Highest dyno numbers through JBA's ?

#42

Breathing some life into this old thread....

I have hit a wall at 650HP @ 5500RPM. Trying to determine if its the 1 5/8ths primaries on the JBA's are the bottleneck?

Anybody putting down more than 650, post up your numbers and setup.

I have hit a wall at 650HP @ 5500RPM. Trying to determine if its the 1 5/8ths primaries on the JBA's are the bottleneck?

Anybody putting down more than 650, post up your numbers and setup.

#44

I suppose the fact that I am even getting 15 PSI out of a P1 procharger should be telling me something is amiss. With my CI and AFR 235 heads, 15 PSI seems like alot?

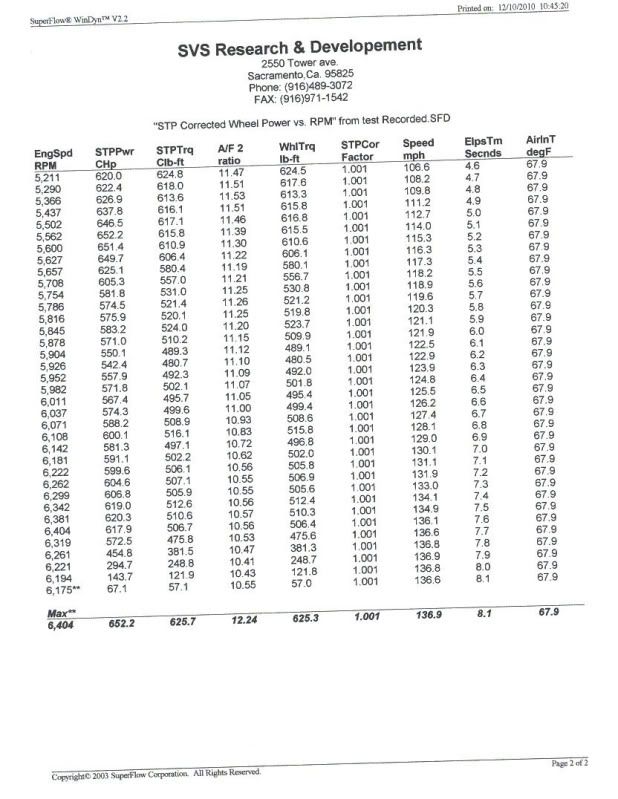

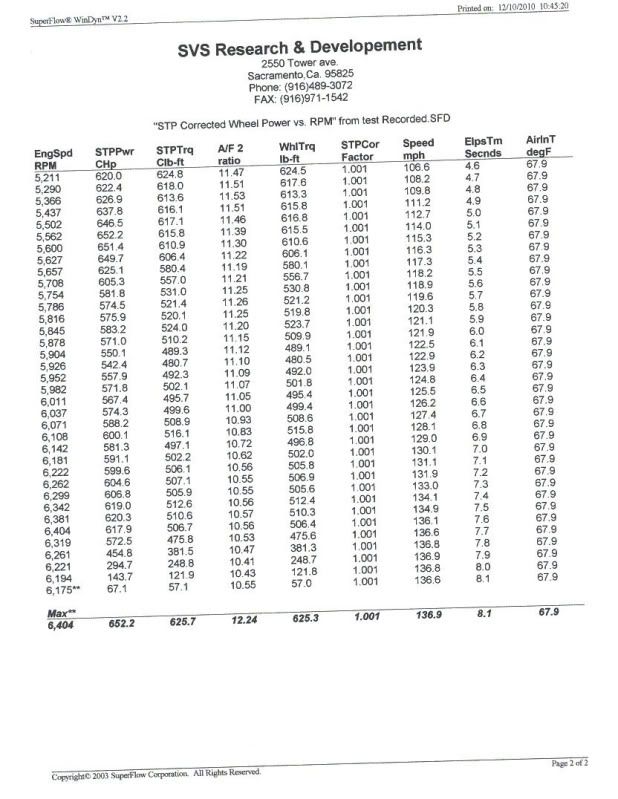

CI: 403

SCR: 9.25:1

Heads: AFR 235 (EDC custom)

Rockers: T&D Shaft 1.7:1

FI: Procharger P1SC1-1 @ 15PSI

intake: LS6 / OEM TB

Cam: 224/232 600/600 114 LSA (EDC)

CATS: No

Catback: Magnaflow 2.5"

Tune: OLSD

HP@: 652 @ 5500 RPM

TQ @: 625 @ 5200 RPM

CI: 403

SCR: 9.25:1

Heads: AFR 235 (EDC custom)

Rockers: T&D Shaft 1.7:1

FI: Procharger P1SC1-1 @ 15PSI

intake: LS6 / OEM TB

Cam: 224/232 600/600 114 LSA (EDC)

CATS: No

Catback: Magnaflow 2.5"

Tune: OLSD

HP@: 652 @ 5500 RPM

TQ @: 625 @ 5200 RPM

Last edited by b727pic; 02-03-2011 at 04:48 PM.

#45

I think you are pushing so much boost cause you have a rather mismatched setup. You have a 403ci and a P1 blower.... I have the JBA's and make over 600rwhp on a whopping 7-8psi. 383ci with a T76 turbo. Sure some long tubes would definitely help though.

#46

if the 403 can't handle the P1, I see no reason to go any bigger? keep in mind my max HP came at around 11PSI. I am spinning the P1 to max impeller speed, which drives the IAT's way up there, so I realize its not the ideal setup. I have an F1C that I was going to install, would be much more efficient. However If I can't get this car to get rid of the air from a P1 (assuming that is the issue) a bigger blower will just get me to the same point, earlier in the RPM band.

#47

if the 403 can't handle the P1, I see no reason to go any bigger? keep in mind my max HP came at around 11PSI. I am spinning the P1 to max impeller speed, which drives the IAT's way up there, so I realize its not the ideal setup. I have an F1C that I was going to install, would be much more efficient. However If I can't get this car to get rid of the air from a P1 (assuming that is the issue) a bigger blower will just get me to the same point, earlier in the RPM band.

All boost is is a measurement of restriction. A honda can make 30+ psi and still make less power than I do at ~8psi. Its about volume and moving the air. Same thing happens if you throw a tiny turbo on a big motor. You choke the motor even though you can run plenty of boost and max out the turbo. You got a big air pump sucking through a small straw which is compounded by exhaling through a small exhaust.

#48

probably....

I absolutely agree about the inefficiencies of my current setup, hence the F1C that is waiting in the wings.

I have been thinking strictly in terms of CFM coming in, then trying to get out.

The P1SC-1 is rated at 1200 CFM, although no way to measure I will take that as a given at max rated impeller speed. I am no scientist to be sure, but here is my math:

Max HP @ 5500 RPM

11 PSI @ 5500 RPM

P1SC-1 Max rated Impeller speed: 65000 (which in theory nets 1200 CFM)

Impeller speed at Max recorded HP: 55,500

Impeller speed Percentage of rated RPM @ max HP: 85%

1200 x .85= 1020 CFM at MAX HP

For the sake of discussion lets assume the exhaust is the bottleneck. my understanding is, that no matter what you throw at it, or how you get there, 1020 CFM is all that will pass through quasi efficiently???

So assuming I put on better flowing intake manifold, or TB, or D1 blower, the point at which I reach 1020 CFM may change, but ultimately the ability to flow more is strictly dependant on changing the characteristics of the bottleneck??

This may be all screwed up, but that is how I have been approaching the situation....

All boost is is a measurement of restriction.

I have been thinking strictly in terms of CFM coming in, then trying to get out.

The P1SC-1 is rated at 1200 CFM, although no way to measure I will take that as a given at max rated impeller speed. I am no scientist to be sure, but here is my math:

Max HP @ 5500 RPM

11 PSI @ 5500 RPM

P1SC-1 Max rated Impeller speed: 65000 (which in theory nets 1200 CFM)

Impeller speed at Max recorded HP: 55,500

Impeller speed Percentage of rated RPM @ max HP: 85%

1200 x .85= 1020 CFM at MAX HP

For the sake of discussion lets assume the exhaust is the bottleneck. my understanding is, that no matter what you throw at it, or how you get there, 1020 CFM is all that will pass through quasi efficiently???

So assuming I put on better flowing intake manifold, or TB, or D1 blower, the point at which I reach 1020 CFM may change, but ultimately the ability to flow more is strictly dependant on changing the characteristics of the bottleneck??

This may be all screwed up, but that is how I have been approaching the situation....