ATI balancer crank pinning write-up.

#21

Launching!

Join Date: Apr 2005

Location: CAIRNS QLD AUST

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

we dont pin ours over here that way

we drill in from the end horozontally

with a guide plate after the ballancer is on

you can put as many pins in as you like

and as long as you like

full length of ballancer hub if you want

we drill in from the end horozontally

with a guide plate after the ballancer is on

you can put as many pins in as you like

and as long as you like

full length of ballancer hub if you want

#27

TECH Addict

iTrader: (16)

too bad there is no writeup on the front ATI pinning method. thats what i am currently attempting. the squared off part is for people who have keyways already machined into the crank. you should be keeping the bit oiled and check to make sure it does not lose its pointed tip. I started slow and then increased pressure gradually for 30 second intervals. I had to go deeper than what procharger recommended to get the pin all the way in perfectly without going too deep. I will say the hardest thing you can run into is thinking you have it deep enough and then taking the damper back off, realizing that you have to put it back on to continue, and finding out just how much of a bitch it is to get it lined back up.

Last edited by I8UR4RD; 04-05-2012 at 07:37 PM.

#28

Launching!

Join Date: Apr 2005

Location: CAIRNS QLD AUST

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

are you trying to drill horizontally along between the crank and balancer from the end ?

or crossways through the ballancer then in to the crank?

if horizontally pic the side withOUT a key way if you have one so you get a half round in both crank and ballancer for the pin

or crossways through the ballancer then in to the crank?

if horizontally pic the side withOUT a key way if you have one so you get a half round in both crank and ballancer for the pin

#29

Launching!

Join Date: Apr 2005

Location: CAIRNS QLD AUST

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

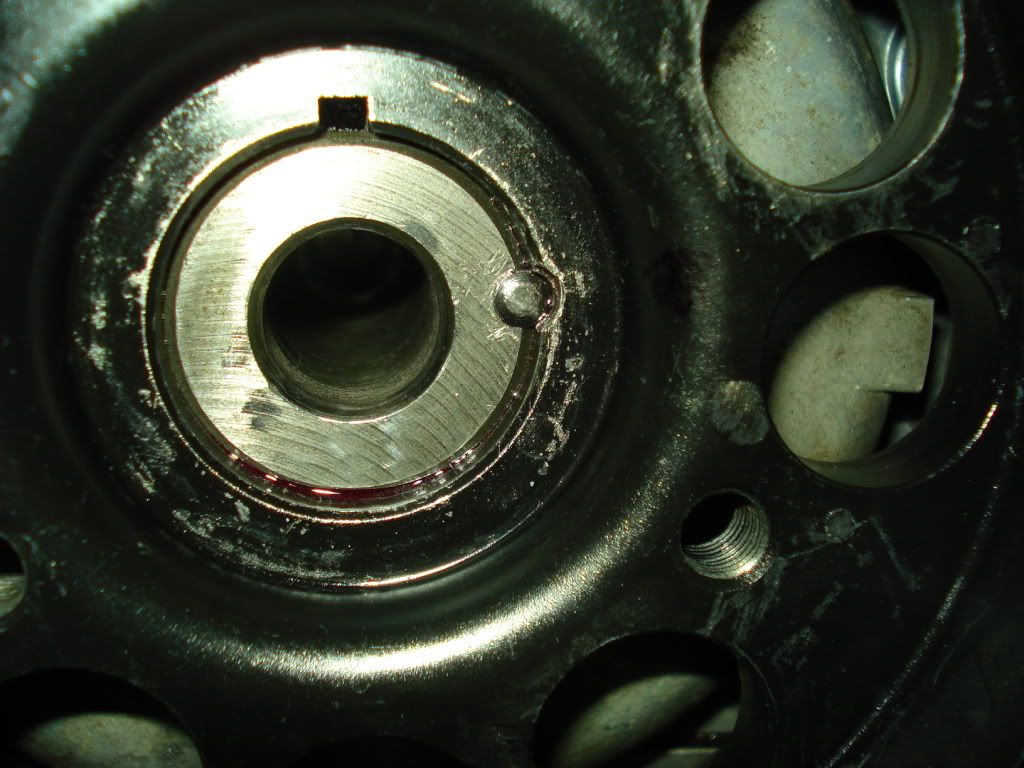

i am drilling from the front currently not the side aka vertically. i am not drilling through the supplied square cut keyway included in the black hub that attatches to the crank snout. I have the hub on the crank snout with the jig inside of it bolted down and I am in the process of drilling it that way. It was the only way I could get the hub to stay still enough to create a new path. i am not seeing much of a dent in the hub. i wanted to drill into a new portion of the hub to make sure that there would be a new half moon keyway for the pin. once i am past the hub i should hit the crank. what i am unsure of is whether or not i should just attatch the jig directly to the crank and bolt it down and start drilling the crank that way. this has been super confusing for me.

ok not sure whats going on there is you ballancer in two parts ours are all one piece like the oem one

with mine and the ones we do here the ballancer is pulled on to the crank and pulled up in to position and torqued up as normal ,then the crank bolt is removed and the jig is fitted to the crank snout hard up against the ballancer rotate the jig so the hole misses the key way and tighten up ,then drill the hole

it should be half in the crank and half in the ballancer

have you got a pic