Anybody go over 80psi with a holley dominator 12-1800 twin pump?

#26

9 Second Club

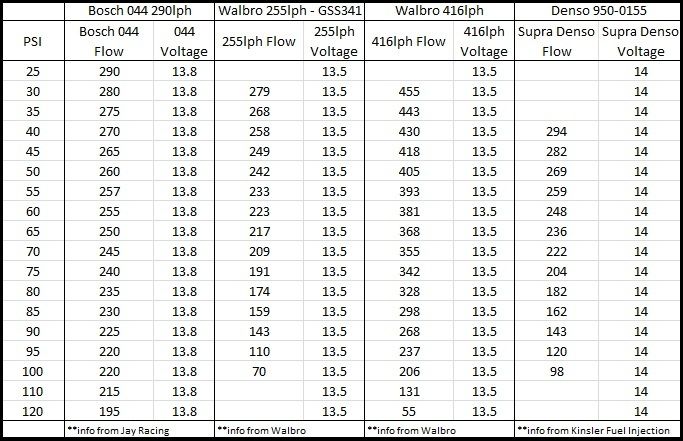

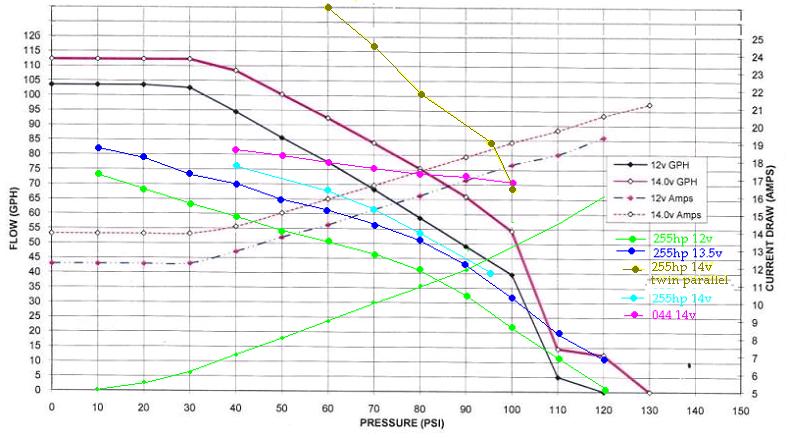

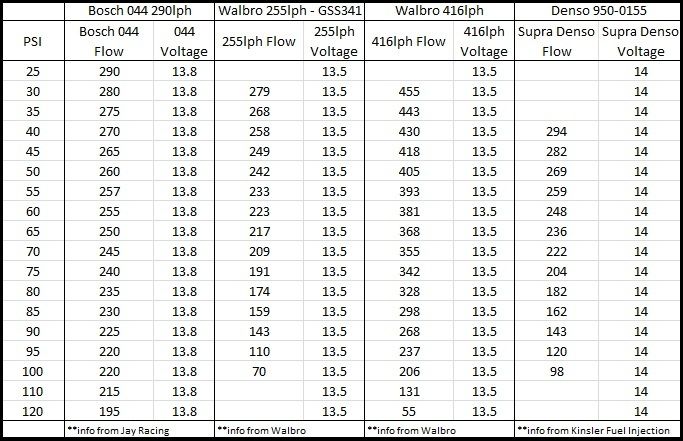

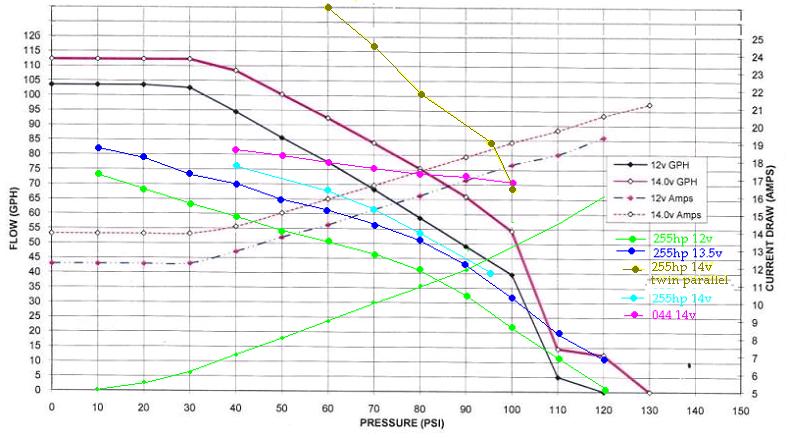

The new 400 series walbros blow the 044 pumps away until you hit 100psi. Even at 95psi they flow more according to this chart. (looks like they are testing it at less voltage too?) The 450lph walbros made for E85 may flow even more at 100 psi I can't find a chart for them.

They are also quieter, cost less, and are made for E85. IMO 2 450walbros would be the way to go.

The flow is not linear and drops rapidly with pressure... At random spots too it seems...

They are also quieter, cost less, and are made for E85. IMO 2 450walbros would be the way to go.

The flow is not linear and drops rapidly with pressure... At random spots too it seems...

What the graphs show, and from various test sources it seems, is that up to 80psi the bigger Walbro's perform better. Great for low boost or n/a engines. Would I trust them on a higher boost engine ? maybe not.

But Ive seen various flow tests and the difference isnt as marked as those results show. But yes at lower pressures the bigger Walbro's do flow more. What the graph doesnt show, is that even at normal n/a pressures, the bigger Walbros pull huge amounts of current. None can be considered drop in due to this, as wiring and connectors would need upgraded for each pump. An 044 can draw some 10-12A depending on pressure, but the bigger Walbro's are easily 50+% more.

What does seem baffling is that the 044 has been around for some 20-30 years, it's design has not changed, and as far as I can see, it is pretty much still one of the best pumps available, and as long as it's genuine Bosch 100% reliable.

#27

8 Second Club

iTrader: (4)

Still, even losing 52% the 400 series still puts out more GPH than the 044. So why is that an issue? I could see if your pushing 90-100psi going with the 044's. But most aren't even hitting 75psi total pressure and the 400's flow 100LPH+ more at that pressure than the 044. So by running 2 400's at "normal" pressures you'd have an additional 200lph+ from the walbros.

#28

What the graphs show, and from various test sources it seems, is that up to 80psi the bigger Walbro's perform better. Great for low boost or n/a engines. Would I trust them on a higher boost engine ? maybe not.

But Ive seen various flow tests and the difference isnt as marked as those results show. But yes at lower pressures the bigger Walbro's do flow more. What the graph doesnt show, is that even at normal n/a pressures, the bigger Walbros pull huge amounts of current. None can be considered drop in due to this, as wiring and connectors would need upgraded for each pump. An 044 can draw some 10-12A depending on pressure, but the bigger Walbro's are easily 50+% more.

What does seem baffling is that the 044 has been around for some 20-30 years, it's design has not changed, and as far as I can see, it is pretty much still one of the best pumps available, and as long as it's genuine Bosch 100% reliable.

But Ive seen various flow tests and the difference isnt as marked as those results show. But yes at lower pressures the bigger Walbro's do flow more. What the graph doesnt show, is that even at normal n/a pressures, the bigger Walbros pull huge amounts of current. None can be considered drop in due to this, as wiring and connectors would need upgraded for each pump. An 044 can draw some 10-12A depending on pressure, but the bigger Walbro's are easily 50+% more.

What does seem baffling is that the 044 has been around for some 20-30 years, it's design has not changed, and as far as I can see, it is pretty much still one of the best pumps available, and as long as it's genuine Bosch 100% reliable.

#29

8 Second Club

iTrader: (16)

theres nothing baffling about why the 400 flows so much and why the flow drops like it does..

it has a bigger inlets and outlet...more area inside its internal passageways for fuel to flow to begin with...

when you finally get to its total flow potential and it has to build pressure you will see a drop related to all of its components (including fluid friction )

it can all be explained by the Bernoulli equation, and by the conservation of energy...both apply here... Bernoulli equation is for conservation of energy in a steady flow system...our fuel systems are "close enough"

the point at 30psi where it takes a turn and starts decresing in flow is where Total velocity has been reached based on the inlet and outlet...the Kinetic energy has reached its maximum for the pump...

from that point on, as pressure increases, the GPH flow will decrease...

and at 100 psi when it changes course again, is where the pump is just out of poop all together....likely it cant overcome the friction of the fuel at pressures above that.

it has a bigger inlets and outlet...more area inside its internal passageways for fuel to flow to begin with...

when you finally get to its total flow potential and it has to build pressure you will see a drop related to all of its components (including fluid friction )

it can all be explained by the Bernoulli equation, and by the conservation of energy...both apply here... Bernoulli equation is for conservation of energy in a steady flow system...our fuel systems are "close enough"

the point at 30psi where it takes a turn and starts decresing in flow is where Total velocity has been reached based on the inlet and outlet...the Kinetic energy has reached its maximum for the pump...

from that point on, as pressure increases, the GPH flow will decrease...

and at 100 psi when it changes course again, is where the pump is just out of poop all together....likely it cant overcome the friction of the fuel at pressures above that.