My First BMW – My First Swap – LS2/T56 into an E36

#121

I guess I have't kept up with this thread very well. I tend to update on the BMW forum more often. That said, I'm true to my word in my very first post - this is a slow build.

These brake lines continue to be my nemesis. It would almost be comical if it weren't so frustrating. I procrastinated quite a bit knowing I had to attack these lines yet again. I'd already redone them previously because I wasn't happy with the crappy flaring tool I used in the first go around. I redid them with a quality Eastwood bench flaring tool. But once I test fit the engine, it was clear that the two rear lines were too close to the JTR headers. So, round three.

The challenges this time around were that I'd have to cut the two hard lines that run to the rear brakes. And I'd have to make new flares on the car. Long story short, I'd posted a few months ago that I found what appeared to be a decent "on car" flaring tool on eBay, shipped from England (search for "Mafco" or "Powerhand" Din flaring tool). Eastwood recently started selling a similar on-car flaring tool, but they don't have a bubble-flare version. And as mentioned in a prevision post, I decided to give Nicopp brake line a try this time. Nicopp is SO much easier to work with. While I made all of the 90 degree bends with a bending tool, sweeping bends can be made by hand. I wish I'd used this stuff the first two times. Yes, it's expensive..and yes, I still had a lot of waste making and remaking lines. But there's no contest between this stuff and the green-coated steel line when it comes to workability.

I also decided that if I was going to get this done, I needed to accept the fact that I'd have to have an extra two unions in the line. The lines were just too long and too cumbersome to successfully bend single lines from the ABS pump down to the frame rails.

They're not gorgeous and they're not 100% to my liking but I think they are good enough. But until I get fluid in the system to check for leaks, I can't be overly confident. I'm debating whether to go ahead and fill and bleed the system next or whether to put the engine and headers back in to make sure all of the clearances are good. I've never done a full system bleed. I do have a Motive pressure bleeder (I've never used it). I'm also not sure if I'll need to get power to the ABS pump to get a full system bleed. I just want to know if I have any leaks!

The red arrow points to a Sharpie mark where the previous lines were just about touching the header.

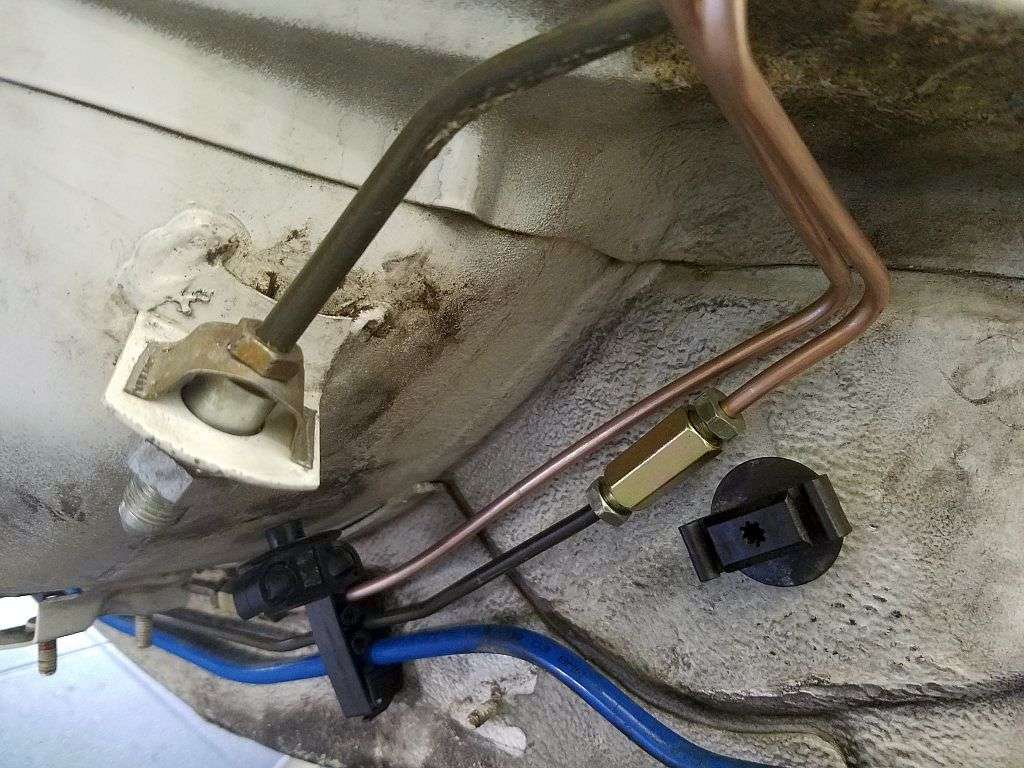

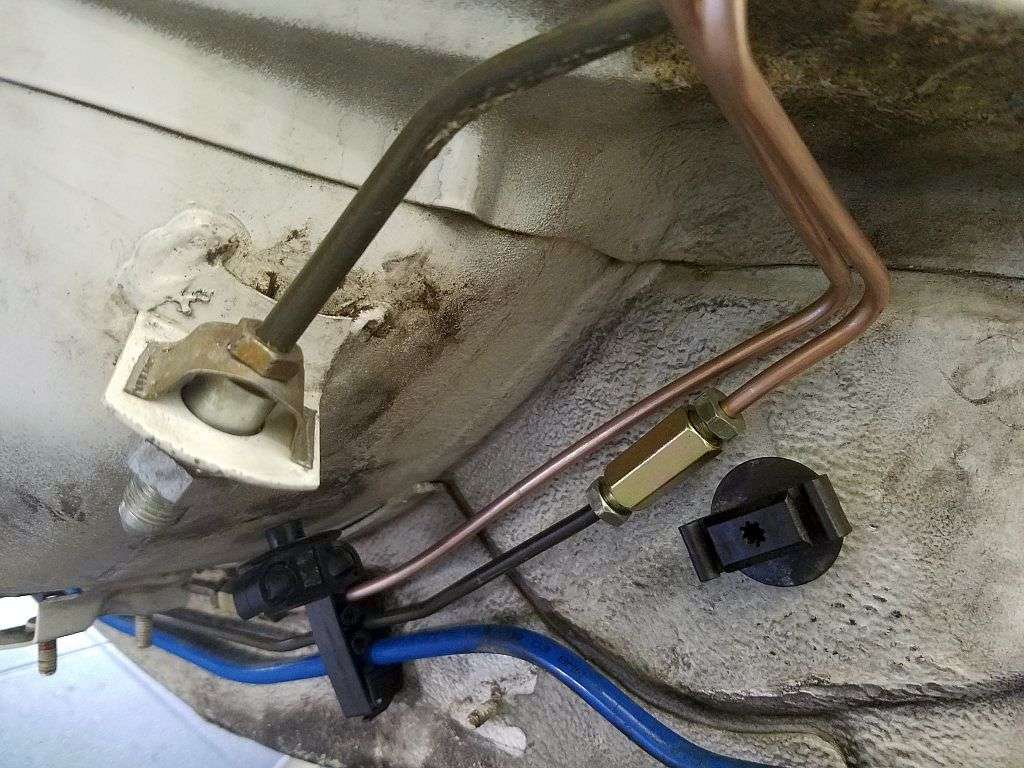

This union ended up further down the frame rail than I wanted. It's very close to where the stock fuel filter/regulator goes. I had originally cut the line further up but there was a slight bend that prevented the flare fitting from sliding down far enough to fit the flaring tool. So I had to cut the line back until I had enough straight line available.

The other union.

This tool, called a Ratch-Cut, makes cutting the line in tight quarters so much easier than using a traditional pipe cutter.

This is the on-car brake flaring tool.

These brake lines continue to be my nemesis. It would almost be comical if it weren't so frustrating. I procrastinated quite a bit knowing I had to attack these lines yet again. I'd already redone them previously because I wasn't happy with the crappy flaring tool I used in the first go around. I redid them with a quality Eastwood bench flaring tool. But once I test fit the engine, it was clear that the two rear lines were too close to the JTR headers. So, round three.

The challenges this time around were that I'd have to cut the two hard lines that run to the rear brakes. And I'd have to make new flares on the car. Long story short, I'd posted a few months ago that I found what appeared to be a decent "on car" flaring tool on eBay, shipped from England (search for "Mafco" or "Powerhand" Din flaring tool). Eastwood recently started selling a similar on-car flaring tool, but they don't have a bubble-flare version. And as mentioned in a prevision post, I decided to give Nicopp brake line a try this time. Nicopp is SO much easier to work with. While I made all of the 90 degree bends with a bending tool, sweeping bends can be made by hand. I wish I'd used this stuff the first two times. Yes, it's expensive..and yes, I still had a lot of waste making and remaking lines. But there's no contest between this stuff and the green-coated steel line when it comes to workability.

I also decided that if I was going to get this done, I needed to accept the fact that I'd have to have an extra two unions in the line. The lines were just too long and too cumbersome to successfully bend single lines from the ABS pump down to the frame rails.

They're not gorgeous and they're not 100% to my liking but I think they are good enough. But until I get fluid in the system to check for leaks, I can't be overly confident. I'm debating whether to go ahead and fill and bleed the system next or whether to put the engine and headers back in to make sure all of the clearances are good. I've never done a full system bleed. I do have a Motive pressure bleeder (I've never used it). I'm also not sure if I'll need to get power to the ABS pump to get a full system bleed. I just want to know if I have any leaks!

The red arrow points to a Sharpie mark where the previous lines were just about touching the header.

This union ended up further down the frame rail than I wanted. It's very close to where the stock fuel filter/regulator goes. I had originally cut the line further up but there was a slight bend that prevented the flare fitting from sliding down far enough to fit the flaring tool. So I had to cut the line back until I had enough straight line available.

The other union.

This tool, called a Ratch-Cut, makes cutting the line in tight quarters so much easier than using a traditional pipe cutter.

This is the on-car brake flaring tool.