87 Trans Am 5.3L w/ 76mm build, in under 3 weeks!!

#1

Alright well i have had pretty much every part for my car sitting here all summer but have been much to busy with other projects to even work on mine once. I am trying to do the entire build in 3 weeks, hoping to get the track the weekend of the nov 5-7. I have one other project that needs to be wrapped up but i am waiting on some parts and more material so that will take a few days away from this to complete when those parts come in.

The build plan is pretty simple for the time being, then go larger over the winter with motor and turbo.

Plan is...

-ENGINE-

Stock 05' 5.3L w/arp 2000 rod bolts

Motorplate/midplate set up

self ported 317 heads, with AES doing the valve job/cleanup

ARP 12pt head studs

ls9 head gaskets

COMP CAMS Turbo cam

Upgraded valve-train

ATI Flexplate

ATI Super damper balancer

Edelbrock 2 piece front cover

ARP every bolt

custom catch can set up -10an

-INTAKE/COLD SIDE-

self ported vic jr intake

accell 1550cfm tb

velocity carb hat

4" cold side A/A intercooler

60mm jgs bov

s76 turbo

Custom air filter

Possibly methanol injected.

-EXHAUST-

1 7/8" stainless custom headers

3" stainless crossover

hks 60mm gate or dual 44mm tials

5" stainless downpipe

5" VIBRANT PERFORMANCE muffler

-FUEL-

E85

80lb injectors

Fast rails

Magnafuel boost reg

BG King sumo pump

-10 feed to dual -8

-8 return

sumped stock tank

-ELECTRONICS-

MSBC-1 Boost controller

Lingenfelter lnc002 2 step

boost/ fuel pressure gauges

stock ecu

-TRANS-

TH400 with all goodies and brake

YANK turbo converter

an lines and large cooler w/fan

quarterstick shifter

BMR trans crossmember modded

-REAR/SUSPENSION-

MIDWEST CHASSIS fab 9" w/3.50's

MIDWEST CHASSIS LCA's / panhard

MIDWEST CHASSIS anti roll bar

MIDWEST CHASSIS Torque arm

currently stock shocks/struts and brakes but possibly drag set up

i will be converting from power to manual brakes as well

-WHEELS/TIRES-

BILLET SPECIALTIES 15x3.5 fronts, 15x10 rear

dont have tires yet

Ok so i obviously have my work cut out for me and im sure i wont get much sleep as this is all going to get worked on after the 8-5 work so this is probably going to be my 6-12 2nd job every day lol. Wish me luck. I will try to do my best with updating this thread with pics daily but might not happen if i am focusing on the car alot.

heres what she looks like currently lol. A shell, no motor, no trans, no rear, no gas tank, no suspension, nothing but front suspension and some wiring.

The build plan is pretty simple for the time being, then go larger over the winter with motor and turbo.

Plan is...

-ENGINE-

Stock 05' 5.3L w/arp 2000 rod bolts

Motorplate/midplate set up

self ported 317 heads, with AES doing the valve job/cleanup

ARP 12pt head studs

ls9 head gaskets

COMP CAMS Turbo cam

Upgraded valve-train

ATI Flexplate

ATI Super damper balancer

Edelbrock 2 piece front cover

ARP every bolt

custom catch can set up -10an

-INTAKE/COLD SIDE-

self ported vic jr intake

accell 1550cfm tb

velocity carb hat

4" cold side A/A intercooler

60mm jgs bov

s76 turbo

Custom air filter

Possibly methanol injected.

-EXHAUST-

1 7/8" stainless custom headers

3" stainless crossover

hks 60mm gate or dual 44mm tials

5" stainless downpipe

5" VIBRANT PERFORMANCE muffler

-FUEL-

E85

80lb injectors

Fast rails

Magnafuel boost reg

BG King sumo pump

-10 feed to dual -8

-8 return

sumped stock tank

-ELECTRONICS-

MSBC-1 Boost controller

Lingenfelter lnc002 2 step

boost/ fuel pressure gauges

stock ecu

-TRANS-

TH400 with all goodies and brake

YANK turbo converter

an lines and large cooler w/fan

quarterstick shifter

BMR trans crossmember modded

-REAR/SUSPENSION-

MIDWEST CHASSIS fab 9" w/3.50's

MIDWEST CHASSIS LCA's / panhard

MIDWEST CHASSIS anti roll bar

MIDWEST CHASSIS Torque arm

currently stock shocks/struts and brakes but possibly drag set up

i will be converting from power to manual brakes as well

-WHEELS/TIRES-

BILLET SPECIALTIES 15x3.5 fronts, 15x10 rear

dont have tires yet

Ok so i obviously have my work cut out for me and im sure i wont get much sleep as this is all going to get worked on after the 8-5 work so this is probably going to be my 6-12 2nd job every day lol. Wish me luck. I will try to do my best with updating this thread with pics daily but might not happen if i am focusing on the car alot.

heres what she looks like currently lol. A shell, no motor, no trans, no rear, no gas tank, no suspension, nothing but front suspension and some wiring.

Last edited by 408trans_am; 10-15-2010 at 11:08 PM.

#3

here is a pic of what it used to look like, i know many will probably recognize it.

Last edited by 408trans_am; 10-15-2010 at 02:36 AM.

#6

Thanks guys i will try my best. Well i took off most of today as some of the material for the other project showed up so i worked on that most of the day and spent a little time on my car. This will be a quick update and ill be back out in the garage the rest of the night.

Anywho, heres what i accomplished. may not look like much but i had to do a ton of work to get this 4" dp through a non turbo k member. i have less than a 1/8" all around, not to mention making it able to slide in place with the motor in.

Now for my car.......

First thing i did was weld the 4" aluminum v-band to the carb hat, i forgot to take pics of this but ill add them later. This was pretty tricky since the carb hat is cast and an oval shaped, and the v band isnt cast and is round. But its done.

I am using an accell 4150 style tb and a velocity carb hat, well the carb hat is for a "4 barrel tb" so its supposed to have a center threaded hole to secure the hat to, well the open accell has 2 on the sides. Typical for anything i use, just never can bolt anything together. So i had to make something and heres what i came up with.

TB and HAT(see the predicament) ....

materials....

This would have been the easy route, but i didnt want a flat bar across the tb, so that wouldnt work for me....

Round bar would work better, but i wouldnt be able to bolt it down to the tb....

Cut 2 small flat pieces and bolted them to the tb....

Cut the round bar and notched it to fit in the center of the flat bar....

Welded together....

Now i needed to attach either a nut to it so i could bolt it down, but i thought a threaded stud would be easier to install and take apart, just having a nut to remove on the to of the tb. so 3/8" threaded rod welded to the center it was....

Heres what the finished product looks like.... ready for powder coat

Heres what it looks like with the HAT installed....

Now i dont want boost leaking out so i made a rubber gasket to fit snugly under the washer and nut....

Rubber gasket installed....

I am going to start porting the intake tonight along with some other welding if i have time.

Anywho, heres what i accomplished. may not look like much but i had to do a ton of work to get this 4" dp through a non turbo k member. i have less than a 1/8" all around, not to mention making it able to slide in place with the motor in.

Now for my car.......

First thing i did was weld the 4" aluminum v-band to the carb hat, i forgot to take pics of this but ill add them later. This was pretty tricky since the carb hat is cast and an oval shaped, and the v band isnt cast and is round. But its done.

I am using an accell 4150 style tb and a velocity carb hat, well the carb hat is for a "4 barrel tb" so its supposed to have a center threaded hole to secure the hat to, well the open accell has 2 on the sides. Typical for anything i use, just never can bolt anything together. So i had to make something and heres what i came up with.

TB and HAT(see the predicament) ....

materials....

This would have been the easy route, but i didnt want a flat bar across the tb, so that wouldnt work for me....

Round bar would work better, but i wouldnt be able to bolt it down to the tb....

Cut 2 small flat pieces and bolted them to the tb....

Cut the round bar and notched it to fit in the center of the flat bar....

Welded together....

Now i needed to attach either a nut to it so i could bolt it down, but i thought a threaded stud would be easier to install and take apart, just having a nut to remove on the to of the tb. so 3/8" threaded rod welded to the center it was....

Heres what the finished product looks like.... ready for powder coat

Heres what it looks like with the HAT installed....

Now i dont want boost leaking out so i made a rubber gasket to fit snugly under the washer and nut....

Rubber gasket installed....

I am going to start porting the intake tonight along with some other welding if i have time.

Last edited by 408trans_am; 10-15-2010 at 04:57 PM.

Trending Topics

#8

I am going to a motor plate set up and hopefully a tubular k member with no mounts for extra clearance.

#11

Got a little more done tonight as i am leaving tomorrow morning to go camping with my parents(committed months ago and cant back out on parents lol) so i will be looking the whole weekend to that.

Here are the pics of the 4" aluminum v band welded to the carb hat, again its not that pretty, but welding to cast sucks and it was also a decent gap....

I did start porting the vic jr, typically takes me about 8 hours to port one, this one already was ported from a reputable shop, but it left alot to be desired so i will have probably 6 hours more porting to do. I got 2 runners roughed in before it got dark out....

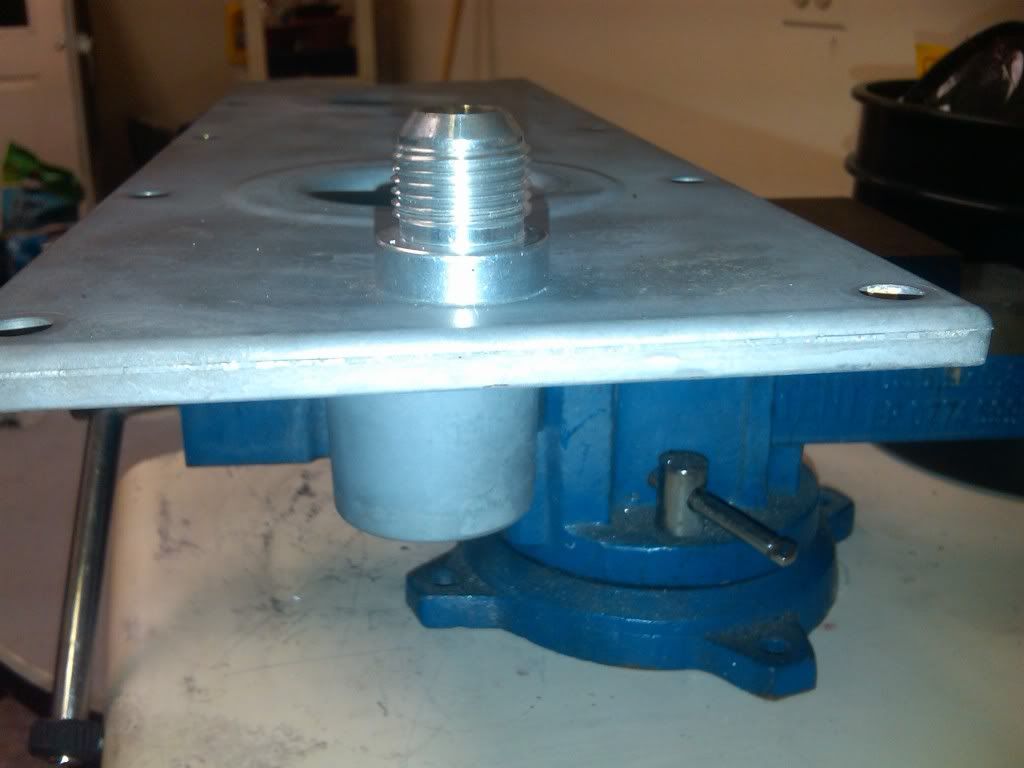

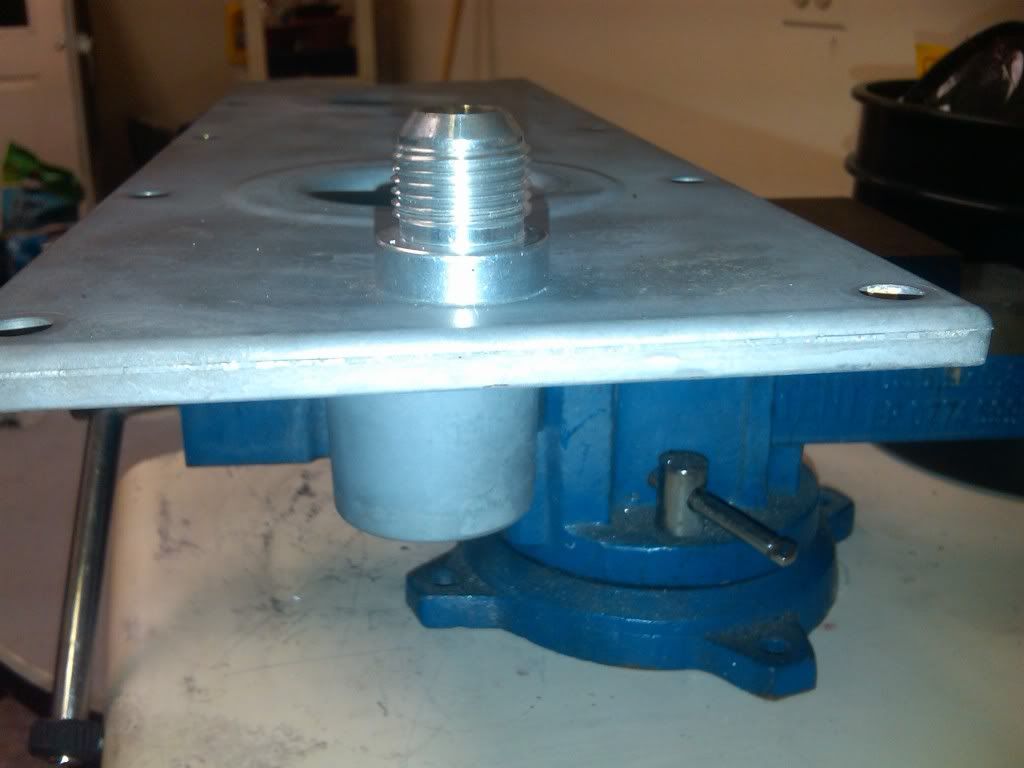

I also got the oil pan drilled and welded in a -12an bung for the oil drain. Problem was that i already powder coated the pan, so i had to be careful and keep cooling, which is terrible since aluminum welds much better preheated, came out good....

Also got the -10 an bung welded in the front of the valley cover, going to run -10an lines from both valve covers and valley cover to a custom catch can set up. This is the same process i went through with the oil pan, just didnt want to bore you with both....

what i am working with....

hole drilled....

pressed in....

Welded in....

Finished product....

Thats all for tonight and probably this weekend, maybe ill work on it later sunday.

Here are the pics of the 4" aluminum v band welded to the carb hat, again its not that pretty, but welding to cast sucks and it was also a decent gap....

I did start porting the vic jr, typically takes me about 8 hours to port one, this one already was ported from a reputable shop, but it left alot to be desired so i will have probably 6 hours more porting to do. I got 2 runners roughed in before it got dark out....

I also got the oil pan drilled and welded in a -12an bung for the oil drain. Problem was that i already powder coated the pan, so i had to be careful and keep cooling, which is terrible since aluminum welds much better preheated, came out good....

Also got the -10 an bung welded in the front of the valley cover, going to run -10an lines from both valve covers and valley cover to a custom catch can set up. This is the same process i went through with the oil pan, just didnt want to bore you with both....

what i am working with....

hole drilled....

pressed in....

Welded in....

Finished product....

Thats all for tonight and probably this weekend, maybe ill work on it later sunday.

#18

Thanks.

Thanks, yea this is my first car so i have been around thirdgens and definitely love a clean one.

Its from Ram Air Hood .com, Its the ram air 2, they do have a ram air 1 which is shorter.

http://www.ramairhood.com/photo_gall...ta_gallery.htm

Last edited by 408trans_am; 10-17-2010 at 04:37 PM.