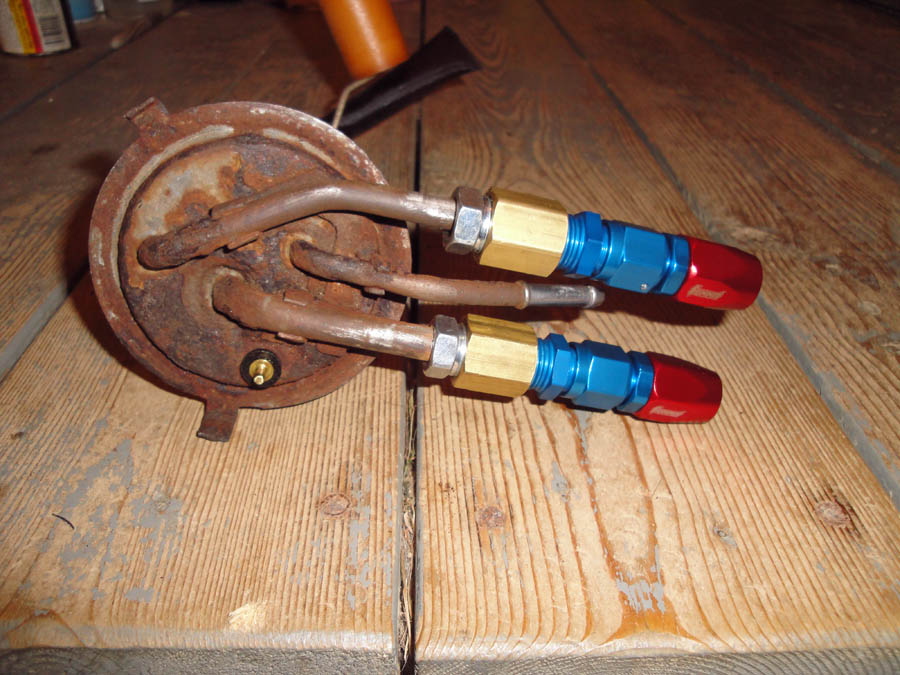

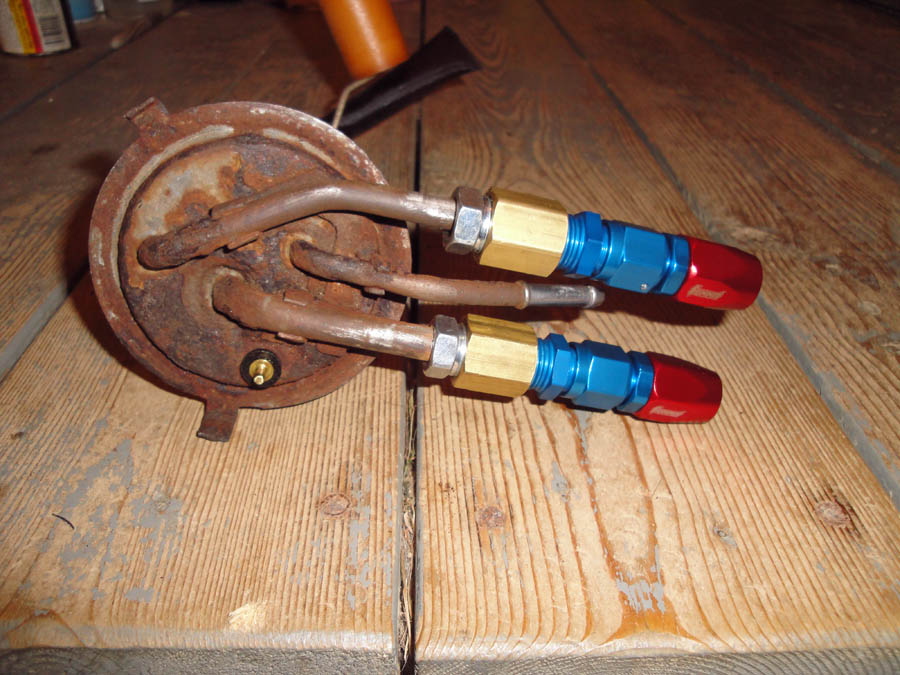

Nasty old rusty gas tank is out. What a mess! But it is very solid on the inside so no worries here other than cosmetics. Sending unit looks pretty gnarly too and I couldn't source one locally so I'm reusing it!

Sending unit after I modified it to accept -6 AN lines. It is almost a crime to put such pretty pieces of hardware on such an old POS isn't it?

If you do need to have the fuel level sender replaced.

Racetronix offer these sending units for the Buick GN Turbos,

with in tank pumps.

http://www.racetronix.biz/items.asp?...atus=0&Tp=&Bc=

Nasty old rusty gas tank is out. What a mess! But it is very solid on the inside so no worries here other than cosmetics. Sending unit looks pretty gnarly too and I couldn't source one locally so I'm reusing it!

Sending unit after I modified it to accept -6 AN lines. It is almost a crime to put such pretty pieces of hardware on such an old POS isn't it?

If you do need to have the fuel level sender replaced.

Racetronix offer these sending units for the Buick GN Turbos,

with in tank pumps.

http://www.racetronix.biz/items.asp?...atus=0&Tp=&Bc=

Last edited by Ollie8974; 07-01-2013 at 08:55 PM.

#93

Love the build, but I'm admittedly baffled you didn't spend the $30 or less on the idler relocation.

coloradov8swapmoifiedaccesorybracket001.jpg?t=1292837482

coloradov8swapmoifiedaccesorybracket001.jpg?t=1292837482

#94

I've ran my belt setup the same as the op's for two years and my fuel system is plumbed the same as his too and never had an issue with either. Car made 587rwhp at 12.8lbs of boost with the mpt 70 and I have it on e85 and 14lbs of boost now with a pt7675 and still no issues. I wasn't planning on running my fuel system like that but the regulator I ended up with only had one port on it.

#96

You do need to build a timing table but that is surprisingly easy, or you can find one that someone has already built online. The MS community is very open to sharing tunes/tables.

Having said that, it is really not a plug and play ECM. You can buy the MS pre built but you still need to figure out a wiring harness to connect your engine to the MS, not that hard but a bit time consuming.

But more importantly, if you have an electronic automatic overdrive transmission the MS will not control it (4L60E/4L80E). The ability to control it is there, but you have to purchase more hardware, and you have even more work and more tuning to get the transmission shifting properly.

I am not telling you this to discourage you. I just want to be up front. If you decide to do a swap with any type of after market ECM there is going to be a steep learning curve. Personally I think the MS is quite easy, but that is just my opinion!

My Monte is out running and driving. I have a great tune in the engine and at only 5 lbs of boost this car is retarded. I can't believe how much *** this motor is kicking, flooring the gas at almost any speed below 40 MPH blows the tires off!

It looks like 7 lbs of boost is all I am going to be able to make with the stock truck injectors, but thanks to the awesome datalogging on the MS it is pretty easy to see what my limits will be.

I strongly suggest the MS if you are mechanically/electrically inclined. It is a pretty kick butt piece of hardware for a very reasonable price.

#98

Quick update for anyone following along.

The car is an absolute animal. The lowly 5 lbs. of boost I am feeding it makes it just too much fun. I can't wait to get some bigger injectors and crank it up. I have no idea what it is making to the wheels right now but it is a lot.

The poor little 7.5" rear end is about to give up. The posi is almost certainly dead as it only does one wheel peels now, but it is still pretty cool.

All the hand wringing posts about stuff I had done wrong was nothing more than that, hand wringing. Power steering and alternator work flawlessly. The fuel system keeps the mix fat as hell at about 11.4 right up to 6200 RPM, and the wastegate easily holds 5 PSI just like it should.

So here is a vid from earlier tonight, not the most impressive ever but it does show the old girl strutting her stuff. Dyno vid to come soon, although it may wait until I get new injectors so I can really crank up the boost.

Right now though I am just having too much fun to worry about that stuff. This car rips!

The car is an absolute animal. The lowly 5 lbs. of boost I am feeding it makes it just too much fun. I can't wait to get some bigger injectors and crank it up. I have no idea what it is making to the wheels right now but it is a lot.

The poor little 7.5" rear end is about to give up. The posi is almost certainly dead as it only does one wheel peels now, but it is still pretty cool.

All the hand wringing posts about stuff I had done wrong was nothing more than that, hand wringing. Power steering and alternator work flawlessly. The fuel system keeps the mix fat as hell at about 11.4 right up to 6200 RPM, and the wastegate easily holds 5 PSI just like it should.

So here is a vid from earlier tonight, not the most impressive ever but it does show the old girl strutting her stuff. Dyno vid to come soon, although it may wait until I get new injectors so I can really crank up the boost.

Right now though I am just having too much fun to worry about that stuff. This car rips!

#99

#100