'99 WS6 LQ408 build. Update: 11.4 @ 125

#81

Launching!

iTrader: (1)

Join Date: Aug 2009

Location: Louisiana

Posts: 298

Likes: 0

Received 0 Likes

on

0 Posts

Be lucky you have the time to work on your car. Unfortunately my work and school schedule don't allow me to.Lucky i have a few days off between turnarounds and pulled my transmission out to get rebuilt.It will be a few months before i am able to get it back in.

I did enjoy reading your build thread.

I did enjoy reading your build thread.

#82

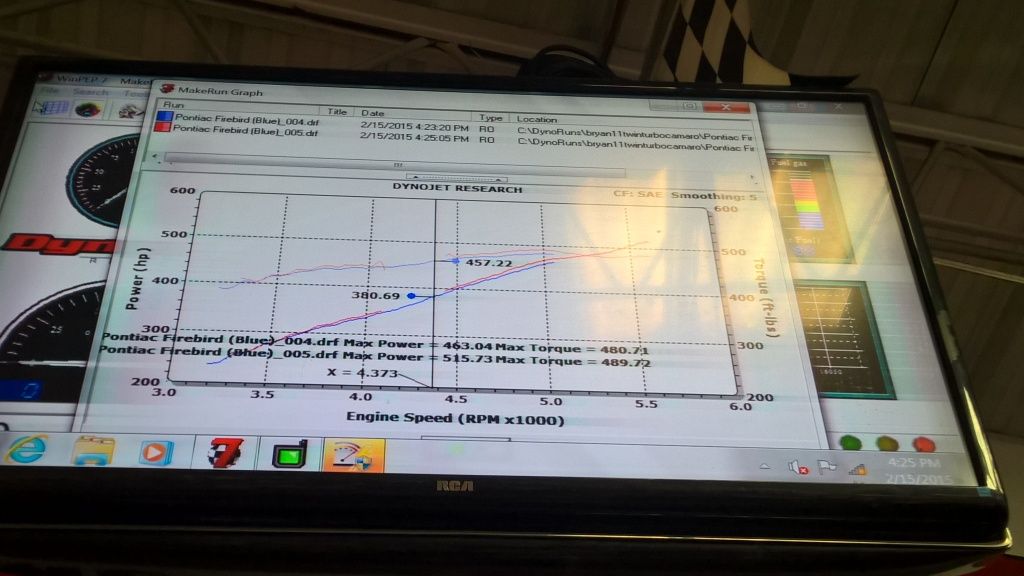

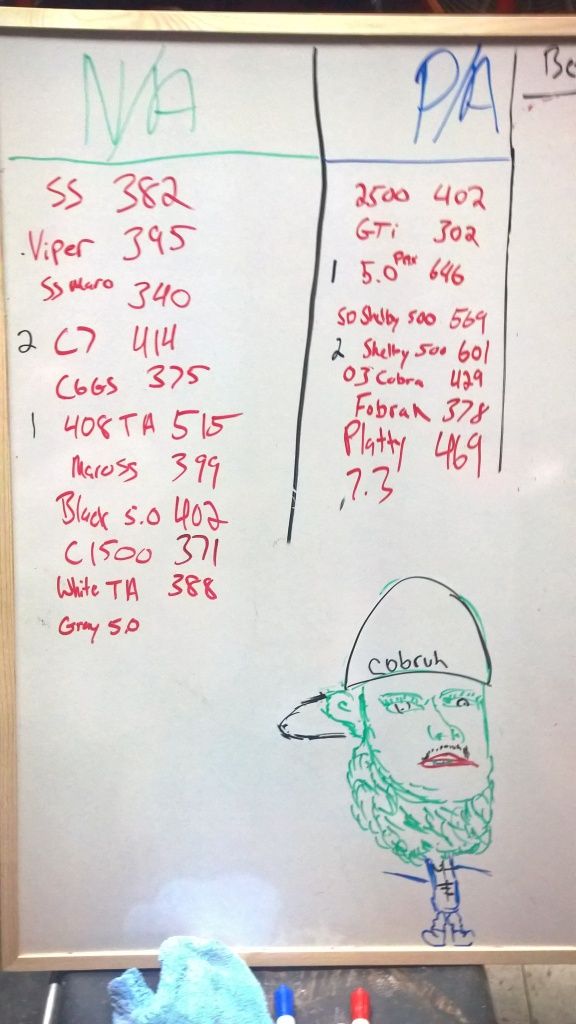

Finally some action. I won the dyno competition today out of 11 cars in the NA class. Not saying much though because 90% were stock or close to it. But I did beat 5 of the 8 cars in the power adder class. Pretty neat seeing a c7, couple gt500s, chevy ss, and a 2000 viper all dyno though.

So anyways I made 515hp and 490tq. As you can see from the chart below the HP just keep going up until the guy let off the first time. The second time I told him to bounce it off the rev limiter and the hp just kept going. I didnt have my hp tuners on me to move the rev limiter higher so we didnt find what peak hp was. My guess is because of the Edelbrock Pro Flo intake. Too bad because it looks like I could have got a lot more than 515hp

Also the air fuel ratio was very rich at 11.7:1. You can see the unburt fuel in the video. I think between getting the A/F ratios a lot leaner and spinning it a little higher I could get a good amount more out of it

If anyone is interested I'll try to remember who was who and what was done to the car

2014 Chevy SS, auto, catback, intake, tune - 382

2000 Viper, manual, bone stock and 20k miles - 395

2013 Camaro SS, auto, catback, intake, tune - 340

2015 C7 Vette, auto, bone stock - 414

???? C6 Vette GS, auto, catback - 375

2012 Camaro SS, auto, ???? - 399

2013 Mustang GT, ????, catback, intake - 402

2005? Chevy 1500, auto, LS1 swap, cam, intake, exhaust, tune - 371

2000 Firebird, T-56, cam only (from what he says), SLP lid, catback, cut out, 188k miles - 388

????(new) Volkswagen GTI, manual, stage 1 (whatever that means) - 302

2014 Mustang GT, manual, internal work, procharged - 646

2014 GT500, manual, ???? - 569

2012 GT500, manual, 2014 blower swap, bolt ons - 601

2003 Cobra, manual, blower swap, bolt ons, - 429

2000 Mustang GT 2V, manual, procharged, stock internals, bolt ons - 378

Stay tuned. Shooting for 10.9 Feb 27th at Stick Wars. Hopefully I get it so I can stop this NA stuff and get the boost build going

Last edited by Jc803; 02-16-2015 at 03:45 PM.

#83

I really really hate you guys. Remember when I posted the pic of my wife drying my car? And then immediately after I ripped a rocker arm bolt right out the head? Well I adjusted the suspension today and was making some test passes on the road I live off of to get it in top shape for Stick Wars in two weeks. On the way my wife said, "Hey since the car is washed lets take a couple pictures" and I say "sure, great idea, those should hold over those ******** on LS1tech". (jk, didnt really say that).

But once again immediately after, as in 2 minutes later, I'm ripping through gears and now something is seriously wrong. And I dont mean its the sound of valve springs breaking again, or the rocker arm ripping out the head. I mean something is crunching in this thing. Like bad. Like I dont even want to pull the head off because I'm fearing what I will see. So after I noticed I turned the engine off and pulled into a fire station and got it towed 2 streets over to my apartment.

Damage is to be determined. But here are the couple pics I got. Also after the pictures is the professional video made of the dyno day if anyone is interested

But once again immediately after, as in 2 minutes later, I'm ripping through gears and now something is seriously wrong. And I dont mean its the sound of valve springs breaking again, or the rocker arm ripping out the head. I mean something is crunching in this thing. Like bad. Like I dont even want to pull the head off because I'm fearing what I will see. So after I noticed I turned the engine off and pulled into a fire station and got it towed 2 streets over to my apartment.

Damage is to be determined. But here are the couple pics I got. Also after the pictures is the professional video made of the dyno day if anyone is interested

#84

Found the problem already and what do you know. Ripped another rocker arm bolt out the head. Except this time it wasnt the #6 intake valve, it was the #6 exhaust valve. But the #6 intake valve thread is the one I had repaired and although the threads didnt get messed up the bolt was loose. I'm not sure what is causing this. My only guess is that when they repaired it I noticed that after I screwed the bolt in by hand it was still a little loose and I could wiggle it left and right up and down.

So this time I'm going to pull the head off and try to put in a time sert again since it seemed really strong and the bolt was tight. Put one on both bolt holes. Also this time I want to find a way to drill at the perfect angle so I dont have to spend another $200 to ship the head and $100 to have it repaired.

Any ideas on how to drill straight down? My only idea is to find a long cylinder with a hole in it the exact size of the drill bit and hold it down over the hole sitting flush with the head.

So this time I'm going to pull the head off and try to put in a time sert again since it seemed really strong and the bolt was tight. Put one on both bolt holes. Also this time I want to find a way to drill at the perfect angle so I dont have to spend another $200 to ship the head and $100 to have it repaired.

Any ideas on how to drill straight down? My only idea is to find a long cylinder with a hole in it the exact size of the drill bit and hold it down over the hole sitting flush with the head.

#85

TECH Fanatic

iTrader: (18)

I did a Helicoil repair on my Land Rover's cylinder head which is just a mini-SBC. All I did was made sure I was really comfortable (I was laying across the engine because it's 4.5 inches taller than stock) and just did it by hand spinning the bit as slow as I could go without it not cutting and galling up. I used a bolt with a piece of string tired to it judge the angle and just held the drill real still and the insert when in without a hitch and the original bolt torqued to spec like nothing was wrong. Don't know if that helps any.

#86

Any tips for ideas help. Thanks. The first time I tried I did it with the head on the car and drilled the angle slightly off and that was a $300 mistake. This time I'm going to pull the head off even though its a huge pain in the butt and takes 20 times longer. But if I do get it right then it will be well worth it

#89

TECH Regular

iTrader: (3)

Join Date: Apr 2012

Location: michigan

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

Your saying after it was repaired you could wiggle the rocker arm stud with your bare hand after it was ran in, Are you torquing the rocker stud to spec , like 45 ft lbs ? Just want to clarify your torquing those studs down.

Have you ever put some black sharpie on the valve stem tip and and rolled the motor over to see your witness marks for pr length. It's not the best way to check it but can give you a pretty good idea of where your at

It's odd you keep ripping rocker studs out of the heads, almost as if there not getting torqued.

Oh ya and sexy pics of the gf, I mean car

Have you ever put some black sharpie on the valve stem tip and and rolled the motor over to see your witness marks for pr length. It's not the best way to check it but can give you a pretty good idea of where your at

It's odd you keep ripping rocker studs out of the heads, almost as if there not getting torqued.

Oh ya and sexy pics of the gf, I mean car

#90

@Blown 06, I'm glad because my first thought was that I'm not sending it to Golen again and was hoping you could still help. Golen did a great job with the weld, the perfect angle, and machining it back flat again. It just seems that the tap they used is the right thread, its just slightly larger in diameter than the bolts.

I'm going to try the timesert again first though. Except this time I'm going to take the time to take the head off before drilling. Last time with the head on the cowl got in the way of the drill and I think thats what threw the alignment off. I figure its worth a try, if I get it wrong again then it makes no difference.

@My6speedZ, yes, texas is a great state for racing which leads to many great machine shops. But I live in El Paso. Literally as far west of Texas as you can go. Mexico and new Mexico both are only a couple miles from me. El Paso is a dirty, barren desert with nothing to do, no tourist attractions, no reason to ever come here, nothing. Even the DA for racing is probably as bad as it can get. Everyone here is Mexican. Probably 40% of them are illegal. They all speak Spanish. And if you ever come across a white, black, or asian person you already know they are military or family of a military member. You might as well consider El Paso = Juarez, Mexico. Long story short, the machine shops are horrible and I dont trust a single one. They do junk work and way over charge. Thats why I do 100% of the work on my car except for the paint job and bottom end, both of which were done in Tampa, FL.

@BigSmokey10, I torqued them down to 22 ftlbs which I believe is correct. 45 ftlbs would probably pull the aluminum threads out. And no to be more clear, once I torque it down it stays and doesnt move at all. I meant when I screw the bolt in halfway I can wiggle it a little. It seems to work though because it didnt get pulled out this time.

Yea I checked pushrod length with the adjustable checker tool that Comp makes. Great investment. I also did the marker trick to be sure. The third thing I did was swap the pushrods, rocker arms, mounts, and bolts from the #6 and #8 cylinders. That way I knew if it happened again, depending on which bolt from which cylinder gets pulled out, that would narrow down if it was the rocker arms/push rods, or something with that cylinder. So now that it happened on the same cylinder that tells me its not the rocker arms or push rods.

Yea I double and triple check the torques. I torque them one at a time going in firing order as I turn the crank by hand a 1/4 turn at a time. I even made a notch on my timing cover the last time I pulled the heads to know exactly where TDC is. When they're all done I recheck them all the same way.

I'm going to try the timesert again first though. Except this time I'm going to take the time to take the head off before drilling. Last time with the head on the cowl got in the way of the drill and I think thats what threw the alignment off. I figure its worth a try, if I get it wrong again then it makes no difference.

@My6speedZ, yes, texas is a great state for racing which leads to many great machine shops. But I live in El Paso. Literally as far west of Texas as you can go. Mexico and new Mexico both are only a couple miles from me. El Paso is a dirty, barren desert with nothing to do, no tourist attractions, no reason to ever come here, nothing. Even the DA for racing is probably as bad as it can get. Everyone here is Mexican. Probably 40% of them are illegal. They all speak Spanish. And if you ever come across a white, black, or asian person you already know they are military or family of a military member. You might as well consider El Paso = Juarez, Mexico. Long story short, the machine shops are horrible and I dont trust a single one. They do junk work and way over charge. Thats why I do 100% of the work on my car except for the paint job and bottom end, both of which were done in Tampa, FL.

@BigSmokey10, I torqued them down to 22 ftlbs which I believe is correct. 45 ftlbs would probably pull the aluminum threads out. And no to be more clear, once I torque it down it stays and doesnt move at all. I meant when I screw the bolt in halfway I can wiggle it a little. It seems to work though because it didnt get pulled out this time.

Yea I checked pushrod length with the adjustable checker tool that Comp makes. Great investment. I also did the marker trick to be sure. The third thing I did was swap the pushrods, rocker arms, mounts, and bolts from the #6 and #8 cylinders. That way I knew if it happened again, depending on which bolt from which cylinder gets pulled out, that would narrow down if it was the rocker arms/push rods, or something with that cylinder. So now that it happened on the same cylinder that tells me its not the rocker arms or push rods.

Yea I double and triple check the torques. I torque them one at a time going in firing order as I turn the crank by hand a 1/4 turn at a time. I even made a notch on my timing cover the last time I pulled the heads to know exactly where TDC is. When they're all done I recheck them all the same way.

#91

TECH Fanatic

iTrader: (18)

Wow, i hate that for you man. Never knew west Texas was that bad. I spent a couple months in Amarillo and a few days in Lubbock and Dallas respectively. Didn't seem to bad around those parts.

If you set the rocker with to much lifter pre-load after it pumps up you could be adding extra stress causing the failure, just a thought. I know you checked the height, but how did you measure the preload?

If you set the rocker with to much lifter pre-load after it pumps up you could be adding extra stress causing the failure, just a thought. I know you checked the height, but how did you measure the preload?

Last edited by My6speedZ; 02-19-2015 at 12:06 AM.

#93

Here's a question while I'm waiting on parts. I've had quite a few local guys say that I should brace the radiator support because I cut it and now the chassis will twist more.

What do you guys think. My opinion is cutting the radiator support shouldn't change anything because there's a k member on both sides of frame, lower radiator support, bumper support connected to both sides of frame, trans cross member, sub frame connectors, and a fire wall.

So I just don't see how cutting a thin radiator support would change anything.

What do you guys think. My opinion is cutting the radiator support shouldn't change anything because there's a k member on both sides of frame, lower radiator support, bumper support connected to both sides of frame, trans cross member, sub frame connectors, and a fire wall.

So I just don't see how cutting a thin radiator support would change anything.

#94

TECH Fanatic

iTrader: (18)

Here's a question while I'm waiting on parts. I've had quite a few local guys say that I should brace the radiator support because I cut it and now the chassis will twist more.

What do you guys think. My opinion is cutting the radiator support shouldn't change anything because there's a k member on both sides of frame, lower radiator support, bumper support connected to both sides of frame, trans cross member, sub frame connectors, and a fire wall.

So I just don't see how cutting a thin radiator support would change anything.

What do you guys think. My opinion is cutting the radiator support shouldn't change anything because there's a k member on both sides of frame, lower radiator support, bumper support connected to both sides of frame, trans cross member, sub frame connectors, and a fire wall.

So I just don't see how cutting a thin radiator support would change anything.

If you w wanted to clean things up. You could do a nice piece of metal in this shape:

with two L-brackets reaching back to the radiator. Paint it body color and it will clear your new intake, tie the sides together, and support the radiator. Round bar would look nice.

#95

That's actually the same shape I had in mind, but I also agree with you that the radiator support doesn't change a thing.

Plus like I said before that's just a rough cut. I'm going to cut it further down and make some end caps to weld on when I put in a griffin radiator then just make some brackets to hold it in like the guy did on "project tin can"

Plus like I said before that's just a rough cut. I'm going to cut it further down and make some end caps to weld on when I put in a griffin radiator then just make some brackets to hold it in like the guy did on "project tin can"

Last edited by Jc803; 10-12-2015 at 02:44 AM.

#97

Yea its got to be something else because like I said I switched the rocker arms, bolts, and push rods in both intake and exhaust from #6 and #8 cylinders and the problem happened again on #6, just the exhaust side instead of the intake side this time. I'm going to replace the lifters this time and have a look around at everything else. But besides the lifters I don't really see anything else that it could be. My only theory is maybe when the heads were made there might just be a weak spot or something up with the aluminum around the #6 pedestal area.

#100

I can't remember if the top of my head what the lifter pre load is but I remember it checked out fine.

The heads were new years ago. It's been a while though because I'm pretty sure they don't make 225 heads anymore.

If everything checks out Ok then I'm beginning to think there's just a soft spot in that area of the heads so I'm just not going to spin it too high anymore because both times it's happened I was spinning the hell out of it. That's why I have the rev limiter set a little lower than most guys and why I didn't spin it that high on the dyno

The heads were new years ago. It's been a while though because I'm pretty sure they don't make 225 heads anymore.

If everything checks out Ok then I'm beginning to think there's just a soft spot in that area of the heads so I'm just not going to spin it too high anymore because both times it's happened I was spinning the hell out of it. That's why I have the rev limiter set a little lower than most guys and why I didn't spin it that high on the dyno