'03 S-10 Build

#41

TECH Apprentice

Thread Starter

I have the new CPW urethane mounts in and made another attempt to bolt in the motor. Still having the same issue with the pulley making contact with the idler arm @ the frame.

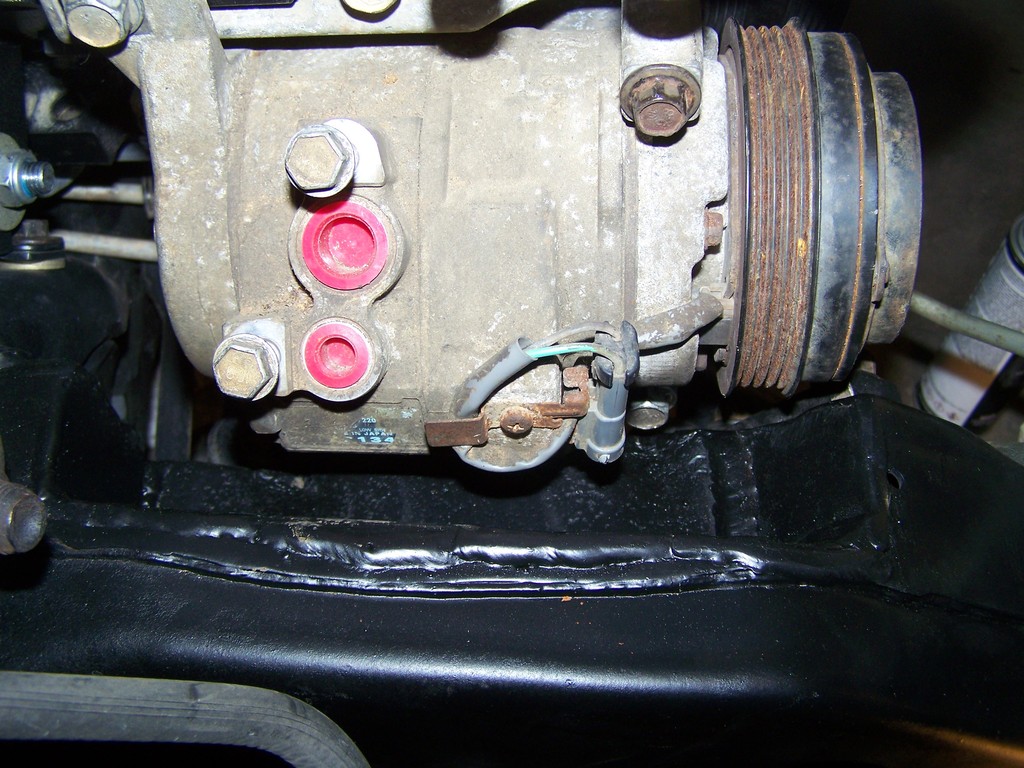

So at this point I will be cutting the upper section of the arm and redrilling the frame to get the arm mounted. See the pic above. Here are the shots of the compressor front & rear. Still not "home" in the engine mount and already has contact in front.

I will make the attempt to get the arm cut and positioned to weld this evening. Shouldn't be too difficult. Once everything is positioned and bolted down I can get the arm rewelded.

So at this point I will be cutting the upper section of the arm and redrilling the frame to get the arm mounted. See the pic above. Here are the shots of the compressor front & rear. Still not "home" in the engine mount and already has contact in front.

I will make the attempt to get the arm cut and positioned to weld this evening. Shouldn't be too difficult. Once everything is positioned and bolted down I can get the arm rewelded.

Last edited by gsjimmy; 12-08-2016 at 08:00 AM. Reason: photo add

#42

TECH Fanatic

iTrader: (20)

I did exactly this to the passenger side. Wanted to do driver side, but the fabricated radiator had a dumb fill neck sticking out a mile on mine that prevented it. But yeah, just like yours with the MAF in the elbow before the bend into the throttle. With an airflow straightener, I'm not too worried about turbulence.

#43

TECH Apprentice

Thread Starter

Well, I dropped the engine in after making my cut and rewelding the idler arm. Still hits. Think that I can "clearance" the arm enough to gain clearance. Otherwise it's off to the parts store to get a new arm and start over. Another thought is to make a relief cut into the frame and recess the mount area into the frame .375 to .50. and then weld up the frame/ this would move the arm away from the compressor by that much without effecting the geometry of the idler location relative to the drag link.

I would need to add reinforcements over my weld (diamond shaped plates) to reduce any flex.

Thoughts?

Also, does anyone have a clearanced A/C box for a 2nd gen S-10? Looking for one that is done, otherwise I have to do that. Should be the last items needed to get the engine into the truck. Then it's the little crap, cut/relocate the rear coils upward, hoses, a/c lines.......

Side note: Looks like I will be a Ford Mechanic tonight. My kid blew up the front hub on his Exploder. Hoping to beat the weather 0* overnights. Why does this always happen when its raining/snowing/below zero or nuclear hot out? Never on a day when it's 75*, SUNNY WITH A LITE BREEZE.

Oh well, back to work.

I would need to add reinforcements over my weld (diamond shaped plates) to reduce any flex.

Thoughts?

Also, does anyone have a clearanced A/C box for a 2nd gen S-10? Looking for one that is done, otherwise I have to do that. Should be the last items needed to get the engine into the truck. Then it's the little crap, cut/relocate the rear coils upward, hoses, a/c lines.......

Side note: Looks like I will be a Ford Mechanic tonight. My kid blew up the front hub on his Exploder. Hoping to beat the weather 0* overnights. Why does this always happen when its raining/snowing/below zero or nuclear hot out? Never on a day when it's 75*, SUNNY WITH A LITE BREEZE.

Oh well, back to work.

#44

TECH Fanatic

iTrader: (20)

Well, I dropped the engine in after making my cut and rewelding the idler arm. Still hits. Think that I can "clearance" the arm enough to gain clearance. Otherwise it's off to the parts store to get a new arm and start over. Another thought is to make a relief cut into the frame and recess the mount area into the frame .375 to .50. and then weld up the frame/ this would move the arm away from the compressor by that much without effecting the geometry of the idler location relative to the drag link.

Good luck with it all, I remember the whole thing fighting pretty hard for me, too. But the almost constant question "What's that thing got, a 350?" makes it all worth while... especially when I tell them it's a 346 like the condescending *** I am lol!

#45

TECH Apprentice

Thread Starter

This is around the 6-7 time I've had the engine in the chassis. First 2 were without the a/c compressor. Piece of cake, dropped right in, start was in place. Now I wonder what the hell I'm doing!

Put a BBC into a '64 Nova, no issues. BBB swap from a SBB in my GS, swapped auto's to manuals, worked on Vettes, Mopars, Fords, Nissans, the whole shebang. Even build a couple Frankenbikes, but this one is a fight now. The A/C is a must (Hot & Humid summers). I will win this, just need to think on it!

Seems like relocating the idler mount inward that 1/2 inch could be what solves the issue. Guess we'll see.

Put a BBC into a '64 Nova, no issues. BBB swap from a SBB in my GS, swapped auto's to manuals, worked on Vettes, Mopars, Fords, Nissans, the whole shebang. Even build a couple Frankenbikes, but this one is a fight now. The A/C is a must (Hot & Humid summers). I will win this, just need to think on it!

Seems like relocating the idler mount inward that 1/2 inch could be what solves the issue. Guess we'll see.

#47

TECH Apprentice

Thread Starter

Well, it's really freakin' cold out now. Progress is slowing down on the truck. Monday had Scouts, Tuesday had an Eagle Scout board of review, last night confirmation, now we are getting ready for the kids to come home for X-mas (Virginia and Colorado, as well as the local kids).

Still waiting to get the wire harness and ECU back. I also was only able to take a quik look at the idler arm situation. I should be able to move the mount in over the weekend and maybe get the cab tilted back. I also need to plug my attic access in the shop, all my heat is going out the roof vent!

Still waiting to get the wire harness and ECU back. I also was only able to take a quik look at the idler arm situation. I should be able to move the mount in over the weekend and maybe get the cab tilted back. I also need to plug my attic access in the shop, all my heat is going out the roof vent!

#48

TECH Apprentice

Thread Starter

Was able to get an hour in the shop last night. Stripped off the pass side fender and a/c suitcase. Did some measuring on the cut I need to make (a/c & frame). Should be able to get a good clean and paint done this weekend and possibly get the cab lifted & box removed. Ideally the frame should come out to be able to get the frame sorted & engine installed. (maybe I'll do that). Nothing picture worthy at this point.

Body dolly is out behind the shop, may have to sweep it off and bring it in. Then the shop will be less cluttered if I put my loose parts in the box!

Next week I have to get a Pathfinder finished, and a parts truck scrapped.

Body dolly is out behind the shop, may have to sweep it off and bring it in. Then the shop will be less cluttered if I put my loose parts in the box!

Next week I have to get a Pathfinder finished, and a parts truck scrapped.

#50

TECH Apprentice

Thread Starter

Well, just got back from vacation. Still no harness/ECU.

We did manage to get the Pathfinder moving under its own power, soon to be out of my shop! Then I can pull the box and cab on the S-10 and get things mounted and plumbed!

Now if the harness would get here.......

We did manage to get the Pathfinder moving under its own power, soon to be out of my shop! Then I can pull the box and cab on the S-10 and get things mounted and plumbed!

Now if the harness would get here.......

#52

TECH Apprentice

Thread Starter

Just found out why the Pathfinder won't stay in its lane (without a fight). Wrong pitman arm. Opps. Should be aligned and out of the shop today. Just little things left and the kid heads back to CO. Getting ready to pull the box & cab.

Also just heard back on the wiring, may get it out on Friday. Sounds like I need the engine mounted up now.

Tonight I will section another 1/2" on the upper section of my notch and do the final trim at the front by the idler arm. With the body off the frame, should be easy to work on (so I say now!).

Will pull off the box, do the trim and see about the cab ........ wish me luck.

Also just heard back on the wiring, may get it out on Friday. Sounds like I need the engine mounted up now.

Tonight I will section another 1/2" on the upper section of my notch and do the final trim at the front by the idler arm. With the body off the frame, should be easy to work on (so I say now!).

Will pull off the box, do the trim and see about the cab ........ wish me luck.

#53

TECH Apprentice

Thread Starter

Also ordered up my front suspension parts. New upper & lower control arms, new springs and new ZQ8 Delphi shocks. Looks like next week before they get here.

#55

TECH Apprentice

Thread Starter

Finally made some progress. Was able to pull the box and get it on the chassis roller, loaded it full of my small parts, bumpers, fenders and so forth. Attached the engine to the trans (fits well with the right bellhousing) and am ready to lift the cab (tilt back) to install the engine.

I also cleaned and painted the trans X-member. Still need to clean & paint the attaching hardware. Also, my front suspension parts started to show up. Still waiting on springs and 1 lower control arm. Finally have the correct deCarbon front shocks (was running with KYB's).

So, if all goes well this week, I will have the front suspension changed out and the frame painted. In a perfect world the firewall would be done too.

Nothing photo worthy, just a bunch of prep work.

Gabbini - Thanks, trying to get this done by March. Winter beater's plates expire then, would like to be driving the S-10 then.

I also cleaned and painted the trans X-member. Still need to clean & paint the attaching hardware. Also, my front suspension parts started to show up. Still waiting on springs and 1 lower control arm. Finally have the correct deCarbon front shocks (was running with KYB's).

So, if all goes well this week, I will have the front suspension changed out and the frame painted. In a perfect world the firewall would be done too.

Nothing photo worthy, just a bunch of prep work.

Gabbini - Thanks, trying to get this done by March. Winter beater's plates expire then, would like to be driving the S-10 then.

Last edited by gsjimmy; 01-03-2017 at 08:46 AM.

#56

TECH Apprentice

Thread Starter

Hold-up's (in no particular order)

1. Kid's Furd Exploder - It's a Ford, what more can I say.

2. Oldest Boy's Pathfinder - After 2+ years in Dad's shop, it finally left to Colorado on Thursday. [Frame off "resto", new driveline, suspension, body & paint]

3. Coming down with the creeping crud. Lost about a week on this one!

Wife heads out to AZ next week, planning to get things done. Shop is fairly straight now, have room to work and am not sick. We'll see I guess!

1. Kid's Furd Exploder - It's a Ford, what more can I say.

2. Oldest Boy's Pathfinder - After 2+ years in Dad's shop, it finally left to Colorado on Thursday. [Frame off "resto", new driveline, suspension, body & paint]

3. Coming down with the creeping crud. Lost about a week on this one!

Wife heads out to AZ next week, planning to get things done. Shop is fairly straight now, have room to work and am not sick. We'll see I guess!

#57

TECH Apprentice

Thread Starter

I was able to get 1/2 inch taken out on the upper side of the frame rail last night. This will cure the "tightness" at the top of the A/C pump. I then made a bunch of measurements and cut out the idler arm. Took 1/2 inch out in the side to side section and then cut on the diagonal about an inch or so from the vertical part of the idler where it bolts into the frame.

Measured the distance from the inner tie rod to the frame to insure the location remained constant (within a 1/16th). Also verified the actual location of the arm for being square. (nothing moved).

Tonight I should be able to tack down the corners of the frame piece I removed and verify that this has cured my interference issue with the pulley.

Once that is correct, I will be welding up the section and adding some diamond shaped plates over the welded areas so as not to leave butt welded seams in what I think is a high stress area (steering is kinda important).

Worst case, I will have to find a wrecked S-10 and cut off a new frame horn to do a repair.

Measured the distance from the inner tie rod to the frame to insure the location remained constant (within a 1/16th). Also verified the actual location of the arm for being square. (nothing moved).

Tonight I should be able to tack down the corners of the frame piece I removed and verify that this has cured my interference issue with the pulley.

Once that is correct, I will be welding up the section and adding some diamond shaped plates over the welded areas so as not to leave butt welded seams in what I think is a high stress area (steering is kinda important).

Worst case, I will have to find a wrecked S-10 and cut off a new frame horn to do a repair.

#58

TECH Apprentice

Thread Starter

Progress from last night. Was able to push the idler into position (taped with 100 mph tape) and set the engine into position. I did notice a little movement on the pass side wheel (expected).

The cutoff section will slide into the frame and I have plenty of clearance on the tie rod when traversing side to side. I was also able to bolt on the exhaust manifold on the pass side to start checking clearance there. looks like I'm a little tight on the rear side of the upper control arm. I have all new front suspension ready to go on, so an alignment is going to be needed.

Question, can I just clearance the upper control arm, or do I need to weld in support after getting the clearance? It appears that there will some rubbing against the manifold.

The cutoff section will slide into the frame and I have plenty of clearance on the tie rod when traversing side to side. I was also able to bolt on the exhaust manifold on the pass side to start checking clearance there. looks like I'm a little tight on the rear side of the upper control arm. I have all new front suspension ready to go on, so an alignment is going to be needed.

Question, can I just clearance the upper control arm, or do I need to weld in support after getting the clearance? It appears that there will some rubbing against the manifold.

#60

TECH Addict

iTrader: (47)

High mount a/c is just in the way of a turbo! No need for all that real estate to be taken up, when a/c fits nice down below, besides, who wants to see a ugly a/c compressor, on such a nice swap?

GS, I hate to ask this now, but why are you pulling the motor every time? Is it so you have room to work? When I did mine, I made sure I was able to "service" my a/c compressor with everything in place.

GS, I hate to ask this now, but why are you pulling the motor every time? Is it so you have room to work? When I did mine, I made sure I was able to "service" my a/c compressor with everything in place.