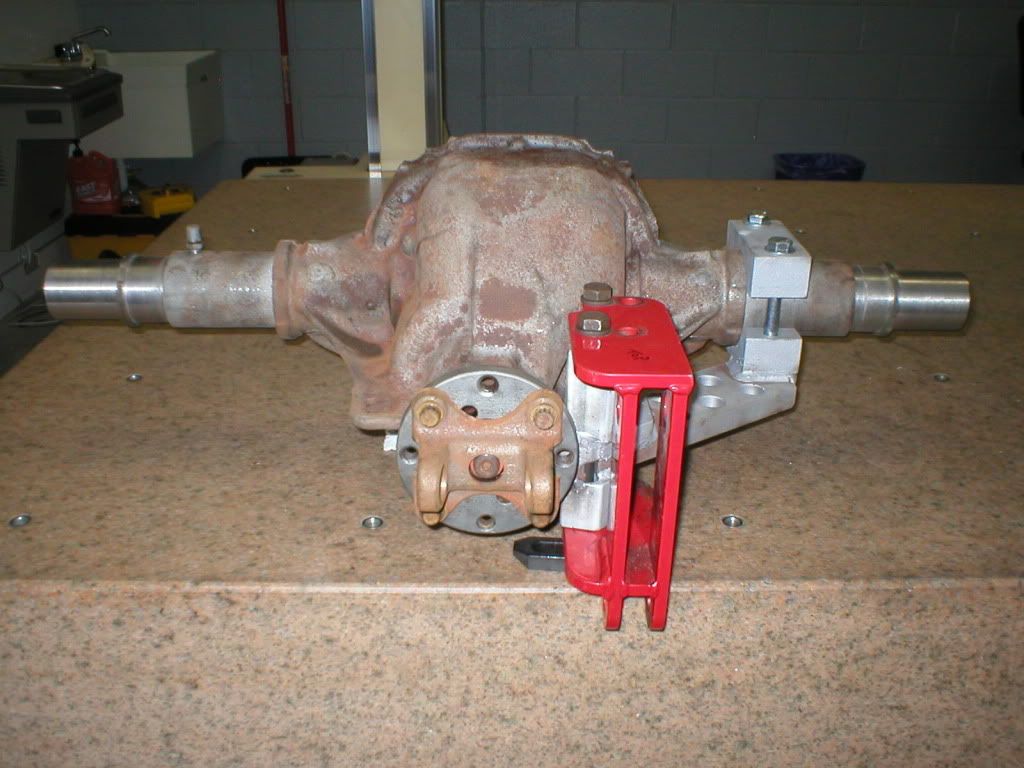

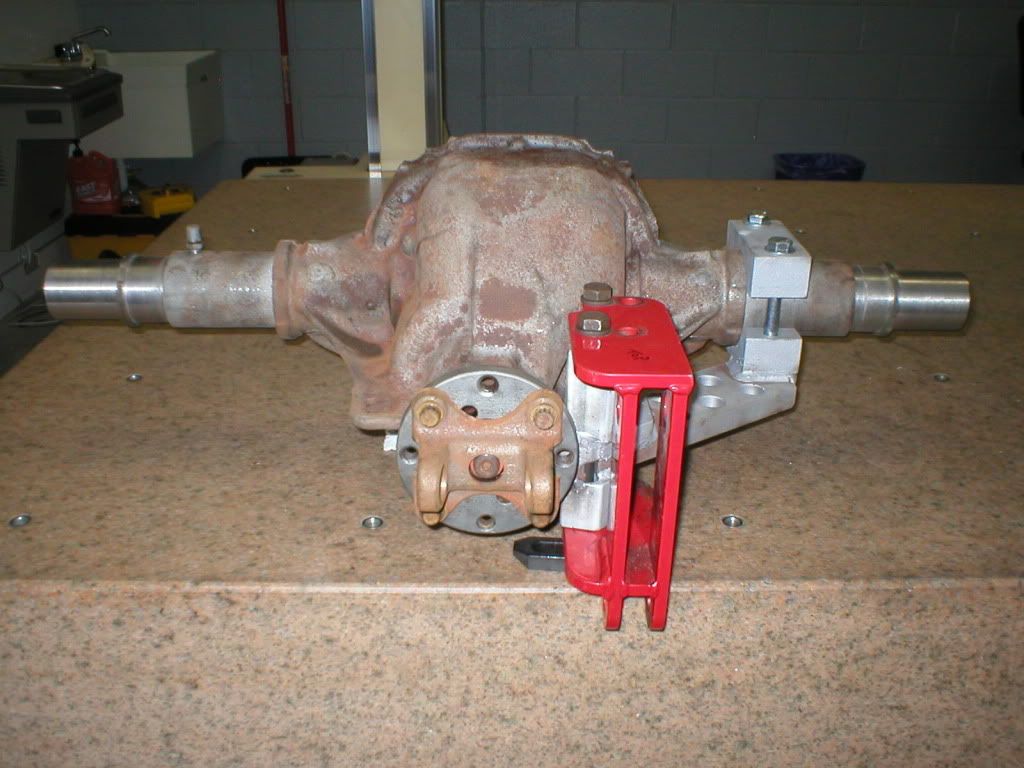

8.8 with bolt-on T/A mount

#21

I made this myself, I'd have to look into possibly making them to sell but I really want to test it out more and make sure it's a solid piece. I'm sure there is room for improvement in the design and I wouldn't want to sell something that's garbage or prone to breaking easily.

#22

For me it was very cheap. I actually just bummed scrap stock off my boss and a friend and the bolts were a few bucks at the local hardware store. I have access to a bridgeport so the rest was just measuring and cutting. If I were to make them I would need to find another housing and see if I can't simplify the design so most of it could be cnc cut and then just bolted together. This weekend I'm planning on see what I have to clear if any to fit the new UMI drag bar I just bought so its just the little things I'd like to perfect beforehand.

#23

For me it was very cheap. I actually just bummed scrap stock off my boss and a friend and the bolts were a few bucks at the local hardware store. I have access to a bridgeport so the rest was just measuring and cutting. If I were to make them I would need to find another housing and see if I can't simplify the design so most of it could be cnc cut and then just bolted together. This weekend I'm planning on see what I have to clear if any to fit the new UMI drag bar I just bought so its just the little things I'd like to perfect beforehand.

#26

#28

Good looking mount! I love the ingenuity. However if I may just say that you could weld a piece of bar stock to the axle tube and then with a cut in the axle tube mount it would not move. But I know you said you don't want to weld on the housing... but a viable solution to some peoples skepticism.

#30

#35

#37

hahaha

hahahaThanks for all your work bud keep up the great work ! Do you have updated pics of it ? Thought I had seen some prototype design ealrier?

#38

I wonder why no one copies the mustang torque arm conversion. Like copy the torque arm and make a TA mount up front for it.

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

https://ls1tech.com/forums/gears-axl...8-project.html

#39

This is the mount I made, its a complete bolt-on unit as I didn't want to do any welding on the cast iron housing. Only made 3 passes with it so far but it held up to a 1.55 60' in a 3700lb car. I ran into a few issues with it, the bracket is outboard more toward the driver side because I used the 31 spline truck flange which is much larger OD than than car one. In order to make this work I had to use the second set of torque arm bracket holes and ended up grinding off one of the other holes to clear the housing. I think this winter I'm going to switch to a regular style yoke and get rid of the flange all together because the clearance between it and the t/a mount it very close now. The only other issue I ran into was getting the rear sway bar to fit, its on there fine but its very close and could hit it if vibrates any. The easy solution here is to just make some spacers fr it and move it down 1/2" or so but I won't worry about that because I'm going to buy a drag bar this winter and figure it out then. Let me know what you think.

there is already a hole on both sides I just have to make a bracket thats attached and bolt it up.

there is already a hole on both sides I just have to make a bracket thats attached and bolt it up.