Making My Own Mufflers, D%#& It!

#21

Wow....kudos to you for trying something really homebrewed. No matter the result, you'll have one heck of a conversation piece.

"Nice exhaust, what brand is it?"

"ME!"

"Nice exhaust, what brand is it?"

"ME!"

#22

No one has any muffler designs they think are good?

I know the Turbo style are kind of restrictive, but do a good job of lowering the noise.

Does anyone know how to cut the low frequency sounds and let the higher frequency sounds through?

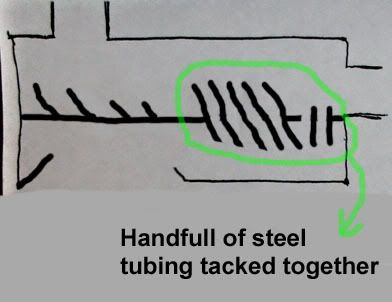

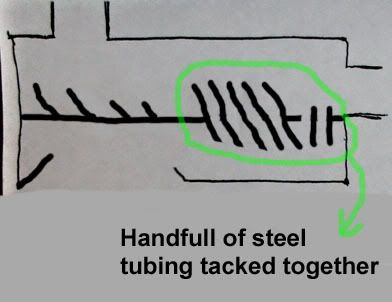

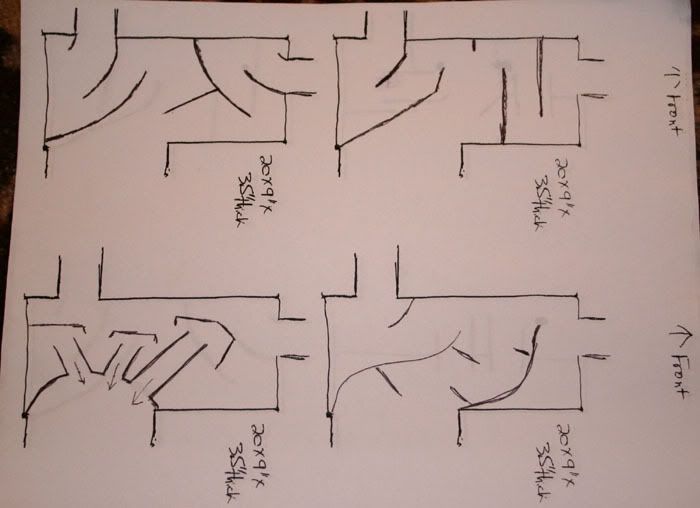

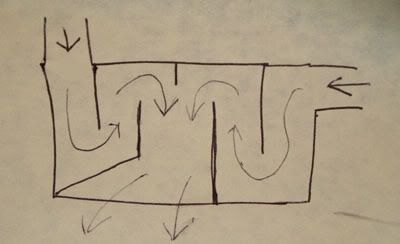

Here's a design I had floating around my head.

The tubing would act kind of like the MAF screens we so often take out. I'm thinking a small diameter tube will still flow well, but block the low frequency sounds letting the higher freq. through. I don't think I've ever seen this design before. Maybe it doesn't muffle the sound very well or maybe it sounds weird. A weird sounding exhaust might be cool.

Who knows man, making your own muffler is kind of crazy when you think about it.

I know the Turbo style are kind of restrictive, but do a good job of lowering the noise.

Does anyone know how to cut the low frequency sounds and let the higher frequency sounds through?

Here's a design I had floating around my head.

The tubing would act kind of like the MAF screens we so often take out. I'm thinking a small diameter tube will still flow well, but block the low frequency sounds letting the higher freq. through. I don't think I've ever seen this design before. Maybe it doesn't muffle the sound very well or maybe it sounds weird. A weird sounding exhaust might be cool.

Who knows man, making your own muffler is kind of crazy when you think about it.

Last edited by JasonWW; 06-24-2007 at 06:36 PM.

#23

I've got 18 new muffler designs to post up, but don't have time today. I did pick up a new Cherry Bomb brand Turbo muffler for 30 bucks and I'm going to cut it open. If I'm lucky I can reuse the hi-temp packing material in my new muffler to help make it quieter.

Edit: There is no packing material in it. Pretty disappointing, really.

Edit: There is no packing material in it. Pretty disappointing, really.

Last edited by JasonWW; 06-28-2007 at 12:12 AM.

#24

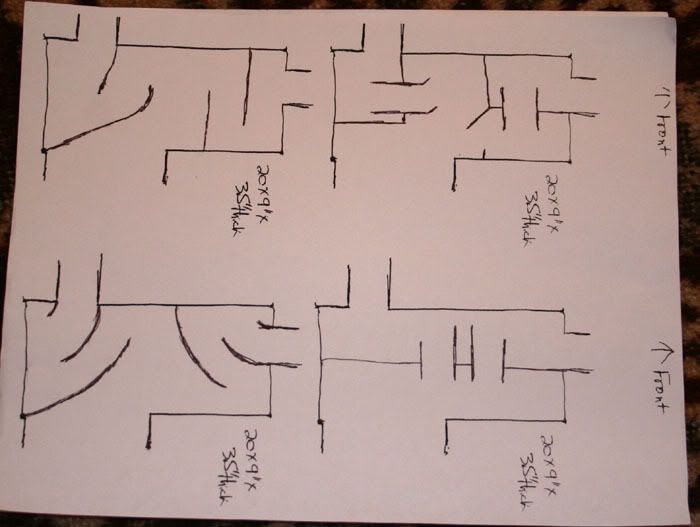

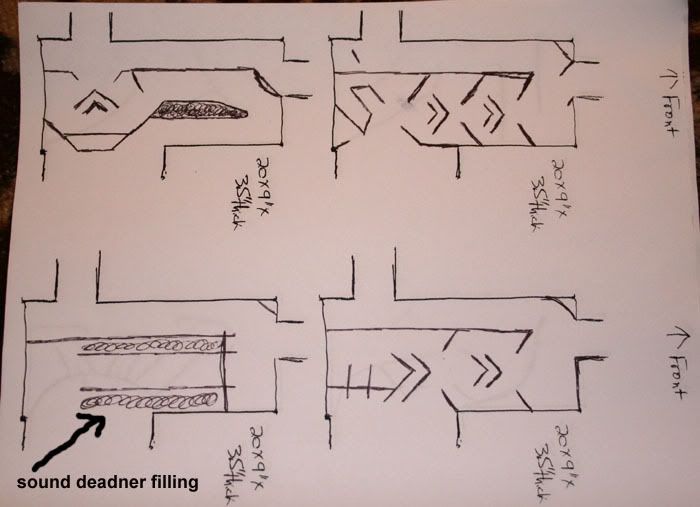

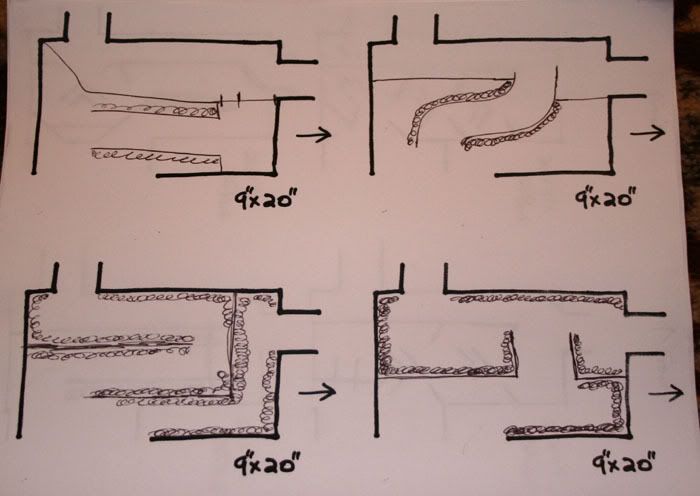

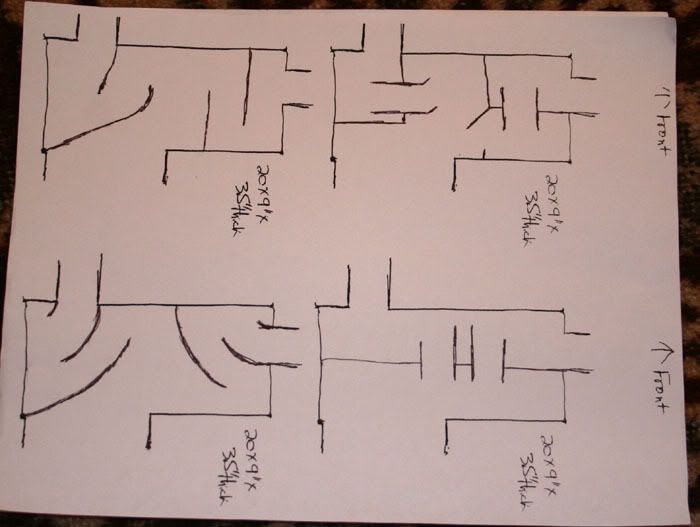

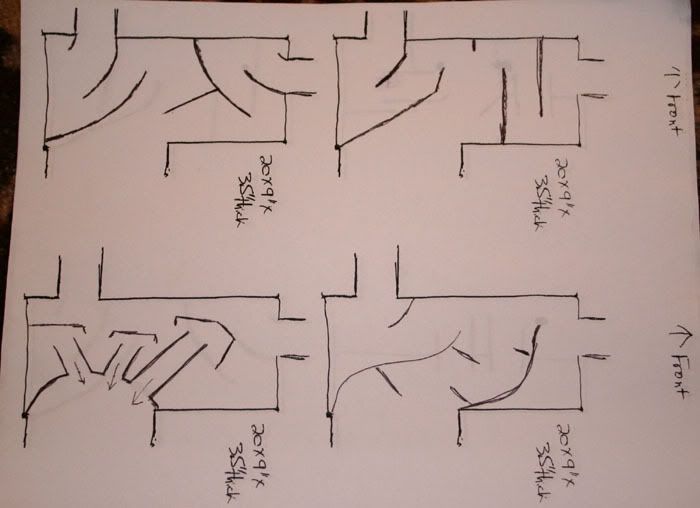

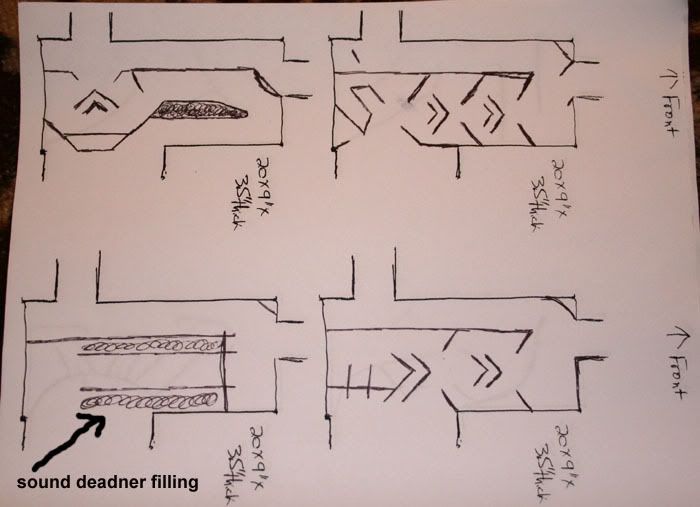

Here are a bunch of new ideas. Some use filler material to absorb sound and some don't.

Here is the Turbo muffler from Cherry Bomb that I cut open. I was hoping it would have some sound absorbing material in it. I could sandwich the material between the metal walls and some perforated steel similar to how Magnaflow does it to make things even more quieter.

Here is the Turbo muffler from Cherry Bomb that I cut open. I was hoping it would have some sound absorbing material in it. I could sandwich the material between the metal walls and some perforated steel similar to how Magnaflow does it to make things even more quieter.

Last edited by JasonWW; 07-01-2007 at 09:15 PM.

#26

After a lot of research it seems the most common material used to absorb sound is steel wool and high temp fiberglass. You place the steel wool right behind some perforated tubing or panel to help absorb and spread the heat evenly and then use the fiberglass or muffler packing behind it to absorb more of the sound waves. Interestly enough, you can buy muffler packing on ebay. It seems there are motorcycle mufflers that can be taken apart so they can be repacked when needed. I may see if any local cycle shops know anything about muffler design or about how different densities effect the sound.

Right now it looks like I will split the muffler into 2 sections, one will be a long winding path with the walls recieving the sound absorbing materials and the other section will be very short and contain a valve of some sort to act as a bypass. I'm not sure whether to make it electrically operated or vacuum operated. I can trigger it a couple of ways as well. There are RPM triggers, adjustable vacuum triggers and throttle position triggers. I may use a combo of each. Lets say for instance, only open above 60% throttle and 2500 rpm or maybe only open above 3000 rpm and less than 8" vacuum. Something like that.

I like using a vacuum diaphram on the valve because it will be open (no vacuum) when the engine is off. So it will rumble for a second right when you crank up the car. An electric solenoid may be quicker to open, though for the times you want to blip the throttle.

An electric solenoid may be quicker to open, though for the times you want to blip the throttle.

Another thought to control the bypass would be to use a reed style valve. I could adjust the tension to start opening it up as the exhaust pressure starts to build. The only potential problem with that is I'm not sure whether the valve will rattle at lower rpms due to the engine pulses you get at idle ot it my sound strange under deceleration.

As for right now I added a couple of resonator tips that have a lot of holes and packing in them right after the stock cats in place of the turn downs. They are kind of like mini magnaflows. They are really too short to make a big difference, but the noise level at higher rpms went down noticably. Interior resonance and idle volume only went down a hair. The biggest difference is that under deceleration the popping noises are gone and are replaced with a much mellower sound. I think this is the one:

3A Racing 62-2354

http://3aracing.com/catalog2006/page053.htm

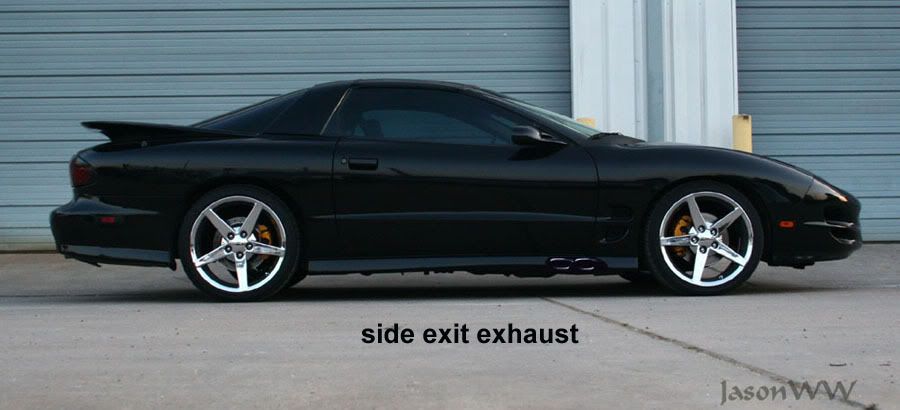

There seems to be a few general laws involved here. One is the smaller the muffler the louder it will be. The larger, the quieter. This is assuming the same style of muffler. Second id that the long runs of tubing to the rear also help to reduce the noise level. Since my muffler will be kind of small for handling both banks of the LS1 engine, I'm not running converters, plus it will exit by the passengers door this tells me I need to pull out all the stops as far as making it as quiet as I can.

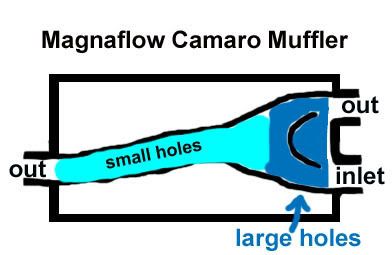

I also took a good look in my camaro style Magnaflow muffler I took off the rear and I'll post a diagram of how it's made and the internal flow pattern for it. Since I couldn't find this info here or on the web, I figured maybe there are some other folks wondering about this as well.

Right now it looks like I will split the muffler into 2 sections, one will be a long winding path with the walls recieving the sound absorbing materials and the other section will be very short and contain a valve of some sort to act as a bypass. I'm not sure whether to make it electrically operated or vacuum operated. I can trigger it a couple of ways as well. There are RPM triggers, adjustable vacuum triggers and throttle position triggers. I may use a combo of each. Lets say for instance, only open above 60% throttle and 2500 rpm or maybe only open above 3000 rpm and less than 8" vacuum. Something like that.

I like using a vacuum diaphram on the valve because it will be open (no vacuum) when the engine is off. So it will rumble for a second right when you crank up the car.

An electric solenoid may be quicker to open, though for the times you want to blip the throttle.

An electric solenoid may be quicker to open, though for the times you want to blip the throttle. Another thought to control the bypass would be to use a reed style valve. I could adjust the tension to start opening it up as the exhaust pressure starts to build. The only potential problem with that is I'm not sure whether the valve will rattle at lower rpms due to the engine pulses you get at idle ot it my sound strange under deceleration.

As for right now I added a couple of resonator tips that have a lot of holes and packing in them right after the stock cats in place of the turn downs. They are kind of like mini magnaflows. They are really too short to make a big difference, but the noise level at higher rpms went down noticably. Interior resonance and idle volume only went down a hair. The biggest difference is that under deceleration the popping noises are gone and are replaced with a much mellower sound. I think this is the one:

3A Racing 62-2354

http://3aracing.com/catalog2006/page053.htm

There seems to be a few general laws involved here. One is the smaller the muffler the louder it will be. The larger, the quieter. This is assuming the same style of muffler. Second id that the long runs of tubing to the rear also help to reduce the noise level. Since my muffler will be kind of small for handling both banks of the LS1 engine, I'm not running converters, plus it will exit by the passengers door this tells me I need to pull out all the stops as far as making it as quiet as I can.

I also took a good look in my camaro style Magnaflow muffler I took off the rear and I'll post a diagram of how it's made and the internal flow pattern for it. Since I couldn't find this info here or on the web, I figured maybe there are some other folks wondering about this as well.

Last edited by JasonWW; 07-11-2007 at 01:18 AM.

#27

Well, I've learned a lot more about exhausts and sound suppression for an internal combustion engine. One of the main things that stands out is the relationship between back pressure and the noise level. They are almost directly related. More backpressure equals less noise and vise versa. This lead me to a variable backpressure valve. It's kind of like an electric cutout, except the butterfly valve is mounted IN the pipe and is partially blocking the exhaust flow as opposed to being mounted on the side of the pipe.

Here is a really good article on a variable backpressure valve.

http://autospeed.drive.com.au/cms/A_0883/article.html

Here is part 3 which goes into detail about the control box.

http://autospeed.drive.com.au/cms/A_0893/article.html

If you want to see part one, go here. The valve isn't mentioned, it's more about the exhaust construction.

http://autospeed.drive.com.au/cms/A_0877/article.html

Here is an update in the valve along with it's new controls.

http://autospeed.drive.com.au/cms/A_2291/article.html

This Australin website, along with the US version, do a lot with exhaust systems, so if you want to learn more just check them out.

Here is a brief look at another type of valve. Just scroll down a little.

http://autospeed.drive.com.au/cms/A_1744/article.html

Using this technology should allow me to build a very small muffler under the passengers feet and still be very quiet while cruising. It has all the switches and controls needed to make it work with the list of requirements I put in the first post and it will allow full unrestricted flow when needed for maximum power. Using this valve means my muffler doesn't have to be built super quiet. I will probably design one that will flow very well and be similar to a Magnaflow.

I've also found that as far as a filler goes to absorb sound through a perforated metal panel or tube, you can use just stainless steel wool or you can add a high performance ceramic based wool with it. In order to keep the filler from falling out over time it's best to use material that is made of just one long strand. Anyway, I'll report back when I have more info.

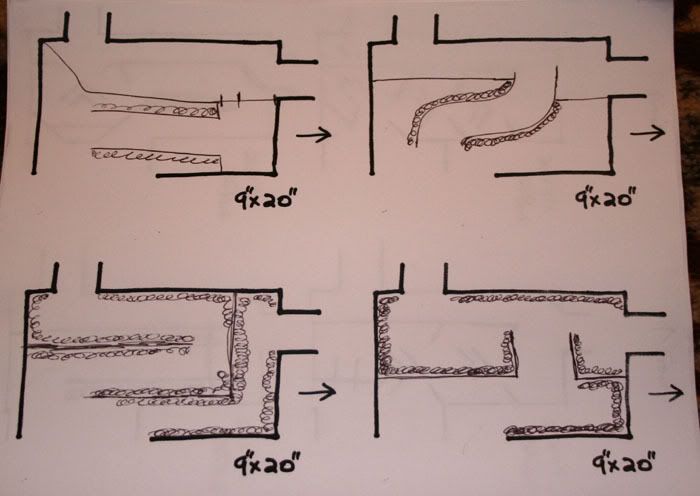

I did make a cardboard mock up of the muffler and I came up with a pretty cool idea to make the botton floor panel removable and to have all the baffling mounted to it. That way I can make multiply baffle designs and just drop the old one down and pop the new one in. It's pretty sweet. The one thing I'm still working one is being able to seal it up. I first thought the flanges of the 16 ga. stainlees steel would work well, but now I'm thinking it may warp some and create leaks. I may need to fab some thick flanges to it. We'll see.

The one thing I'm still working one is being able to seal it up. I first thought the flanges of the 16 ga. stainlees steel would work well, but now I'm thinking it may warp some and create leaks. I may need to fab some thick flanges to it. We'll see.

Here is a really good article on a variable backpressure valve.

http://autospeed.drive.com.au/cms/A_0883/article.html

Here is part 3 which goes into detail about the control box.

http://autospeed.drive.com.au/cms/A_0893/article.html

If you want to see part one, go here. The valve isn't mentioned, it's more about the exhaust construction.

http://autospeed.drive.com.au/cms/A_0877/article.html

Here is an update in the valve along with it's new controls.

http://autospeed.drive.com.au/cms/A_2291/article.html

This Australin website, along with the US version, do a lot with exhaust systems, so if you want to learn more just check them out.

Here is a brief look at another type of valve. Just scroll down a little.

http://autospeed.drive.com.au/cms/A_1744/article.html

Using this technology should allow me to build a very small muffler under the passengers feet and still be very quiet while cruising. It has all the switches and controls needed to make it work with the list of requirements I put in the first post and it will allow full unrestricted flow when needed for maximum power. Using this valve means my muffler doesn't have to be built super quiet. I will probably design one that will flow very well and be similar to a Magnaflow.

I've also found that as far as a filler goes to absorb sound through a perforated metal panel or tube, you can use just stainless steel wool or you can add a high performance ceramic based wool with it. In order to keep the filler from falling out over time it's best to use material that is made of just one long strand. Anyway, I'll report back when I have more info.

I did make a cardboard mock up of the muffler and I came up with a pretty cool idea to make the botton floor panel removable and to have all the baffling mounted to it. That way I can make multiply baffle designs and just drop the old one down and pop the new one in. It's pretty sweet.

The one thing I'm still working one is being able to seal it up. I first thought the flanges of the 16 ga. stainlees steel would work well, but now I'm thinking it may warp some and create leaks. I may need to fab some thick flanges to it. We'll see.

The one thing I'm still working one is being able to seal it up. I first thought the flanges of the 16 ga. stainlees steel would work well, but now I'm thinking it may warp some and create leaks. I may need to fab some thick flanges to it. We'll see.

#28

For anyone interested in sound or noise control, here is a very long article dealing with several different situations. Very good stuff.

http://www.nonoise.org/hearing/noisecon/noisecon.htm

Here is a very cool article on a muffler being made. This is the Magnaflow style with a straight through design.

http://www.rogueengineering.com/Merc...e=Construction

http://www.nonoise.org/hearing/noisecon/noisecon.htm

Here is a very cool article on a muffler being made. This is the Magnaflow style with a straight through design.

http://www.rogueengineering.com/Merc...e=Construction

#29

Another observation, if you want a beefy sounding idle, but a limited noise level at higher RPM, you can tweak the amount of restriction in the exhaust system so that at low flow conditions like idle and cruising the EBP (exhaust back pressure) is nice and low. Then as flow increases, the EBP starts to climb do to the restriction you added and the noise level gets lower. You can actually have the idle sound level louder than the redline sound level. That's cool if that's what you want, but I think I would want the opposite.

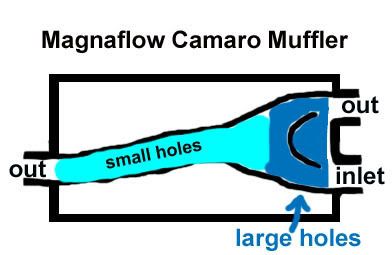

Louder at high RPM and quieter at idle and cruise. I think the key to that is using a absorbtion muffler design. This is like the Magnaflows we all know.

From post 11:

These type of mufflers only create about 10-15% restriction which is the lowest of any muffler type. Louvered core mufflers are more restrictive and the reverse flow or "turbo" mufflers are the worst. Anyway, The high frequencies go through the holes and get absorbed in the packing. This leaves only the low frequiencies which sound nice. Now at low RPM's the gas is flowing fairly slowly, so more of the sound is able to get through the holes. This can create a very quiet idle and cruise sound level. As the RPM's and the exhaust gas velocity go up the sound has less chance to go through the holes and this raises the noise level.

Using a variable back pressure device can allow us to have a more hi-tech control over the sound level, but it's more complicated. I think ideally I'd like to have a single 3" pipe (or 3.5" if possible) all mandrel bent turns and run it to the rear. Then fab up a 30" long cylinder muffler about 10" in diameter. Have it in the stock location with a single outlet behind the drivers side tire. That way I can slide a stainless sleeve into the muffler to block different numbers of the holes in the core. It would let you fine tune the sound.

Anyway, running around with no mufflers at all really helps keep you motivated to find a good exhaust solution.

Louder at high RPM and quieter at idle and cruise. I think the key to that is using a absorbtion muffler design. This is like the Magnaflows we all know.

From post 11:

These type of mufflers only create about 10-15% restriction which is the lowest of any muffler type. Louvered core mufflers are more restrictive and the reverse flow or "turbo" mufflers are the worst. Anyway, The high frequencies go through the holes and get absorbed in the packing. This leaves only the low frequiencies which sound nice. Now at low RPM's the gas is flowing fairly slowly, so more of the sound is able to get through the holes. This can create a very quiet idle and cruise sound level. As the RPM's and the exhaust gas velocity go up the sound has less chance to go through the holes and this raises the noise level.

Using a variable back pressure device can allow us to have a more hi-tech control over the sound level, but it's more complicated. I think ideally I'd like to have a single 3" pipe (or 3.5" if possible) all mandrel bent turns and run it to the rear. Then fab up a 30" long cylinder muffler about 10" in diameter. Have it in the stock location with a single outlet behind the drivers side tire. That way I can slide a stainless sleeve into the muffler to block different numbers of the holes in the core. It would let you fine tune the sound.

Anyway, running around with no mufflers at all really helps keep you motivated to find a good exhaust solution.

#31

Thanks for the stinger link.

I should point out that my earlier thought of using reed valves probably won't work, as the exhaust gasses seem to pulse out instead of a steady flow. A reed style valve would make a lot of noise.

I thought I had posted this link, but I guess not.

https://ls1tech.com/forums/generation-iii-external-engine/502513-magnaflow-s-off-kook-s-headers.html

This car is running 4x9x18 Magnaflows straight off the headers.

I love the simplicity compared to me making a mandrel bent stainless steel y-pipe, I-pipe and going under the axle. The only down side is that the ground clearance is not very good for my car on the drivers side. I may just cut a hole in the floor and weld in a flat plate so that the muffler can tuck up a bit higher.

I actually like my resonator tips right after each stock cat, but it just drones too much while cruising. It's hard to talk to someone. It's great with the windows down and the stereo cranked, though. I wonder if just adding a length of pipe to direct the flow to the side of the car instead of under it would fix things?

I wonder if just adding a length of pipe to direct the flow to the side of the car instead of under it would fix things?

The only real unknown about the twin Magnaflows is whether it will drone while cruising. It's a bit of a gamble, but it's less work than making your own muffler. Damn 16 ga stainless is expensive! Perforated stainless tubing isn't too pricey, neither is stainless steel wool or a hightech sound absorbing material like AcoustiFill.

Does anyone know why mufflers are not made of aluminum? I know it can't be welded to steel, but you could add a header flange to connect it. It would be light weight, never rust and can be highly polished. I really don't know why it's not being used somewhere by somebody.

I should point out that my earlier thought of using reed valves probably won't work, as the exhaust gasses seem to pulse out instead of a steady flow. A reed style valve would make a lot of noise.

I thought I had posted this link, but I guess not.

https://ls1tech.com/forums/generation-iii-external-engine/502513-magnaflow-s-off-kook-s-headers.html

This car is running 4x9x18 Magnaflows straight off the headers.

I love the simplicity compared to me making a mandrel bent stainless steel y-pipe, I-pipe and going under the axle. The only down side is that the ground clearance is not very good for my car on the drivers side. I may just cut a hole in the floor and weld in a flat plate so that the muffler can tuck up a bit higher.

I actually like my resonator tips right after each stock cat, but it just drones too much while cruising. It's hard to talk to someone. It's great with the windows down and the stereo cranked, though.

I wonder if just adding a length of pipe to direct the flow to the side of the car instead of under it would fix things?

I wonder if just adding a length of pipe to direct the flow to the side of the car instead of under it would fix things?The only real unknown about the twin Magnaflows is whether it will drone while cruising. It's a bit of a gamble, but it's less work than making your own muffler. Damn 16 ga stainless is expensive! Perforated stainless tubing isn't too pricey, neither is stainless steel wool or a hightech sound absorbing material like AcoustiFill.

Does anyone know why mufflers are not made of aluminum? I know it can't be welded to steel, but you could add a header flange to connect it. It would be light weight, never rust and can be highly polished. I really don't know why it's not being used somewhere by somebody.

#32

Here are numerous muffler cut-aways showing the internals.

MUFFLER DESIGNS

Guy making his own mufflers.

http://www.vord.net/cars/mgb_mods/ex...win_pipes.html

MUFFLER DESIGNS

Guy making his own mufflers.

http://www.vord.net/cars/mgb_mods/ex...win_pipes.html

Last edited by JasonWW; 07-27-2007 at 02:12 AM.

#33

I was able to get some more specific prices on the perforated core and it's way up there as well. I think to make a muffler properly with all stainless steel contruction you'd be looking at $500-$600 for a pair of them. It's much more feasable to me to just buy some mufflers and mod them if need be. The big muffler companies must buy their material in bulk and use all of it so they can keep the price down. The only way I could do it cheaply would be to make one from steel. I might get lucky and find a stainless muffler on a stock car at the junkyard and gut it to make my own design, but it's unlikely.

On another subject, I just ran across something totally unique. Now I've looked at all the collector mufflers out there and they are all over $250-$300 each. Check out these collector inserts.

They are made by Car Chemistry and slip into your header collector and the pipe. It looks very easy to install and remove. They run about $65-$75 each at Jegs.

The weld- in units are a bit cheaper:

Here's an article with more pics.

muffler inserts article

They appear to function by mixing hot and cooler exhaust gases to lower the noise level. Very interesting stuff.

On another subject, I just ran across something totally unique. Now I've looked at all the collector mufflers out there and they are all over $250-$300 each. Check out these collector inserts.

They are made by Car Chemistry and slip into your header collector and the pipe. It looks very easy to install and remove. They run about $65-$75 each at Jegs.

The weld- in units are a bit cheaper:

Here's an article with more pics.

muffler inserts article

They appear to function by mixing hot and cooler exhaust gases to lower the noise level. Very interesting stuff.

Last edited by JasonWW; 07-28-2007 at 02:16 AM.

#36

Well, I'm probably going to wrap this topic up. It's become very obvious that there's no way for a single person to compete with the big muffler companies. I thought I could do it cheaper, but nope. I'd be spending more in parts, plus doing all the welding labor which takes time. I'd say the only reason to actually make your own muffler is because you have a very unique size requirement. Even then I would recommend buying a muffler and modding it if at all possible or have a small muffler company make one to your needs. You'd still probably come out ahead.

I think I'm going to try a pair of the Magnaflow 14416's. They are 4" in diameter, have a 14" long body and a 2.5" core. They are polished stainless steel and run about $65 each.

Based on the principles I learned through researching all this, I may also add a variable backpressure valve to the end of each one to actively control the noise level.

While researching I ran across a Ferrari 550 exhaust for sale and I was surprised to see a vacuum operated valve on 2 of the 4 tips just like the C6 Z06. Very cool!

Ferrari also use valves on some pretty complicated systems. I think I see 4 here.

Check out this Capristo Stainless Exhaust for the 430. Perfection.

For only $4,000.

I think I'm going to try a pair of the Magnaflow 14416's. They are 4" in diameter, have a 14" long body and a 2.5" core. They are polished stainless steel and run about $65 each.

Based on the principles I learned through researching all this, I may also add a variable backpressure valve to the end of each one to actively control the noise level.

While researching I ran across a Ferrari 550 exhaust for sale and I was surprised to see a vacuum operated valve on 2 of the 4 tips just like the C6 Z06. Very cool!

Ferrari also use valves on some pretty complicated systems. I think I see 4 here.

Check out this Capristo Stainless Exhaust for the 430. Perfection.

For only $4,000.

Last edited by JasonWW; 08-02-2007 at 09:41 AM.

#37

Here's a radical thought. Why not use a blow off valve on the exhaust system? I mean some are made to mount to the turbo exhaust side so they can handle the heat. Factory exhausts can build up to 20 PSI or more of pressure. A better ehaust system can still get 6-10 PSI of back pressure, so why not bleed it off with a used blow off valve with some 5 PSI springs or so? Sounds crazy, huh?

You could probably run a real quiet exhaust and then have the BOV vented straight out. At higher RPM's the ehaust would be diverted past the muffler and make the exhaust louder. Mmmm, I'm going to look into it.

Or is a valve on the hot side called a wastegate? I don't know. It could look something like this:

Just weld it on before the muffler and put the right pressure spring in there and Voila! I don't know how it would sound, but it might be cool. By bleeding off the back pressure in the exhaust sytem under load or high RPM you will gain more power. I like it in concept.

You could probably run a real quiet exhaust and then have the BOV vented straight out. At higher RPM's the ehaust would be diverted past the muffler and make the exhaust louder. Mmmm, I'm going to look into it.

Or is a valve on the hot side called a wastegate? I don't know. It could look something like this:

Just weld it on before the muffler and put the right pressure spring in there and Voila! I don't know how it would sound, but it might be cool. By bleeding off the back pressure in the exhaust sytem under load or high RPM you will gain more power. I like it in concept.

Last edited by JasonWW; 08-01-2007 at 05:19 AM.

#38

The more I look at them, they are basically just valves. Kind of like a butterfly valve used in and electric cutout or a throttle body. So why not use one after the muffler as a type of variable back pressure device? A wastegate with a vacuum actuator works almost the same as the device in the articles above except the flow size is smaller.

See the butterfly and the actuator?

See the butterfly and the actuator?

#39

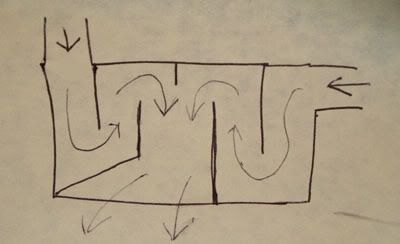

Here is a quick diagram of the magnaflow for the f-body:

As you can see there is a curved wing that divides the incoming gas into 2 sections. The long section has several small holes like you see on most Magnaflow mufflers, but the short side has larger holes. I'm guessing the larger diameter holes help compensate for the shorter path length which means fewer holes in total.

I don't know if Magnaflow made the internals of their mufflers in stainless about 5 years ago, but mine has noticable rust in it. I'd take some pics, but my camera is loaned away for a while. If anyone want's pics, let me know.

Here is a generic pic of this style muffler.

As you can see there is a curved wing that divides the incoming gas into 2 sections. The long section has several small holes like you see on most Magnaflow mufflers, but the short side has larger holes. I'm guessing the larger diameter holes help compensate for the shorter path length which means fewer holes in total.

I don't know if Magnaflow made the internals of their mufflers in stainless about 5 years ago, but mine has noticable rust in it. I'd take some pics, but my camera is loaned away for a while. If anyone want's pics, let me know.

Here is a generic pic of this style muffler.

Last edited by JasonWW; 08-02-2007 at 02:40 PM.