Budget/eBay head studs

#185

TECH Senior Member

iTrader: (127)

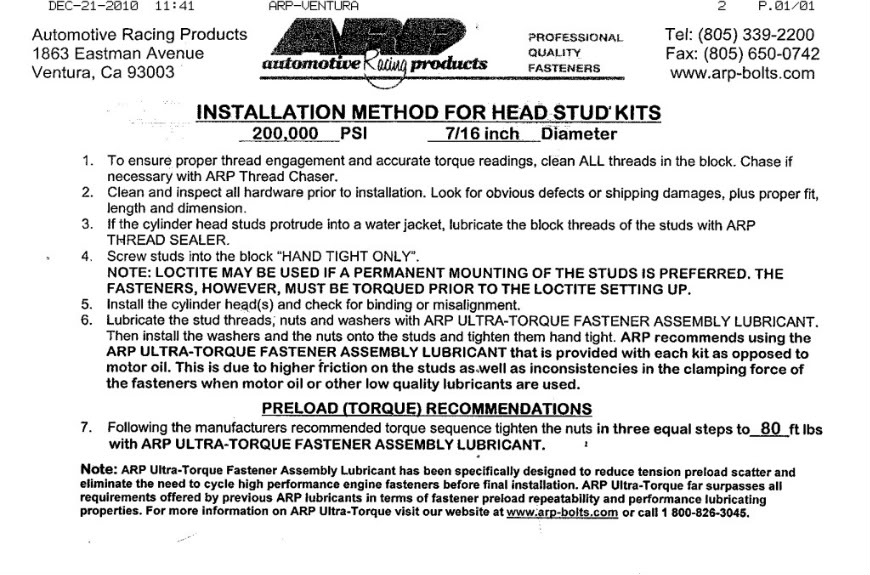

A update. I installed a set of ebay head studs on a customers car per his request on a forged piston and rod stock crank 6. 0 w tfs heads and a btr cam. Single bw s475 w upgraded cover. Made 988rw. On the rollets yesterday. I tq em down to 80lbs. W arp lube on both sides of the washers. Ls9 gaskets w copper spray.

No issues so far.

No issues so far.

#187

#188

Within the context of thread pitch, and being that the nut end of a stud has a finer pitch than the threads of a stock (or aftermarket) head bolt... lb. for lb. of torque, the stud option will apply more clamping force. Simply because there's additional mechanical advantage in the finer thread pitch.

However, this has little to nothing to do with the strength of the bolt/stud.

In actuality, if a stud and bolt had exactly the same strength, the stud would require less torque to exceed it... again, because each pound of torque to a finer pitch will apply more clamping force than a coarser pitch.

Much the same reason a numerically high rear gear ratio will break tire traction easier than a numerically low gear. Mechanical advantage.

#190

in my experience the China eBay studs are junk. I installed a set on my 6.0 and they were breaking around 68ft lbs. Thinking it was a bad batch . My bud had a set of used ones he brought over they made it to 70ish ft lbs. Like others have said threads have alot of Knicks and are not consistent one stud to the next. Also the Allen head holes in end of studs were all messed up, some were off center, some were different sizes.

Here is a China nut next the ARP nut.....no comparison.

Also once I got arps they went on perfect....

Here is a China nut next the ARP nut.....no comparison.

Also once I got arps they went on perfect....

#191

TECH Apprentice

iTrader: (8)

Join Date: Mar 2004

Location: N. IL

Posts: 366

Likes: 0

Received 0 Likes

on

0 Posts

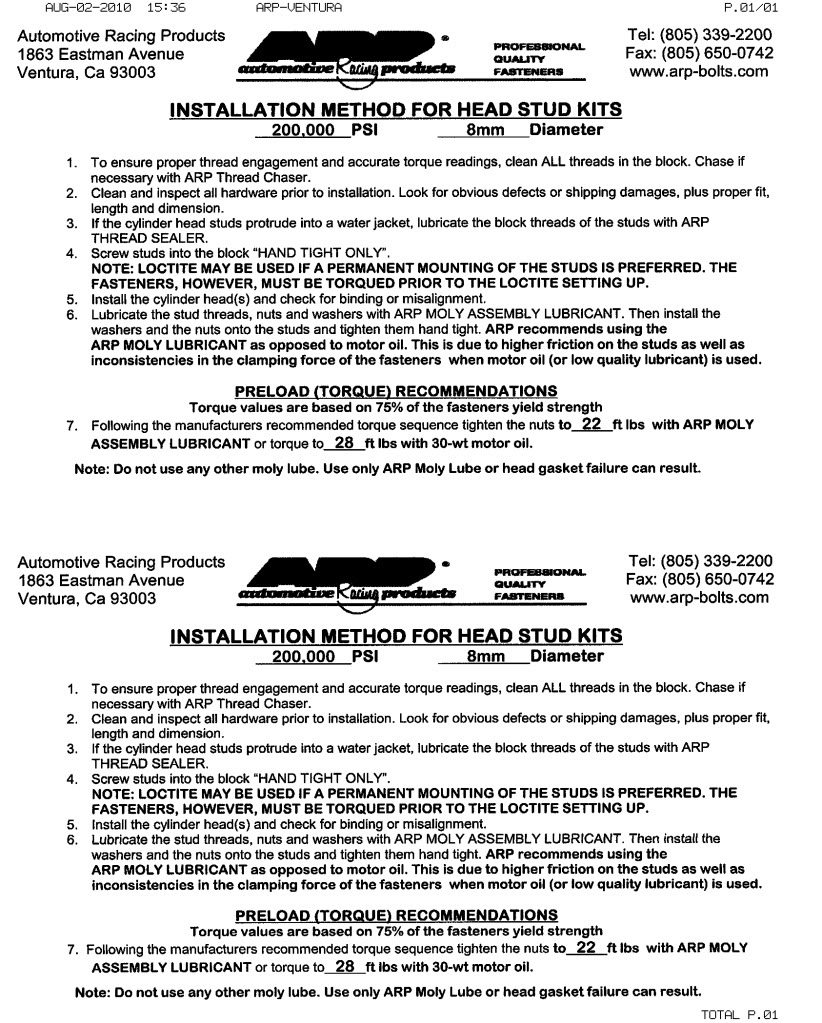

I bought a set of the China studs for my 5.3 from Jegs for $109ish. They were called speed master or something with the word speed in it IIRC. I used permatex assembly lube and torqued them down to 80ft-lbs, twice. First pass was 40, then 60 and final torque was 80. Let them soak over night, came out the next day, loosened all of them and did it again. Nothing broke, they all went smooth, nothing was odd, no burred threads.

Edit: I should say I also chased all the threads with bottoming taps and blew all the junk out of them with compressed air. I tried to make it all as clean as possible, since its a JY build.

This is still an unfinished project, so I can't comment on their performance but installation went without hiccup.

Edit: I should say I also chased all the threads with bottoming taps and blew all the junk out of them with compressed air. I tried to make it all as clean as possible, since its a JY build.

This is still an unfinished project, so I can't comment on their performance but installation went without hiccup.

Last edited by simple; 05-29-2017 at 08:56 PM.

#192

8 Second Club

iTrader: (4)

Over torqueing a fastener is going to over stretch it. You will lose clamping force. Don’t think the china studs are meant to be torqued to 80ftlb? Even 70 is pushing it IMO. They should be treated as a TTY fastener at that point and not reused either. When Alpine motorsports was selling these years ago I was told 65ftlbs was the max. Anyone put a dial indicator on the stud and actually measure stretch?

#193

Over torqueing a fastener is going to over stretch it. You will lose clamping force. Donít think the china studs are meant to be torqued to 80ftlb? Even 70 is pushing it IMO. They should be treated as a TTY fastener at that point and not reused either. When Alpine motorsports was selling these years ago I was told 65ftlbs was the max. Anyone put a dial indicator on the stud and actually measure stretch?

#194

Not to bring up old posts, but i just installed a set of ebay main and head studs into a lm7 with nitrous. Besides not having a spec sheet i feel they were good quality for the price. I did use arp ultra torque lube a torqued to arp specs with absolutly no issue at all. Just thought i would put out a good word

#196

FormerVendor

iTrader: (1)

Join Date: Nov 2008

Location: Santa Ana, CA. USA

Posts: 2,157

Likes: 0

Received 17 Likes

on

17 Posts

Hi ALL, the BEST CASE is to recreate the OEM TASK !

Thus the GM ENGINEERED ASSEMBLY is the TTY or a fastener that has the SAME FEATURES.

MOST engine Assemblers USE a fastener with the same "stance", a China Stud.

The OTHER "stance" is to "UNDERCUT" the ARP STUD for the SAME AL EXPANSION RATE !

THUS YOU ARE CORRECT, thanks for your REPORT !

Lance

Thus the GM ENGINEERED ASSEMBLY is the TTY or a fastener that has the SAME FEATURES.

MOST engine Assemblers USE a fastener with the same "stance", a China Stud.

The OTHER "stance" is to "UNDERCUT" the ARP STUD for the SAME AL EXPANSION RATE !

THUS YOU ARE CORRECT, thanks for your REPORT !

Lance

Last edited by pantera_efi; 06-18-2017 at 07:54 PM.

#198

I stumbled upon this thread while I was looking to see if anyone used threaded rod. No, not "normal" threaded rod, the 170,000 PSI variety. In any case, I thought I would try to clear up some stuff while I was at it:

The studs should be torqued to the stud manufacturers recommended torque, not some other manufacturers recommended torque. The reason being that the torque is based on a percentage (usually around 85%) of the yield strength (in tension) of the stud. I would call this the "proof" strength. Therefore, you can quite possibly go beyond the yield point of your studs by following other manufacturers information.

The yield point is where elastic deformation stops and where plastic deformation begins. Anything in the elastic zone is deformation that your stud will "snap back" from when load is removed. Think a rubber band. Plastic deformation results in a permanent deformity. Think about a stretched out piece of taffy. When the taffy breaks, that's ultimate tensile strength.

Going over the yield point is bad. there is no benefit whatsoever to holding your heads down. No amount of additional torque is going to help anything.

Torque to yield bolts are just that. The 85% of yield guideline is thrown out the window in order to stretch out a weaker grade of material to apply enough tension to hold your heads down. Even this has a bit of safety factor thrown in though, which is how you can sometimes get away with reusing torque to yield bolts. I'd hazard a guess that usually a torque to yield bolt is torqued to a around 90%-95% of yield. Because of the lower safety factor, it's a bit like Russian Roulette when reusing TTY bolts. Definitely don't over torque them!

Now what about friction? Friction causes HUGE discrepancies on how much tension a fastener actually sees. In torque calculations, friction is represented in the "K" factor (scientifical engineering fudge-factor). It's based on the fastener material, the hole material and the lubrication used. In short, if a manufacturer doesn't tell you to use lubrication DON'T DO IT. A bolt can EASILY go from a safe tension in the elastic range into failure mode (beyond it's yield point) by simply adding a drop of oil! Don't believe me? Tap a piece of steel with a #10 thread, screw it in there dry and apply a torque wrench to try to break it, then screw it in with oil in another hole and see how much easier it is to do it.

For some actual examples, although I don't have the properties for 8740 chromemoly, I do have some mechanical specs for ASTM A574 which is pretty close. At an ultimate tensile strength of 190,000 PSI and a yield of 170,000 PSI the proof strength would be around 144,500 PSI

For an 11mm bolt made of the above material, with a "standard" K factor of .2 (dry, steel on steel):

1. A torque for a connection that repeatedly is assembled and disassembled would be around 75% of proof and that would be 78 ft. lbs.

2. A torque for a connection that is seldom taken apart would be around 90% of proof and that would be 94 ft. lbs.

3. Proof strength (85% of yield) would be reached at a torque of 105 ft. lbs.

4. Yield strength would be reached at approximately 123 ft. lbs.

5. Ultimate tensile would be reached at around 137 ft. lbs.

Now, let's add lubrication with a K factor of .15:

1. 59 ft. lbs.

2. 71 ft. lbs.

3. 78 ft. lbs.

4. 92 ft. lbs.

5. 103 ft. lbs.

Although the torque applied is different, the resultant tension is the same in both examples, meaning that the amount of clamping force is the same as well.

So, let's look at the clamping force for the above examples:

1. 10,854 lbs.

2. 13,026 lbs.

3. 14,472 lbs.

4. 17,026 lbs.

5. 19,030 lbs.

That's per fastener.

So multiply the number of pounds of clamping force by the number of studs and that's how many pounds they can hold back before the stud ever "sees" any force at all from your heads. That's why torquing the proper amount to a certain pretension is so important. If one is loose, that one won't be helping so you don't get to multiply it in with the others so it can cause another to fail which can cause a domino effect.

I'm not even getting into the thread shear area which has to be calculated into this when thread depths are more shallow or when a weaker material is used on one side of the connection (aluminum block). This is where a finer thread pitch can help, it otherwise has little effect on anything. Suffice to say that you are OK with an aluminum head at the above torques as long as you have at least 21/32" or so of FULL thread engagment.

Anyway,

back to shopping for stud material at McMaster. I can only seem to find up to 170,000 tensile and I'm too lazy to do more calculations right now so, I guess I'm buying stainless header studs from McMaster first.

And yes, I'm a huge lurker.

The studs should be torqued to the stud manufacturers recommended torque, not some other manufacturers recommended torque. The reason being that the torque is based on a percentage (usually around 85%) of the yield strength (in tension) of the stud. I would call this the "proof" strength. Therefore, you can quite possibly go beyond the yield point of your studs by following other manufacturers information.

The yield point is where elastic deformation stops and where plastic deformation begins. Anything in the elastic zone is deformation that your stud will "snap back" from when load is removed. Think a rubber band. Plastic deformation results in a permanent deformity. Think about a stretched out piece of taffy. When the taffy breaks, that's ultimate tensile strength.

Going over the yield point is bad. there is no benefit whatsoever to holding your heads down. No amount of additional torque is going to help anything.

Torque to yield bolts are just that. The 85% of yield guideline is thrown out the window in order to stretch out a weaker grade of material to apply enough tension to hold your heads down. Even this has a bit of safety factor thrown in though, which is how you can sometimes get away with reusing torque to yield bolts. I'd hazard a guess that usually a torque to yield bolt is torqued to a around 90%-95% of yield. Because of the lower safety factor, it's a bit like Russian Roulette when reusing TTY bolts. Definitely don't over torque them!

Now what about friction? Friction causes HUGE discrepancies on how much tension a fastener actually sees. In torque calculations, friction is represented in the "K" factor (scientifical engineering fudge-factor). It's based on the fastener material, the hole material and the lubrication used. In short, if a manufacturer doesn't tell you to use lubrication DON'T DO IT. A bolt can EASILY go from a safe tension in the elastic range into failure mode (beyond it's yield point) by simply adding a drop of oil! Don't believe me? Tap a piece of steel with a #10 thread, screw it in there dry and apply a torque wrench to try to break it, then screw it in with oil in another hole and see how much easier it is to do it.

For some actual examples, although I don't have the properties for 8740 chromemoly, I do have some mechanical specs for ASTM A574 which is pretty close. At an ultimate tensile strength of 190,000 PSI and a yield of 170,000 PSI the proof strength would be around 144,500 PSI

For an 11mm bolt made of the above material, with a "standard" K factor of .2 (dry, steel on steel):

1. A torque for a connection that repeatedly is assembled and disassembled would be around 75% of proof and that would be 78 ft. lbs.

2. A torque for a connection that is seldom taken apart would be around 90% of proof and that would be 94 ft. lbs.

3. Proof strength (85% of yield) would be reached at a torque of 105 ft. lbs.

4. Yield strength would be reached at approximately 123 ft. lbs.

5. Ultimate tensile would be reached at around 137 ft. lbs.

Now, let's add lubrication with a K factor of .15:

1. 59 ft. lbs.

2. 71 ft. lbs.

3. 78 ft. lbs.

4. 92 ft. lbs.

5. 103 ft. lbs.

Although the torque applied is different, the resultant tension is the same in both examples, meaning that the amount of clamping force is the same as well.

So, let's look at the clamping force for the above examples:

1. 10,854 lbs.

2. 13,026 lbs.

3. 14,472 lbs.

4. 17,026 lbs.

5. 19,030 lbs.

That's per fastener.

So multiply the number of pounds of clamping force by the number of studs and that's how many pounds they can hold back before the stud ever "sees" any force at all from your heads. That's why torquing the proper amount to a certain pretension is so important. If one is loose, that one won't be helping so you don't get to multiply it in with the others so it can cause another to fail which can cause a domino effect.

I'm not even getting into the thread shear area which has to be calculated into this when thread depths are more shallow or when a weaker material is used on one side of the connection (aluminum block). This is where a finer thread pitch can help, it otherwise has little effect on anything. Suffice to say that you are OK with an aluminum head at the above torques as long as you have at least 21/32" or so of FULL thread engagment.

Anyway,

back to shopping for stud material at McMaster. I can only seem to find up to 170,000 tensile and I'm too lazy to do more calculations right now so, I guess I'm buying stainless header studs from McMaster first.

And yes, I'm a huge lurker.

Last edited by OBeer-WAN-Kenobi; 06-26-2017 at 06:31 PM.

#199

I stumbled upon this thread while I was looking to see if anyone used threaded rod. No, not "normal" threaded rod, the 170,000 PSI variety. In any case, I thought I would try to clear up some stuff while I was at it:

The studs should be torqued to the stud manufacturers recommended torque, not some other manufacturers recommended torque. The reason being that the torque is based on a percentage (usually around 85%) of the yield strength (in tension) of the stud. I would call this the "proof" strength. Therefore, you can quite possibly go beyond the yield point of your studs by following other manufacturers information.

The yield point is where elastic deformation stops and where plastic deformation begins. Anything in the elastic zone is deformation that your stud will "snap back" from when load is removed. Think a rubber band. Plastic deformation results in a permanent deformity. Think about a stretched out piece of taffy. When the taffy breaks, that's ultimate tensile strength.

Going over the yield point is bad. there is no benefit whatsoever to holding your heads down. No amount of additional torque is going to help anything.

Torque to yield bolts are just that. The 85% of yield guideline is thrown out the window in order to stretch out a weaker grade of material to apply enough tension to hold your heads down. Even this has a bit of safety factor thrown in though, which is how you can sometimes get away with reusing torque to yield bolts. I'd hazard a guess that usually a torque to yield bolt is torqued to a around 90%-95% of yield. Because of the lower safety factor, it's a bit like Russian Roulette when reusing TTY bolts. Definitely don't over torque them!

Now what about friction? Friction causes HUGE discrepancies on how much tension a fastener actually sees. In torque calculations, friction is represented in the "K" factor (scientifical engineering fudge-factor). It's based on the fastener material, the hole material and the lubrication used. In short, if a manufacturer doesn't tell you to use lubrication DON'T DO IT. A bolt can EASILY go from a safe tension in the elastic range into failure mode (beyond it's yield point) by simply adding a drop of oil! Don't believe me? Tap a piece of steel with a #10 thread, screw it in there dry and apply a torque wrench to try to break it, then screw it in with oil in another hole and see how much easier it is to do it.

For some actual examples, although I don't have the properties for 8740 chromemoly, I do have some mechanical specs for ASTM A574 which is pretty close. At an ultimate tensile strength of 190,000 PSI and a yield of 170,000 PSI the proof strength would be around 144,500 PSI

For an 11mm bolt made of the above material, with a "standard" K factor of .2 (dry, steel on steel):

1. A torque for a connection that repeatedly is assembled and disassembled would be around 75% of proof and that would be 78 ft. lbs.

2. A torque for a connection that is seldom taken apart would be around 90% of proof and that would be 94 ft. lbs.

3. Proof strength (85% of yield) would be reached at a torque of 105 ft. lbs.

4. Yield strength would be reached at approximately 123 ft. lbs.

5. Ultimate tensile would be reached at around 137 ft. lbs.

Now, let's add lubrication with a K factor of .15:

1. 59 ft. lbs.

2. 71 ft. lbs.

3. 78 ft. lbs.

4. 92 ft. lbs.

5. 103 ft. lbs.

Although the torque applied is different, the resultant tension is the same in both examples, meaning that the amount of clamping force is the same as well.

So, let's look at the clamping force for the above examples:

1. 10,854 lbs.

2. 13,026 lbs.

3. 14,472 lbs.

4. 17,026 lbs.

5. 19,030 lbs.

That's per fastener.

So multiply the number of pounds of clamping force by the number of studs and that's how many pounds they can hold back before the stud ever "sees" any force at all from your heads. That's why torquing the proper amount to a certain pretension is so important. If one is loose, that one won't be helping so you don't get to multiply it in with the others so it can cause another to fail which can cause a domino effect.

I'm not even getting into the thread shear area which has to be calculated into this when thread depths are more shallow or when a weaker material is used on one side of the connection (aluminum block). This is where a finer thread pitch can help, it otherwise has little effect on anything. Suffice to say that you are OK with an aluminum head at the above torques as long as you have at least 21/32" or so of FULL thread engagment.

Anyway,

back to shopping for stud material at McMaster. I can only seem to find up to 170,000 tensile and I'm too lazy to do more calculations right now so, I guess I'm buying stainless header studs from McMaster first.

And yes, I'm a huge lurker.

The studs should be torqued to the stud manufacturers recommended torque, not some other manufacturers recommended torque. The reason being that the torque is based on a percentage (usually around 85%) of the yield strength (in tension) of the stud. I would call this the "proof" strength. Therefore, you can quite possibly go beyond the yield point of your studs by following other manufacturers information.

The yield point is where elastic deformation stops and where plastic deformation begins. Anything in the elastic zone is deformation that your stud will "snap back" from when load is removed. Think a rubber band. Plastic deformation results in a permanent deformity. Think about a stretched out piece of taffy. When the taffy breaks, that's ultimate tensile strength.

Going over the yield point is bad. there is no benefit whatsoever to holding your heads down. No amount of additional torque is going to help anything.

Torque to yield bolts are just that. The 85% of yield guideline is thrown out the window in order to stretch out a weaker grade of material to apply enough tension to hold your heads down. Even this has a bit of safety factor thrown in though, which is how you can sometimes get away with reusing torque to yield bolts. I'd hazard a guess that usually a torque to yield bolt is torqued to a around 90%-95% of yield. Because of the lower safety factor, it's a bit like Russian Roulette when reusing TTY bolts. Definitely don't over torque them!

Now what about friction? Friction causes HUGE discrepancies on how much tension a fastener actually sees. In torque calculations, friction is represented in the "K" factor (scientifical engineering fudge-factor). It's based on the fastener material, the hole material and the lubrication used. In short, if a manufacturer doesn't tell you to use lubrication DON'T DO IT. A bolt can EASILY go from a safe tension in the elastic range into failure mode (beyond it's yield point) by simply adding a drop of oil! Don't believe me? Tap a piece of steel with a #10 thread, screw it in there dry and apply a torque wrench to try to break it, then screw it in with oil in another hole and see how much easier it is to do it.

For some actual examples, although I don't have the properties for 8740 chromemoly, I do have some mechanical specs for ASTM A574 which is pretty close. At an ultimate tensile strength of 190,000 PSI and a yield of 170,000 PSI the proof strength would be around 144,500 PSI

For an 11mm bolt made of the above material, with a "standard" K factor of .2 (dry, steel on steel):

1. A torque for a connection that repeatedly is assembled and disassembled would be around 75% of proof and that would be 78 ft. lbs.

2. A torque for a connection that is seldom taken apart would be around 90% of proof and that would be 94 ft. lbs.

3. Proof strength (85% of yield) would be reached at a torque of 105 ft. lbs.

4. Yield strength would be reached at approximately 123 ft. lbs.

5. Ultimate tensile would be reached at around 137 ft. lbs.

Now, let's add lubrication with a K factor of .15:

1. 59 ft. lbs.

2. 71 ft. lbs.

3. 78 ft. lbs.

4. 92 ft. lbs.

5. 103 ft. lbs.

Although the torque applied is different, the resultant tension is the same in both examples, meaning that the amount of clamping force is the same as well.

So, let's look at the clamping force for the above examples:

1. 10,854 lbs.

2. 13,026 lbs.

3. 14,472 lbs.

4. 17,026 lbs.

5. 19,030 lbs.

That's per fastener.

So multiply the number of pounds of clamping force by the number of studs and that's how many pounds they can hold back before the stud ever "sees" any force at all from your heads. That's why torquing the proper amount to a certain pretension is so important. If one is loose, that one won't be helping so you don't get to multiply it in with the others so it can cause another to fail which can cause a domino effect.

I'm not even getting into the thread shear area which has to be calculated into this when thread depths are more shallow or when a weaker material is used on one side of the connection (aluminum block). This is where a finer thread pitch can help, it otherwise has little effect on anything. Suffice to say that you are OK with an aluminum head at the above torques as long as you have at least 21/32" or so of FULL thread engagment.

Anyway,

back to shopping for stud material at McMaster. I can only seem to find up to 170,000 tensile and I'm too lazy to do more calculations right now so, I guess I'm buying stainless header studs from McMaster first.

And yes, I'm a huge lurker.