Tensioner Pulley Location

#1

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

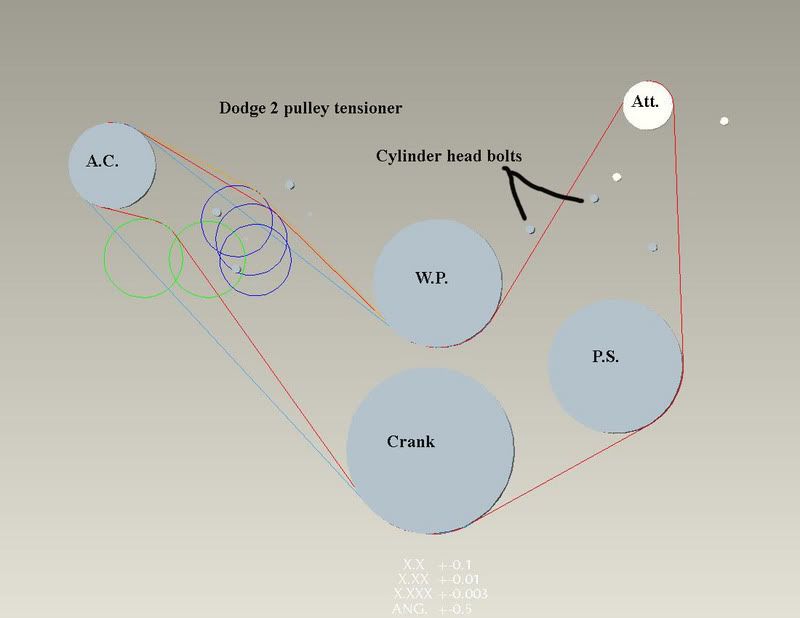

Where would the best place to locate a tensioner pulley for this set-up? I was thinking either to use a vette pulley to the right of the ac compressor or put a pulley to the right of the alternator and above the power steering pump. If I put it by the alternator, is the distance between the ac compressor to large and will it cauce the belt to jump off the water pump pulley? What are some of the aftermarket companies that make different tensioner pulleys? I am planning to make the brackets out of 1/2" aluminum plates and aluminum spacers.

#2

TECH Resident

iTrader: (2)

That top pulley location is'nt going to interfere with your throttle-body hose or MAF, is it? Your situation looks very simular to board member JohnB, who was one of the first to use the same A/C compressor(R4?) that your trying to use. Do a search for his input & photos, which were excellent. Gar

#3

TECH Resident

Join Date: Dec 2004

Location: Baltimore, MD.

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

I would suggest you should put it in the run between the water pump and the AC compressor. Belts work in tension, so you want to put the tensioner on the slack side. In a perfect world, the tensioner would be in between the crank pulley and the water pump (last driven device), but that isn't practical.

You may need an additional idler pulley to pull the belt around the water pump a little further and allow the tensioner to apply tension without making the top and bottom touch (which would be bad).

Just my thoughts....Keep us posted as to what you figure out. I need to make a custom high AC mount for my truck (using C5 access) sometime between now and summer, and its always good to know of potential pitfalls before falling.

'JustDreamin'

You may need an additional idler pulley to pull the belt around the water pump a little further and allow the tensioner to apply tension without making the top and bottom touch (which would be bad).

Just my thoughts....Keep us posted as to what you figure out. I need to make a custom high AC mount for my truck (using C5 access) sometime between now and summer, and its always good to know of potential pitfalls before falling.

'JustDreamin'

#6

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

I cut the factory bracket above the second mounting hole from the bottom. I cut through the ribs. I think there is more than enough metal left. It took about 30 seconds with a long sawzall blade. I may leave it like this or make a new p.s. pump bracket out of the aluminum I buy. I am more concerned with getting something that is functional rather than overall looks right now. There are three mounting points now. ( 2 in front and the one in back that mounts to the side of the engine block)

I was looking at the S&P catalog (LS1 high mount alt & ac on page 78). Do their idler pulleys take up the slack or do you have to adjust the rods on the alt and ac to tighten the belt? It doesn't look like there is enough room for the idler arm to rotate.

I was looking at the S&P catalog (LS1 high mount alt & ac on page 78). Do their idler pulleys take up the slack or do you have to adjust the rods on the alt and ac to tighten the belt? It doesn't look like there is enough room for the idler arm to rotate.

#7

Just about the time I thought I understood how alll the pulley's worked together, I took a look through all the motor pictures on the GM engines site and there seems to be little rhyme nor reason. The one common thing is that you can't run two non tracking pulleys in succession, either smooth side or ribbed side. Some motors have a fairly large span betewwn pulleys as well. I would opt to keep the stock type spring tensioner rather than the fixed/adjustable type.

Andy1

Andy1

Trending Topics

#8

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

I started to price aluminum today. It makes GM brackets look cheap. The best prices I have found have been at mymetalconnection.com. I am going to try to put the katech tensioner between the waterpump and the ac compressor.

#9

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

After looking at some belt tensioners, I am going to try a Dayco 89254 tensioner by the compressor. It has 2 pulleys. I will route the belt below the waterpump and eliminate the idler pulley by the alternator. I'll post pictures after the new brackets are made.

#10

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

Does anyone have dimensions for the mounting holes on the heads and waterpump relative to their assembled positions and the the crank and water pump pulleys? I tried to measure them with the engine in the car but it was hard to get accurate measurements. I am trying to make a cad file to find the best place to mount the tensioner pulley.

#11

76LQ9TA,

I went through similar pains to re-arrange my serpentine routiing. Looking at your illustration, a couple of thoughts come to mind. If you used the FBody alt bracket and idler, and FBody PS pump, then that would efffectively switch their positions. The alt. would be where your PS pump is, and vise-versa. With that, you would gain and idler which would provide increased contact with the crank pulley, yet retain the same basic routing that you have. You''ll just need to add the tensioner somewhere.

Another thing you can try and perhaps with less effort, is to route the belt from the right side of the crank pulley (anti-clockwise), then up and over the WP, then down to the PS pump, the up to the alt, over to the AC, and so on. That way you'd gain increased crank pulley contact without changing the brackets. With this, you could put the tensioner in the stock position and simply replace its pulley with a smooth one (since you'll be running now on the back side of the belt)......... Did you follow that??

Andy1

I went through similar pains to re-arrange my serpentine routiing. Looking at your illustration, a couple of thoughts come to mind. If you used the FBody alt bracket and idler, and FBody PS pump, then that would efffectively switch their positions. The alt. would be where your PS pump is, and vise-versa. With that, you would gain and idler which would provide increased contact with the crank pulley, yet retain the same basic routing that you have. You''ll just need to add the tensioner somewhere.

Another thing you can try and perhaps with less effort, is to route the belt from the right side of the crank pulley (anti-clockwise), then up and over the WP, then down to the PS pump, the up to the alt, over to the AC, and so on. That way you'd gain increased crank pulley contact without changing the brackets. With this, you could put the tensioner in the stock position and simply replace its pulley with a smooth one (since you'll be running now on the back side of the belt)......... Did you follow that??

Andy1

#13

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

I updated the picture. What is a general rule for contact for the belt? The crank pulley has contact with the belt for 83 degrees in its rotation. Thanks for the f-body picture. I don't want to switch to the car accessories because I will still have to make modifications for the AC plus I will have to have a new crank pulley and alternator. I may have room to add another smooth idler pulley between the crank and w.p. Dayco has a good site showing all of the belt tensioners they manufacture. They will send you drawings showing the size too.

I am also looking for the dimensions for the mounting holes in the head from one side to the other and to the waterpump. Also for the belt tensioner to the pass. side front mounting holes in the head.

I am also looking for the dimensions for the mounting holes in the head from one side to the other and to the waterpump. Also for the belt tensioner to the pass. side front mounting holes in the head.

#14

Originally Posted by 76LQ9TA

I updated the picture. What is a general rule for contact for the belt? The crank pulley has contact with the belt for 83 degrees in its rotation. Thanks for the f-body picture. I don't want to switch to the car accessories because I will still have to make modifications for the AC plus I will have to have a new crank pulley and alternator. I may have room to add another smooth idler pulley between the crank and w.p. Dayco has a good site showing all of the belt tensioners they manufacture. They will send you drawings showing the size too.

I am also looking for the dimensions for the mounting holes in the head from one side to the other and to the waterpump. Also for the belt tensioner to the pass. side front mounting holes in the head.

I am also looking for the dimensions for the mounting holes in the head from one side to the other and to the waterpump. Also for the belt tensioner to the pass. side front mounting holes in the head.

I have no idea what the general rule is. I suspect the more accessories (load), the more contact the crank pulley requires. What crank pulley are you planning on? I switched to an LS6 Vette because it's shorter, but the down side was it moved the AC belt quite a bit closer to the motor.

Thanks for the Dayco tip. Is there a better way to look through their tensioners, or do you have to search through by application only?

Below, is a photo of what I did for my LS1 914 conversion. If I can find a different tensioner on the Dayco site, I'd like to shift my tensioner pulley to the left (to gain a little more contact with the WP pulley). If it is simply a left hand version of the stock type tensioner, then that would be good.

I know you asked for the mounting hole centers, but my motor is temporarily installed at the moment, so I can't measure it.

Andy1

#15

Launching!

Thread Starter

iTrader: (1)

Join Date: Jul 2006

Location: Montgomery, IL

Posts: 244

Likes: 0

Received 0 Likes

on

0 Posts

Andy1

I should have measured the motor before I installed it. If that setup is working then the one I am looking at should be fine. The dayco site has a 23 page pdf document with pictures of all of their tensioners and pulleys. I called the auto parts store with the dayco numbers and found the vehicle application. If you send an email to dayco they will send a supplier drawing with relative dimensions of the tensioners. The 89254 tensioner with 2 pulleys may work in that location on your motor too. If you send me some dimensions to locate the axis of the compressor to the w.p. and crank axis I can place the tensioner in there for you like I did in the picture above.

Thanks

I should have measured the motor before I installed it. If that setup is working then the one I am looking at should be fine. The dayco site has a 23 page pdf document with pictures of all of their tensioners and pulleys. I called the auto parts store with the dayco numbers and found the vehicle application. If you send an email to dayco they will send a supplier drawing with relative dimensions of the tensioners. The 89254 tensioner with 2 pulleys may work in that location on your motor too. If you send me some dimensions to locate the axis of the compressor to the w.p. and crank axis I can place the tensioner in there for you like I did in the picture above.

Thanks

#16

TECH Fanatic

iTrader: (13)

Most of the aftermarket systems like S&P and March do not use a spring loaded tensioner. Instead they use an adjustment rod with opposite threads and heim ends to adjust the tension. I am not sure of a guideline for the amount of wrap the belt needs areound a drive or driven pulley, but more is definitely better. Here is a picture of the S&P AC only set up on mine with the remainder being an F-body set up.

Pat

Pat

#17

TECH Resident

Join Date: Dec 2004

Location: Baltimore, MD.

Posts: 841

Likes: 0

Received 0 Likes

on

0 Posts

My off the cuff opinion is that you need more wrap on the crank pulley. It might work just fine like you've got it drawn, but my suspicion is that that amount of wrap probably isn't enough to run the AC, PS, alt, and WP all at full load.

If you compare to the GM setups, they've got alot more wrap and aren't driving the AC compressor (so have less load).

Don't know that I've been of any help here, but that's my thoughts

'JustDreamin'

If you compare to the GM setups, they've got alot more wrap and aren't driving the AC compressor (so have less load).

Don't know that I've been of any help here, but that's my thoughts

'JustDreamin'

#18

Originally Posted by 76LQ9TA

Andy1

I should have measured the motor before I installed it. If that setup is working then the one I am looking at should be fine. The dayco site has a 23 page pdf document with pictures of all of their tensioners and pulleys. I called the auto parts store with the dayco numbers and found the vehicle application. If you send an email to dayco they will send a supplier drawing with relative dimensions of the tensioners. The 89254 tensioner with 2 pulleys may work in that location on your motor too. If you send me some dimensions to locate the axis of the compressor to the w.p. and crank axis I can place the tensioner in there for you like I did in the picture above.

Thanks

I should have measured the motor before I installed it. If that setup is working then the one I am looking at should be fine. The dayco site has a 23 page pdf document with pictures of all of their tensioners and pulleys. I called the auto parts store with the dayco numbers and found the vehicle application. If you send an email to dayco they will send a supplier drawing with relative dimensions of the tensioners. The 89254 tensioner with 2 pulleys may work in that location on your motor too. If you send me some dimensions to locate the axis of the compressor to the w.p. and crank axis I can place the tensioner in there for you like I did in the picture above.

Thanks

I had to move the AC compressor back about 1" to align with the LS6 dampener, then down about 1 1/4" in order to clear my Z06 exhaust manifold. Luckily, the 4 rib Vette AC belt is 1" longer than the FBody one, so that worked out great.

Andy1