Clutch master pushrod modification

#6

Staging Lane

Join Date: Apr 2004

Location: Santa Clara, CA

Posts: 99

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by MrDude_1

yea.

all of the ram "adjustible" ones are just factory units with the end chopped off, threaded, and a rod end screwed on...

all of the ram "adjustible" ones are just factory units with the end chopped off, threaded, and a rod end screwed on...

One note, the cast aluminum end that I cut and threaded turns hollow to slip fit over the steel plunger, so becareful, you can only cut so much off.

#7

On The Tree

iTrader: (2)

Join Date: Nov 2004

Location: Pittsburgh, Pa

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

Do NOT cut the stock one and try to make it adjustable... I did that...and it worked great for a few hundred miles...then the cheap mild steel rod gave out 300 miles from home!!! That sucked..... real bad...

Trending Topics

#10

Staging Lane

Join Date: Apr 2004

Location: Santa Clara, CA

Posts: 99

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by chevysrule94

oh man thats what I did... good luck with it

#11

Launching!

Join Date: Aug 2002

Location: Los Angeles, CA

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by svt

really, i don't see how the steel pushrod is weakened with this modification, do you have any pictures of your mod? this is similar to what tyler sells, except he machines a whole new aluminum peice.

I would also not suggest mounting the master directly to the firewall, as it will flex, and eventually crack. It is not designed to bear that load at all, which is why we have a firewall bracket.

Tyler

#12

On The Tree

iTrader: (2)

Join Date: Nov 2004

Location: Pittsburgh, Pa

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by svt

really, i don't see how the steel pushrod is weakened with this modification, do you have any pictures of your mod? this is similar to what tyler sells, except he machines a whole new aluminum peice.

If I remember correctly the mild steel rod is a bit smaller than 3/8ths die, so when you thread it, the threads dont catch right, then if you go smaller... it cuts in too far and will eventually break.

#13

TECH Fanatic

iTrader: (63)

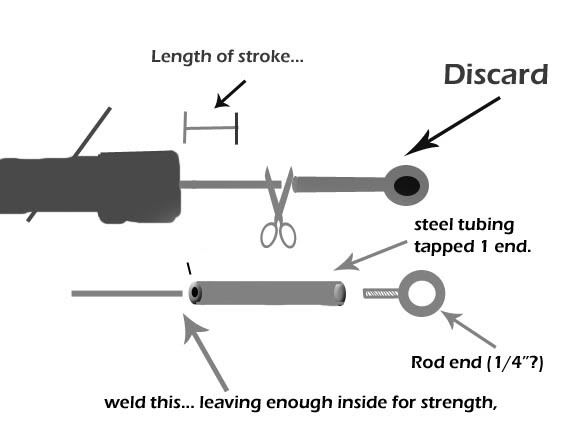

what "I" would do, is chop off the factory pushrod up to 1" from the end of its stroke. from there, I would get a piece of steel tubing, the ID of which, is equal to the diameter of the factory rod. I would then weld the tubing over the rod, cut to my desired length, and tap it for a small rod end. i'll illustrate here in a minute..

olly

olly

#18

TECH Fanatic

iTrader: (63)

it was just a little piece of 5/32 x 1/2"w x 2" L piece of steel like hotrodlane.cc showed you how to do. I went wrong by picking a piece with a tiny 1/4" hole in it, and it snapped right there. I was planning on beefing it up, once I bled it, but I forgot, and got distracted by the pedal pressure and hydraulics. the leverage point was way wrong, which had a lot to do with it. i thought i'd overkill it to be safe, something about my clutch slamming to the floor made me unhappy, dunno why.