Possible lifter/rocker/oiling issue with video

#61

Update:

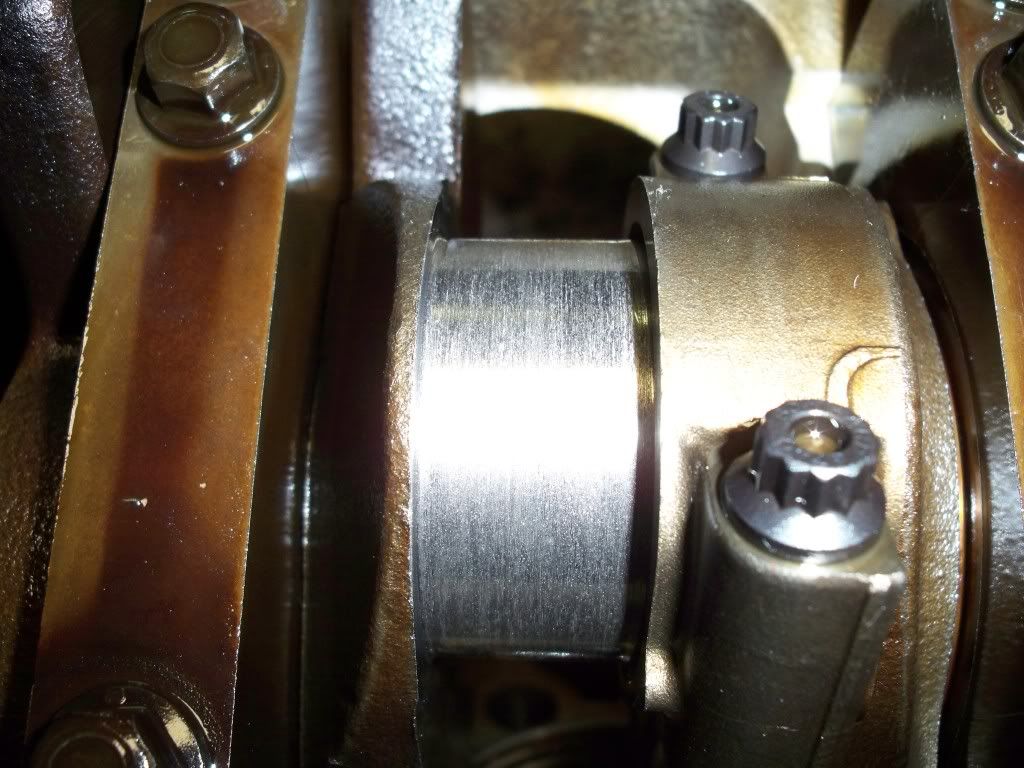

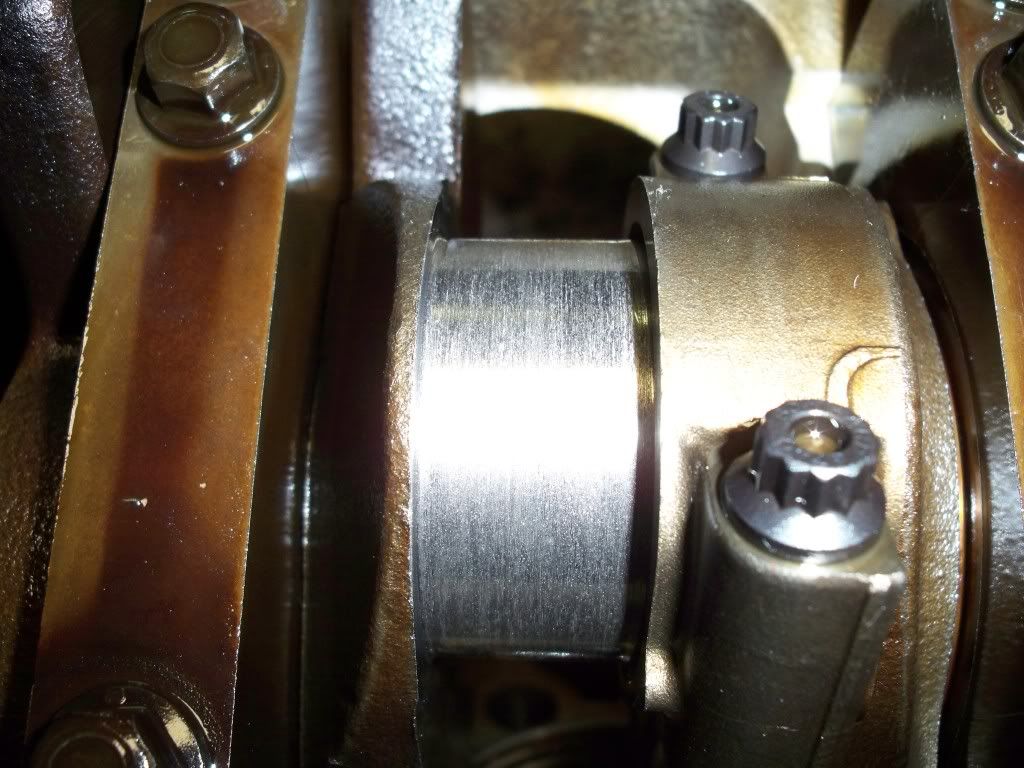

Alright, got sick of the car and didn't wanna even look at it for a few weeks, but now I'm back at it. I pulled out the engine the other day and finally got it on a stand and started to tear it down today. Got a couple problems, but nothing that stands out yet. Take a look.

That's from the driver side, where I haven't pulled off the head until now. That's a gunky mess of metal shavings. Apparently I didn't clean enough. The engine was full of shavings and slight sludgy mess. Could be bearing and other debri, or could be from when I fly cut and had to notch for the ls6 valley cover. I cleaned, shop vac'ed, and doused it with brake cleaner (then sprayed wd 40) when it was down to the bare short block, but obviously that wasn't enough. I've also pulled piston 1 and 2 and no spun bearing. It does have some excessive bearing wear, but nothing that would be making that noise. Sorry for no pics of that, but I left my camera at home and only had my phone, which isn't that clear on close up pics. I'll take some better pics shortly.

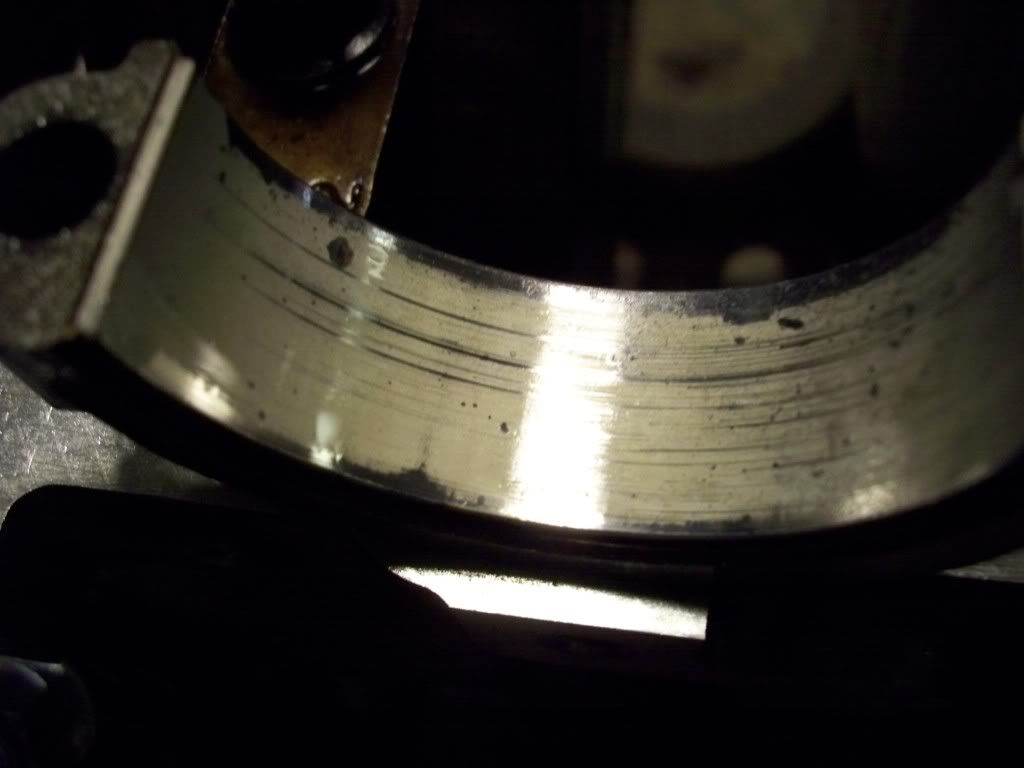

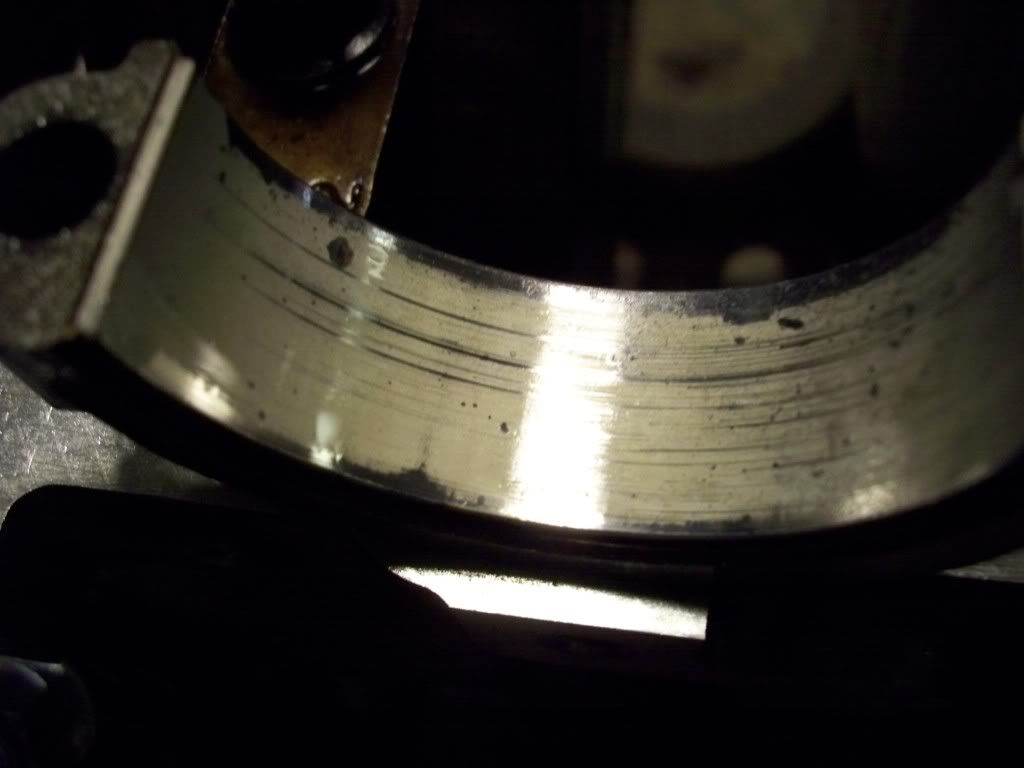

Also, when I pulled the cam I found this on the 2nd lobe from the front of the engine

Now, I inspected the cam when I got it and it was fine, but I do remember it falling a short distance one day while still in the box. I gave it a quick look over before install, but not in depth enough and it's possible I missed seeing that damage. But, again, that shouldn't be causing the noise, only premature wear and gouging of the lifter. And, there was no damage to the lifter, probably since there was very little run time.

All in all, I'm still tearing it down. So, I'll see what happens when I pull the rest of it apart.

Alright, got sick of the car and didn't wanna even look at it for a few weeks, but now I'm back at it. I pulled out the engine the other day and finally got it on a stand and started to tear it down today. Got a couple problems, but nothing that stands out yet. Take a look.

That's from the driver side, where I haven't pulled off the head until now. That's a gunky mess of metal shavings. Apparently I didn't clean enough. The engine was full of shavings and slight sludgy mess. Could be bearing and other debri, or could be from when I fly cut and had to notch for the ls6 valley cover. I cleaned, shop vac'ed, and doused it with brake cleaner (then sprayed wd 40) when it was down to the bare short block, but obviously that wasn't enough. I've also pulled piston 1 and 2 and no spun bearing. It does have some excessive bearing wear, but nothing that would be making that noise. Sorry for no pics of that, but I left my camera at home and only had my phone, which isn't that clear on close up pics. I'll take some better pics shortly.

Also, when I pulled the cam I found this on the 2nd lobe from the front of the engine

Now, I inspected the cam when I got it and it was fine, but I do remember it falling a short distance one day while still in the box. I gave it a quick look over before install, but not in depth enough and it's possible I missed seeing that damage. But, again, that shouldn't be causing the noise, only premature wear and gouging of the lifter. And, there was no damage to the lifter, probably since there was very little run time.

All in all, I'm still tearing it down. So, I'll see what happens when I pull the rest of it apart.

#62

Buddy of mine was at the shop tonight and asked if he could look over the engine. He said the number 6 rod had some up and down movement, so I gave him the go ahead to remove the cap/rod/piston. Got a call 3 minutes later.....spun bearing. About to head back out to my shop to take some pics.

To all that gave advice, Thanks again! Looks like a rebuild is in order. And a lesson....sometime a deal is too good to be true!

To all that gave advice, Thanks again! Looks like a rebuild is in order. And a lesson....sometime a deal is too good to be true!

#63

Alright, just got back from the shop. Obviously was spun before I got the engine by the amount of damage done. It only had about 20 minutes of total running time and never went over 3000 rpms. Looks like a good bit has been ground away, and this explains the shavings everywhere. I just hope the machine shop and cut that journal enough. Also, noticed that number 6 piston also had detonation on it too (from before I ran it) and never thought anything of it. But, now I'm wondering if there was f/i and/or nitrous on this motor, as #6 isn't a common one to have detonation. Anyways, here are the pics

#6 journal

#6 rod bearings (what's left of 'em, they almost over lapped each other)

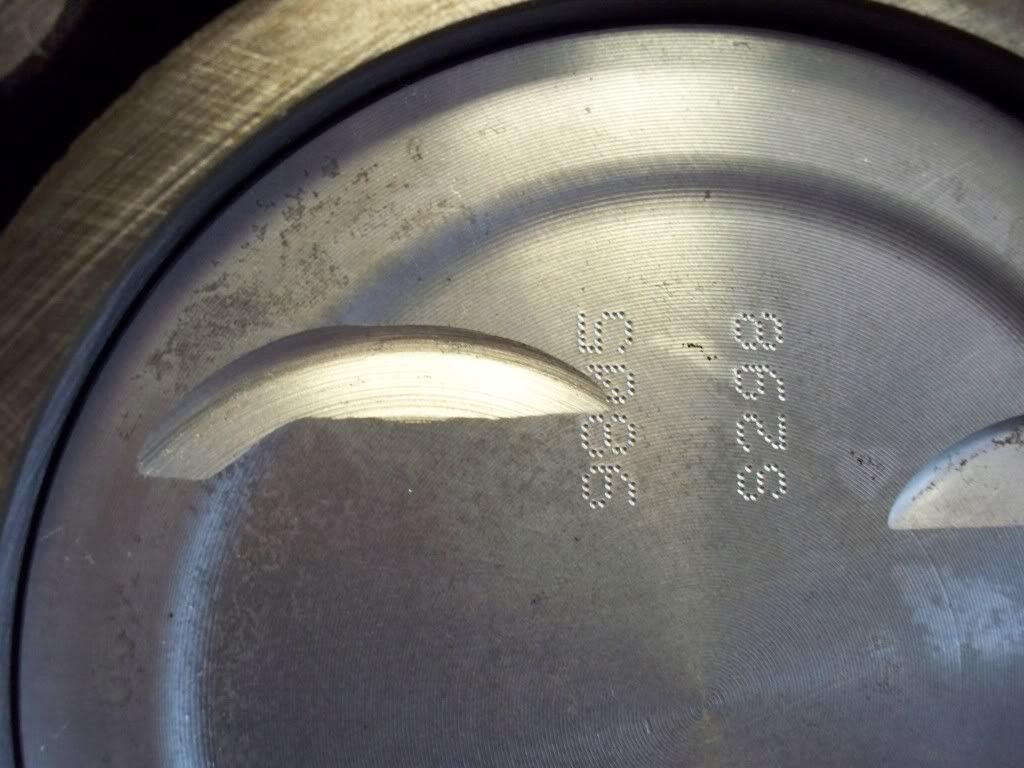

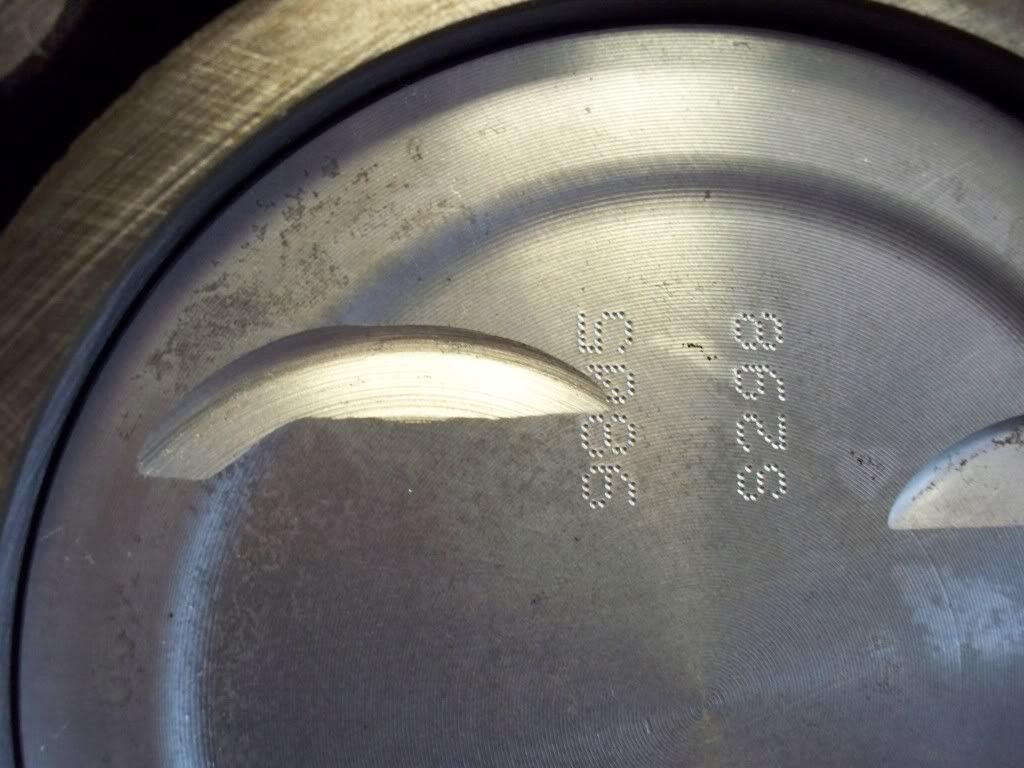

#6 piston

#5 bearings

#5/6 journal

And here's #1/2 journal for comparison

Well, I guess that does it for this thread. Again, thanks everyone for your input. It ended up being the worst case scenario that I was dreading and denying. Hopefully this will help someone one day.

#6 journal

#6 rod bearings (what's left of 'em, they almost over lapped each other)

#6 piston

#5 bearings

#5/6 journal

And here's #1/2 journal for comparison

Well, I guess that does it for this thread. Again, thanks everyone for your input. It ended up being the worst case scenario that I was dreading and denying. Hopefully this will help someone one day.

#65

Wasn't hitting. There's not much space there when the piston is a tdc, so it'll be the first place to detonate with a f/i setup. And yeah, I don't think the crank can be turned far enough to save it, would probably be cheaper finding a used crank and having it polished than turning this one anyway.

#67

Ya. I knew it was a possibility, but I was in denial and hoped it was something else. I'm not super experienced with engines, but I've never heard a spun bearing make such a loud tick like that. I also think you and liljay are right and the damage on #6 is from it hitting the head.

Let this thread be a lesson to all, if Russ says it's a spun bearing....then it's a spun bearing!!!

Let this thread be a lesson to all, if Russ says it's a spun bearing....then it's a spun bearing!!!

#68

TECH Enthusiast

iTrader: (59)

Join Date: Jan 2007

Location: Layton, UT

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for updating us. Nothing more frustrating than spending a good bit of change for something that's broken. I don't know the history behind the whole deal, but shame on the seller if he knew there was a problem and still let that stuff go for 600 bucks. If he didn't know, that's a different story. And maybe I'm wrong, maybe that stuff is worth 600 bucks broken, but I feel differently. Anyways, best of luck on your next project. At least next time you can go into it knowing it's a fresh build. Keep us updated on everything.

Brad

Brad

#69

Well, I gouged the block surface on the number 1 cylinder head bolt hole trying to get it out. Finally took it to a machine shop and it will cost $250-300 to deck the block and get the bolt out. Didn't want to do that, and explained I could get a shortblock for about the same price. Well, owner is an LS guy and we have a couple car guy friends in common around town. He happened to have an LQ4 short block that he was gonna use for a project he had, but scrapped the project. He sold it to me for $300! It's out of an '07 H2 with 3x,xxx miles! It sucks that this happened, but in the end I got a 6.0L like I wanted. And when I'm done with school here in a year, I can rip it back out and build a nice stroker!

#70

Just an update, and slight vent of anger. Got the 6.0 together. It does feel good to know that I'm the one who put the engine together, and no one to blame but me if it fails. Here are some pics of the assembled shortblock and the flycuts I made.

Well that being said, I began to put the heads on with my new ARP bolts after claying for PTV clearance. Everything is going smoothly on the first head and I'm on my final pass of 75ft lbs. the #5 bolt snaps!!! NOT AGAIN!!! I think anyone else but me and this point of this project would just give up and sell everything at this point and just drive honda's around, but not me, lol. I take the head off and luckily I'm able to back out the broken bolt out. I call ARP and they're sending me a new bolt but it won't be here til about Friday. I then reinstalled the head and lubed up a new bolt and tried again. And of course, it all goes smoothly. So I'm just gonna take it as a bad bolt I guess, although it's really really rare to get one from ARP. But, that'd be my luck at this point

It sucks, since I wanted to possible put the engine in the car tomorrow and fire her up, but that won't happen now. I guess it could be worse. I went ahead and snugged up the other head minus one head bolt so I didn't have to keep it in a plastic bag anymore. Here are some pics of the "almost finished" longblock

Well that being said, I began to put the heads on with my new ARP bolts after claying for PTV clearance. Everything is going smoothly on the first head and I'm on my final pass of 75ft lbs. the #5 bolt snaps!!! NOT AGAIN!!! I think anyone else but me and this point of this project would just give up and sell everything at this point and just drive honda's around, but not me, lol. I take the head off and luckily I'm able to back out the broken bolt out. I call ARP and they're sending me a new bolt but it won't be here til about Friday. I then reinstalled the head and lubed up a new bolt and tried again. And of course, it all goes smoothly. So I'm just gonna take it as a bad bolt I guess, although it's really really rare to get one from ARP. But, that'd be my luck at this point

It sucks, since I wanted to possible put the engine in the car tomorrow and fire her up, but that won't happen now. I guess it could be worse. I went ahead and snugged up the other head minus one head bolt so I didn't have to keep it in a plastic bag anymore. Here are some pics of the "almost finished" longblock