'99 WS6 LQ408 build. Update: 11.4 @ 125

#22

TECH Regular

iTrader: (3)

Join Date: Apr 2012

Location: michigan

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

I can't comment on the thread pitch but did it beat up the Rocker cup or push rod tips ?

The end of that rrocker looks beat up

I'd be checking for a bent pushrod or maybe look into replacing that rocker.

Maybe I missed it but what exactly happened?

The end of that rrocker looks beat up

I'd be checking for a bent pushrod or maybe look into replacing that rocker.

Maybe I missed it but what exactly happened?

#23

It did chip at the rocker itself but the cup is untouched. Also the pushrod is fine. What happened was I just installed a LNC-2000 and went to test it. The actual launch part worked then I went to try doing no lift shift from 1st to 2nd and 2nd to 3rd. It seemed liked it worked great but when I slowed down to cruising speed I noticed a vibration, used a little more gas and noticed slight power loss. Pulled the valve cover and found the rocker arm sitting on the edge of the valve retainer and pulled it right off

#25

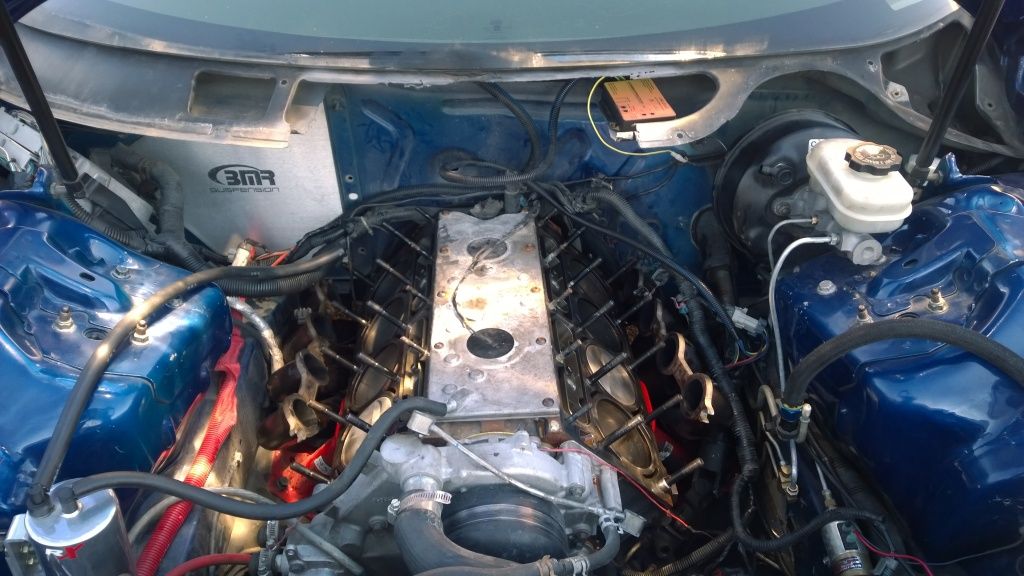

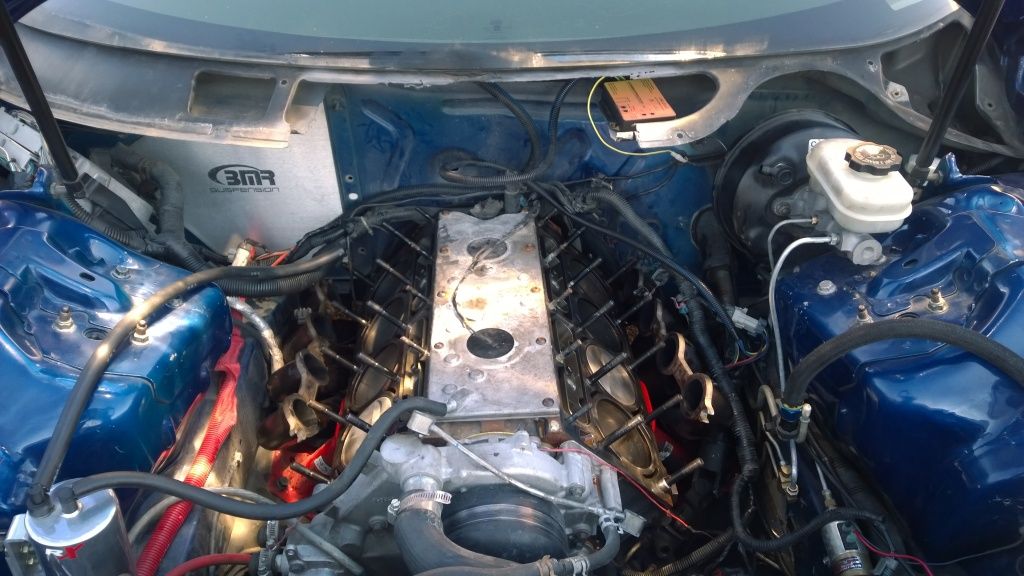

Update: Jan 4 2015. Just put the MWC K member in and now the engine sits lower. The throttle body sits dead level with the top of the hood. With probably 2 washers under all 6 K member bolts and only trimming the bottom layer of the hood you wont have to cut a hole through the hood. If you have a stock K member proceed reading.

This is the only pic I have on me. I can take more if you want just let me know. I know when I was researching it I couldnt find hardly any info I wanted so ask away, I think thats the point of build threads. But to answer some of the questions I had,

1. Its not that much cutting. Didnt have to touch the window. I cut the metal a few inches wider than you see in the plastic because it makes getting the heads in and out a lot easier without having to pull the engine or just any kind of work near the rear of the engine.

2. I have Speed Inc fuel rails that was designed for the FAST 90 and 92mm intakes and modified them to fit. One reason is because I didnt want to spend more money for the Edelbrock fuel rails. The other is because everyone was saying how the Edelbrock fuel rails use a ORB fittings, instead of AN fittings, and that those fittings arent as good as AN fittings for some reason. (I dont know why but I'm no engineer). They also say the orb fittings only screw on a couple of threads and that worries them. So I just cut some strips of aluminum, bolted them in place behind the fuel rails, then used a marker for where I needed to drill through the bottom of the fuel rail for bolts to fit through with lock nuts. If anyone is doing this be sure to not drill too high because you'll go through where the fuel runs. I've never had any problems and leaks modifying them this way.

3. Its possible to use a factory or aftermarket WS6 hood without the intake or throttle body sticking through. You will have to cut the support layer out from the center. (And while I was at it I also cut the rest of the support from the rear of the hood so air could flow through. Now it runs 15-20 degrees cooler as long as I'm moving. But this is not required). After you've cut the center of support out you'll have to turn the throttle body upside down, extend the wiring harness, and weld on a new throttle cable bracket on the right side of the intake. I was too lazy to do all this so I made a clean cut hole for the TB.

4. Many people dont know it, but they dont only make a LS1/LS6 or L92/LS3 Pro Flo XT. There is also a LS2 intake. The differences between it and the LS1/6 intake is the LS2 version uses a round LS2 seal for the TB gasket, has 4 bolt holes that will fit pretty much any aftermarket 4 bolt TB or LS2 TB, and the neck is angled more downwards which will make it easier to connect to the lids on F bodies. The LS1/6 version is a 3 bolt that uses the LS1 paper gasket, requires an adaptor if you want to use an aftermarket 4 bolt TB, and the neck is almost straight so you'll have to be more creative to connect it to a lid.

Sorry for the long post, just want to help anyone that had the same questions I did.

The air filter on the throttle body is temporary. After I wrap up a few things I'm going to make an aluminum box sort of like an SLP lid except the air filter will be sitting straight up instead of flat. That way instead of only a 2" by 10" opening (however big it is) it will be the whole size of the air filter, then it will have 4" aluminum pipe running to the 90mm TB

You can see here where the intake barely touching with the hood completely closed. If you have solid motor mounts like I do you could flip the throttle body around and not have to cut a hole through the hood. If it barely touching bothers you or you have poly motor mounts you could always shim the K member down slightly

If you are lazy like me and take the easy way out this is what it looks like if you cut a hole for the TB

This is the only pic I have on me. I can take more if you want just let me know. I know when I was researching it I couldnt find hardly any info I wanted so ask away, I think thats the point of build threads. But to answer some of the questions I had,

1. Its not that much cutting. Didnt have to touch the window. I cut the metal a few inches wider than you see in the plastic because it makes getting the heads in and out a lot easier without having to pull the engine or just any kind of work near the rear of the engine.

2. I have Speed Inc fuel rails that was designed for the FAST 90 and 92mm intakes and modified them to fit. One reason is because I didnt want to spend more money for the Edelbrock fuel rails. The other is because everyone was saying how the Edelbrock fuel rails use a ORB fittings, instead of AN fittings, and that those fittings arent as good as AN fittings for some reason. (I dont know why but I'm no engineer). They also say the orb fittings only screw on a couple of threads and that worries them. So I just cut some strips of aluminum, bolted them in place behind the fuel rails, then used a marker for where I needed to drill through the bottom of the fuel rail for bolts to fit through with lock nuts. If anyone is doing this be sure to not drill too high because you'll go through where the fuel runs. I've never had any problems and leaks modifying them this way.

3. Its possible to use a factory or aftermarket WS6 hood without the intake or throttle body sticking through. You will have to cut the support layer out from the center. (And while I was at it I also cut the rest of the support from the rear of the hood so air could flow through. Now it runs 15-20 degrees cooler as long as I'm moving. But this is not required). After you've cut the center of support out you'll have to turn the throttle body upside down, extend the wiring harness, and weld on a new throttle cable bracket on the right side of the intake. I was too lazy to do all this so I made a clean cut hole for the TB.

4. Many people dont know it, but they dont only make a LS1/LS6 or L92/LS3 Pro Flo XT. There is also a LS2 intake. The differences between it and the LS1/6 intake is the LS2 version uses a round LS2 seal for the TB gasket, has 4 bolt holes that will fit pretty much any aftermarket 4 bolt TB or LS2 TB, and the neck is angled more downwards which will make it easier to connect to the lids on F bodies. The LS1/6 version is a 3 bolt that uses the LS1 paper gasket, requires an adaptor if you want to use an aftermarket 4 bolt TB, and the neck is almost straight so you'll have to be more creative to connect it to a lid.

Sorry for the long post, just want to help anyone that had the same questions I did.

The air filter on the throttle body is temporary. After I wrap up a few things I'm going to make an aluminum box sort of like an SLP lid except the air filter will be sitting straight up instead of flat. That way instead of only a 2" by 10" opening (however big it is) it will be the whole size of the air filter, then it will have 4" aluminum pipe running to the 90mm TB

You can see here where the intake barely touching with the hood completely closed. If you have solid motor mounts like I do you could flip the throttle body around and not have to cut a hole through the hood. If it barely touching bothers you or you have poly motor mounts you could always shim the K member down slightly

If you are lazy like me and take the easy way out this is what it looks like if you cut a hole for the TB

Last edited by Jc803; 01-04-2015 at 07:25 PM.

#27

I'd love to have real slicks but the welds are my only set of wheels since I only drive the car once a week or two. And one of the next things I want to do is shorten the axles since I just finished the mini tubs. But I dont want to buy a set a rear wheels just to run bias plys 4 times a year just to buy two more sets of wheels after axles are shortened. So I just run DRs for best of both worlds for now.

But long story short I do completely agree, bias plys are bad *** for a stick

But long story short I do completely agree, bias plys are bad *** for a stick

#28

TECH Fanatic

iTrader: (42)

I saw that there were 2 different manifolds Edelbrock 7139 and 7140. I didnt know the 7140 angled down. Sounds like that would be a better bet for clearance and a better TB option sine there is only a $10 difference. I dont mind cutting the hood support at all since I plan on getting a WS6 style cowl hood. I was just unsure how much of the windshield cowl had to be cut.

As far as the fuel rails go. Edelbrock 3629 is only $125 shipped. Is there that big of a difference in the fittings? What did you do for lines?

Also, what are you running for a throttle body?

I appreciate the detailed response man

As far as the fuel rails go. Edelbrock 3629 is only $125 shipped. Is there that big of a difference in the fittings? What did you do for lines?

Also, what are you running for a throttle body?

I appreciate the detailed response man

#29

11 Second Club

iTrader: (9)

Join Date: Jan 2004

Location: Sioux Center, Iowa

Posts: 538

Likes: 0

Received 0 Likes

on

0 Posts

I run 28x12.5x15 ET Streets full time, only last about 2 years of street/strip driving mixed and rain is out of the question but being i sold all street only nittos im only buying one set of rear tires

#31

@Spectre86. The 7140 is the one you want for sure. Even if places are charging $10 more, if you get the 7139 and plan to use a any 4 bolt aftermarket or LS2 throttle body you'll have to buy the adapter which I'm sure is more than $10. Also like I said the 7140 uses the LS2 TB seal which is reusable and way better than the LS1 paper gasket used on the 7139.

If you look at the pic that 93camaro put up you can see exactly how much of the hood support is required to be cut. You dont have to cut as much as I did, I just wanted to cut the rear of the hood for more air flow to help cooling.

As far as fuel rails, I dont want to be the guy that says one type of rail and fittings is better than the other because I haven't compared the two for myself, so reading online is all I have. If you ask me I'd say there is no difference, I saw guys making over 1,000 hp with the Edelbrock rails.

But if you do want rails with AN fittings and the fuel line to go from the rail to the factory hard line like I do, then I got everything from Speed Inc

http://www.speedinc.com/shop-by-vehi...rail-sets.html

That link has the fuel rails, and if you go to the drop down box you can choose to add fuel line and fittings to connect the rails to factory hard lines for an extra $100. Total comes out to be $229.98

The next picture is what the rails, fittings, and fuel line going to factory hard line looks like. Everything just screws together. The picture after that is where I cut the cowl. I cut it wide and stopped right above the coils. You dont have to cut that wide, but it does make getting the intake in and out easier and also I have my LNC-2000 mounted in the cowl now.

If you look at the pic that 93camaro put up you can see exactly how much of the hood support is required to be cut. You dont have to cut as much as I did, I just wanted to cut the rear of the hood for more air flow to help cooling.

As far as fuel rails, I dont want to be the guy that says one type of rail and fittings is better than the other because I haven't compared the two for myself, so reading online is all I have. If you ask me I'd say there is no difference, I saw guys making over 1,000 hp with the Edelbrock rails.

But if you do want rails with AN fittings and the fuel line to go from the rail to the factory hard line like I do, then I got everything from Speed Inc

http://www.speedinc.com/shop-by-vehi...rail-sets.html

That link has the fuel rails, and if you go to the drop down box you can choose to add fuel line and fittings to connect the rails to factory hard lines for an extra $100. Total comes out to be $229.98

The next picture is what the rails, fittings, and fuel line going to factory hard line looks like. Everything just screws together. The picture after that is where I cut the cowl. I cut it wide and stopped right above the coils. You dont have to cut that wide, but it does make getting the intake in and out easier and also I have my LNC-2000 mounted in the cowl now.

#32

Well guys its game over for me, that is unless anyone else has an idea. I bought a timesert kit along with some longer inserts than what comes with the kit. It installed great in no time but I made the angle slightly off and now the rocker arm wont go on because its hitting the top of the head where the valve cover gasket goes.

Does anyone know how much it would cost to have the hole welded and retapped? Or how much could I get for selling the heads?

Sorry for the short lived thread again. I'll leave it up, but its probably going to be a very long time before I do anything else. I'm getting out the army next year so I'm putting all my money towards paying off credit cards and loans. But it will be back on the road one day better than ever

Does anyone know how much it would cost to have the hole welded and retapped? Or how much could I get for selling the heads?

Sorry for the short lived thread again. I'll leave it up, but its probably going to be a very long time before I do anything else. I'm getting out the army next year so I'm putting all my money towards paying off credit cards and loans. But it will be back on the road one day better than ever

#34

Oh trust me I'd love to. Tinkering on this thing is my one and only hobby. I just like having the safety of money in the bank especially when I'm about to get out the army and have to find a new job, plus my wife is a full time college student with no job, plus its going to cost thousands for the move from here in Texas to wherever we decide to go (I'm leaning towards South Carolina since thats where I used to live).

But I havent given up. I'm going to call around and get some prices on how much it would cost to weld the bolt hole and re tap it. But if it does cost a ridiculous amount of money then I'd rather get some ported LQ4 heads and go right into the turbo build. Only reason I havent boosted the car yet is because my personal goal was to run 10s all motor on 91 oct and T56 here in El Paso where the altitude is stupid high. Anywhere else in the country I would be in 10s already.

But we'll see. Taking it one step at a time and playing it safe

But I havent given up. I'm going to call around and get some prices on how much it would cost to weld the bolt hole and re tap it. But if it does cost a ridiculous amount of money then I'd rather get some ported LQ4 heads and go right into the turbo build. Only reason I havent boosted the car yet is because my personal goal was to run 10s all motor on 91 oct and T56 here in El Paso where the altitude is stupid high. Anywhere else in the country I would be in 10s already.

But we'll see. Taking it one step at a time and playing it safe

#36

TECH Senior Member

iTrader: (28)

you will get that head fixed, find a good race engine shop will do it easy. you need them to put the hole back in the right place, looks like the cert is higher up, not just square off the pad. thouse afr heads are nice over any used truck junkas you know.

if your looking for ideas on the lip, I used the stock filter with a nice bellow in a taller lid i made. over a cone filter inside like you said you were thinking about, but that might be better, sure you can get more filter but not sure how close it will be to the inside walls

if your looking for ideas on the lip, I used the stock filter with a nice bellow in a taller lid i made. over a cone filter inside like you said you were thinking about, but that might be better, sure you can get more filter but not sure how close it will be to the inside walls

#38

Heres an update. I couldnt get around to doing anything because my mother in law passed away and I spent a week in South Carolina for that. Then I spent another week playing Army in middle of the horrible desert of El Paso, and going back for another week Monday.

But I did get a chance today to pull the heads. Bought a $15 valve spring compressor from Oreilly but the junk doesnt work just as I expected. I have a nice head on motor valve spring compressor but I obviously cant use it in my situation.

Also (the BIG yay) I finally got my spindles back from Midwest Chassis and they were right this time. So now I can finally put on all of the suspension that I paid $4k for back in July.... Well, not quite yet. I have to get the car running first because I pulled the heads and everything in my apartment parking lot, which is also on a hill. Not the best place to change the whole front end. But glad I have all of the suspension now.

And P.S. I've heard a lot of local guys and guys online saying you cant pull heads with ARP head studs because there isnt enough room. Not true. I had more than enough room as you can see from the pic. Maybe the HVAC box gets in the way, thats the only thing I can think of. But other than that theres nothing to get in the way

But I did get a chance today to pull the heads. Bought a $15 valve spring compressor from Oreilly but the junk doesnt work just as I expected. I have a nice head on motor valve spring compressor but I obviously cant use it in my situation.

Also (the BIG yay) I finally got my spindles back from Midwest Chassis and they were right this time. So now I can finally put on all of the suspension that I paid $4k for back in July.... Well, not quite yet. I have to get the car running first because I pulled the heads and everything in my apartment parking lot, which is also on a hill. Not the best place to change the whole front end. But glad I have all of the suspension now.

And P.S. I've heard a lot of local guys and guys online saying you cant pull heads with ARP head studs because there isnt enough room. Not true. I had more than enough room as you can see from the pic. Maybe the HVAC box gets in the way, thats the only thing I can think of. But other than that theres nothing to get in the way

Last edited by Jc803; 10-26-2014 at 01:24 AM.

#39

Staging Lane

iTrader: (7)

Join Date: Jul 2011

Location: Plano, Tx

Posts: 77

Likes: 0

Received 0 Likes

on

0 Posts

Amazing build bro. Sorry about your misfortunes. Im curious to what your turbo setup will be. I'm actually deployed right now and trying to plan out my lq4 turbo build. Do you think you will be keeping the Pro Flow? Also I hope all goes well when you get out. I know that it can be a very rough transition, but we've made it this far. We can handle anything. Any info would be greatly appreciated.

#40

Thats pretty funny, I was planning my turbo build while I was in Afghanistan Dec 2012-Aug2013. Had a 96 Z28 then and the plan was to swap in a LQ4 and boost it, but I ended up buying my WS6 instead and seeing what it could do on motor.

But anyways, the plan was a LQ4 with a t4 BW s480. Even bought a Huron Speed t4 kit. But then I went 408ci so now the plan is a t6 BW s480 with the race cover, ball bearings, and all the bells and whistles to keep back pressure down. I kept the cold side of the Huron kit but sold the t4 hot side. I'm just going to buy their turbo manifolds and fabricate a t6 hotside myself. My current compression ratio is 11:1 so I'll swap the pistons out to drop it to 9:1 if possible. For fuel I'm planning to use Aeromotive for everything except the fuel pump since everyone says the A1000 overheats. So I guess I'll go with the Magnafuel MP-4302. I hate the purple theme of magnafuel but at least no one will see the pump. I will also get a metal '98 or LT1 fuel tank and weld in a sump with -08AN feed to pump, then to a Y block with -06 AN from block to rails, then a -06AN return line. Not sure on fuel injectors yet. I want to buy everything else and have the estimated power level set in stone before I buy those.

I will definitely be keeping the Pro Flo XT. I actually bought it just for the turbo build and went ahead and put it on just to see if the NA power would be any better over the FAST 90 intake I had on it. Turn out I lost .2 tenths in the 1/4 NA but thats fine. But I honestly think it would be better than the FAST if the cam was matched up to it because it keeps pulling until the cam falls off. But anyways, for boost I hear its great, flows great, looks great, and you dont have to worry about it breaking like a plastic FAST or LS6 intake. Plus I'm about to buy one of those Kurt Urban vapor vent set ups and it will tuck away nicely underneath the manifold.

Thanks for everything and good luck out there and stay safe

But anyways, the plan was a LQ4 with a t4 BW s480. Even bought a Huron Speed t4 kit. But then I went 408ci so now the plan is a t6 BW s480 with the race cover, ball bearings, and all the bells and whistles to keep back pressure down. I kept the cold side of the Huron kit but sold the t4 hot side. I'm just going to buy their turbo manifolds and fabricate a t6 hotside myself. My current compression ratio is 11:1 so I'll swap the pistons out to drop it to 9:1 if possible. For fuel I'm planning to use Aeromotive for everything except the fuel pump since everyone says the A1000 overheats. So I guess I'll go with the Magnafuel MP-4302. I hate the purple theme of magnafuel but at least no one will see the pump. I will also get a metal '98 or LT1 fuel tank and weld in a sump with -08AN feed to pump, then to a Y block with -06 AN from block to rails, then a -06AN return line. Not sure on fuel injectors yet. I want to buy everything else and have the estimated power level set in stone before I buy those.

I will definitely be keeping the Pro Flo XT. I actually bought it just for the turbo build and went ahead and put it on just to see if the NA power would be any better over the FAST 90 intake I had on it. Turn out I lost .2 tenths in the 1/4 NA but thats fine. But I honestly think it would be better than the FAST if the cam was matched up to it because it keeps pulling until the cam falls off. But anyways, for boost I hear its great, flows great, looks great, and you dont have to worry about it breaking like a plastic FAST or LS6 intake. Plus I'm about to buy one of those Kurt Urban vapor vent set ups and it will tuck away nicely underneath the manifold.

Thanks for everything and good luck out there and stay safe

Last edited by Jc803; 10-26-2014 at 08:18 PM.