Is this a no-no? turbo mount pics inside

#1

TECH Regular

Thread Starter

iTrader: (21)

Join Date: Feb 2009

Posts: 465

Likes: 0

Received 0 Likes

on

0 Posts

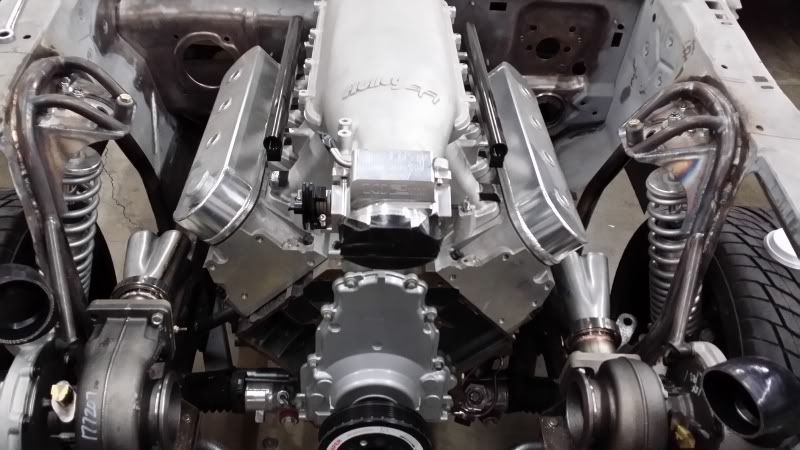

Was told by another member that using the compressor bolts for mounting isn't a good idea. Kinda makes since now that I think of it. Anyone have some input? Thanks

#4

9 Second Club

iTrader: (12)

Visualize the headers growing from thermal expansion. Ask yourself what will be the path of least resistance to that growth?

In your case, since you have the compressor housing braced at the front and back you can be fairly certain there wont be any rotation or flexing in the compressor housing. There will be stress at the connection between the compressor housing and the center cartridge (i.e. compressor housing is fixed & header is pushing turbine housing forward). At the other end of the growth, there will be stress at the elbows coming out of the header flange and at the flange bolts. I personally thing that just a support underneath the turbo to support the weight, yet still allowing the turbo to move forward thermal expansion, will be a lot easier on the turbo and the headers.

Your installation looks top notch, and it's a shame to re-do the nice supports, but I do think you are putting things in a tight bind at operating temps.

In your case, since you have the compressor housing braced at the front and back you can be fairly certain there wont be any rotation or flexing in the compressor housing. There will be stress at the connection between the compressor housing and the center cartridge (i.e. compressor housing is fixed & header is pushing turbine housing forward). At the other end of the growth, there will be stress at the elbows coming out of the header flange and at the flange bolts. I personally thing that just a support underneath the turbo to support the weight, yet still allowing the turbo to move forward thermal expansion, will be a lot easier on the turbo and the headers.

Your installation looks top notch, and it's a shame to re-do the nice supports, but I do think you are putting things in a tight bind at operating temps.

Last edited by Chevy406; 10-11-2013 at 08:36 AM.