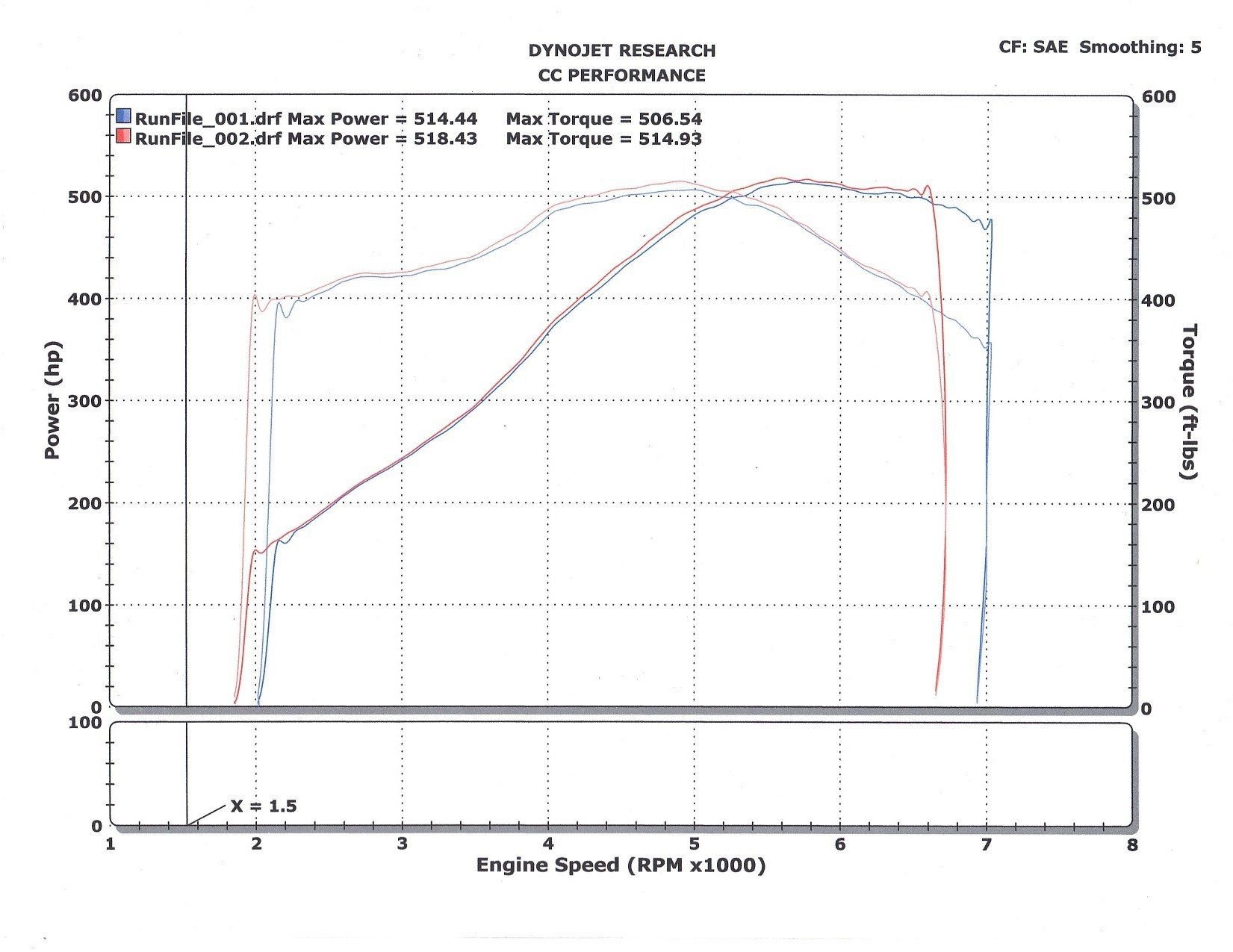

this car still just doesnt wanna make great numbers

#21

Thread Starter

Joined: Mar 2011

Posts: 3,690

Likes: 162

From: Wilmington, DE

heads are 69.5 c.c I think, pushrods were 8 inch length. used the rockers to get proper preload. he said the crower instructions said as long as u weren't x amount from this way and x amount of turns from the other way and that little tool they give u sits flat ur good.

compression check yielded 195 to 200 on all 8 which is slightly better than expected.

if preload was off by enough to drop 35 or more horse wouldn't the motor be telling us something?

compression check yielded 195 to 200 on all 8 which is slightly better than expected.

if preload was off by enough to drop 35 or more horse wouldn't the motor be telling us something?

#22

Thread Starter

Joined: Mar 2011

Posts: 3,690

Likes: 162

From: Wilmington, DE

the break in to the best of my knowledge was hot enough to get coolant through it and check leaks. don t know of he carried rpm there. then it sat. a week later strapped on dyno to get beat on. lots of little mini pulls since we were struggling with the afr which turned out to be injector issues.

he is 100 percent not thinking it's bottom end related. he knows the short block guy for a long time, used him a lot, and never once had an issue.....at least that's what I was told

one thing tho, due to pushrod holes not being big enough, after first dyno attempt so like 12 to 15 mini pulls, both heads came off to clearance the holes. new gaskets were used, heads were not machined

he is 100 percent not thinking it's bottom end related. he knows the short block guy for a long time, used him a lot, and never once had an issue.....at least that's what I was told

one thing tho, due to pushrod holes not being big enough, after first dyno attempt so like 12 to 15 mini pulls, both heads came off to clearance the holes. new gaskets were used, heads were not machined

#23

Doesn't look the the valvetrain is unstable. I was curious if the pushrods were too short and the valves weren't opening the whole way since compression was good they're not too long. You said you had an AFR issue until the injector swap. What's the afr and timing?

#25

Assuming the before was on the same Dyno and they didn't change the Dyno configuration id want to know:

SAE graph since you posted a STD graph. If conditions were miserable your SAE correction may get you to where you think you should be

Fuel pressure during a pull

Injector duty cycle during the pull

Lifter preload

A dyno pull without the Y pipe, i.e. open headers

Confirmation if they physically removed the MAF because if they did then they had to do a speed density tune.

Confirmation that 97kPa is normal for your DA/area

SAE graph since you posted a STD graph. If conditions were miserable your SAE correction may get you to where you think you should be

Fuel pressure during a pull

Injector duty cycle during the pull

Lifter preload

A dyno pull without the Y pipe, i.e. open headers

Confirmation if they physically removed the MAF because if they did then they had to do a speed density tune.

Confirmation that 97kPa is normal for your DA/area

Last edited by ddnspider; 08-29-2020 at 09:54 PM.

The following users liked this post:

jmilz28 (04-12-2021)

#27

#28

Too many people get hung up on dyno numbers. Numbers vary by dyno, calibration, temperature (which may or may not be accurately accounted for) the drivetrain from trans to tires plays a big role, one tuner will say a car should make this much and another would say something different. If the combo is running, not throwing any codes, prod length is correct (I'm assuming he has verified this already) injectors are firing and compression is in check then he should be good. If it was fueling I'd believe he would have an issue up top. The msd intake is meh. I got one and it seems to make a bit more peak and carry power slightly further than a fast but makes a bit less torque. His cam is a pretty healthy size for the cubes in a street car with plastic intake. I'm not so sure the heads are optimal for his cam and intake. Good head for sure but the ports are huge and the msd, being what it is, will force peak power in that 6400ish rpm range. The cam and heads should work well together but the intake is obviously a bottleneck for PEAK power. That being said he made decent HP for what it is. I'm sure it runs hard up top but that engine will want more than what his Intake will allow. I personally believe the cam and heads are playing a part with his "low" torque numbers. I would imagine he "should" be making 400 torque at 3500, not 3000. His combo likely just isnt doing it for that rpm. Something to note is if he cracked that intake open, the injector ports have these lame little gaskets that are designed by a child. Or intentionally cheap for cost reductio . They can easily get screwed up and cause a possible vacuum leak at the injector port. The msd intake also requires a different o ring for injectors. They sell it as a kit. At least this was the case for my ls1 injectors, may be different for ls2. Not sure what else can be done. Maybe cam is off more than they think? What else could be wrong, looks like you checked all the major boxes.

The following users liked this post:

jmilz28 (04-12-2021)

The following users liked this post:

jmilz28 (04-12-2021)

#32

Thread Starter

Joined: Mar 2011

Posts: 3,690

Likes: 162

From: Wilmington, DE

I don t have a lot of experience racing, like less than 15 passes. I'm trash. if I was better I would see what it runs at the track but the trap would naturally be low without experience

tuner also says no signs of vacuum leak

tuner also says no signs of vacuum leak

Last edited by Floorman279; 08-29-2020 at 09:46 PM.

#34

You could be still flowing enough fuel to maintain an AFR but with dropping pressure the spray pattern isn't atomizing like it should. IE, the tune had to add more fuel to compensate for the dropping pressure. It's been seen on here many times.

I don't hold much faith in Dyno numbers but you have a baseline to work fr so back to back changes should be fairly accurate. I calculated Darths rwhp from IDC and guessed 700 and he dynod 692 so it can be very accurate if setup right.

I don't hold much faith in Dyno numbers but you have a baseline to work fr so back to back changes should be fairly accurate. I calculated Darths rwhp from IDC and guessed 700 and he dynod 692 so it can be very accurate if setup right.

#35

Thread Starter

Joined: Mar 2011

Posts: 3,690

Likes: 162

From: Wilmington, DE

You could be still flowing enough fuel to maintain an AFR but with dropping pressure the spray pattern isn't atomizing like it should. IE, the tune had to add more fuel to compensate for the dropping pressure. It's been seen on here many times.

I don't hold much faith in Dyno numbers but you have a baseline to work fr so back to back changes should be fairly accurate. I calculated Darths rwhp from IDC and guessed 700 and he dynod 692 so it can be very accurate if setup right.

I don't hold much faith in Dyno numbers but you have a baseline to work fr so back to back changes should be fairly accurate. I calculated Darths rwhp from IDC and guessed 700 and he dynod 692 so it can be very accurate if setup right.

by idc do u mean get the injector duty cycle posted on here to give us a better understanding.....i can get those on monday

The following users liked this post:

jmilz28 (04-12-2021)

#38

Thread Starter

Joined: Mar 2011

Posts: 3,690

Likes: 162

From: Wilmington, DE

I have lonnies twin pumps both in tank. great kit. been on there since my ls1 build so 5000 miles. only ever had one on for that time, still only running one. I do think he runs single 250s in his kit. I have the window switch to activate the second pump if needed

#39

#40

Thread Starter

Joined: Mar 2011

Posts: 3,690

Likes: 162

From: Wilmington, DE

Well if it is making inadequate pressure then your entire curve could be off. I'd imagine the computer would dump more fuel to compensate thus raising the IDC. They key for a good combustion cycle is air speed and fuel atomization. Even if computer dumps more fuel it wouldnt be atomizing properly. So you said a shop built this for you, are you able to do any troubleshooting on your own or is this 100% on the shop?

so I figured let a pair of experienced ppl build it so I won't have any issues. you see how that worked out. I'm goona give him a little more time with the car, I still think it's a tune/fuel quality issue. on monday I will get the injector duty cycle for u guys, and have him monitor the fuel pressure during a pull......does that sound like the next move?

assuming it's not worth turning on the second pump yet?