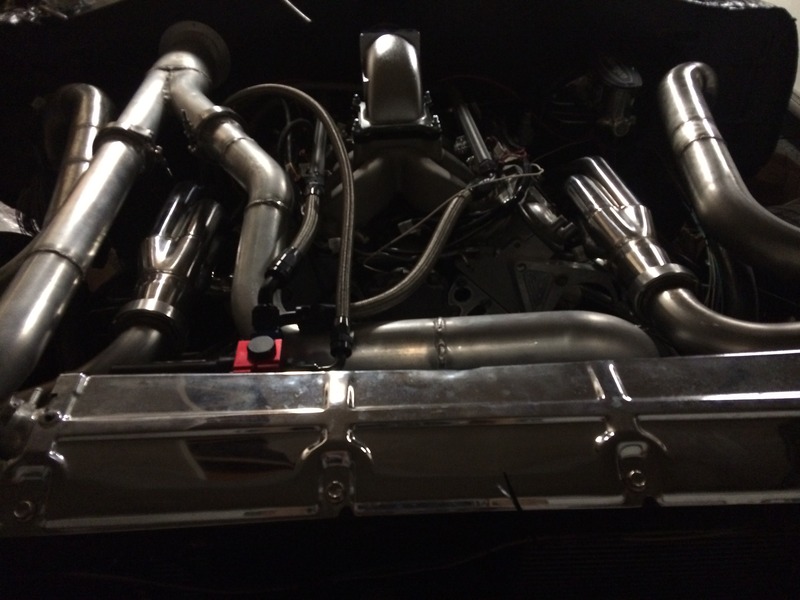

Twin Turbo LSX Datsun 280Z

#1201

Man it looks like you have a little positive camber. That goes a long way when you load the rear.

Having the right combination of facny parts helps too. A glide and an AMS 1000 on a slow ramp is likley the best case scenario anyone could ask for....but its not realistic for 99% of the people that would race in a street enviroment. still really stong info-the feathering is a serious issue with my Mickeys and my rear end is not stong enough to do a burnout every time I take the car ou to seek traction!

A glide and an AMS 1000 on a slow ramp is likley the best case scenario anyone could ask for....but its not realistic for 99% of the people that would race in a street enviroment. still really stong info-the feathering is a serious issue with my Mickeys and my rear end is not stong enough to do a burnout every time I take the car ou to seek traction!

Having the right combination of facny parts helps too.

A glide and an AMS 1000 on a slow ramp is likley the best case scenario anyone could ask for....but its not realistic for 99% of the people that would race in a street enviroment. still really stong info-the feathering is a serious issue with my Mickeys and my rear end is not stong enough to do a burnout every time I take the car ou to seek traction!

A glide and an AMS 1000 on a slow ramp is likley the best case scenario anyone could ask for....but its not realistic for 99% of the people that would race in a street enviroment. still really stong info-the feathering is a serious issue with my Mickeys and my rear end is not stong enough to do a burnout every time I take the car ou to seek traction!

#1202

Trucks gonna roll out pretty hard if I can get it back together.

#1203

#1204

Thanks I don't really know much. I just test a **** ton on the street rolling vbox stuff. As you can see lots of bare road lol

Use the mickey on the track, that is where they are designed to work and they work very well.

Honestly still can't believe the life the nitto have offered compared to the mickey.

The tread is always like this, absolutely no feathering like the mickey

Just a little tire though, I run them on a 9" weld.

Honest to god truth the mickey go from amazing g to marbles in zero time when they feather under heavy power and breaking traction.... Too soft

The nitto break traction in a strange way too. They rumble on my car, very noticeable

With no air applied to the gate it makes 4psi of boost. 22psi on gate makes 22psi of boost. Past that the compressor is dying. 31 on the gate makes 25 at 6k and down to 23 by 7k

So in that vid... I go wot with no air on the gate... You can see it ride 4psi..... You then see me arm the ams1000 and it does the commanded ramp. I let it ride 4psi for a second so it can be seen what is happening.

I will take a pic of my actual ramp timing and pressures

Here is another vid same thing. To show u the roads are. Nothing special and plain asphalt

But the nitto is a God send for a street tire. IF you know how to use it. My mickeys will never touch the street again

Nitto 555r vbox roll in. 3.4 100-150, 4.1 60-130 - YouTube

I have never used the nt05

Use the mickey on the track, that is where they are designed to work and they work very well.

Honestly still can't believe the life the nitto have offered compared to the mickey.

The tread is always like this, absolutely no feathering like the mickey

Just a little tire though, I run them on a 9" weld.

Honest to god truth the mickey go from amazing g to marbles in zero time when they feather under heavy power and breaking traction.... Too soft

The nitto break traction in a strange way too. They rumble on my car, very noticeable

With no air applied to the gate it makes 4psi of boost. 22psi on gate makes 22psi of boost. Past that the compressor is dying. 31 on the gate makes 25 at 6k and down to 23 by 7k

So in that vid... I go wot with no air on the gate... You can see it ride 4psi..... You then see me arm the ams1000 and it does the commanded ramp. I let it ride 4psi for a second so it can be seen what is happening.

I will take a pic of my actual ramp timing and pressures

Here is another vid same thing. To show u the roads are. Nothing special and plain asphalt

But the nitto is a God send for a street tire. IF you know how to use it. My mickeys will never touch the street again

Nitto 555r vbox roll in. 3.4 100-150, 4.1 60-130 - YouTube

I have never used the nt05

Excellent info as usual and

#1205

With no air applied to the gate it makes 4psi of boost. 22psi on gate makes 22psi of boost. Past that the compressor is dying. 31 on the gate makes 25 at 6k and down to 23 by 7k

So in that vid... I go wot with no air on the gate... You can see it ride 4psi..... You then see me arm the ams1000 and it does the commanded ramp. I let it ride 4psi for a second so it can be seen what is happening.

I will take a pic of my actual ramp timing and pressures

Last edited by Forcefed86; 12-03-2015 at 12:50 PM.

#1207

Originally Posted by Forcefed86

How do you have the boost ramp rate setup for the track? Are you "all in" by 100 mph or so?

Last edited by oscs; 12-03-2015 at 05:21 PM.

#1208

Originally Posted by Blown06

What kind of fuel flow numbers are you seeing at the top of high gear?

Last edited by oscs; 12-03-2015 at 05:38 PM.

#1209

Its funny to watch his run- boost gauge stays pegged the whole time- and me with a 6 speed its bouncing around the whole pass like

#1210

Yeah sweet sticker, have to have it I'm an idiot lol

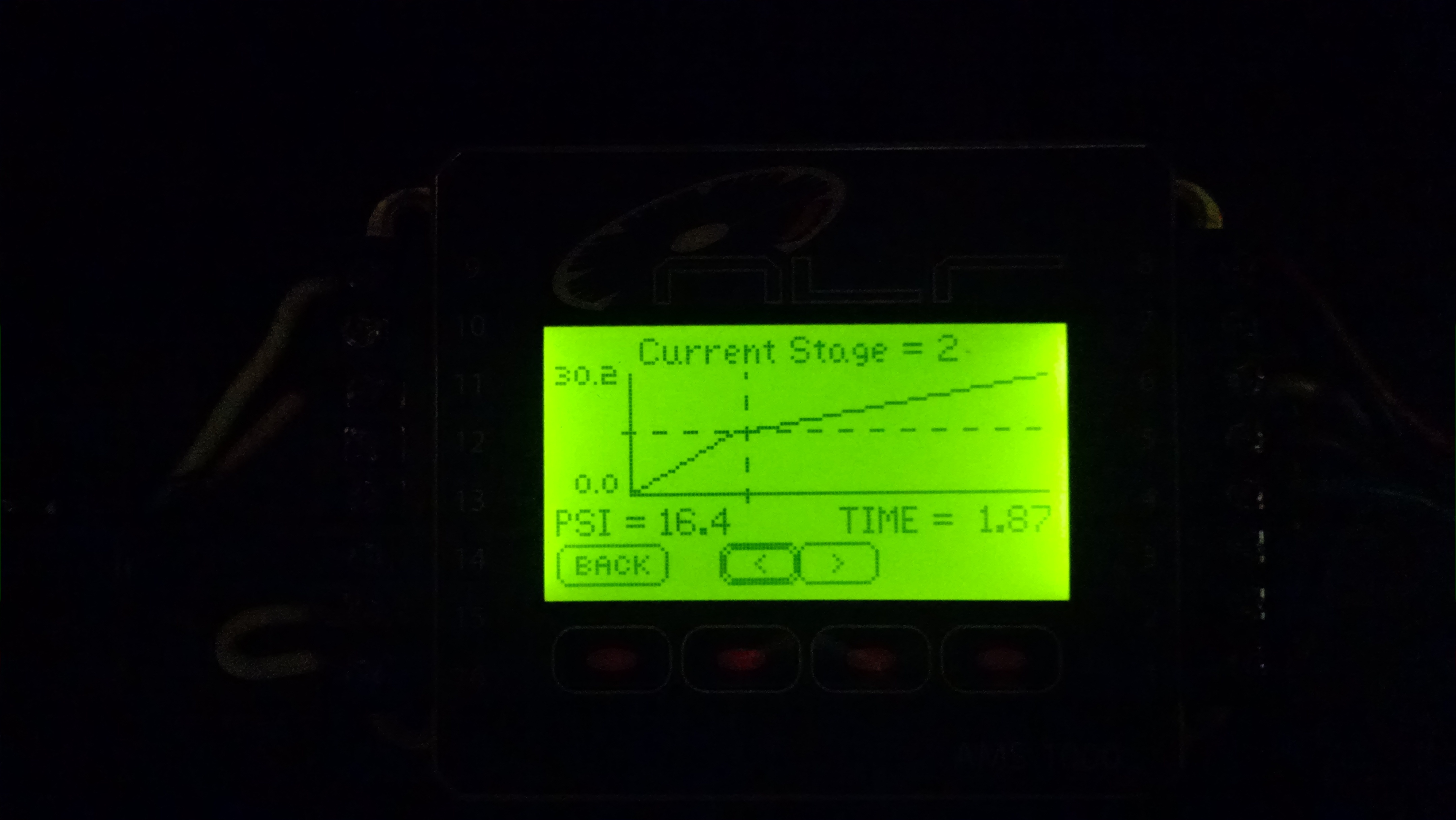

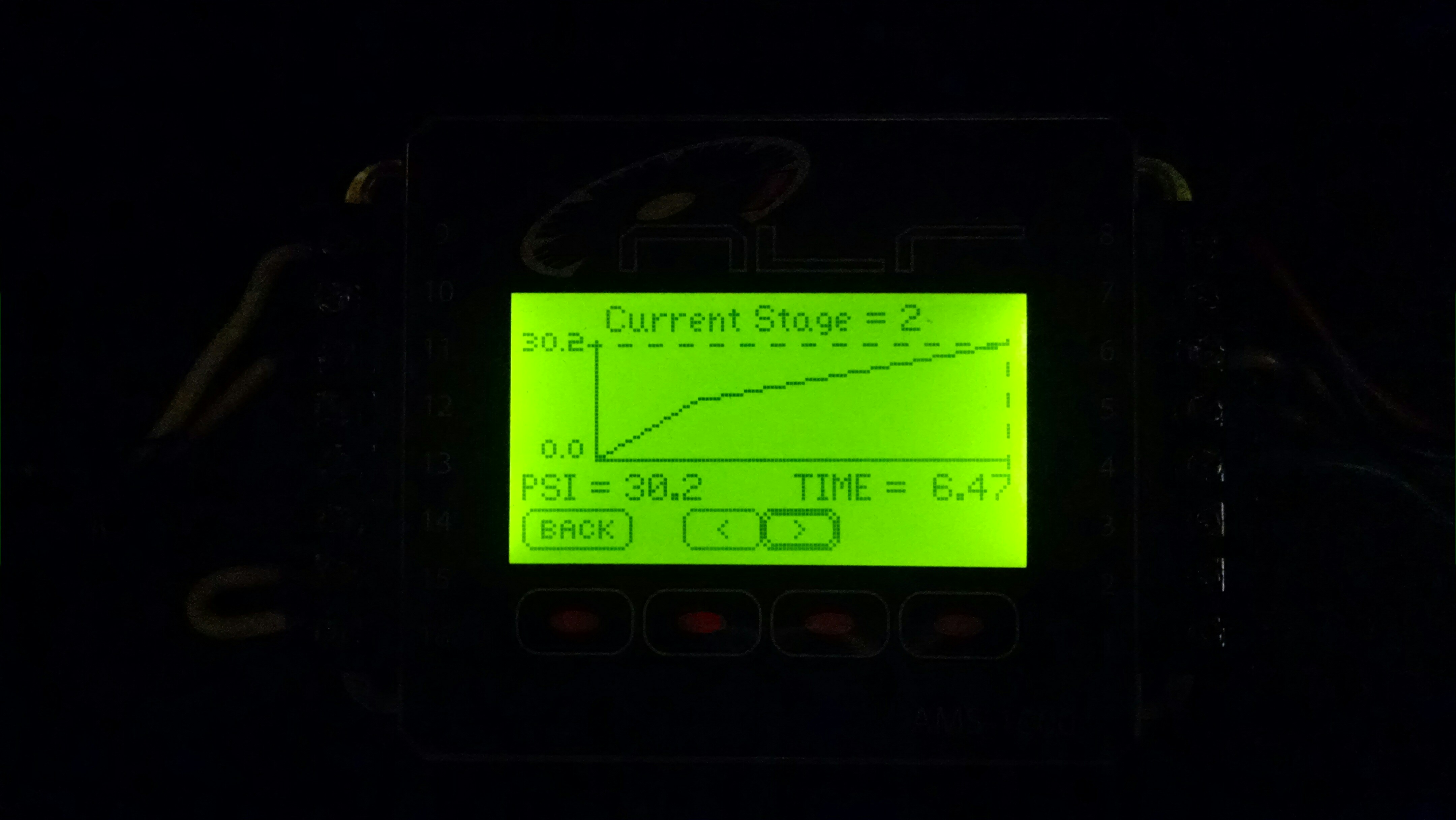

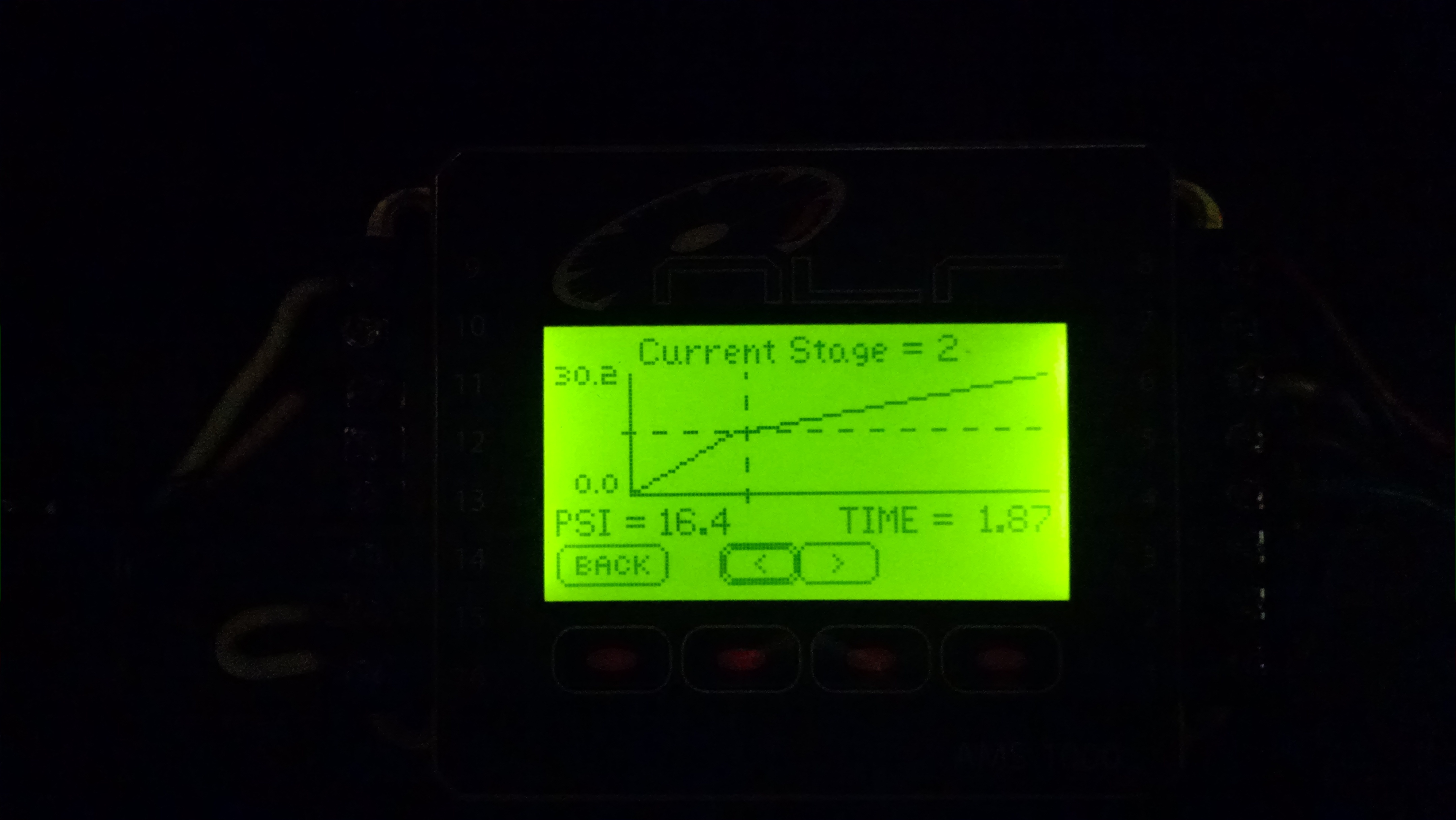

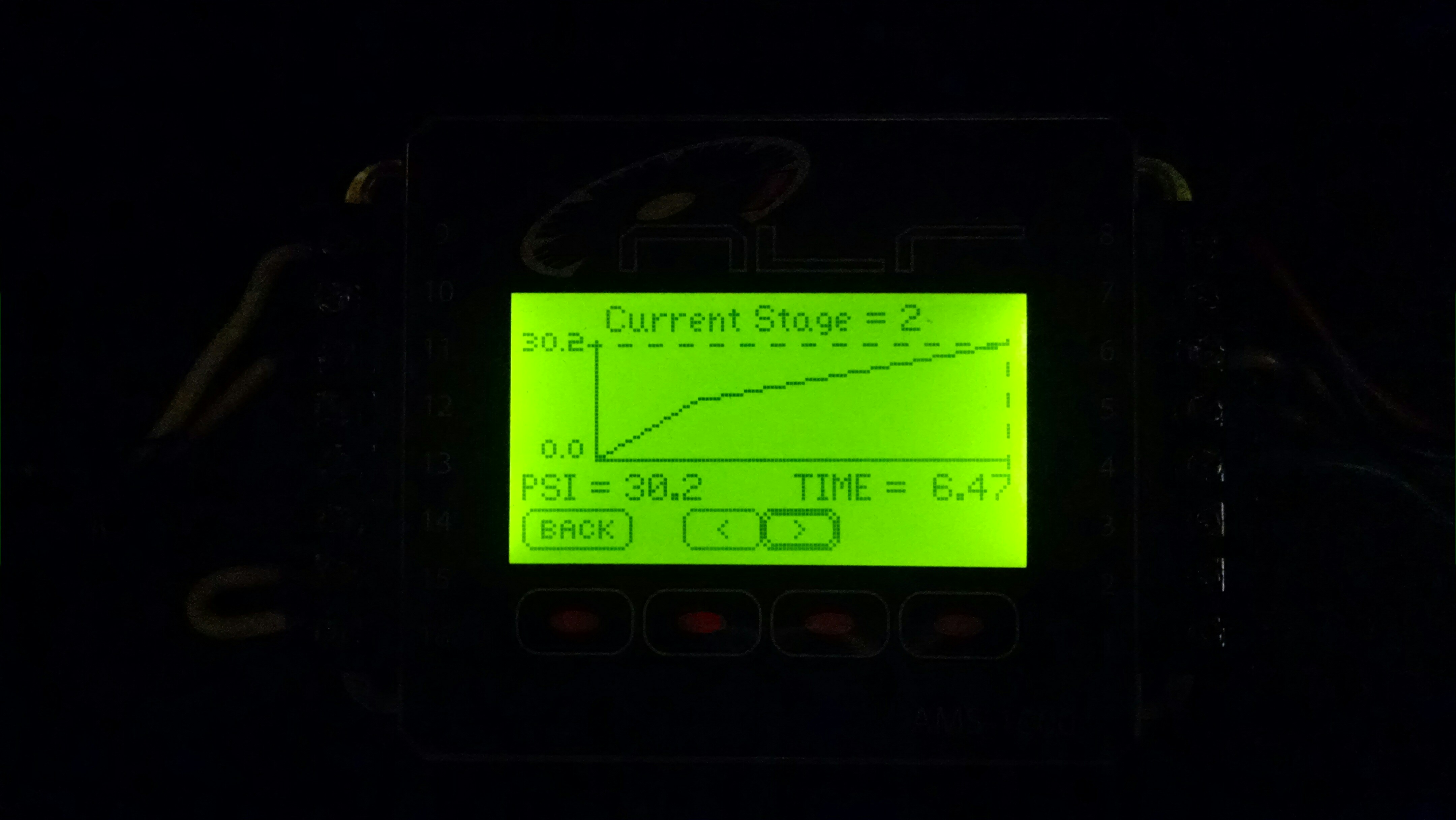

Here is the controller setup on the street. It's hitting full boost faster that 6.4 because the turbo dies up top. Beyond 22 on the gate the boost increases very slowly till its just done all together then drops

It's peaking around 115 on street

At the track I run a single stage time based.

On 8.50 pass i left on 6psi, it was 1.8 seconds (50mph) to full boost (21psi)

Here is the controller setup on the street. It's hitting full boost faster that 6.4 because the turbo dies up top. Beyond 22 on the gate the boost increases very slowly till its just done all together then drops

It's peaking around 115 on street

At the track I run a single stage time based.

On 8.50 pass i left on 6psi, it was 1.8 seconds (50mph) to full boost (21psi)

#1212

I don't have the best data in the world (spinning) but in high gear around 6400rpm it was flowing right around 1300 lb/hr of E85 so what is that translate to 1050 CHP or something? That was at 26lbs of boost. I'm pretty sure this was the hit that the rocker bolt back out on. I'll get much more clean data at the track Saturday.

#1213

I see you start at "0" have you considered or tried to start at spring pressure? Your track ramp rate looks like my street rate

#1214

Using .80 on the scale that brings the car up to an estimated 1050 CHP.. I know conditions are not perfect but i expected to see Consumption numbers higher than that at that RPM range. BUT im far from an expert so i could be wrong?

#1216

Originally Posted by rotary1307cc

1300lb/hr at .80bsfc is 1625hp

Last edited by oscs; 12-04-2015 at 11:09 AM.

#1217

This was around 1200rwhp on my car..... stock crank, Compstar rods. Single 88mm T4.

It was only held together by the flywheel/trans and the 2 rods clamping the journal together.

Luckily mine didn't really damage anything as the motor shut down due to loss of reluctor wheel signal I'm guessing.

You should build a motor before nothing is useable once that grenades.

It was only held together by the flywheel/trans and the 2 rods clamping the journal together.

Luckily mine didn't really damage anything as the motor shut down due to loss of reluctor wheel signal I'm guessing.

You should build a motor before nothing is useable once that grenades.

#1218

Originally Posted by gnx7

This was around 1200rwhp on my car..... stock crank, Compstar rods. Single 88mm T4.

It was only held together by the flywheel/trans and the 2 rods clamping the journal together.

Luckily mine didn't really damage anything as the motor shut down due to loss of reluctor wheel signal I'm guessing.

You should build a motor before nothing is useable once that grenades.

It was only held together by the flywheel/trans and the 2 rods clamping the journal together.

Luckily mine didn't really damage anything as the motor shut down due to loss of reluctor wheel signal I'm guessing.

You should build a motor before nothing is useable once that grenades.