PWM Fan/Fuel Pump Question

#22

The pull up resistor keeps the ECU control wire high (SSR off) until it is pulled low by ECU to turn on.

#24

Switching devices are very efficient when they are on or when they are off. They are not efficient during the time they switch from on to off or vice versa. That's when heat is generated. The more times per second that the device is switched on or off, the more heat is generated and does not have a chance to cool.

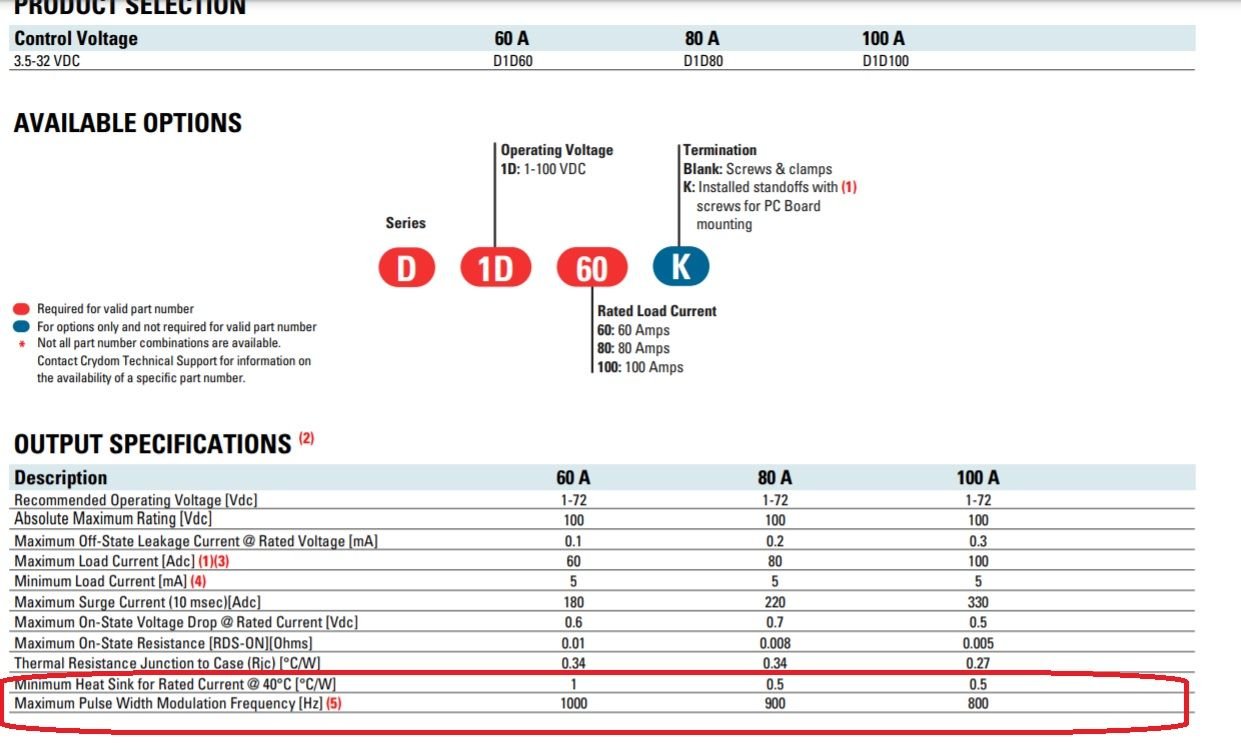

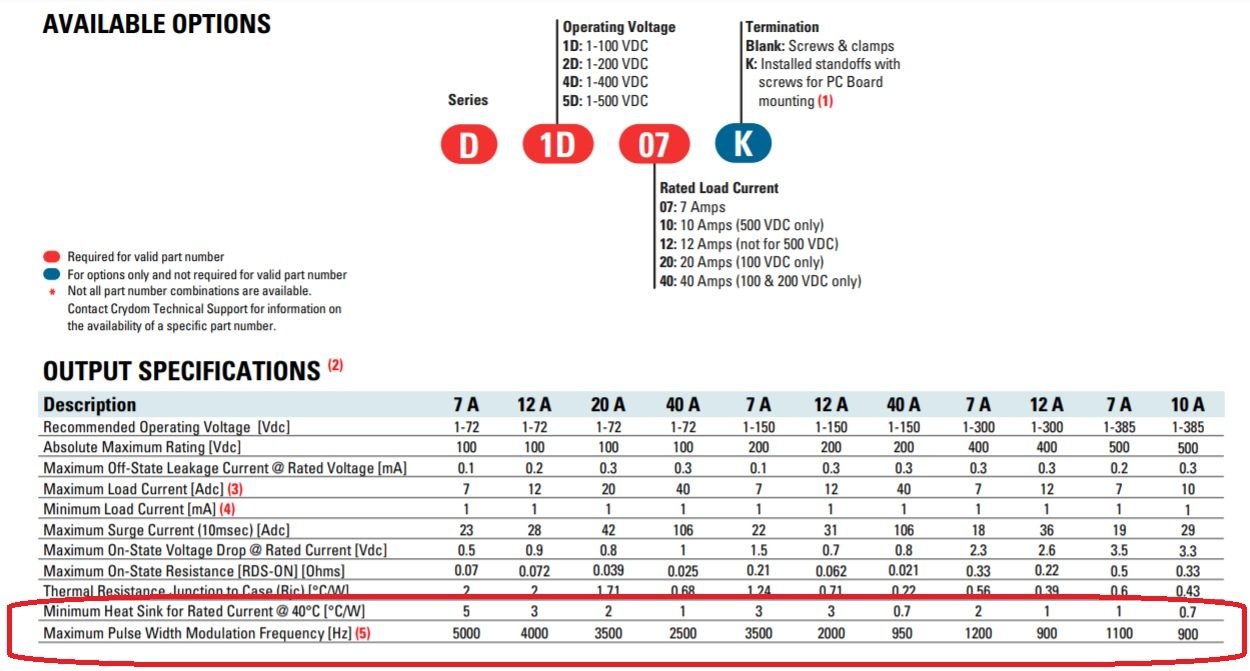

The devices that can tolerate high KHz switching rates have special components designed to minimize the amount of time taken to switch and therefore survive higher rates. The crydon device is rated to 2,500hz, and at that frequency, it can't even handle 40A. Motor noise typically goes away at about 20,000hz, so that's not even close.

#25

9 Second Club

My 60A Crydom I think states 1000Hz max, but the 100A Crydom is 800Hz max.

Someone did like to an SSR before where their specs claimed 25kHz, but when I've never found any others even remotely close, I'd question whether it is correct or not.

#29

#30

Thanks.

I plan on logging fuel temps, but not sure where to place sensor.

I can easily stash it pre/post pump, or post regulator. I am using a 8an pressure port fitting and sensor does not protrude into the main bore area.

https://www.summitracing.com/parts/f...RoChMgQAvD_BwE

I plan on logging fuel temps, but not sure where to place sensor.

I can easily stash it pre/post pump, or post regulator. I am using a 8an pressure port fitting and sensor does not protrude into the main bore area.

https://www.summitracing.com/parts/f...RoChMgQAvD_BwE

#31

Logging fuel pressure is great, also good for engine safety. Logging fuel temps is diminishing returns IMHO.

Let us know how loud the fuel pump gets with the low frequency PWM.

Let us know how loud the fuel pump gets with the low frequency PWM.

Last edited by LSswap; 02-17-2021 at 01:07 PM.

(running a termy x so only 4 i/o)

(running a termy x so only 4 i/o)