Looking for guys who make 900+rwhp with turbo: block opinions

#22

TECH Senior Member

iTrader: (21)

Originally Posted by 427

This question is tough to answer, its interesting to read the reply's so far. I have some LS2 info gathered from a engine we just took apart that had been raced hard and maintained well through its life. The pics attached(I hope they are attached!) will show you some cylinder and block damage that seems to be the norm when dealing with the aluminum block. The deck cracks also show up on high hp iron blocks eventually, but we have not been able to disect enough engines to be hard and fast about facts. This paticular block is cracked in 7 places and was performing fine.

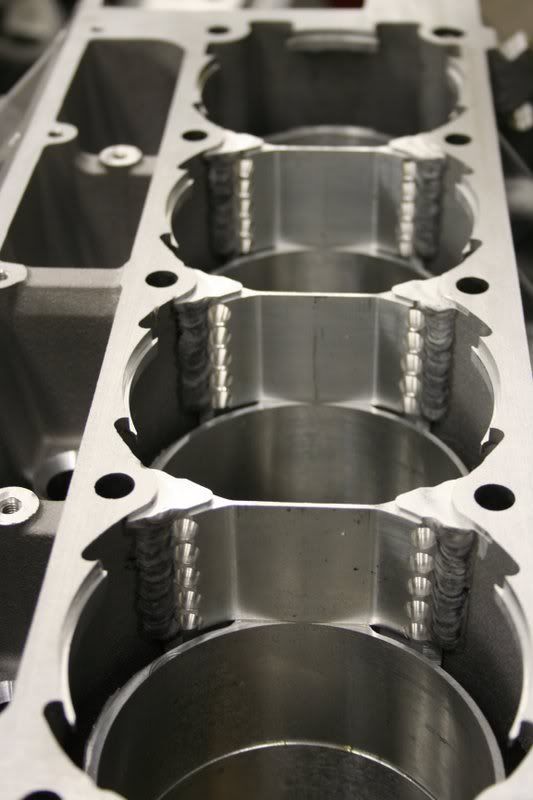

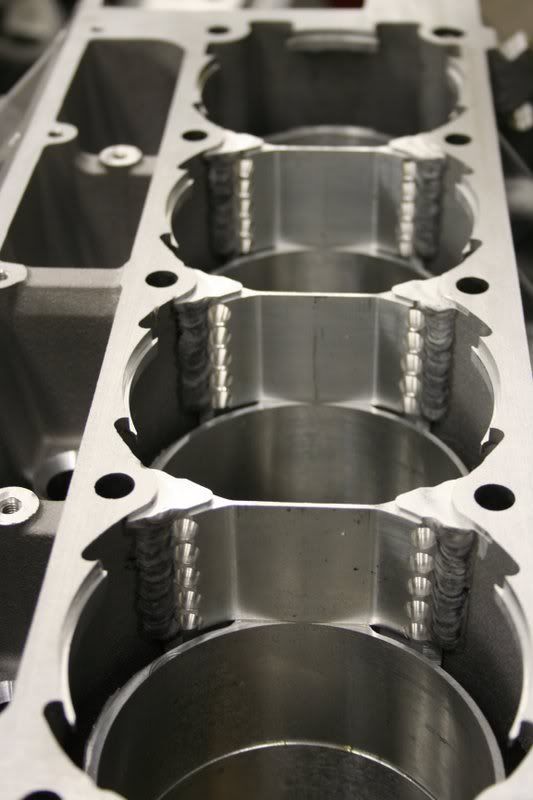

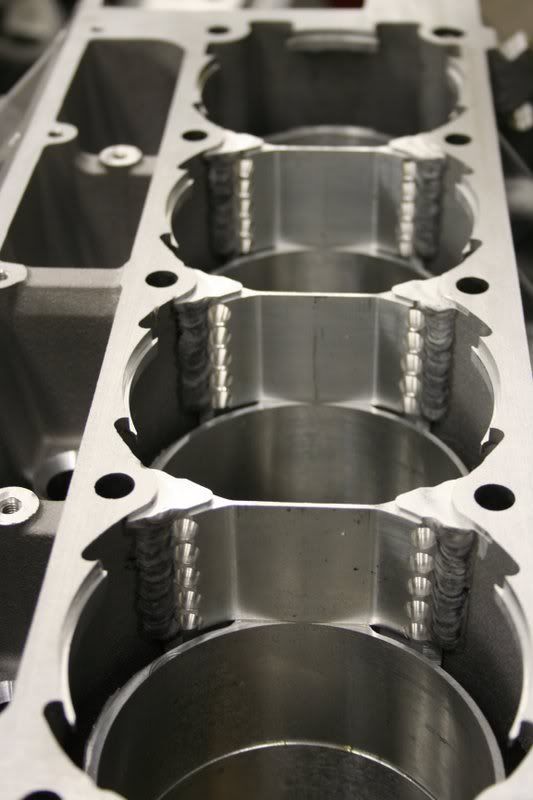

The cylinder shot shows the "smoky" look of the walls. I believe this is caused by the wall flexing under load, not staying round. This would cause some blow-by and lost power, this is worse in aluminum blocks we see.

You will also notice the lack of a defined stop point for the top ring, it should be 360 degree's around the bores top edge, but it changes pattern near the head bolts showing that the block is flexing from the head bolt load.

At 1200+ flywheel hp I would still use iron block, but the aftermarket blocks may change that. Who is going to be the first to push one to find the limit????

Kurt

The cylinder shot shows the "smoky" look of the walls. I believe this is caused by the wall flexing under load, not staying round. This would cause some blow-by and lost power, this is worse in aluminum blocks we see.

You will also notice the lack of a defined stop point for the top ring, it should be 360 degree's around the bores top edge, but it changes pattern near the head bolts showing that the block is flexing from the head bolt load.

At 1200+ flywheel hp I would still use iron block, but the aftermarket blocks may change that. Who is going to be the first to push one to find the limit????

Kurt

Thats some good info Kurt......

Looks like i should find that 90 lbs elsewhere lol

Kyle

#23

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

We just took the Nova apart after Drag Week to change the cam and lifters and check it out. The cylinders show some of the same loading, but the deck is not cracking. I think the Nova is living because of the supercharger not producing the crazy low rpm torque of a turbo engine. The Nova peak torque is around 800+ ft pounds and makes 1160hp. A 1160hp hyd cam turbo engine would produce 1250+ ft pounds, that is hard on the block/crank combo.

I am really expecting the new Dart, GM and World block to move us forward on these problems. Only time will tell.

Kurt

I am really expecting the new Dart, GM and World block to move us forward on these problems. Only time will tell.

Kurt

Originally Posted by SSilverSSurfer

was there any problems like that in the nova kurt? at what kind of power would you expect that kind of damage? thanks for the info

#24

TECH Senior Member

iTrader: (21)

Join Date: Nov 2001

Location: Cecil County Raceway!!!

Posts: 8,484

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 427

This question is tough to answer, its interesting to read the reply's so far. I have some LS2 info gathered from a engine we just took apart that had been raced hard and maintained well through its life. The pics attached(I hope they are attached!) will show you some cylinder and block damage that seems to be the norm when dealing with the aluminum block. The deck cracks also show up on high hp iron blocks eventually, but we have not been able to disect enough engines to be hard and fast about facts. This paticular block is cracked in 7 places and was performing fine.

The cylinder shot shows the "smoky" look of the walls. I believe this is caused by the wall flexing under load, not staying round. This would cause some blow-by and lost power, this is worse in aluminum blocks we see.

You will also notice the lack of a defined stop point for the top ring, it should be 360 degree's around the bores top edge, but it changes pattern near the head bolts showing that the block is flexing from the head bolt load.

At 1200+ flywheel hp I would still use iron block, but the aftermarket blocks may change that. Who is going to be the first to push one to find the limit????

Kurt

The cylinder shot shows the "smoky" look of the walls. I believe this is caused by the wall flexing under load, not staying round. This would cause some blow-by and lost power, this is worse in aluminum blocks we see.

You will also notice the lack of a defined stop point for the top ring, it should be 360 degree's around the bores top edge, but it changes pattern near the head bolts showing that the block is flexing from the head bolt load.

At 1200+ flywheel hp I would still use iron block, but the aftermarket blocks may change that. Who is going to be the first to push one to find the limit????

Kurt

#25

TECH Junkie

iTrader: (4)

Originally Posted by 427

This question is tough to answer, its interesting to read the reply's so far. I have some LS2 info gathered from a engine we just took apart that had been raced hard and maintained well through its life. The pics attached(I hope they are attached!) will show you some cylinder and block damage that seems to be the norm when dealing with the aluminum block. The deck cracks also show up on high hp iron blocks eventually, but we have not been able to disect enough engines to be hard and fast about facts. This paticular block is cracked in 7 places and was performing fine.

The cylinder shot shows the "smoky" look of the walls. I believe this is caused by the wall flexing under load, not staying round. This would cause some blow-by and lost power, this is worse in aluminum blocks we see.

You will also notice the lack of a defined stop point for the top ring, it should be 360 degree's around the bores top edge, but it changes pattern near the head bolts showing that the block is flexing from the head bolt load.

At 1200+ flywheel hp I would still use iron block, but the aftermarket blocks may change that. Who is going to be the first to push one to find the limit????

Kurt

The cylinder shot shows the "smoky" look of the walls. I believe this is caused by the wall flexing under load, not staying round. This would cause some blow-by and lost power, this is worse in aluminum blocks we see.

You will also notice the lack of a defined stop point for the top ring, it should be 360 degree's around the bores top edge, but it changes pattern near the head bolts showing that the block is flexing from the head bolt load.

At 1200+ flywheel hp I would still use iron block, but the aftermarket blocks may change that. Who is going to be the first to push one to find the limit????

Kurt

#29

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

The C5R would be slightly better than a LS2 in the mains, but weaker on the deck. It was designed around a road race engine that produces under 700hp. At 1200hp they have a hard time holding head gaskets, and the mains are moving all over at that level. My feeling is the LS2 is a better block if you add main caps, even better with a girdle. The new blocks should make all these old news for the high power LS engines.

Kurt

Kurt

Originally Posted by onfire

How does the C5R compare?

#34

12 Second Club

Join Date: Mar 2003

Location: Central FL/ East AL

Posts: 147

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 427

Its a drag engine with around 400 runs.

Kurt

Kurt

a girdled LS2 would live long enough to save up for an aftermarket piece later on down the road. I'm on the fence between a LS2 alum block and the ferrous 6.0L block. I don't want to give up that 90lbs and my power/e.t goals are 200ish hp less.

a girdled LS2 would live long enough to save up for an aftermarket piece later on down the road. I'm on the fence between a LS2 alum block and the ferrous 6.0L block. I don't want to give up that 90lbs and my power/e.t goals are 200ish hp less.Subscribing.

#35

TECH Junkie

iTrader: (3)

Join Date: May 2003

Location: Clayton, North Carolina

Posts: 3,898

Likes: 0

Received 6 Likes

on

6 Posts

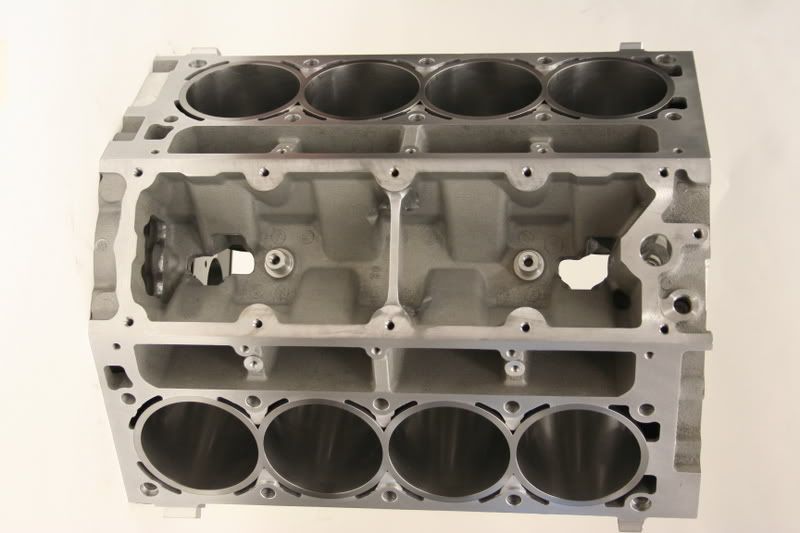

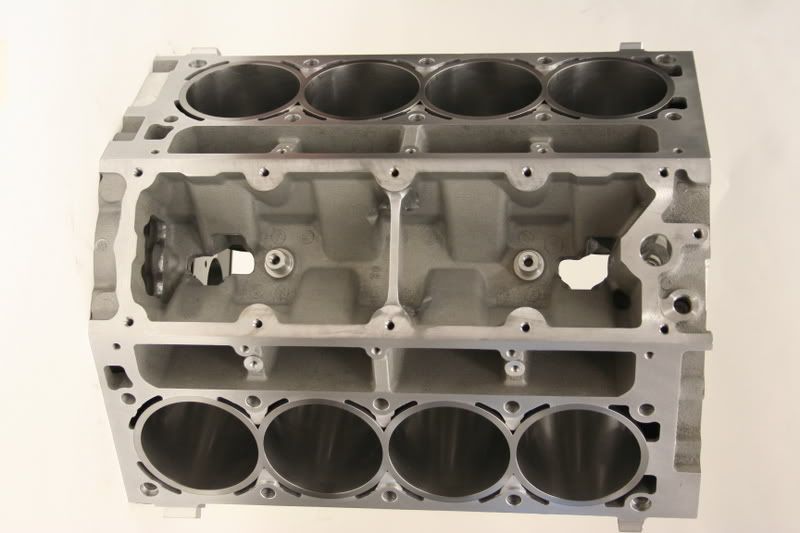

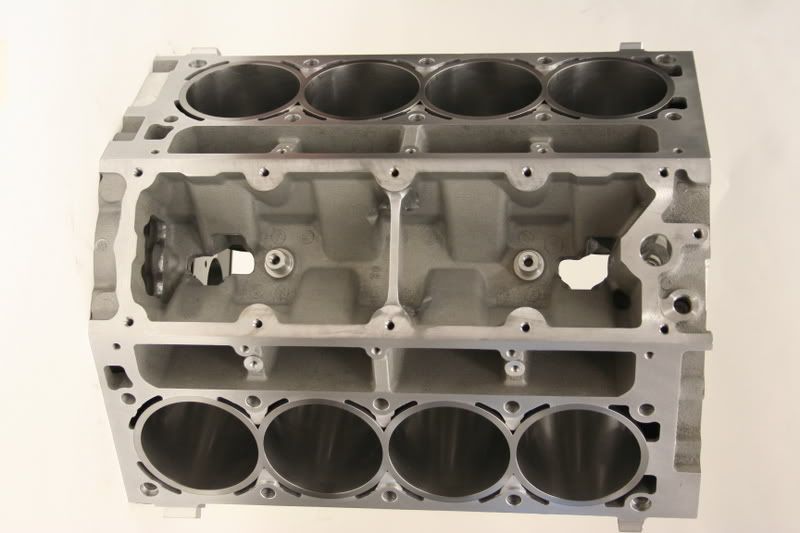

Phil- That block looks great. Can't wait to see what can be done with it.

Dude- I have done the welding on the deck and it does tend to help but you need to replace all the sleeves after welding to do it right. The circle is just a picture flaw, I am not great with cameras.

Darricks- We normally would like to see this engine back sooner as it does not have a dry sump oiling system, but 400 runs is not unreasonable for a drag engine that is cared for properly. I think the LS2 might be a good fit for your goals.

Kurt

Dude- I have done the welding on the deck and it does tend to help but you need to replace all the sleeves after welding to do it right. The circle is just a picture flaw, I am not great with cameras.

Darricks- We normally would like to see this engine back sooner as it does not have a dry sump oiling system, but 400 runs is not unreasonable for a drag engine that is cared for properly. I think the LS2 might be a good fit for your goals.

Kurt

#36

Originally Posted by Pro Stock John

95% of the big boys will reccomend iron blocks for that power goal Phil. I think Mike Brown might be the only holdout to go LS2. I'm on the fence, but I have not put that many passes on my shortblock yet.

It is the only block (other than solid waterless) that puts the stress and distortion below the deck and between the cylinders. All Closed deck blocks pass the stress and distortion through the deck and cylinders as the cracking and ovaling of the cylinders in 427's LS2 pics. demonstrate.

We should get a chance to inspect it since he's pulling the engine and retiring the TA for the lighter new car.

PS* The billet mains were doweled to not rely on the aluminum registers to locate the main caps and the sleeves are incredibly thick at the upper cylinders.

[IMG]

[/IMG]

[/IMG]

#37

TECH Senior Member

iTrader: (21)

Originally Posted by Quick Carl

This is what Mike has been testing for us. It's not a stock LS2 GM block, so that wouldn't be a fair test for stock. He has a worse case situation for testing with an LS1/LS6 (bay to bay windows, thinner cast than LS2) and clearanced for a max. stroker even though he doesn't run one. He held up his end in running the *** out of it for us with a best of 8K+ 8.41 @ 169 in his 3650# car.

It is the only block (other than solid waterless) that puts the stress and distortion below the deck and between the cylinders. All Closed deck blocks pass the stress and distortion through the deck and cylinders as the cracking and ovaling of the cylinders in 427's LS2 pics. demonstrate.

We should get a chance to inspect it since he's pulling the engine and retiring the TA for the lighter new car.

PS* The billet mains were doweled to not rely on the aluminum registers to locate the main caps and the sleeves are incredibly thick at the upper cylinders.

[IMG] [/IMG]

[/IMG]

It is the only block (other than solid waterless) that puts the stress and distortion below the deck and between the cylinders. All Closed deck blocks pass the stress and distortion through the deck and cylinders as the cracking and ovaling of the cylinders in 427's LS2 pics. demonstrate.

We should get a chance to inspect it since he's pulling the engine and retiring the TA for the lighter new car.

PS* The billet mains were doweled to not rely on the aluminum registers to locate the main caps and the sleeves are incredibly thick at the upper cylinders.

[IMG]

[/IMG]

[/IMG]

Bad ***..... what does the block run $$ wise???

#38

LS1Tech Co-Founder

iTrader: (34)

The LS2 that Kurt has posted pics of has led a hard life and has been in a heavy mid 8 second car. I would imagine that the owner of that block would indicate he's made 1100 crank hp (or higher) through that block.

#40

Yes, the block Kurt has shown has seen a hard life. I'm not sure of the cars weight, but a typical F body would have to make at least the 1100 HP to run 8"s. He didn't say if the main caps were stock, but doweling seams to help the cap walk in the LS engines.

NA$TY-TA, I'm not in sales, but to give you an idea, ballpark would be similar to the MID's that we do $2600-2800 with a core. That would include multiple stress relieving, Heavy wall sleeves (min. .150 thrust wall @ 4.200 bore NA), decking, boring, finish honing, align honing, tapping for 1/2" head studs, re-boring the head dowels for exact location of head to bores,Durabond 1 pc. cam bearings installed. All CNC'd off crank/cam centerline. Theres a ton of benefits, but I don't want to do an advertisement and hijack the thread. It was interesting to see the pics Kurt posted of the LS2 and brought this up for discussion .

NA$TY-TA, I'm not in sales, but to give you an idea, ballpark would be similar to the MID's that we do $2600-2800 with a core. That would include multiple stress relieving, Heavy wall sleeves (min. .150 thrust wall @ 4.200 bore NA), decking, boring, finish honing, align honing, tapping for 1/2" head studs, re-boring the head dowels for exact location of head to bores,Durabond 1 pc. cam bearings installed. All CNC'd off crank/cam centerline. Theres a ton of benefits, but I don't want to do an advertisement and hijack the thread. It was interesting to see the pics Kurt posted of the LS2 and brought this up for discussion .