Carnage pics. what do you think?

#1

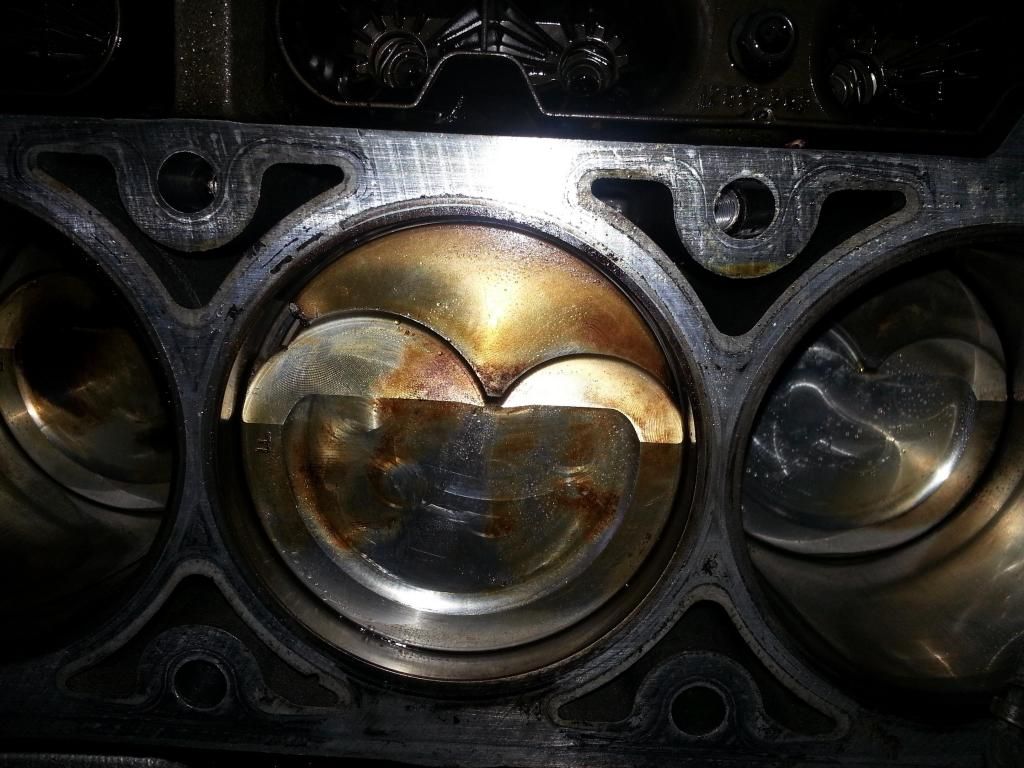

So this is the carnage, finally found out what blew apart in my vette. Im imagining the lifter blew apart. oil pressure dropped caused the rest of the lifters to fail. and then shrapnel from the lifter hit between the crank and the piston causing the marring underneath. the rest of the cylinders look similar to this picture so i didnt bother posting them all. and nearly ever lobe in the cam is torn up as well.

im imagining a good hone, bearings, cam, pistons, oil pump, lifters and i think thats it. (hopefully)

motor is a LS2 with a 402. let me know what you guys think

im imagining a good hone, bearings, cam, pistons, oil pump, lifters and i think thats it. (hopefully)

motor is a LS2 with a 402. let me know what you guys think

#5

Trending Topics

#9

Glad you're getting it to Kim Barr. He'll lead you the right direction. Well, we obviously know the ticking sound you documented a while back was from a lifter. I don't think one lifter went and caused the other to follow suit though. To me, since all look bad, and your cam is torn up, I think it was either worn out springs, oil that didn't have enough ZDDP in it, or valve lash was incorrect. Get Kim to check every.thing and tell you what is salvageable. Keep in mind, if it get too pricey. you have a good core to send to ERL for them to resleeve and give you a 427 or larger motor. They run $5800 now, so just keep it in mind.

Did the heads look ok? You've got some badass heads on top, so you'll make good power as long as the cam is a good size.

The carriage on the cam honestly pisses me off. Knowing the background of this car before you bought it and knowing how little you had even driven it, leads me to believe you didn't cause this failure at all. Whomever put together the top in is to blame here IMO.

Did the heads look ok? You've got some badass heads on top, so you'll make good power as long as the cam is a good size.

The carriage on the cam honestly pisses me off. Knowing the background of this car before you bought it and knowing how little you had even driven it, leads me to believe you didn't cause this failure at all. Whomever put together the top in is to blame here IMO.

#10

Glad you're getting it to Kim Barr. He'll lead you the right direction. Well, we obviously know the ticking sound you documented a while back was from a lifter. I don't think one lifter went and caused the other to follow suit though. To me, since all look bad, and your cam is torn up, I think it was either worn out springs, oil that didn't have enough ZDDP in it, or valve lash was incorrect. Get Kim to check every.thing and tell you what is salvageable. Keep in mind, if it get too pricey. you have a good core to send to ERL for them to resleeve and give you a 427 or larger motor. They run $5800 now, so just keep it in mind.

Did the heads look ok? You've got some badass heads on top, so you'll make good power as long as the cam is a good size.

The carriage on the cam honestly pisses me off. Knowing the background of this car before you bought it and knowing how little you had even driven it, leads me to believe you didn't cause this failure at all. Whomever put together the top in is to blame here IMO.

Did the heads look ok? You've got some badass heads on top, so you'll make good power as long as the cam is a good size.

The carriage on the cam honestly pisses me off. Knowing the background of this car before you bought it and knowing how little you had even driven it, leads me to believe you didn't cause this failure at all. Whomever put together the top in is to blame here IMO.

hopefully i can get some good news from kim barr. ive heard great things about him, and your build sold me haha.

heads looked good though. so hopefully it wont be a ridiculous amount.

Last edited by sick_tight; 03-26-2014 at 06:17 PM.

#11

looks like both of my cam failures from my z06, LS6 & LS2. The LS6 has springs and a LG g5somthing and a tune, the LS2 had TFS heads, Vindicator, YT rockers. LS6 was way worse cam failure, symptom was just a loss of oil PSI at idle, no "abnormal" ticking from a FAST/Long Tube car. The LS2 was randomly found when doing some routine maintance, something made me pull the valley plate for no reason and I saw the damage to the visable lifters.

Currently in a long spanned 402 build with the LS2, currently clocked in at about 2 years now lol. I have come to the conclusion that a combination of aggressive lobe cam, weakened valve springs (overly high seat pressure can have the same effect), high RPM's, and improper preload all added to my failure. I purchase the LS6 as modified, and I did the modification to the LS2, trusting a vendor's pushrod length. When I installed the LS2 into the z06 after the LS6 failure, I properly measured for the correct length pushrod for the near perfect preload, but the damages was already done. (LS2 build already had 10-15k on it when swapped)

Currently in a long spanned 402 build with the LS2, currently clocked in at about 2 years now lol. I have come to the conclusion that a combination of aggressive lobe cam, weakened valve springs (overly high seat pressure can have the same effect), high RPM's, and improper preload all added to my failure. I purchase the LS6 as modified, and I did the modification to the LS2, trusting a vendor's pushrod length. When I installed the LS2 into the z06 after the LS6 failure, I properly measured for the correct length pushrod for the near perfect preload, but the damages was already done. (LS2 build already had 10-15k on it when swapped)

#12

looks like both of my cam failures from my z06, LS6 & LS2. The LS6 has springs and a LG g5somthing and a tune, the LS2 had TFS heads, Vindicator, YT rockers. LS6 was way worse cam failure, symptom was just a loss of oil PSI at idle, no "abnormal" ticking from a FAST/Long Tube car. The LS2 was randomly found when doing some routine maintance, something made me pull the valley plate for no reason and I saw the damage to the visable lifters.

Currently in a long spanned 402 build with the LS2, currently clocked in at about 2 years now lol. I have come to the conclusion that a combination of aggressive lobe cam, weakened valve springs (overly high seat pressure can have the same effect), high RPM's, and improper preload all added to my failure. I purchase the LS6 as modified, and I did the modification to the LS2, trusting a vendor's pushrod length. When I installed the LS2 into the z06 after the LS6 failure, I properly measured for the correct length pushrod for the near perfect preload, but the damages was already done. (LS2 build already had 10-15k on it when swapped)

Currently in a long spanned 402 build with the LS2, currently clocked in at about 2 years now lol. I have come to the conclusion that a combination of aggressive lobe cam, weakened valve springs (overly high seat pressure can have the same effect), high RPM's, and improper preload all added to my failure. I purchase the LS6 as modified, and I did the modification to the LS2, trusting a vendor's pushrod length. When I installed the LS2 into the z06 after the LS6 failure, I properly measured for the correct length pushrod for the near perfect preload, but the damages was already done. (LS2 build already had 10-15k on it when swapped)

luck of the draw. how were your cylinder walls? similar to mine in the pictures? did your lifter fail and fall into the rotating assembly or was it compartmentalized to the top end needing to be gone through? I guess i should send my heads and bottom end to Kim and see what he says. in this case i think ill go with a professional opinion. i wonder how much it will cost kim to go through and tell me whats wrong. i just need to call already.

i just want to rip through some gears on the vette sometime this summer! hopefully i can!!

maybe i can get some where close to project YOLO, now that would be something! im going to also focus on gutting and lightening the vette as much as i can braille knockoff, no AC, ect and see how light i can get her.

#13

The cylinder walls on yours makes me think that there was too much thrust on the pistons allowing them to rock in the bore, causing the abnormal wear. EDIT- but now that I look closer I can see where it could possibly be from the lifter getting pinched between piston and crank, but I would have thought that the piston would break more than what it looks like.

On the LS6 all I did was pull the cam and drop the lifters out the bottom when I did the LS2 swap. So I never looked any farther than that.

On the LS2, when I found the wear on the journels I could see, I went ahead and pulled the heads in anticipation of just being a cam/lifter swap but turned for the worse after that. Each piston was touched by a valve so I pulled the block. Found that the front cam bearing had brass showing, and then found that a spec of something made it through the main bearings (not badly, but not good).

On the LS6 all I did was pull the cam and drop the lifters out the bottom when I did the LS2 swap. So I never looked any farther than that.

On the LS2, when I found the wear on the journels I could see, I went ahead and pulled the heads in anticipation of just being a cam/lifter swap but turned for the worse after that. Each piston was touched by a valve so I pulled the block. Found that the front cam bearing had brass showing, and then found that a spec of something made it through the main bearings (not badly, but not good).

#14

damn! yeah, i definitely run away when it comes to buying an already modified car but i saw the trickflo's and the fact that it had a forged stroker and i couldnt pass it up.

luck of the draw. how were your cylinder walls? similar to mine in the pictures? did your lifter fail and fall into the rotating assembly or was it compartmentalized to the top end needing to be gone through? I guess i should send my heads and bottom end to Kim and see what he says. in this case i think ill go with a professional opinion. i wonder how much it will cost kim to go through and tell me whats wrong. i just need to call already.

i just want to rip through some gears on the vette sometime this summer! hopefully i can!!

maybe i can get some where close to project YOLO, now that would be something! im going to also focus on gutting and lightening the vette as much as i can braille knockoff, no AC, ect and see how light i can get her.

luck of the draw. how were your cylinder walls? similar to mine in the pictures? did your lifter fail and fall into the rotating assembly or was it compartmentalized to the top end needing to be gone through? I guess i should send my heads and bottom end to Kim and see what he says. in this case i think ill go with a professional opinion. i wonder how much it will cost kim to go through and tell me whats wrong. i just need to call already.

i just want to rip through some gears on the vette sometime this summer! hopefully i can!!

maybe i can get some where close to project YOLO, now that would be something! im going to also focus on gutting and lightening the vette as much as i can braille knockoff, no AC, ect and see how light i can get her.

#15

My A/C never worked as it is, and even in my DD i hardly run it. im thinking its that issue you mentioned to me before. but im thinking about doing some minor gutting to it. definitely going to clean up the wiring harness and while its sitting apart cleaning the entire underside and parts. even once the motor is fixed i need to get the trans worked over and take it to TDP to get a stage 2 installed. hopefully it will fix my 2nd and 6th gear issues.

i do want some kirkeys in there, i HATE the stock Z seats as it is. this may take a bit of time to get ready, especially since its going to be done right.

i do want some kirkeys in there, i HATE the stock Z seats as it is. this may take a bit of time to get ready, especially since its going to be done right.