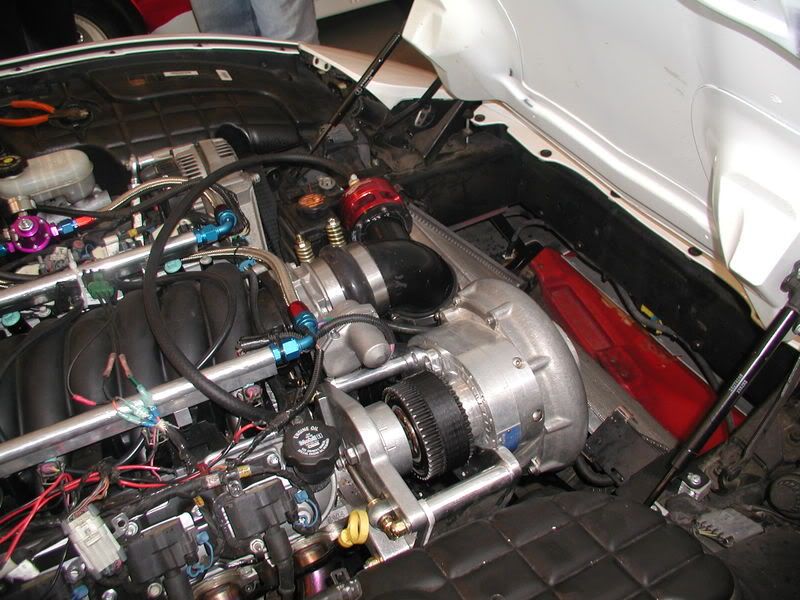

12 rib pulley for my ATI damper for procharger F2 set-up

#22

We've gone down this path on a C5. First the "J" bracket will need to be replaced with something stronger. The "J" design will break. We snapped a C5 bracket, and the C5 design is much better than the f-body. Second, you will need a cog set up regardless just to turn the F2. We have found that if the blower has its own dedicated belt you can get away with using a 30mm cog drive. You can get the 30mm cog crank pulley from ATI, its part of their C5 kit. You can also get the kevlar belts in 30mm, I think they are called Pollychain. Finally, I would suggest getting the ATI SuperPulley, which is a cog overrun or sprag clutch pulley for the blower. It allows the blower to free spin when you let off the gas or inbetween shifts. This pulley will be a life saver for your belts. I believe this pulley currently only comes in one size and only in 50mm wide. We had to mill it down some just to fit the brackets.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

#23

We've gone down this path on a C5. First the "J" bracket will need to be replaced with something stronger. The "J" design will break. We snapped a C5 bracket, and the C5 design is much better than the f-body. Second, you will need a cog set up regardless just to turn the F2. We have found that if the blower has its own dedicated belt you can get away with using a 30mm cog drive. You can get the 30mm cog crank pulley from ATI, its part of their C5 kit. You can also get the kevlar belts in 30mm, I think they are called Pollychain. Finally, I would suggest getting the ATI SuperPulley, which is a cog overrun or sprag clutch pulley for the blower. It allows the blower to free spin when you let off the gas or inbetween shifts. This pulley will be a life saver for your belts. I believe this pulley currently only comes in one size and only in 50mm wide. We had to mill it down some just to fit the brackets.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

#24

Man that's a lot of very helpful info, Thanks a ton. 30psi is a lot, I'm glad I decided to go with the lsx. Is it crucial to get that ATI Superpully? I know it will help but I was hoping the Procharger race bypass would be sufficient because I just purchased the standard ati damper. The race bypass is said to be good to 2200hp and I don't plan to go near that.

Hope that makes sense, maybe I wasn't clear enough before.

Just an FYI, try to make a blower bracket that has four bolts instead of the three like the J bracket.

Oh one more thing I forgot is that the C5 we developed didn't use an intercooler so since you are using one you should be able to reduce the boost some pushing through it.

#25

Why do I need a custom bracket? It fit's on the 8 rib bracket as far as I can tell, I bolted it on with no problems, I havn't bolted it to the engine yet though. Is there any thing in perticular you know about why it won't work?

#27

Well, first the SuperPulley has nothing to do with the bypass or damper. You absolutely need the Procharger Big Red Race bypass, thats a given. What the superpulley will do is reduce the stress on everything(belts, brackets, crank) during decel or shifting. It takes I believe 100+ hp or maybe more to turn the F2, so imagine trying to slow that thing down from redline. It creates a lot of stress. The superpulley which goes on the blower will allow it to freewheel like a bicycle. So you have the standard ATI Superdamper, thats fine because as you know the f-body has a dedicated belt for the blower, which you want. Similar to your old kit the 8rib crank pulley bolted to the front of the damper. The same goes true for your cog set up, just buy a cog crank pulley to fit, the wider the better. It will just bolt to the front of the damper as before. Now you will have the same belt configuration as before but using a cog drive.

Hope that makes sense, maybe I wasn't clear enough before.

Just an FYI, try to make a blower bracket that has four bolts instead of the three like the J bracket.

Oh one more thing I forgot is that the C5 we developed didn't use an intercooler so since you are using one you should be able to reduce the boost some pushing through it.

Hope that makes sense, maybe I wasn't clear enough before.

Just an FYI, try to make a blower bracket that has four bolts instead of the three like the J bracket.

Oh one more thing I forgot is that the C5 we developed didn't use an intercooler so since you are using one you should be able to reduce the boost some pushing through it.

#28

Just FYI (agreeing with these guys) an F2 is a whole different animal than even an F1r. The F2 will blow your stock brackets apart, even at idle, not to mention the strain it will put on all of you accessories. A 12 rib would have to be sooooo tight it will probably kill your water pump, alternator (and brackets) etc. I would go cog (procharger won't normally sell 12 rib f2s much anymore unless you ask, but it WILL slip) and put it on it's own drive. If you've ever seen an F2 in full action, you'd understand. If you are concerned about a $400 pulley, you may be in for a surprise when you start putting the rest of the custom stuff together. If you aren't going to spin the F2 hard, you may be better off in an F1r.

#29

We've gone down this path on a C5. First the "J" bracket will need to be replaced with something stronger. The "J" design will break. We snapped a C5 bracket, and the C5 design is much better than the f-body. Second, you will need a cog set up regardless just to turn the F2. We have found that if the blower has its own dedicated belt you can get away with using a 30mm cog drive. You can get the 30mm cog crank pulley from ATI, its part of their C5 kit. You can also get the kevlar belts in 30mm, I think they are called Pollychain. Finally, I would suggest getting the ATI SuperPulley, which is a cog overrun or sprag clutch pulley for the blower. It allows the blower to free spin when you let off the gas or inbetween shifts. This pulley will be a life saver for your belts. I believe this pulley currently only comes in one size and only in 50mm wide. We had to mill it down some just to fit the brackets.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

I found the super pulley you're talking about, it's ****** awesome and seems to be well worth the $500 it costs. It only comes in 75mm right now, does that mean I will have to use a 75mm on the crank as well? It doesn't sound like a bad idea actually if they make one to fit on the ati damper I have. If thats the case then I can use a 70mm belt, shouldn't have any more issues with belt slip. Where can I get this pollychain? Thanks for all the help. This thing is going to way surpass my original goals.

#31

One thing that I will add is to make sure that you have ALOT of belt wrap on the crank and blower pulley. We found on the C5 with little wrap on the crank (about 35%) that it would slip the belt and rip the cogs right off. We went to about 80% wrap on both pullies and it was much happier.

#32

One thing that I will add is to make sure that you have ALOT of belt wrap on the crank and blower pulley. We found on the C5 with little wrap on the crank (about 35%) that it would slip the belt and rip the cogs right off. We went to about 80% wrap on both pullies and it was much happier.

#34

We've gone down this path on a C5. First the "J" bracket will need to be replaced with something stronger. The "J" design will break. We snapped a C5 bracket, and the C5 design is much better than the f-body. Second, you will need a cog set up regardless just to turn the F2. We have found that if the blower has its own dedicated belt you can get away with using a 30mm cog drive. You can get the 30mm cog crank pulley from ATI, its part of their C5 kit. You can also get the kevlar belts in 30mm, I think they are called Pollychain. Finally, I would suggest getting the ATI SuperPulley, which is a cog overrun or sprag clutch pulley for the blower. It allows the blower to free spin when you let off the gas or inbetween shifts. This pulley will be a life saver for your belts. I believe this pulley currently only comes in one size and only in 50mm wide. We had to mill it down some just to fit the brackets.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

Just so you know with the 402 you plan on running and the pullies I suggested above you will be at 30+ psi of boost. Thats where we were with a 408 and L92 heads.

Good luck and be prepared to break ****, the F2 is one bad bitch.

#35

Its hard to say. He broke everything with the F2 on a 30mm running all the accessories. Initially, the idler pulley broke at idle, then went the power steering pump bracket, then went the alternator bracket. He actually used a heim joint to hold the alternator from flexing and moving. I posted some pics of the round 1 trial set up below. The heim joint worked nice, it allowed us to center the belt on the pullies. After he got that fixed, then it tore the center out of the water pump pulley, twice. He also went through a fair number of belts during testing because of all the flexing and not enough wrap on the crank pulley. So after all that the power steering went in the pile of unused parts, along with the AC. X-RACER made a custom alternator bracket as you have seen in previous pictures that mounted the alternator backwards and ran off the AC crank pulley. So now the blower had its own dedicated belt (still 30mm) that just touched the water pump pulley enough to spin it. Now in this current set up the 30mm is working just fine.

Here is a link to the current pics:

https://ls1tech.com/forums/showthrea...835&highlight=

And the ones from the first set up

#37

Man, thats a lot of pulleys, trying to keep it a street car huh. Lucky for me, mine is more drag race oriented, so The only pulleys I have to worry about are the head unit and crank. The alternater will be on its own belt and that's it, all other pulleys deleted

#38

On a side note what ever happed to the Cartek car they were building? kinda fell off the list and haven't heard much lately. Any updates?

#39

Best of luck! Post up if you need help on anything!

#40

Thanks again guys, I just wanted to follow up. Shouldn't have any belt slip now

The last one is for a big block, my engine builder is making it work on my ati damper. With these pulleys at 7000rpms I'll be at 60000 for the blower It's rated at 65000 but I think this is a good starting point.

It's rated at 65000 but I think this is a good starting point.

The last one is for a big block, my engine builder is making it work on my ati damper. With these pulleys at 7000rpms I'll be at 60000 for the blower

It's rated at 65000 but I think this is a good starting point.

It's rated at 65000 but I think this is a good starting point.