porting 799 head questions

#1

On The Tree

Thread Starter

Join Date: Sep 2011

Location: dayton ohio

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

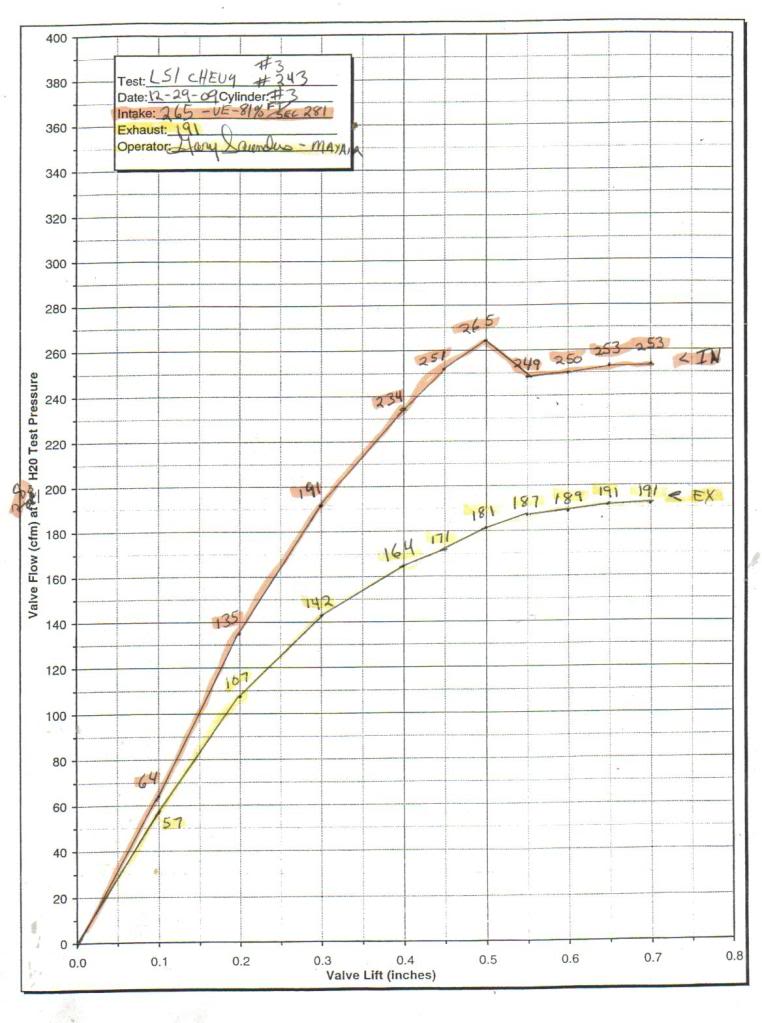

I started flowing a set of 799stock heads and right out pf the gate we had 240 out of the gate on the intake. I was geeked at the numbers being this was at. 600 lift when we ran the test. Inside the intake port is a boss hanging down which is related to the rocker bolt. We ground the boss out and smoothed that area. Reflowed that port and had 249 @ .400 when we hit the 500test she fell off and started nose diving by 40cfm

What I do wrong

What I do wrong

#2

Maybe the boss hanging down worked like an air foil? Can you get some pics before, after and during? I'm in for your progress....faults and gains...we might all learn something here

#3

All of the aftermarket ported 243 and other cathedral port heads always have this area removed and you can actually see the thread for the rocker arm bolt. Did you test with rocker bolt installed? It may create turbulence if there is just a gaping threaded hole there.

#4

On The Tree

Thread Starter

Join Date: Sep 2011

Location: dayton ohio

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

Yes

I installed a rocker.....bolt.......and the rail they sit on

The end of the rocker bolt does stick into the chamber by about. 125+/-

But I just can't figure out where I went wrong with the numbers

I will post pics over the weekend

its just amazing that with the boss in their she levels out at. 600@240 frm and with it removed it fall off at. 400 lift

Nothing else had been touched yet

pics to come though

I installed a rocker.....bolt.......and the rail they sit on

The end of the rocker bolt does stick into the chamber by about. 125+/-

But I just can't figure out where I went wrong with the numbers

I will post pics over the weekend

its just amazing that with the boss in their she levels out at. 600@240 frm and with it removed it fall off at. 400 lift

Nothing else had been touched yet

pics to come though

#5

TECH Senior Member

iTrader: (28)

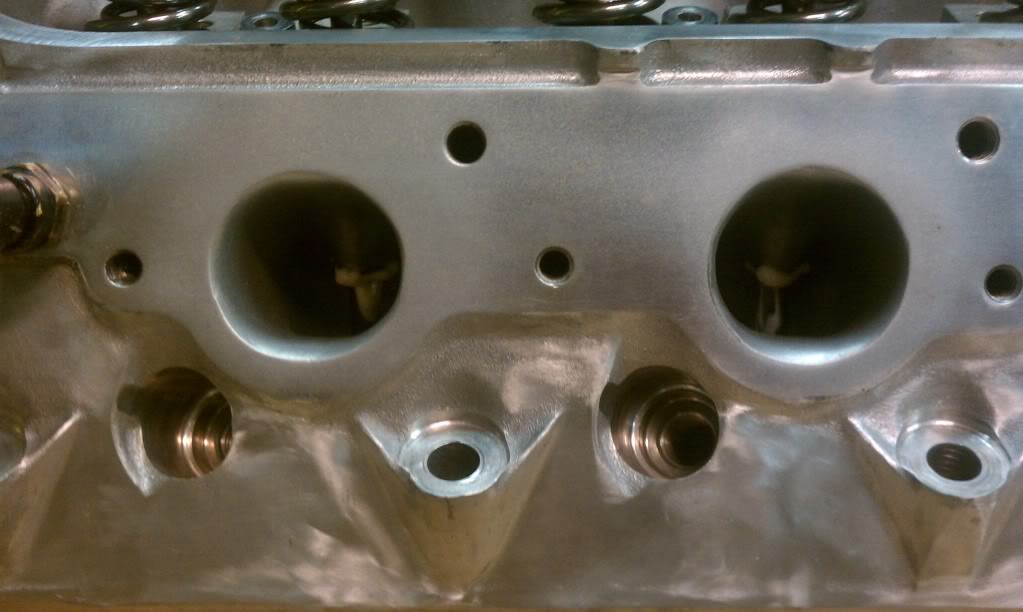

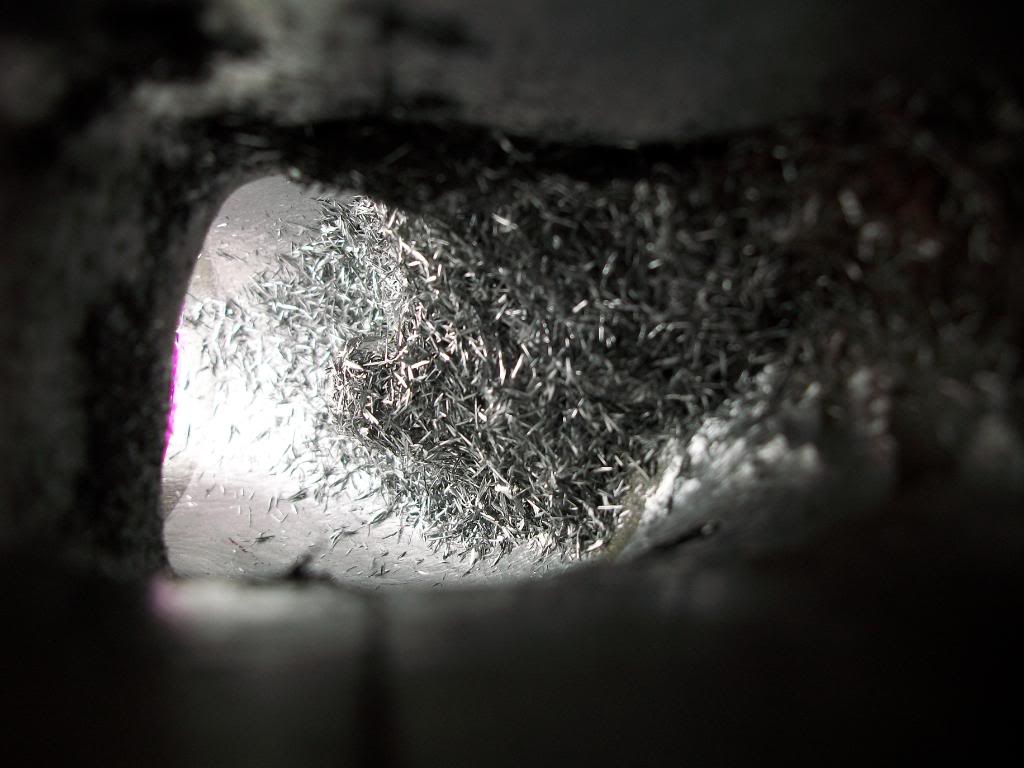

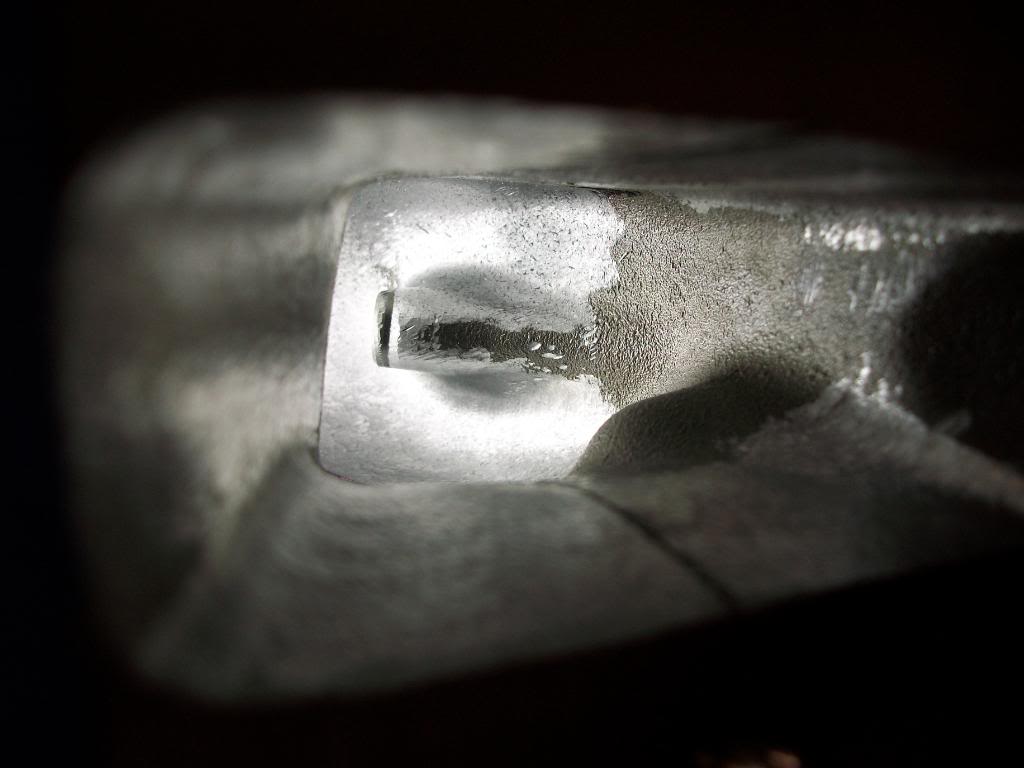

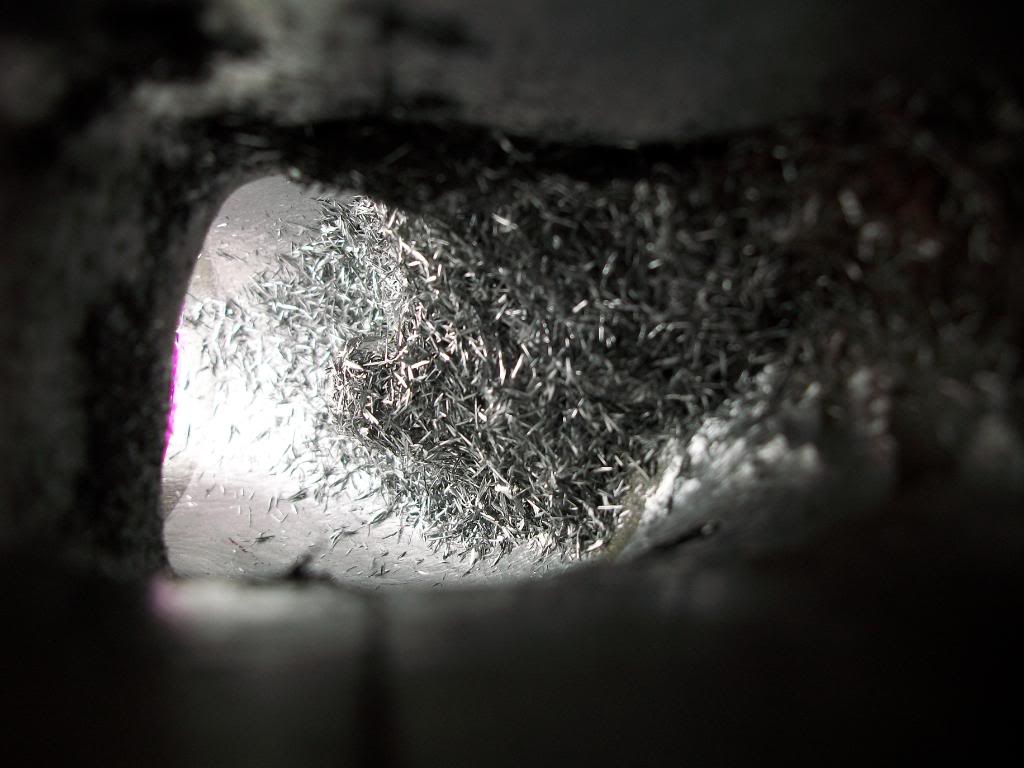

pics like this

Did you measure how big the port is there now. Map the port, It just got really big 3.x (CSA) for the rest of the port (size). And were that is (to the ssr) and what happens when it gets that big that fast. How did it sound .5 and up

You still have the stock valve job, and throat. Some good work there and ssr, will help the port out alot for were it is now.

Did you measure how big the port is there now. Map the port, It just got really big 3.x (CSA) for the rest of the port (size). And were that is (to the ssr) and what happens when it gets that big that fast. How did it sound .5 and up

You still have the stock valve job, and throat. Some good work there and ssr, will help the port out alot for were it is now.

#6

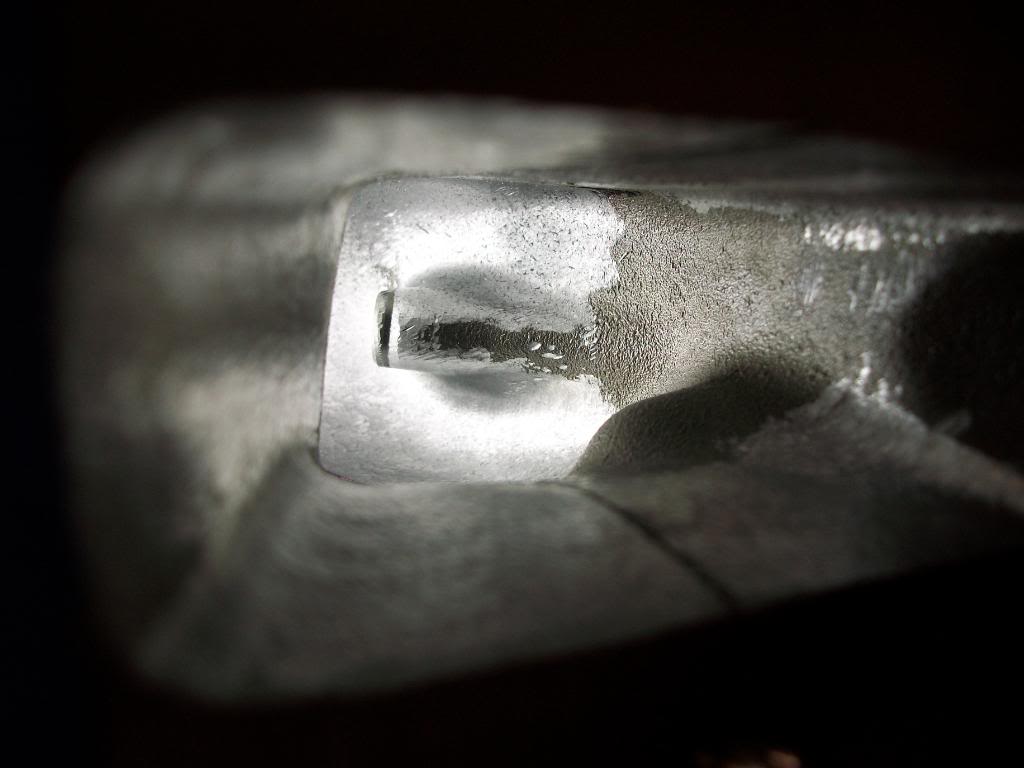

When I did mine I took a lot off of and around the valve guide, then knife edged it...did a lot of cleaning up work in the bowl and throat running into the bowl, then gasket matched all the ports and blended everything.

I polished everything up to a mirror finish so I could easily see any disturbances, then when I wad happy with it all I went back through and roughed it all up with 80 grit.....remember a slightly rough finish with 80 grit will create air pickets to aid in flow and actually out flow the same port that has been polished

I polished everything up to a mirror finish so I could easily see any disturbances, then when I wad happy with it all I went back through and roughed it all up with 80 grit.....remember a slightly rough finish with 80 grit will create air pickets to aid in flow and actually out flow the same port that has been polished

#7

TECH Addict

iTrader: (15)

That's why the engineers made the head the way they did...in my eyes cnc porting is the only to way to get ACCURATE and REPEATABLE results which is the key...even if you get that port flowing better above 400 lift you will still have 7 to go, not that it ain't possible it's just HARD to do...good luck and keep us posted

I am currently working on modeling both the ls1 and ls6 heads with computational fluid dynamics software in order to analyze and eventually write my own cnc Program so I'm very interested on hearing people's experiences of what will and won't work...

I am currently working on modeling both the ls1 and ls6 heads with computational fluid dynamics software in order to analyze and eventually write my own cnc Program so I'm very interested on hearing people's experiences of what will and won't work...

Trending Topics

#8

I should have stock in poster board companies lol....I use it to make patterns for EVERYTHING....it is amazing how two things can look the same till you hold a poster board cut out up to both of them.

Sharpies are also my friend

Sharpies are also my friend

#9

On The Tree

Thread Starter

Join Date: Sep 2011

Location: dayton ohio

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

yes the pics were what i am looking for

i see the rocker boss is gone in your pic to so i guess i am on the right track and all

now what about the flat side of the intake guide, is it best to cut it totally out and come to a mild point behind the guide or leave it half way in and take the rest out

i am going to work on the seat area and bowl also, tear drop the front side of the guide

what about the floor????? any modding going on their

thanks for the help guys

i see the rocker boss is gone in your pic to so i guess i am on the right track and all

now what about the flat side of the intake guide, is it best to cut it totally out and come to a mild point behind the guide or leave it half way in and take the rest out

i am going to work on the seat area and bowl also, tear drop the front side of the guide

what about the floor????? any modding going on their

thanks for the help guys

#10

On The Tree

Thread Starter

Join Date: Sep 2011

Location: dayton ohio

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

i read about mervs mcss having head issues and i guess this is what i want to try and avoid if all possible, i mean even pro cnc stuff can fail, which is a shame for what it costs, but i just am tring to do a low buget build on this ls project of mine but its not working and i figured i could save alot of cheeder on heads if i do it myself and with the help of other members here

keep the posts coming please

keep the posts coming please

#11

Just remember all it takes is just getting too thin, or breaking through in one little spot in one port, so be conservative if your not sure....or be ready to possibly buy another stock head if you do go too deep in a spot.

After saying that, I ended up taking a lot out of my stock 241's. Best way to go about it is if you can picture in your head how the air will flow through the ports, then try and give the air the best smoothest path through the port, bowl and around the valve.....start by taking out all the Sharp edges, around out all the tight turns.

In my heads there was a hell of a lip made by the iron pressed in valve seat so I also needed to use an iron bit to blend the back of the seat into the port.

If you do, or do not nick the face of the valve seat plan on spending the money on a good quality valve job when your finished all the porting.....no use have a great flowing head if the valves don't seal

After saying that, I ended up taking a lot out of my stock 241's. Best way to go about it is if you can picture in your head how the air will flow through the ports, then try and give the air the best smoothest path through the port, bowl and around the valve.....start by taking out all the Sharp edges, around out all the tight turns.

In my heads there was a hell of a lip made by the iron pressed in valve seat so I also needed to use an iron bit to blend the back of the seat into the port.

If you do, or do not nick the face of the valve seat plan on spending the money on a good quality valve job when your finished all the porting.....no use have a great flowing head if the valves don't seal

#12

On The Tree

Thread Starter

Join Date: Sep 2011

Location: dayton ohio

Posts: 131

Likes: 0

Received 0 Likes

on

0 Posts

yep

i agree on the valve job

this is why i am not going to grind the seats or deck the head until i get the porting done....just in case

just for grins what would be the bigest valve i can stick in these heads with a 3.905 finish bore of my 5.3??????????

i agree on the valve job

this is why i am not going to grind the seats or deck the head until i get the porting done....just in case

just for grins what would be the bigest valve i can stick in these heads with a 3.905 finish bore of my 5.3??????????

#20

They were not flowed before or after, and have not seen the track yet, but they registered a good gain on the butt dyno.

Even beat a few sport bikes running these heads

Even beat a few sport bikes running these heads