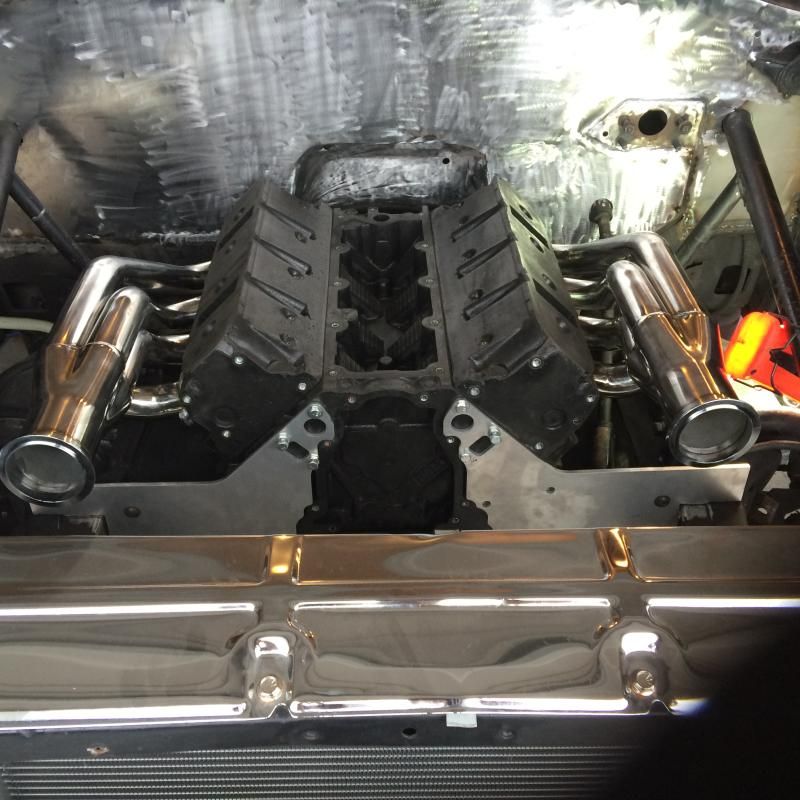

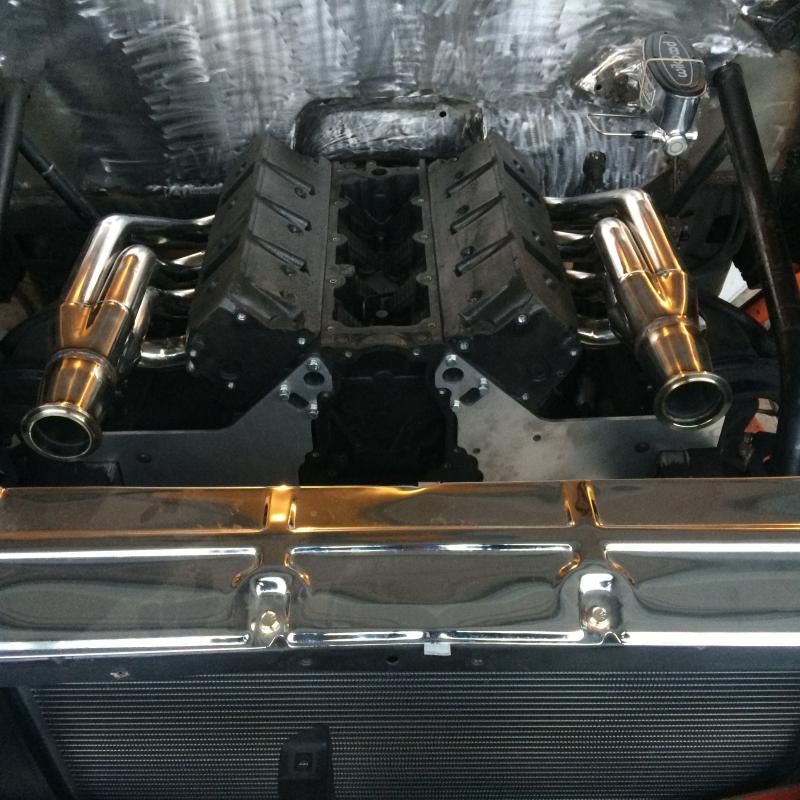

69 Chevelle ls turbo build

#21

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

#23

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

I ended up buying two small bits to get the wholes started. Once they were started it was easy with my poverty bits.

#24

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

#25

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

#28

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

#30

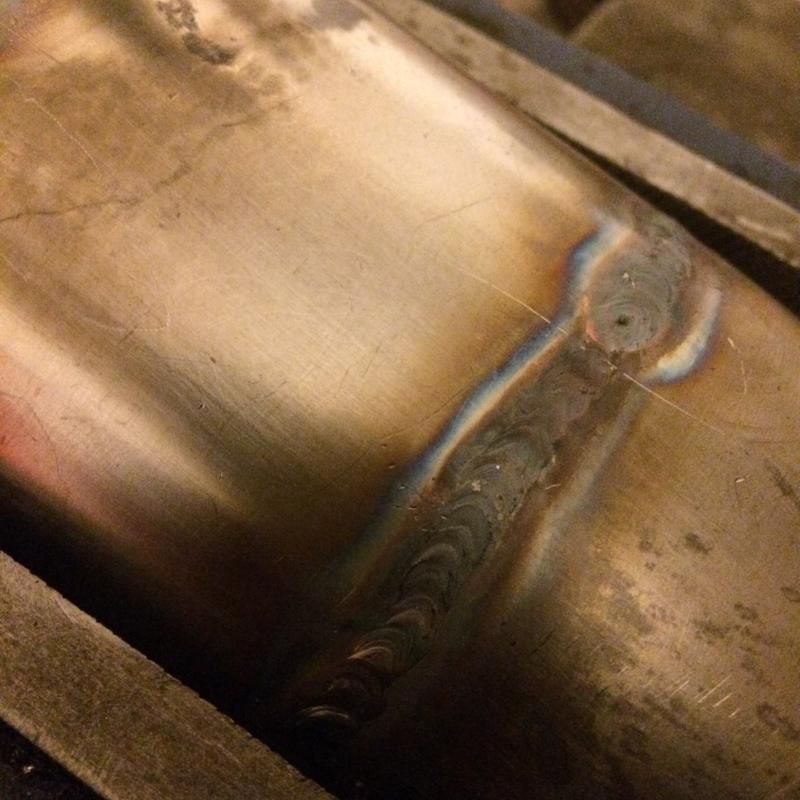

Looks good. A little on the hot side for the welds. When the welds are that dark and dull, that's a sign. Also try not to leave a divit at the end of the weld.

Try swirling the torch in a circular motion after the last dab of filler and hold the torch over it while the post flow is going and keep it there until the weld doesn't appear to glow orange. This works for me anyhow.

I really like your turbo layout and piping thus far. This is going to be a sick build for sure.

Try swirling the torch in a circular motion after the last dab of filler and hold the torch over it while the post flow is going and keep it there until the weld doesn't appear to glow orange. This works for me anyhow.

I really like your turbo layout and piping thus far. This is going to be a sick build for sure.

#31

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

Looks good. A little on the hot side for the welds. When the welds are that dark and dull, that's a sign. Also try not to leave a divit at the end of the weld.

Try swirling the torch in a circular motion after the last dab of filler and hold the torch over it while the post flow is going and keep it there until the weld doesn't appear to glow orange. This works for me anyhow.

I really like your turbo layout and piping thus far. This is going to be a sick build for sure.

Try swirling the torch in a circular motion after the last dab of filler and hold the torch over it while the post flow is going and keep it there until the weld doesn't appear to glow orange. This works for me anyhow.

I really like your turbo layout and piping thus far. This is going to be a sick build for sure.

#33

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

#35

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC

#38

Joined: Mar 2003

Posts: 10,244

Likes: 1,531

From: The City of Fountains

#40

Thread Starter

Joined: Aug 2006

Posts: 5,364

Likes: 2

From: Summerville, SC