Anyone use exhaust pressure to control WG?

#1

Having an issue with my WG setup.

With my manual BC turned all the way down (no boost going to the top port on WG) I can't get the boost under 16psi. This is too much for the street and I just spin. If I drop the WG spring pressure I can make less boost, though I can't make the 20-25psi I want at the track.

Instead of a costly c02 and a electronic controller, I was thinking of running the top port of the WG to the exhaust manifold and using exhaust pressure. This should allow me to run a much smaller spring for street driving. I already have a large coil of copper tubing plumbed to my exh to measure back pressure. I'd like to "T" into this and run it through the manual boost controller (pneumatic valve on the dash) and then to the top port of the WG. Should give me more than enough pressure.

I think the carbon and dirty exhaust gas will gum up my pneumatic valve/manual boost controller. Also not excited about getting sooty exh gas in the WG chamber. Any ideas on a kind of filter I could run? I do run E85 so it's not as bad as pump gas. What kind of of inline filter could hold up and not get all gummed up? Maybe a small pressure pot chamber with filter media of some sort stuffed in it?

Any ideas?

With my manual BC turned all the way down (no boost going to the top port on WG) I can't get the boost under 16psi. This is too much for the street and I just spin. If I drop the WG spring pressure I can make less boost, though I can't make the 20-25psi I want at the track.

Instead of a costly c02 and a electronic controller, I was thinking of running the top port of the WG to the exhaust manifold and using exhaust pressure. This should allow me to run a much smaller spring for street driving. I already have a large coil of copper tubing plumbed to my exh to measure back pressure. I'd like to "T" into this and run it through the manual boost controller (pneumatic valve on the dash) and then to the top port of the WG. Should give me more than enough pressure.

I think the carbon and dirty exhaust gas will gum up my pneumatic valve/manual boost controller. Also not excited about getting sooty exh gas in the WG chamber. Any ideas on a kind of filter I could run? I do run E85 so it's not as bad as pump gas. What kind of of inline filter could hold up and not get all gummed up? Maybe a small pressure pot chamber with filter media of some sort stuffed in it?

Any ideas?

#5

8 Second Club

iTrader: (19)

#6

For simplicity sake, I love the manual boost **** on the dash. Very easy to dial in, no wiring, controllers, or guessing with noid duty cycles etcÖ. Iím sure this will work. I just donít think it will work for long without some sort of good filter. I donít have a clue how fine of a filter or what type I would need to filter exh soot/carbon. The pressure sending unit I used to measure back pressure was full of soot. Was thinking Iíd try a standard inline fuel filter? They filter down to 5-7 micron. Iím worried this will just clogg in short order though. May need some sort of staged filter media. Was hoping to find something cheap and pre-madeÖ

Both ports are plumbed to the intake, the top port goes through the regulator and is adjustable in the cab.

A lot of diesel guys do this, works well. Also OP when I setup my system to check BP on my 7.3 I was getting a lot of soot clogging my guage. I was told to utilize the coils on the copper tubing (don't make a straight line to the gate or guage) I never had a problem afterwords. You will however have to make it a habit of cleaning the system. If you get time hop on a few diesel forums there is a wealth of information on what you are trying to do.

Quick example here:

http://www.thedieselgarage.com/forum...ad.php?t=73200

Quick example here:

http://www.thedieselgarage.com/forum...ad.php?t=73200

My backpressure setup is coiled. About 4 coils 7Ē in diameter before I go into my gauge. (tiny copper gauge line)

Last edited by Forcefed86; 05-21-2014 at 09:14 AM.

#7

Just do it with air. It would be right up your alley

It would just as variable as an ams or leash... just have to change manually

Just need a tank and 10 dollar regulator. Just change the regulator pressure to control dome pressure

It would just as variable as an ams or leash... just have to change manually

Just need a tank and 10 dollar regulator. Just change the regulator pressure to control dome pressure

Trending Topics

#8

TECH Fanatic

iTrader: (18)

I donít think my setup will handle all the boost this turbo will put outÖ I think if I put 100% of the exhaust pressure to the top port it would over boost. 20ish psi is my goal at the moment. New billet 76 with larger exh housing and wheel is on the way. So I donít want to pin the gate shut.

For simplicity sake, I love the manual boost **** on the dash. Very easy to dial in, no wiring, controllers, or guessing with noid duty cycles etcÖ. Iím sure this will work. I just donít think it will work for long without some sort of good filter. I donít have a clue how fine of a filter or what type I would need to filter exh soot/carbon. The pressure sending unit I used to measure back pressure was full of soot. Was thinking Iíd try a standard inline fuel filter? They filter down to 5-7 micron. Iím worried this will just clogg in short order though. May need some sort of staged filter media. Was hoping to find something cheap and pre-madeÖ

Both ports are plumbed to the intake, the top port goes through the regulator and is adjustable in the cab.

Thanks! Iíll look into that.

Thank!

My backpressure setup is coiled. About 4 coils 7Ē in diameter before I go into my gauge. (tiny copper gauge line)

For simplicity sake, I love the manual boost **** on the dash. Very easy to dial in, no wiring, controllers, or guessing with noid duty cycles etcÖ. Iím sure this will work. I just donít think it will work for long without some sort of good filter. I donít have a clue how fine of a filter or what type I would need to filter exh soot/carbon. The pressure sending unit I used to measure back pressure was full of soot. Was thinking Iíd try a standard inline fuel filter? They filter down to 5-7 micron. Iím worried this will just clogg in short order though. May need some sort of staged filter media. Was hoping to find something cheap and pre-madeÖ

Both ports are plumbed to the intake, the top port goes through the regulator and is adjustable in the cab.

Thanks! Iíll look into that.

Thank!

My backpressure setup is coiled. About 4 coils 7Ē in diameter before I go into my gauge. (tiny copper gauge line)

How do you currently have your mbc hooked up!?

#10

I kinda like the idea of using the pressure already built up in the exhaust. That way I wouldn’t need the added weight of tanks/pumps, hassle of filling it, or added electronics. I’m sure it would work great but I’m trying to cut weight and keep things simple.

I'm not asking you to use exhaust or 100% dc. Use manifold. pressure. A four port solenoid will allow you to use a lower spring but get higher boost. You could figure out the DC for 20 psi and put it on a switch for the track.

How do you currently have your mbc hooked up!?

How do you currently have your mbc hooked up!?

Plumbed like so... Are you suggesting I could put a lighter spring in and pull/plug the bottom port. Or close it off with the solenoid? how is the 4 port thing relevant. How would i route the 4 ports on the diagram below?

-thanks

No spring, I use a regulator and both ports.

Last edited by Forcefed86; 05-21-2014 at 10:06 AM.

#13

There is no need for any electronics or solenoids

If you want just single stage control the plumbing would look identical to what u pictured just no check valve and it is hooked to the air supply instead of the exhaust

Want 5psi on the dome....adjust the regulator to 5psi... it is always there, it won't leak on the top half of the dome

Want 15 psi on the dome put 15 on it.

You just have an infinitely variable spring is all. Plumbed like that there is no air consumption

With two regulators, a check valve, and orifice, and single solenoid you can have a dual stage controller and variable ramp from one stage to the other... like a cheap ams500

.

If you want just single stage control the plumbing would look identical to what u pictured just no check valve and it is hooked to the air supply instead of the exhaust

Want 5psi on the dome....adjust the regulator to 5psi... it is always there, it won't leak on the top half of the dome

Want 15 psi on the dome put 15 on it.

You just have an infinitely variable spring is all. Plumbed like that there is no air consumption

With two regulators, a check valve, and orifice, and single solenoid you can have a dual stage controller and variable ramp from one stage to the other... like a cheap ams500

.

#14

There is no need for any electronics or solenoids

If you want just single stage control the plumbing would look identical to what u pictured just no check valve and it is hooked to the air supply instead of the exhaust

Want 5psi on the dome....adjust the regulator to 5psi... it is always there, it won't leak on the top half of the dome

Want 15 psi on the dome put 15 on it.

You just have an infinitely variable spring is all. Plumbed like that there is no air consumption

With two regulators, a check valve, and orifice, and single solenoid you can have a dual stage controller and variable ramp from one stage to the other... like a cheap ams500

.

If you want just single stage control the plumbing would look identical to what u pictured just no check valve and it is hooked to the air supply instead of the exhaust

Want 5psi on the dome....adjust the regulator to 5psi... it is always there, it won't leak on the top half of the dome

Want 15 psi on the dome put 15 on it.

You just have an infinitely variable spring is all. Plumbed like that there is no air consumption

With two regulators, a check valve, and orifice, and single solenoid you can have a dual stage controller and variable ramp from one stage to the other... like a cheap ams500

.

Ah, I’m pick’n up what your put’n down. Assuming I have no leaking pressure on the fancy china gate I could see that working well.

I’ll put in a lighter spring and block the bottom signal then see what applying all the boost to the top port alone gets me. If that works I’ll put a vac noid I can control in the cab on the lower port.

I think most isolators work with a liquid on one end? I guess you could use that on a WG upper chamber, may boil or something weird though. Unless there is some sort of "air isolator" I’m unaware of?

Last edited by Forcefed86; 05-21-2014 at 11:46 AM.

#15

9 Second Club

Exactly what are you trying to achieve ?

Simply more boost ? Lots of boost pressure options ? Other ? Just a couple of boost pressures ?

The cheapest and easiest way to obtain more boost with it plumbed exactly as you have it..

Is basically just put another valve in the bottom port line and either completely vent it, or isolate so no boost is helping blow the gate open.

Whether that's another mechanical valve or an electrical solenoid, doesnt really matter.

Whilst cheap and nasty, something like this configured correctly will be able to do the above so much easier, and give you a wide range of control when plumbed correctly. with easy adjustment in cabin.

http://www.ebay.com/itm/2013-New-HDi-electronic-boost-controller-EBC-R-universal-Turbo-Contr-0411emtr/231087869355?_trksid=p2047675.c100005.m1851&_trkparms=aid%3D222008%26algo%3DSIC.MOTORS%26ao%3D1%26asc%3D18908%26meid%3D7061967356915064530%26pid%3D100005%26prg%3D8579%26rk%3D3%26rkt%3D6%26sd%3D380899993828&rt=nc

Simply more boost ? Lots of boost pressure options ? Other ? Just a couple of boost pressures ?

The cheapest and easiest way to obtain more boost with it plumbed exactly as you have it..

Is basically just put another valve in the bottom port line and either completely vent it, or isolate so no boost is helping blow the gate open.

Whether that's another mechanical valve or an electrical solenoid, doesnt really matter.

Whilst cheap and nasty, something like this configured correctly will be able to do the above so much easier, and give you a wide range of control when plumbed correctly. with easy adjustment in cabin.

http://www.ebay.com/itm/2013-New-HDi-electronic-boost-controller-EBC-R-universal-Turbo-Contr-0411emtr/231087869355?_trksid=p2047675.c100005.m1851&_trkparms=aid%3D222008%26algo%3DSIC.MOTORS%26ao%3D1%26asc%3D18908%26meid%3D7061967356915064530%26pid%3D100005%26prg%3D8579%26rk%3D3%26rkt%3D6%26sd%3D380899993828&rt=nc

#17

9 Second Club

Really you need to be looking at an electronic controller to make this easy. Yes you probably can do it manually with more than one control valve, but it's just a lot of ******* about.

Of course on the other hand...choose the right aftermarket ecu, and you can easily run multiple boost levels without the additional cost of a controller.

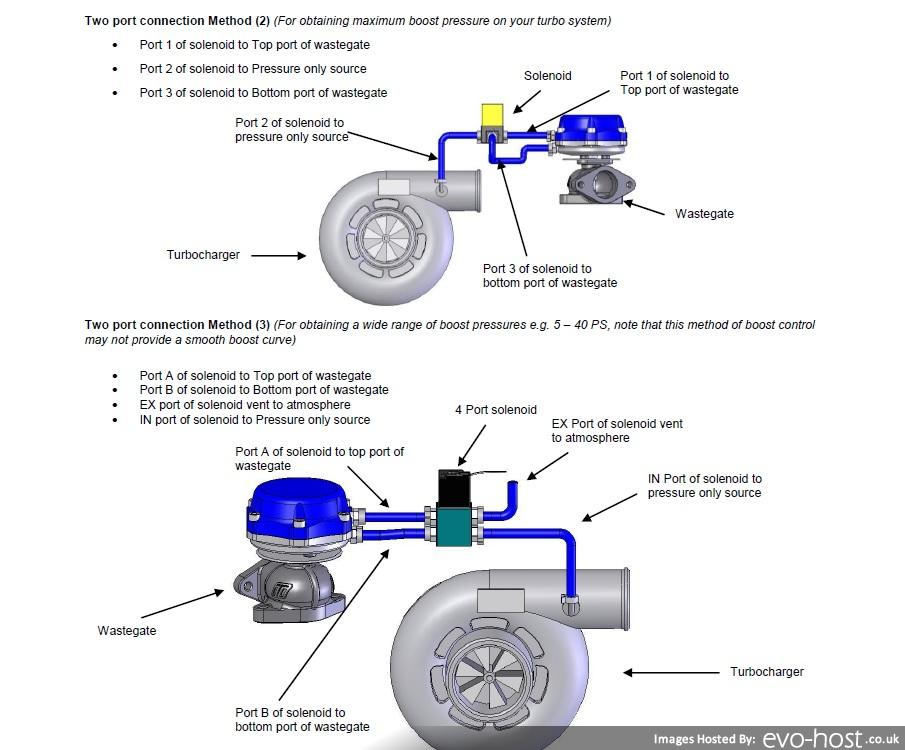

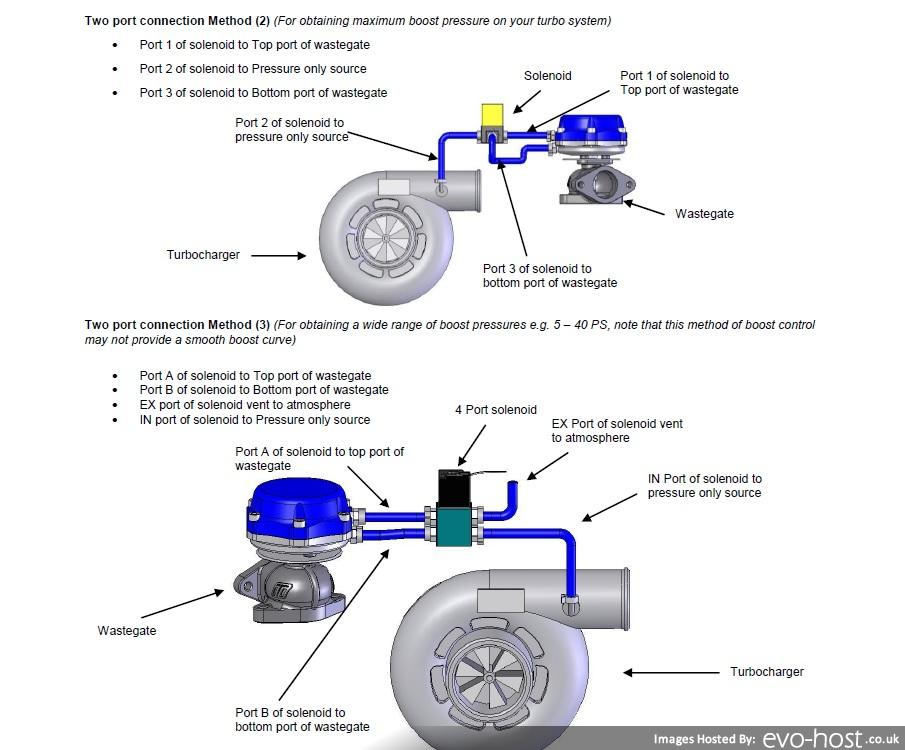

In the image below taken from Turbosmarts instructions are the two plumbing methods that will offer the widest range of control without resorting to high pressure air

Having tried and currently using the top setup using only a 3 port solenoid, it does work, albeit not quite as per instructions.

Ive only tried from base spring at 0.7bar, approx 7-8psi through 1.6 bar, approx 23psi. That is equating to 0% duty to around 50% duty at the solenoid, so there is more to go. Wont try more until I get my water/meth back working again.

Plumbing exactly as is made control around the middle very difficult. So I added a small section of hard pipe between the top chamber and solenoid and drilled a 0.9mm hole in it to vent some air.

This would almost be the same as using the 4 port solenoid method, and restricting how much air can be expelled out the vent port.

It may ultimately reduce how much pressure you can apply to the top chamber, but it would be a very very small amount. But it makes a huge difference in how easy it is to control the gate at lower boost levels.

Even the cheap egay controller I linked to would work with this, and give you 3 boost levels overall.

Controller off = spring only.

Controller at Lo = a level higher than spring of your choosing

Controller at Hi = a high level of your choosing.

But obviously more expensive controllers or ecu control can refine things a bit better and give more options.

Of course on the other hand...choose the right aftermarket ecu, and you can easily run multiple boost levels without the additional cost of a controller.

In the image below taken from Turbosmarts instructions are the two plumbing methods that will offer the widest range of control without resorting to high pressure air

Having tried and currently using the top setup using only a 3 port solenoid, it does work, albeit not quite as per instructions.

Ive only tried from base spring at 0.7bar, approx 7-8psi through 1.6 bar, approx 23psi. That is equating to 0% duty to around 50% duty at the solenoid, so there is more to go. Wont try more until I get my water/meth back working again.

Plumbing exactly as is made control around the middle very difficult. So I added a small section of hard pipe between the top chamber and solenoid and drilled a 0.9mm hole in it to vent some air.

This would almost be the same as using the 4 port solenoid method, and restricting how much air can be expelled out the vent port.

It may ultimately reduce how much pressure you can apply to the top chamber, but it would be a very very small amount. But it makes a huge difference in how easy it is to control the gate at lower boost levels.

Even the cheap egay controller I linked to would work with this, and give you 3 boost levels overall.

Controller off = spring only.

Controller at Lo = a level higher than spring of your choosing

Controller at Hi = a high level of your choosing.

But obviously more expensive controllers or ecu control can refine things a bit better and give more options.

#18

Looks like 7 days of rain in our forecast so I won't get to play with it anytime soon.

#19

9 Second Club

IMO for the low setting leave as is.

For the high setting just add another valve that you either full open to vent, or fully close on the bottom port to completely block any boost signal from assisting the spring. That will allow you a much higher high setting, as you're only blowing boost into the top chamber.

Still simple and cheap and technology free.

For the high setting just add another valve that you either full open to vent, or fully close on the bottom port to completely block any boost signal from assisting the spring. That will allow you a much higher high setting, as you're only blowing boost into the top chamber.

Still simple and cheap and technology free.

#20

IMO for the low setting leave as is.

For the high setting just add another valve that you either full open to vent, or fully close on the bottom port to completely block any boost signal from assisting the spring. That will allow you a much higher high setting, as you're only blowing boost into the top chamber.

Still simple and cheap and technology free.

For the high setting just add another valve that you either full open to vent, or fully close on the bottom port to completely block any boost signal from assisting the spring. That will allow you a much higher high setting, as you're only blowing boost into the top chamber.

Still simple and cheap and technology free.

Lots of options... just need to test them to see where I'm at.