SN95 5.3 TH400 3.27 build thread - 10.88/134.86 - NOW LQ9

#241

8 Second Truck Club

iTrader: (32)

If your looking at actual fuel consumption, aka Holley EFI in lbs./hr, then no, maximum fuel consumption is not at peak torque.

If your looking at a VE table and overlay a pull, the biggest number you hit will likely be "around" torque peak. At which point you should NOT be adding a bunch of timing as that is the point where the engine is seeing the most cylinder pressure.

If your looking at a VE table and overlay a pull, the biggest number you hit will likely be "around" torque peak. At which point you should NOT be adding a bunch of timing as that is the point where the engine is seeing the most cylinder pressure.

#242

8 Second Club

iTrader: (3)

If your looking at actual fuel consumption, aka Holley EFI in lbs./hr, then no, maximum fuel consumption is not at peak torque.

If your looking at a VE table and overlay a pull, the biggest number you hit will likely be "around" torque peak. At which point you should NOT be adding a bunch of timing as that is the point where the engine is seeing the most cylinder pressure.

If your looking at a VE table and overlay a pull, the biggest number you hit will likely be "around" torque peak. At which point you should NOT be adding a bunch of timing as that is the point where the engine is seeing the most cylinder pressure.

#243

If your looking at actual fuel consumption, aka Holley EFI in lbs./hr, then no, maximum fuel consumption is not at peak torque.

If your looking at a VE table and overlay a pull, the biggest number you hit will likely be "around" torque peak. At which point you should NOT be adding a bunch of timing as that is the point where the engine is seeing the most cylinder pressure.

If your looking at a VE table and overlay a pull, the biggest number you hit will likely be "around" torque peak. At which point you should NOT be adding a bunch of timing as that is the point where the engine is seeing the most cylinder pressure.

#245

http://www.ebay.com/itm/361297424236?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT

#246

Any chance you damaged the old alternator by spinning it too fast, and that's why it stopped working well even when you kept revs more reasonable? Or it's possible that it was just worn out.

#247

The 145a unit has been great, 13.8v minimum. Usually around 14v at WOT even with the cooling fan and meth pump going.

#248

Small update....I upgraded the cam to a later-model LS6 cam! WOW, smooth idle, no valvetrain noise....LOVE IT!

The BTR 218/223 112 lsa cam seems to have made the power up top I think, but fuel consumption between the 2 cams is identical. Looks like the LS6 cam lost 1 psi of boost pressure interestingly...not sure if that's good or bad??

The BTR 218/223 112 lsa cam seems to have made the power up top I think, but fuel consumption between the 2 cams is identical. Looks like the LS6 cam lost 1 psi of boost pressure interestingly...not sure if that's good or bad??

#249

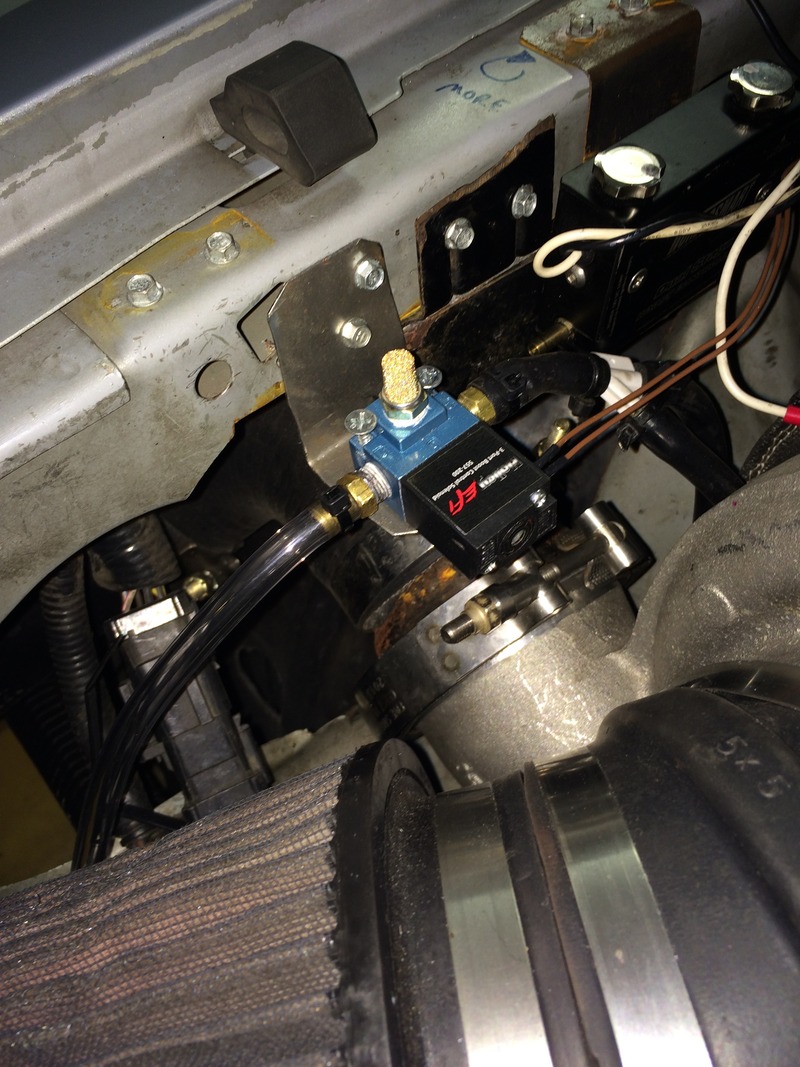

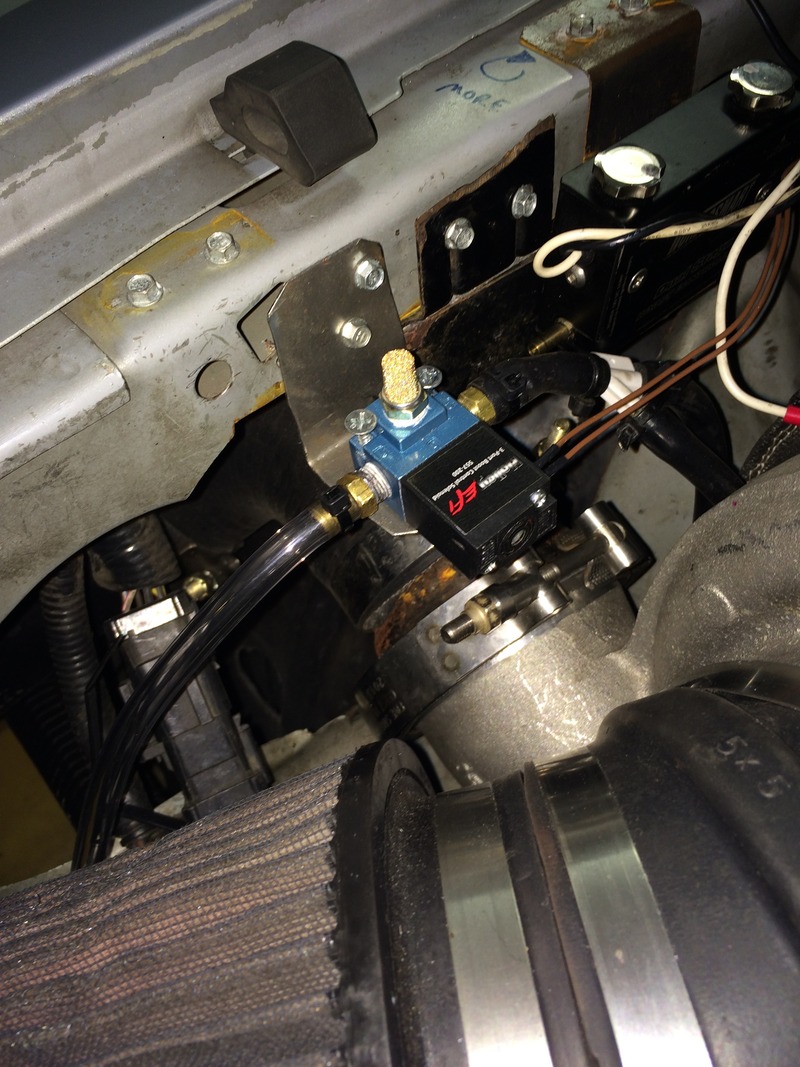

The final upgrade....

Finally got the Holley boost control working. Being that this is a HP ecu which only has 4 outputs, I already used up 3 with the elec fan meth system. I was down to 1, so I can only run 1 boost solenoid vs the more desireable 2 solenoids. Using the compressor cover as the pressure source for dome pressure. Boost vs speed is now working nicely which minimal tuning.

Running 7psi springs in the gates, 8psi in the domes yields 14psi. I could alway buy a stand alone controller for the elec fan to free-up another output and then I could go dual solenoid, but lets see how this works out after some more time.

Dam roads still have salt/dust so its real hard to try and get traction around here.

Finally got the Holley boost control working. Being that this is a HP ecu which only has 4 outputs, I already used up 3 with the elec fan meth system. I was down to 1, so I can only run 1 boost solenoid vs the more desireable 2 solenoids. Using the compressor cover as the pressure source for dome pressure. Boost vs speed is now working nicely which minimal tuning.

Running 7psi springs in the gates, 8psi in the domes yields 14psi. I could alway buy a stand alone controller for the elec fan to free-up another output and then I could go dual solenoid, but lets see how this works out after some more time.

Dam roads still have salt/dust so its real hard to try and get traction around here.

#252

#253

Upper are UPR double adjustable. Lowers are UMI adjustable, but they have the helm joint on one end that is already worn out after ~2000-3000 miles and pops. This I'm not happy about and from what I'm reading is normal??? Debating on replacing the joints OR replacing the entire LCA with something with regular poly ends on both ends.

#254

TECH Resident

Upper are UPR double adjustable. Lowers are UMI adjustable, but they have the helm joint on one end that is already worn out after ~2000-3000 miles and pops. This I'm not happy about and from what I'm reading is normal??? Debating on replacing the joints OR replacing the entire LCA with something with regular poly ends on both ends.

Is this from our crappy PA roads/poor quality heim ends or just running solid ends on the street period? Love your build! And X2 on the salt and gravel. I can't wait for this crap to wash away. Come on rain!

#255

Launching!

I use Maximum Motorsports lower control arms with spherical bearings at both ends, on a purely street-driven car, and haven't had any problems with popping or clunking. I don't know whether UMI uses a lower-quality bearing, or whether your conditions are just harsher than mine (probably!).

One thing you might want to check when you take the control arms off is whether the bolt that goes through the axle end of the control arm is the correct diameter for the bearing. For the '99-04 era cars, Ford switched to a larger (14mm, up from 12mm) diameter bolt for the lower control arms. If you are using the smaller diameter pre-'99 bolt in a control arm intended for a later model year, the bolt is 2mm undersized and may contribute to clunking.

One thing you might want to check when you take the control arms off is whether the bolt that goes through the axle end of the control arm is the correct diameter for the bearing. For the '99-04 era cars, Ford switched to a larger (14mm, up from 12mm) diameter bolt for the lower control arms. If you are using the smaller diameter pre-'99 bolt in a control arm intended for a later model year, the bolt is 2mm undersized and may contribute to clunking.

#256

I use Maximum Motorsports lower control arms with spherical bearings at both ends, on a purely street-driven car, and haven't had any problems with popping or clunking. I don't know whether UMI uses a lower-quality bearing, or whether your conditions are just harsher than mine (probably!).

One thing you might want to check when you take the control arms off is whether the bolt that goes through the axle end of the control arm is the correct diameter for the bearing. For the '99-04 era cars, Ford switched to a larger (14mm, up from 12mm) diameter bolt for the lower control arms. If you are using the smaller diameter pre-'99 bolt in a control arm intended for a later model year, the bolt is 2mm undersized and may contribute to clunking.

One thing you might want to check when you take the control arms off is whether the bolt that goes through the axle end of the control arm is the correct diameter for the bearing. For the '99-04 era cars, Ford switched to a larger (14mm, up from 12mm) diameter bolt for the lower control arms. If you are using the smaller diameter pre-'99 bolt in a control arm intended for a later model year, the bolt is 2mm undersized and may contribute to clunking.

#257

When you built the hot side around the stock k-member, was the routing you took the only way you could make it work? Or was there any other options?

Also, could you not fit regular truck manifolds due to the stock K?

Also, could you not fit regular truck manifolds due to the stock K?

#258

I seem to remember the truck manifolds running into a PS pump or sway bar - cant remember. The LS3 mani's were just made for this car

#259

Launching!

With the LS3 manifolds and either the UPR adapters or modified Mustang engine mounts, the collectors land very neatly between the front hoop of the K-member and the front sway bar. It really does package very well. There's plenty of room on the passenger's side of the engine if you're using the truck accessory layout, so you don't necessarily HAVE to mount the turbo up high like that, but it's by far the most logical option if you don't want to use a scavenge pump and want to run the exhaust out the back.

#260

Shoot, I was hoping I could use the stock truck manifolds. That's a bummer. Glad yall mentioned that before I welded the v-bands on this week! lol.

Edit: so if you were to do it all over again, would you have used an aftermarket k-member? Or do you see no point in an aftermarket K for this setup in the SN95 platform?

Edit: so if you were to do it all over again, would you have used an aftermarket k-member? Or do you see no point in an aftermarket K for this setup in the SN95 platform?

Last edited by NateLS1Mustang; 03-07-2016 at 06:38 PM.