Twin Turbo LS Boat Engine

#242

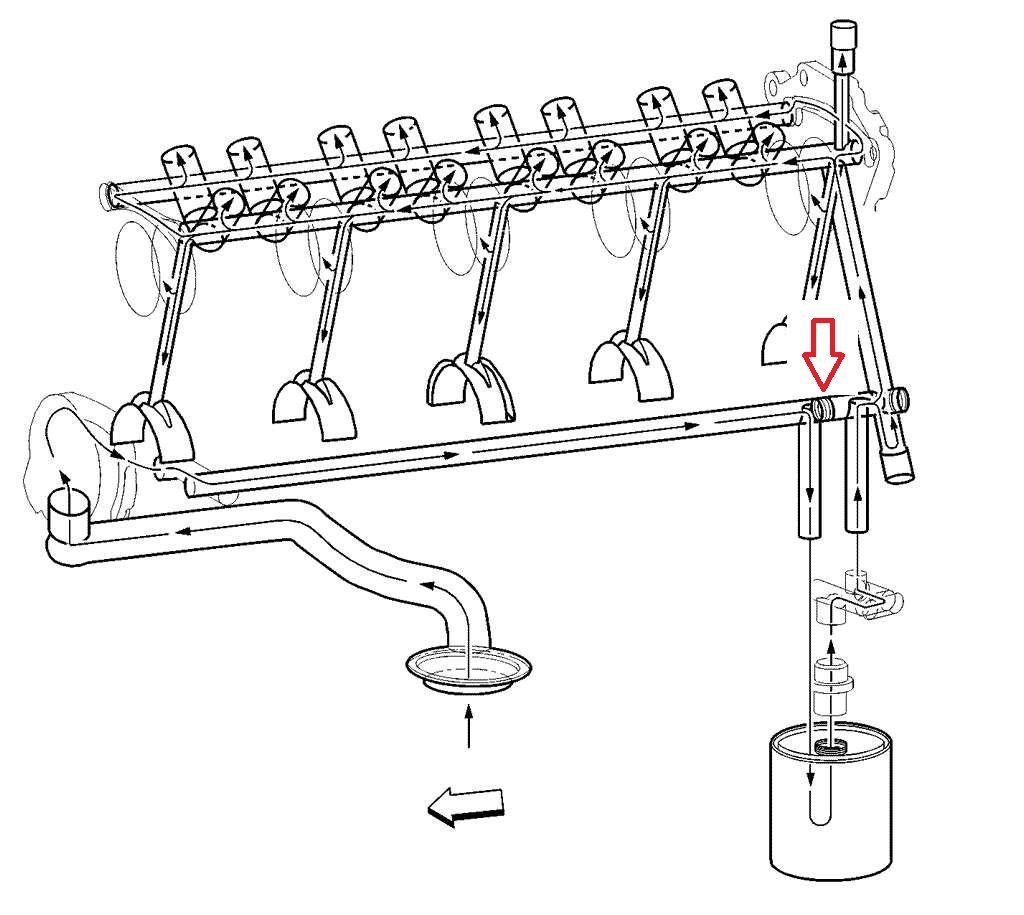

Looking at the back (flywheel end) of the engine, there is a plug in the block, bottom left. Top right if the engine is upside down. Behind that plug is the dumbbell. That oil galley is drilled the entire length of the engine and the dumbbell is a divider of sorts, blocking the passage where the oil filter taps into the galley. Without the dumbbell, oil would not flow through the oil filter and just go straight through and up to the main galley and on to all the bearings and lifters..

If you're going to attempt using the block you have, definitely pull those plugs, remove the dumbbell, clean out that passage, and put a new bumbbell in.

What oil are you using? Filter?

Last edited by SethU; 06-07-2017 at 04:26 PM.

#244

9 Second Club

I just worry about the angle the motor is on when the boat is trimmed up going hard out pulling 5500rpm or so, sump is a front hump and has to be as there is insufficient room at the back under the engine for a rear sump, although a mate runs a LS1 TT in a race boat with the same sump and never had an issue, duno why do most serious engines use dry sump? Must be good reasons

I'm certainly not steering you away from one. Fitting one will pretty much guarantee a good solid oil supply....but as yet you dont really know for sure if you did not have that.

As Seth said, you really need to log oil pressure and I'd go one further and say to use a proper ecu that can offer a safety trip if oil pressure misbehaves even the slightest bit.

That way you can protect the engine, but also get a picture of what's going on in order to resolve it.

TBH even if you go dry sump....I'd be saying to do the same, as you can also get protection against the belt failing on the dry sump setup.

At the minute you've had problems, but just do not know what the actual cause was, or when etc. It just makes it so much harder to fix.

#245

Great thanks for that. I have been using a semi synthetic high zinc penrite oil 10w 40 and just a normal ryco filter, I will talk to the builder about the dumbell and cleaning. When I got the last tune done I asked tuner about data logging, he said my ecu was capable but I needed to invest quite a bit into buying the extra bits to make it work. He did install some safety parameters, water temp and intake temperature but couldn't do oil as I don't have the sensors required,I will talk to the sparky who supplied ecu and wired it, he is really good and should be able to guide me with the bits I need. I don't want to spend the money on dry sump, can't even afford it, I have always been an advocate for wet sump, a mate who runs a race boat told me from the outset to dry sump as he does, most marathon boats do, I thought I could get away with it, after your feedback maybe I still can, still have the accumulator in my shed, maybe I should install that, just never thought I would have an issue running the boat in a straight line as that's all its done on this last build

#246

9 Second Club

Then for now, get a good engine, stay wet sump and apply good and proper safeties to prevent harm

If these are repeatedly tripped, then yes you'll need to figure out why.

An oil pressure sensor is cheap.

If these are repeatedly tripped, then yes you'll need to figure out why.

An oil pressure sensor is cheap.

#247

Back at it again, so we figured out that the Borg Warner turbos were robbing too much oil from the engine and thats why we kept running bearings, high volume oil pump or not. To rectify this I did what a mate has successfully done with his twin turbo LS boat and restricted the oil flow to the turbos (Beargo turbos) with restrictors in the oil lines at each turbo. We stopped lunching engines but now after a bit of racing and general use I have torched my turbos, they need all new cores . So they are getting rebuilt. We plan to open up the restrictors but not to the full -4 size that was recommended and initially used. It seems that really I would have been far better off with ball bearing turbos that dont require anywhere near as much oil. Has anyone had issues like this from turbos robbing too much oil? You need to keep in mind we are running constantly at around 5000rpm or so for minutes on end, not like a car where your off the throttle into corners, in a jetboat if you're off the throttle you have no steering. Any input appreciated

#248

9 Second Club

Nope.

Presumably in a boat you have plenty of room for a good oil pan design, both that can "scavenge" to some degree, and with plenty of capacity. So oil supply should never be an issue regardless of pump used ?

Trying to restrict oil to turbos was never going to end well, but yes if you believe that is an issue, BB turbos would require much less oil. BB turbos would almost certainly need cooling water too for such an application too.

Presumably in a boat you have plenty of room for a good oil pan design, both that can "scavenge" to some degree, and with plenty of capacity. So oil supply should never be an issue regardless of pump used ?

Trying to restrict oil to turbos was never going to end well, but yes if you believe that is an issue, BB turbos would require much less oil. BB turbos would almost certainly need cooling water too for such an application too.

#249

Ok cheers. Re sump, thats one thing we did at the last engine chernobyl. We added a hole front section into the rear sump that I run to give another 4 litres or so oil capacity and fitted big drain backs off each head in case any oil was hanging up. I fitted the restrictors at that time as well , so to be fair I never 100% knew that the restrictors stopped my engine running bearings or the new sump helped. But when you think about two -4 lines feeding turbos with massive drain backs running constantly at 5-5500 rpm it must be a lot easier for the engine oil to flow that way rather than being forced thru all the engine bearings aye?

Last edited by Huffa; 06-13-2020 at 02:17 PM.

#250

Looks like you made some excellent mods to keep oil above the pump pickup. With extended rpm in marine use, oil return to pan is key. Sounds like you were pumping the pan dry not just because of the turbos either. Yes, the oil will take the least path of resistance and the -4 lines are much bigger than engine clearances but it all adds up to volume/loss. If you're seeing expected oil pressure then you have enough volume to feed the engine and turbos. Do you log oil pressure? If so, what did it show before and after turbo restrictors were installed? How are you defining the required oil level? With that boat bouncing around and possibly exposing the pickup, an oil accumulator might be a good safety to keep things healthy.

#251

So after the last failure and at the same time restrictors went in I had an engine oil data logging parameter set up to the ecu. Only thing is I have to school myself up on how to hook up the laptop and read it. However I have always noted the oil pressure and in the last race we did it got down to about 50psi or so at wot after going hard for 20 minutes, it was still at the 10psi per thousand rpm just. The kind of racing we do is not tight turning so I have never been too concerned about surge, I just run the oil level to the full mark on the stick which we checked was correct when sump was off. I will learn how to read the data logging so I can compare what we have been running with restrictors to going back to open feed. So do you think I can run any restrictors what so ever? Did get hold of an accumulator but trying to fit it somewhere was a nightmare and I felt it was just a bandaid

#252

9 Second Club

The turbo feed is a red herring...it's not like those -4 lines just pump into nothing. There are bearings and orifices in the turbos too.

And when the oil pump has enough capacity at say 2000rpm...at 5k, a lot is or should be getting bypassed at the relief anyway.

But monitoring oil pressure and temperature would be a simple first start. Although presumably temps are easily kept in check ?

The oil pan mods may well have already solved any issues you were having, you just created the turbo death by starving them of oil.

And when the oil pump has enough capacity at say 2000rpm...at 5k, a lot is or should be getting bypassed at the relief anyway.

But monitoring oil pressure and temperature would be a simple first start. Although presumably temps are easily kept in check ?

The oil pan mods may well have already solved any issues you were having, you just created the turbo death by starving them of oil.

#253

Im hearing you. Yes I keep a good eye on oil pressure gauge, oil temp gauge is currently not working due to the capillary Autometer sender unit braking when pulling engine out last time, but the the engine runs a big water cooled oil cooler, always ran in a good range on the gauge when it was working

#255

8 Second Club

iTrader: (4)

How much oil are you running in the system? Just to the full mark on the dip stick? I could literally ruin 8qts in my LS1 pan. And that eliminated 90% of my oil pressure issues with my drag car. The high volume pump made it worse as well. Now I have an improved racing baffle and overfill 2 qts. Been ok ever since.

I agree 100% never restrict a journal turbo. Thats not your issue. The high volume pump likely is and it's very common to "pump the pan dry" with aftermarket pumps. Or even high volume factory pumps (DOD style). The fact that the boat is "nose up somewhat compared to a car compounds the problem. I'd put a standard oil pump on it. Not a high volume for starters. The turbos aren't "sucking the system dry". You can also improve the drains in the heads back to the block. Kurt Urban is a big name in the LS world. He ran oil restricting push rods in his turbo shop truck for over 100k I believe. The factory tends to over-oil the top end a bit. An accumulator is great for a drag car but when a boat gets up on a plane or is nose up the entire time its racing oil is all going the the rear of the pan. A good pan and overfilling the system are the easiest ways fight this IMO. Sounds like your on your way.

I agree 100% never restrict a journal turbo. Thats not your issue. The high volume pump likely is and it's very common to "pump the pan dry" with aftermarket pumps. Or even high volume factory pumps (DOD style). The fact that the boat is "nose up somewhat compared to a car compounds the problem. I'd put a standard oil pump on it. Not a high volume for starters. The turbos aren't "sucking the system dry". You can also improve the drains in the heads back to the block. Kurt Urban is a big name in the LS world. He ran oil restricting push rods in his turbo shop truck for over 100k I believe. The factory tends to over-oil the top end a bit. An accumulator is great for a drag car but when a boat gets up on a plane or is nose up the entire time its racing oil is all going the the rear of the pan. A good pan and overfilling the system are the easiest ways fight this IMO. Sounds like your on your way.

#256

9 Second Club

IMO, overfilling is a wrong term....fill to what is needed. But yes, you could easily overfill a standard type oil pan in a car.

If there is space, it should be easy to make a very deep pan, with good windage, and keeping the oil mass nowhere near the crank, and also well contained and protected against surge/movement. Allowing a huge amount of oil if need be, but never a "high" level as with a normal car type setup where ground clearance would always be an issue.

Obviously a dry sump is another option, but I can't see it being necessary at all.

If there is space, it should be easy to make a very deep pan, with good windage, and keeping the oil mass nowhere near the crank, and also well contained and protected against surge/movement. Allowing a huge amount of oil if need be, but never a "high" level as with a normal car type setup where ground clearance would always be an issue.

Obviously a dry sump is another option, but I can't see it being necessary at all.

#258

Has anyone had anything to do with running an external pump solely for feeding turbos? Was thinking about a crank driven pump? I dont want a full dry sump, 1 for the cost and 2 for the extra lines. Its already very busy in the engine bay

#259

9 Second Club

If you're going for an external pump...may as well do a dry sump.

Although some rear mount people run a standalone oil system for their turbos using an electric pump. Which is simple. I guess at a stretch that would be an option...but the turbos are not starving your engine of oil.

Although some rear mount people run a standalone oil system for their turbos using an electric pump. Which is simple. I guess at a stretch that would be an option...but the turbos are not starving your engine of oil.