drive pressure with vsr billet 7875

#21

8 Second Club

iTrader: (4)

I run 8 new plugs initially on an overly low timing tune and cut the plugs to help dial in the fuel. Mainly using WB02, but making sure all the fuel readings on the plugs look similar. Then tune off the leanest cylinder if individual fuel trims arenít an option. Once you have the fueling dialed in and know how all 8 plugs react to the indicated WB02 AFR reading I mainly look at the heat markings on the leanest plug and donít bother cutting the threads off.

Easy plug access is overlooked on a lot on turbo builds. Kinda makes or breaks the tuning process IMO. If it takes you a couple hours to change plugs many donít bother and are more likely to run into problems. If you know what to look for and watch plugs really closely while make baby stepsÖ itís pretty hard to hurt an engine. Strap/threads *should* let you know when the CC is starting to get too hot. Iíve not followed this method being lazy a few times myselfÖ thatís usually when I hurt an engine.

#22

Yes I was doing what Adam mentions, just looking at the ground strap. I think I had good fuel---even for that PSI. I think hitting fuel cut and pedaling it is what did me in.

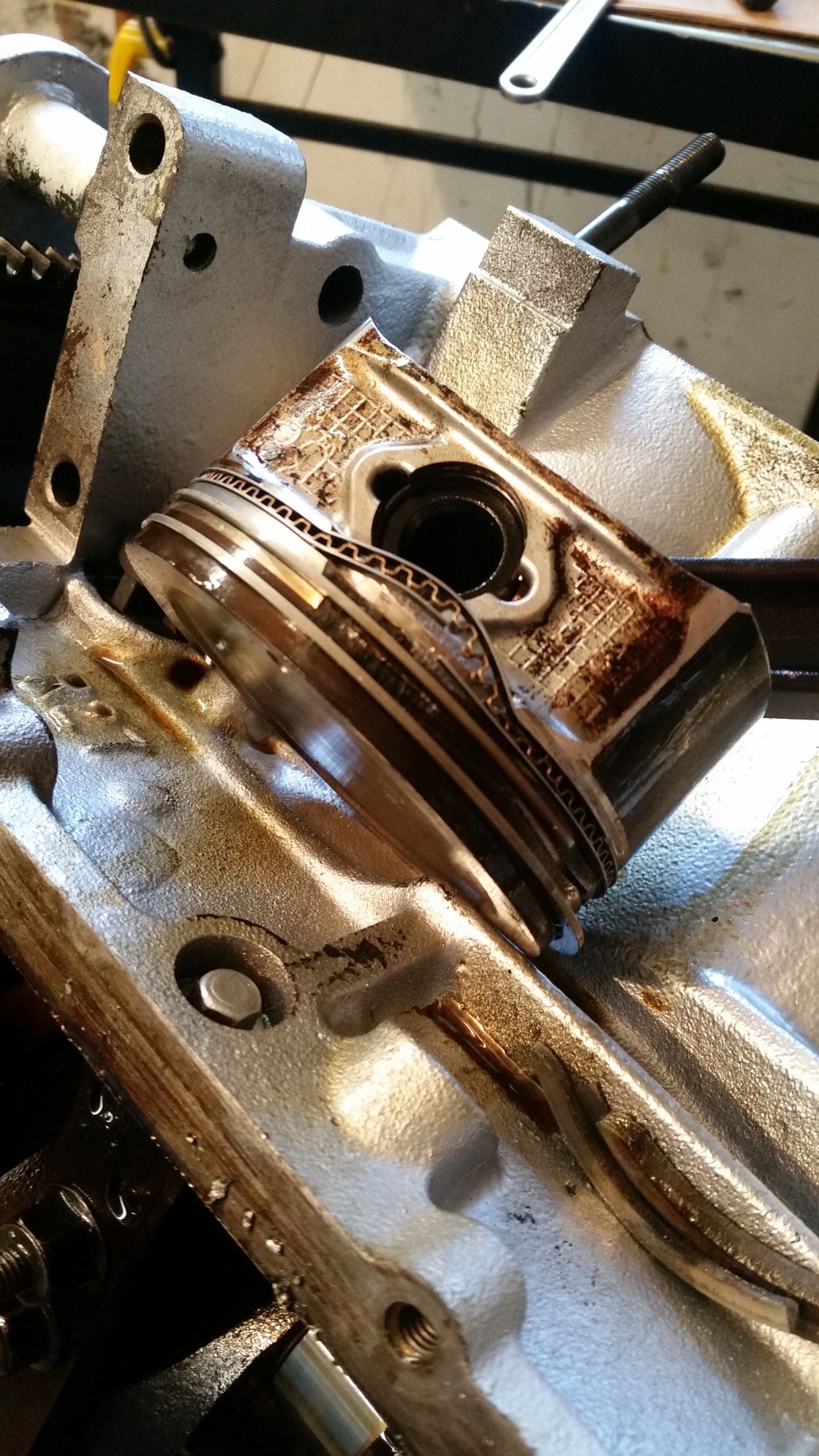

I'm kinda hoping for collapsed oil rings since this motor was really dirty and I didn't pull the rings out of all the pistons and clean them. I just checked gap on 2 or 3 top rings and slapped a cam in it. The way it puffs out the breather though---not holding my breath over it. Looking at an Ls2 pull out tonight

Andrew I think the 78/75 has a 75mm diameter turbine wheel. I did not measure it. I can when I have time to tear the motor back out.

Stevie, if you know any good books or links for learning about turbo cams, please share. I'' have to dig out my copy of Corky Bell's book, but I don't remember if it had a chapter on valve timing events. I don't think it did.

I'm kinda hoping for collapsed oil rings since this motor was really dirty and I didn't pull the rings out of all the pistons and clean them. I just checked gap on 2 or 3 top rings and slapped a cam in it. The way it puffs out the breather though---not holding my breath over it. Looking at an Ls2 pull out tonight

Andrew I think the 78/75 has a 75mm diameter turbine wheel. I did not measure it. I can when I have time to tear the motor back out.

Stevie, if you know any good books or links for learning about turbo cams, please share. I'' have to dig out my copy of Corky Bell's book, but I don't remember if it had a chapter on valve timing events. I don't think it did.

#23

Oh hey, one last question before I go and actually get something done today.

I didn't have my water/meth kit up and running yet (broke a nozzle when my charge pipe blew off)

Do you guys think I could have saved the motor if it was spraying? I have it set to spray during a pressure/rpm window (no PWM or ramp, just on and off) and it would have been spraying at the time.

I didn't have my water/meth kit up and running yet (broke a nozzle when my charge pipe blew off)

Do you guys think I could have saved the motor if it was spraying? I have it set to spray during a pressure/rpm window (no PWM or ramp, just on and off) and it would have been spraying at the time.

#24

8 Second Club

iTrader: (4)

Water meth can work some miracles for sure. Depends a lot on how big the mistake is and how much water/meth you are spraying.

I don’t think Corky thought the camshaft was something that needed much detail in his maximum boost book. I believe the only attention given to camshaft selection was this one liner. They weren’t using race fuels then and weren’t pushing very large boost numbers or near 1:1 back pressures.

Check out David Vizards cam books. "How to Build & Modify Chevrolet Small-Block V-8 Camshafts & Valvetrains” and “How to build horsepower”. They have some good info in them IMO. One of his books said something along the lines of a typical 2:1 turbo setup should shoot for shoots for -25*of overlap… which is a ton! But all his turbo small block cams I’ve seen have had over 125* LSA. They have also been on setups with very responsive and relatively small turbos. Wide LSA really helps with detonation when you don’t have the octane. Figure if you have instant boost, you aren’t concerned with the low end NA performance loss. So a wide LSA won’t hurt much.

His small twin SBC build in that book used a 200/234, 126 LSA installed 9 deg retarded! (sounds almost like the LS9 cam… Hmm) His end results were still 1000 HP by 5000 rpm, 1100 ft-lb at 28 psi, plus a glass-smooth idle. All with very mild heads that flow less than the typical LS head.

The newer larger turbos spool so well these days it makes more sense to me to shoot for 1:1 BP range and a semi aggressive “NA style” cam (on auto trans builds) . Grab another 78/75 and run twins on that LS2 with the cam you have.

I don’t think Corky thought the camshaft was something that needed much detail in his maximum boost book. I believe the only attention given to camshaft selection was this one liner. They weren’t using race fuels then and weren’t pushing very large boost numbers or near 1:1 back pressures.

Camshafts

Make no mistake in the fact that turbo performance cams are very different from atmospheric performance cams. The characteristics of long duration and high overlap for atmo cams are unwelcome in a turbo system. The street turbo, which is generally small, operates with exhaust manifold pressure somewhat higher than intake boost pressure. This situation, when presented with long-duration, high-overlap cams, creates a huge amount of reversion. Thus the "turbo cam" tends to become a low-duration, very limited overlap cam.

** Rule: It is hard to find a turbo cam that works better than the stock item.

Make no mistake in the fact that turbo performance cams are very different from atmospheric performance cams. The characteristics of long duration and high overlap for atmo cams are unwelcome in a turbo system. The street turbo, which is generally small, operates with exhaust manifold pressure somewhat higher than intake boost pressure. This situation, when presented with long-duration, high-overlap cams, creates a huge amount of reversion. Thus the "turbo cam" tends to become a low-duration, very limited overlap cam.

** Rule: It is hard to find a turbo cam that works better than the stock item.

His small twin SBC build in that book used a 200/234, 126 LSA installed 9 deg retarded! (sounds almost like the LS9 cam… Hmm) His end results were still 1000 HP by 5000 rpm, 1100 ft-lb at 28 psi, plus a glass-smooth idle. All with very mild heads that flow less than the typical LS head.

The newer larger turbos spool so well these days it makes more sense to me to shoot for 1:1 BP range and a semi aggressive “NA style” cam (on auto trans builds) . Grab another 78/75 and run twins on that LS2 with the cam you have.

Last edited by Forcefed86; 03-31-2017 at 12:03 PM.

#26

I'm kinda sick right now so I didnt

get very far into the motor. The oil looks good though

I HOPE MY CAM IS OKAY

you can skip my yappin to see the puffin that the hurt motor is doing at ~6:45 mark

get very far into the motor. The oil looks good though

I HOPE MY CAM IS OKAY

you can skip my yappin to see the puffin that the hurt motor is doing at ~6:45 mark

Last edited by truckdoug; 03-31-2017 at 03:22 PM. Reason: forgot to make it chooch

#27

8 Second Club

iTrader: (4)

Yank them heads off man, might just be a gasket. Even a 4.8 would boogy with some boost and they are dirt cheap. Smaller cubes will make the smaller turbo go farther as well.

That’s a bummer you can’t turn the fuel cut off the rev limiter. I’d ditch the rev limiter all together on that setup. Might Split the oil filter. If the pans easy to get to that may tell you a lot too.

That’s a bummer you can’t turn the fuel cut off the rev limiter. I’d ditch the rev limiter all together on that setup. Might Split the oil filter. If the pans easy to get to that may tell you a lot too.

#28

FormerVendor

iTrader: (2)

Honestly the cam isn't bad at all for that set-up, and some might even want more overlap than it has right now (-5@.050).

You could open the exhaust valve later and close the exhaust valve earlier to negate some of the effects of reversion during the overlap event and possibly lower back pressure by a few psi. More overlap can and will drive exhaust back pressure up and boost down, and less overlap can and will reduce exhaust back pressure and/or increase boost pressure.

Right now you're opening the exhaust valve at 51*BBDC and closing it at 3* BTDC. You could change that to 48* BBDC and 6* BTDC. This would shorten the exhaust lobe up 6 degrees, but leave the intake duration, LSA and ICL alone.

Honestly though, I don't think you'd see much gain if any at all. It might even make less power. The nature of the beast with a small turbo is high exhaust gas pressure. It is what it is on a given sized engine.

You could open the exhaust valve later and close the exhaust valve earlier to negate some of the effects of reversion during the overlap event and possibly lower back pressure by a few psi. More overlap can and will drive exhaust back pressure up and boost down, and less overlap can and will reduce exhaust back pressure and/or increase boost pressure.

Right now you're opening the exhaust valve at 51*BBDC and closing it at 3* BTDC. You could change that to 48* BBDC and 6* BTDC. This would shorten the exhaust lobe up 6 degrees, but leave the intake duration, LSA and ICL alone.

Honestly though, I don't think you'd see much gain if any at all. It might even make less power. The nature of the beast with a small turbo is high exhaust gas pressure. It is what it is on a given sized engine.

#29

9 Second Club

There should be zero issue with the ecu cutting fuel for rpm limits etc, and naturally during any cut, the wideband can display lean. That does not necessarily mean any individual cylinder is lean though.

Although given some people claim bent rods on stock engines when hitting the rev limiter...maybe the OEM/HPT rev limiter setup is just **** and badly controlled ?

Although given some people claim bent rods on stock engines when hitting the rev limiter...maybe the OEM/HPT rev limiter setup is just **** and badly controlled ?

#30

TECH Addict

iTrader: (1)

Originally Posted by stevieturbo

There should be zero issue with the ecu cutting fuel for rpm limits etc, and naturally during any cut, the wideband can display lean. That does not necessarily mean any individual cylinder is lean though.

Although given some people claim bent rods on stock engines when hitting the rev limiter...maybe the OEM/HPT rev limiter setup is just **** and badly controlled ?

Although given some people claim bent rods on stock engines when hitting the rev limiter...maybe the OEM/HPT rev limiter setup is just **** and badly controlled ?

#31

9 Second Club

There were a few posts a while back, where setups that had otherwise ran great...shortly after the driving hitting the limiters hard the engine developed trouble, and some bent rods.

It would seem a very unlikely or almost impossible scenario, but as it happened a few people, there must be something in it.

I've never used the OEM ecu's so couldnt comment but certainly with a good aftermarket ecu you could sit on the limiter nearly all day without worry ( well...maybe that's a bit much lol )

It would seem a very unlikely or almost impossible scenario, but as it happened a few people, there must be something in it.

I've never used the OEM ecu's so couldnt comment but certainly with a good aftermarket ecu you could sit on the limiter nearly all day without worry ( well...maybe that's a bit much lol )

#33

9 Second Club

iTrader: (10)

You don't want to hit the rev limiter on a boosted setup especially with water meth. This has been common knowledge for many many years on the hptuners forums as OEM uses a fuel cut. Cut fuel while still spraying water meth and it's not good. What I do is set my limiter super high and put something like -10 degrees of timing 400 rpm before the limiter. Your rev limiter should have been around 7000-7200 rpm. 6200 is very low for cammed ls and the lower the rev limiter is the worse off you are because of cylinder pressure.

Last edited by Nitroused383; 03-31-2017 at 05:57 PM.

#34

**** thats a damn good idea. so simple. fuuuuuuu

hey adam did you look at the video at it puffing? i've never had a headgasket go (i was an NA big block guy in my former life) can you push the headgasket into the lifter tray area?

i just kind of assumed it was ring lands.

the Ls2 is not gonna happen. dude had it outside for year covered with a tarp. wow, very rust. much corrosion.

hey adam did you look at the video at it puffing? i've never had a headgasket go (i was an NA big block guy in my former life) can you push the headgasket into the lifter tray area?

i just kind of assumed it was ring lands.

the Ls2 is not gonna happen. dude had it outside for year covered with a tarp. wow, very rust. much corrosion.

#36

Honestly the cam isn't bad at all for that set-up, and some might even want more overlap than it has right now (-5@.050).

You could open the exhaust valve later and close the exhaust valve earlier to negate some of the effects of reversion during the overlap event and possibly lower back pressure by a few psi. More overlap can and will drive exhaust back pressure up and boost down, and less overlap can and will reduce exhaust back pressure and/or increase boost pressure.

Right now you're opening the exhaust valve at 51*BBDC and closing it at 3* BTDC. You could change that to 48* BBDC and 6* BTDC. This would shorten the exhaust lobe up 6 degrees, but leave the intake duration, LSA and ICL alone.

Honestly though, I don't think you'd see much gain if any at all. It might even make less power. The nature of the beast with a small turbo is high exhaust gas pressure. It is what it is on a given sized engine.

You could open the exhaust valve later and close the exhaust valve earlier to negate some of the effects of reversion during the overlap event and possibly lower back pressure by a few psi. More overlap can and will drive exhaust back pressure up and boost down, and less overlap can and will reduce exhaust back pressure and/or increase boost pressure.

Right now you're opening the exhaust valve at 51*BBDC and closing it at 3* BTDC. You could change that to 48* BBDC and 6* BTDC. This would shorten the exhaust lobe up 6 degrees, but leave the intake duration, LSA and ICL alone.

Honestly though, I don't think you'd see much gain if any at all. It might even make less power. The nature of the beast with a small turbo is high exhaust gas pressure. It is what it is on a given sized engine.

hey martin, thanks for responding. I appreciate you freely giving your hard-won knowledge instead of giving me the hard sell. I can't say when for sure, but you just got a new customer.

#38

TECH Fanatic

Its a Gt42 turbine wheel copy. Its on the smallish side for a 6.0.

2 to 1 is still okish, you should have no problem making 750 (your probably close there now at 15psi)

2 to 1 is still okish, you should have no problem making 750 (your probably close there now at 15psi)