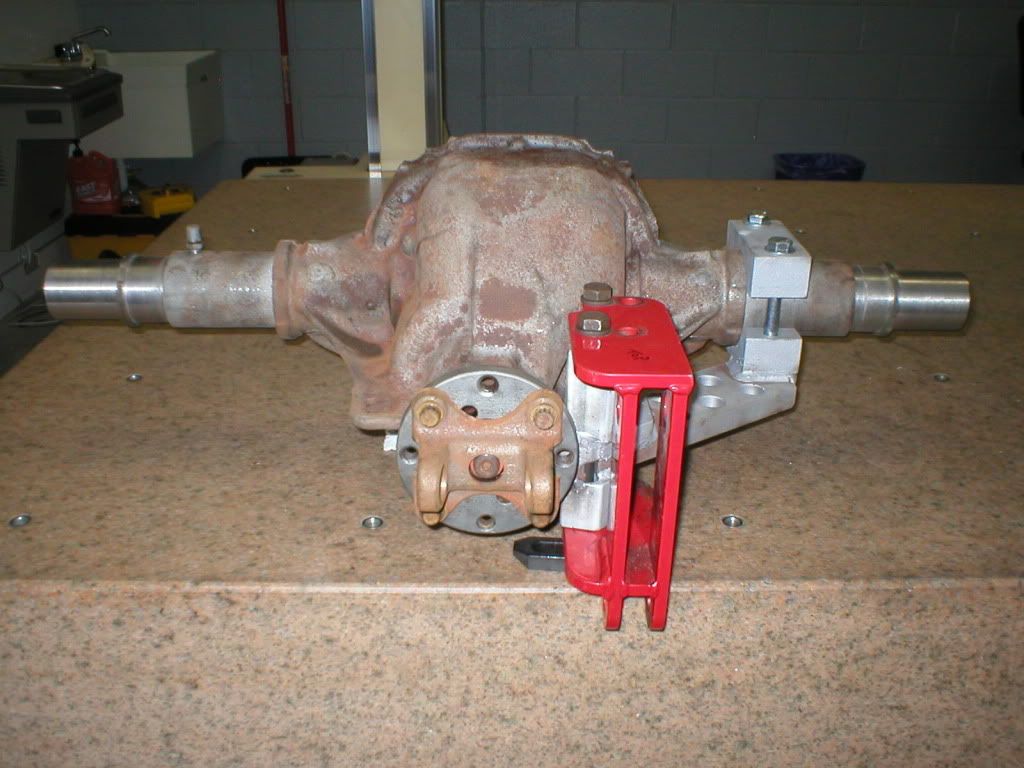

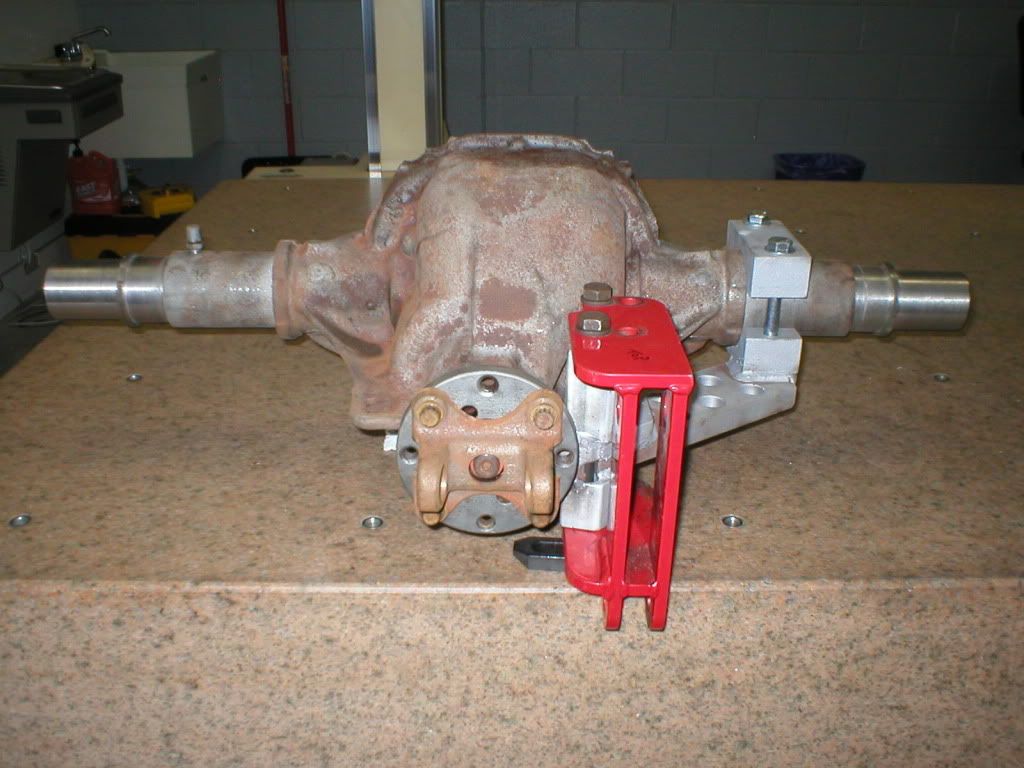

8.8 with bolt-on T/A mount

#1

This is the mount I made, its a complete bolt-on unit as I didn't want to do any welding on the cast iron housing. Only made 3 passes with it so far but it held up to a 1.55 60' in a 3700lb car. I ran into a few issues with it, the bracket is outboard more toward the driver side because I used the 31 spline truck flange which is much larger OD than than car one. In order to make this work I had to use the second set of torque arm bracket holes and ended up grinding off one of the other holes to clear the housing. I think this winter I'm going to switch to a regular style yoke and get rid of the flange all together because the clearance between it and the t/a mount it very close now. The only other issue I ran into was getting the rear sway bar to fit, its on there fine but its very close and could hit it if vibrates any. The easy solution here is to just make some spacers fr it and move it down 1/2" or so but I won't worry about that because I'm going to buy a drag bar this winter and figure it out then. Let me know what you think.

#4

its sandwiched on the webbing coming off the housing, we initially were going to weld to the housing so we machined some of it off but there was still enough to use. Bolt bolt holes for the t/a mount go through that webbing. I could also weld the part hat clamps on the axle tube to the tube itself if need be its all open for improvement.

#5

TECH Resident

iTrader: (3)

Join Date: Mar 2009

Location: Bonne Terre, MO

Posts: 863

Likes: 0

Received 0 Likes

on

0 Posts

Really good engineering. I have ? about the bolt on part. Besides it puking the driveshaft, what could potentially happen if it slipped/stripped, and the rear end tried to rotate? Hope it never does but just wondering if maybe you could put in some xtra insurance.

Trending Topics

#8

Only one way to find out, I never claimed this was a bulletproof design but trust me I wouldn't be driving it if i didn't feel comfortable with it. I'll try to get you guys some more pics but it's gonna be tough with the rear in the car. I may take it out this winter to make up some additional axle bracing some of the really high hp 8.8 guys are using.

#9

TECH Fanatic

iTrader: (8)

Honestly, maybe I'm just not enough of an engineer to figure it out but I can't figure out how it won't rotate on the axle tube based on the pictures and your explanation. But if it didn't rotate on a 1.55 60' then it should be good!

I wish you the absolute best of luck with this setup despite my skepticism, I love seeing these innovative new ways to put a good rear under our cars without breaking the bank. IMO it's funny that with the huge aftermarket for our cars, there has yet to be a mass-produced "budget" rear for us after all these years. These fabricated 8.8s might be the closest thing if a company were to put it into production.

I wish you the absolute best of luck with this setup despite my skepticism, I love seeing these innovative new ways to put a good rear under our cars without breaking the bank. IMO it's funny that with the huge aftermarket for our cars, there has yet to be a mass-produced "budget" rear for us after all these years. These fabricated 8.8s might be the closest thing if a company were to put it into production.

#10

I wonder why no one copies the mustang torque arm conversion. Like copy the torque arm and make a TA mount up front for it.

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

#11

I wonder why no one copies the mustang torque arm conversion. Like copy the torque arm and make a TA mount up front for it.

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

IDK how that one even adjusts? much less the next to no ground clearance.. the whole arm looks like it would hang lower then the rear swaybar. and if what you mean is how it ataches and make a side mount like the one above uses well he kinda did and alot of the ones on TGO do use both front bolts and clamp on the one side..

there is a nice one where he took cut plates the shape around the pininon area and slid each one up so even worst case the bolts broke the shape of these plates going around the pinion area of the rear would stop it from moving. plus he could weld them on like that

#12

Honestly, maybe I'm just not enough of an engineer to figure it out but I can't figure out how it won't rotate on the axle tube based on the pictures and your explanation. But if it didn't rotate on a 1.55 60' then it should be good!

I wish you the absolute best of luck with this setup despite my skepticism, I love seeing these innovative new ways to put a good rear under our cars without breaking the bank. IMO it's funny that with the huge aftermarket for our cars, there has yet to be a mass-produced "budget" rear for us after all these years. These fabricated 8.8s might be the closest thing if a company were to put it into production.

I wish you the absolute best of luck with this setup despite my skepticism, I love seeing these innovative new ways to put a good rear under our cars without breaking the bank. IMO it's funny that with the huge aftermarket for our cars, there has yet to be a mass-produced "budget" rear for us after all these years. These fabricated 8.8s might be the closest thing if a company were to put it into production.

just behind the yoke there is two mounting holes he used I think only one alot use both

#13

Honestly, maybe I'm just not enough of an engineer to figure it out but I can't figure out how it won't rotate on the axle tube based on the pictures and your explanation. But if it didn't rotate on a 1.55 60' then it should be good!

I wish you the absolute best of luck with this setup despite my skepticism, I love seeing these innovative new ways to put a good rear under our cars without breaking the bank. IMO it's funny that with the huge aftermarket for our cars, there has yet to be a mass-produced "budget" rear for us after all these years. These fabricated 8.8s might be the closest thing if a company were to put it into production.

I wish you the absolute best of luck with this setup despite my skepticism, I love seeing these innovative new ways to put a good rear under our cars without breaking the bank. IMO it's funny that with the huge aftermarket for our cars, there has yet to be a mass-produced "budget" rear for us after all these years. These fabricated 8.8s might be the closest thing if a company were to put it into production.

#15

My point though was that this conversion has been "tested to destruction" by the manufacturer. Yet it only uses 2 grade eight 3/8" bolts to keep the housing from rotating.

#16

yes, I would agree I dont see an issue with the bolts being used.. I think it will be fine

#18

I made this myself, I'd have to look into possibly making them to sell but I really want to test it out more and make sure it's a solid piece. I'm sure there is room for improvement in the design and I wouldn't want to sell something that's garbage or prone to breaking easily.

#20

This looks great, given that my car is mostly street/autox with just a few (2-3) 1/8mi days per year, this looks stout enough for my use, hope it works out!

Another design I had always thought would work for this, and for the 8.5" 10-bolt, would be mounting to the diff cover, as used in the GNX torque arm design:

http://home.comcast.net/~buickgnx/GNX/susp.htm

I wonder why no one copies the mustang torque arm conversion. Like copy the torque arm and make a TA mount up front for it.

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

The instructions for this kit says it uses two 3/8" bolts to hold it to the rear pumpkin, thats all thats keeping the rear from rotating, the ends of it are just clamped on.

http://www.maximummotorsports.com/co...TASS-2H_LG.jpg

http://home.comcast.net/~buickgnx/GNX/susp.htm