Our latest 9" install at SNL Performance

#1

BullF-16 Called us up awhile back to get one of our fabricated 9" IRS kits, after talking with him for a bit he decided to have it installed at SNL Performance in Fort Worth. SNL is also the home of Monster Clutch Company.

Since SNL is one of our largest dealers I decided I would come down for the install to answer any questions and to snap a few photo's.

Jim (BullF-16) chose the Strange 35 spline S-Trac pumpkin along with our big 35 spline inner stubs.

This way he gets a Lifetime warranty for the entire rear since the Strange S-Trac comes with a lifetime warranty plus all the Gforce parts are covered by our Lifetime warranty as well.

Our 9" kits also come with 300m axles, billet outer stubs and all the brackets and hardware to bolt right in.

Our 9" kit for the Camaro was designed to be bolted into the IRS Camaro, it's much more then a stock housing, it's a fully fabricated housing using all laser cut and cnc machined parts plus it's fully tig welded in our jig.

The face plates are 3/8" thick and the covers are 3/16" thick. We designed our housing for use in 2000+hp applications but it works great in a stock Camaro as well since it bolts right in with many pumpkin options available.

Just one look by customers and they see why our fabricated 9" is the bad boy on the market!

For Jim's 9" kit, we used a new driveshaft that we have been working with Dynotech Driveshafts to develop for the new Camaro.

It is an aluminum shaft with no cv joint on the front. This greatly reduces the weight on the nose of the shaft. This eliminates vibrations and gives the car a nice firm feel.

It uses an aluminum splined slip assembly in the front, it's not anything like the old steel slip shafts from the old days.

Dynotech has been making and selling shafts like this to the GT500 Mustang guys for a while now and they just love them.

The shafts are spun on Dynotechs high speed ballancer and tested before leaving Dynotech.

The great thing about the new shaft is it dropped a little over 9 lbs over the stock shaft. The stock shaft weighed in at about 24 lbs, the new Dynotech shaft weighs in at just 15 lbs.

We will be offering these new driveshafts for OEM replacement shafts in the very near future at a great price.

The install photo's speak for themselves, it took about 5 hours for the removal of the stock parts and install of the 9" kit. Jim also had a clutch installed so we were there all day.

Jim is a very happy customer to say the least

Here is Jim's 9" laid out before we packed it up for the trip to SNL (Monster Clutch Co.)

Here we are at SNL Performance in Fortworth

First off we got everything unpacked and laid out for assembly.

Step 1 is installing the studs in the housing and putting the pumpkin in.

Dont forget to put a bead of silicone around the pumpkin, our housings are precision machined so no gasket is needed.

Next step before tightening down the studs is installing the inner stubs to make sure the pumpkin is lined up with the bearing bores.

Again, a little bit of silicone around the bearings to seal the stubs in.

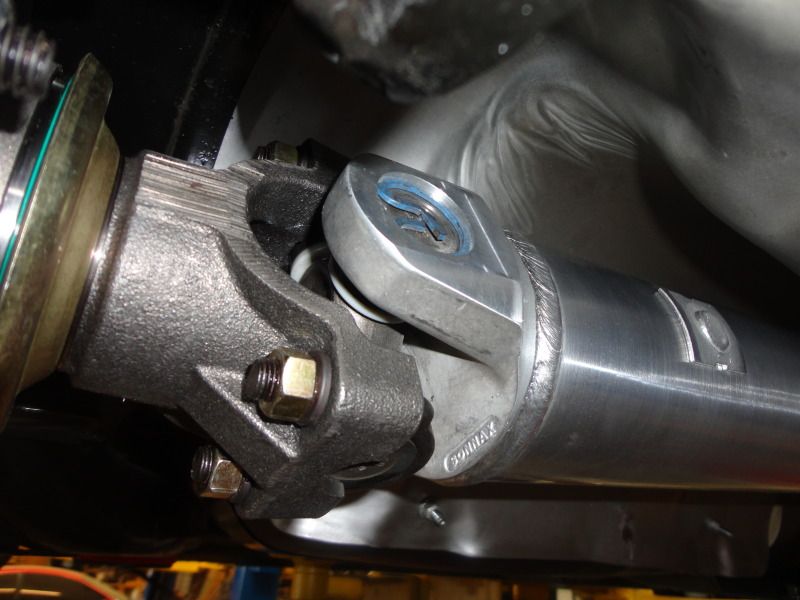

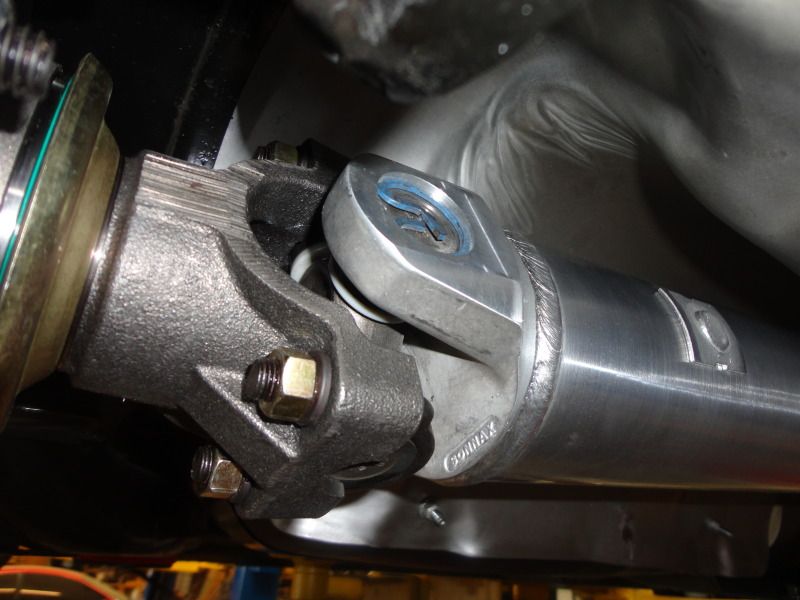

Next up was installing the new Dynotech driveshaft

All done except for putting cat back on

We didnt have to cut anything on the Stainless works cat back, just had to loosen some clamps and twist some pipes here and there to get everything to clear.

Since SNL is one of our largest dealers I decided I would come down for the install to answer any questions and to snap a few photo's.

Jim (BullF-16) chose the Strange 35 spline S-Trac pumpkin along with our big 35 spline inner stubs.

This way he gets a Lifetime warranty for the entire rear since the Strange S-Trac comes with a lifetime warranty plus all the Gforce parts are covered by our Lifetime warranty as well.

Our 9" kits also come with 300m axles, billet outer stubs and all the brackets and hardware to bolt right in.

Our 9" kit for the Camaro was designed to be bolted into the IRS Camaro, it's much more then a stock housing, it's a fully fabricated housing using all laser cut and cnc machined parts plus it's fully tig welded in our jig.

The face plates are 3/8" thick and the covers are 3/16" thick. We designed our housing for use in 2000+hp applications but it works great in a stock Camaro as well since it bolts right in with many pumpkin options available.

Just one look by customers and they see why our fabricated 9" is the bad boy on the market!

For Jim's 9" kit, we used a new driveshaft that we have been working with Dynotech Driveshafts to develop for the new Camaro.

It is an aluminum shaft with no cv joint on the front. This greatly reduces the weight on the nose of the shaft. This eliminates vibrations and gives the car a nice firm feel.

It uses an aluminum splined slip assembly in the front, it's not anything like the old steel slip shafts from the old days.

Dynotech has been making and selling shafts like this to the GT500 Mustang guys for a while now and they just love them.

The shafts are spun on Dynotechs high speed ballancer and tested before leaving Dynotech.

The great thing about the new shaft is it dropped a little over 9 lbs over the stock shaft. The stock shaft weighed in at about 24 lbs, the new Dynotech shaft weighs in at just 15 lbs.

We will be offering these new driveshafts for OEM replacement shafts in the very near future at a great price.

The install photo's speak for themselves, it took about 5 hours for the removal of the stock parts and install of the 9" kit. Jim also had a clutch installed so we were there all day.

Jim is a very happy customer to say the least

Here is Jim's 9" laid out before we packed it up for the trip to SNL (Monster Clutch Co.)

Here we are at SNL Performance in Fortworth

First off we got everything unpacked and laid out for assembly.

Step 1 is installing the studs in the housing and putting the pumpkin in.

Dont forget to put a bead of silicone around the pumpkin, our housings are precision machined so no gasket is needed.

Next step before tightening down the studs is installing the inner stubs to make sure the pumpkin is lined up with the bearing bores.

Again, a little bit of silicone around the bearings to seal the stubs in.

Next up was installing the new Dynotech driveshaft

All done except for putting cat back on

We didnt have to cut anything on the Stainless works cat back, just had to loosen some clamps and twist some pipes here and there to get everything to clear.

#7

Not sure if the owner of the car hangs out on here.

Thanks

Chris