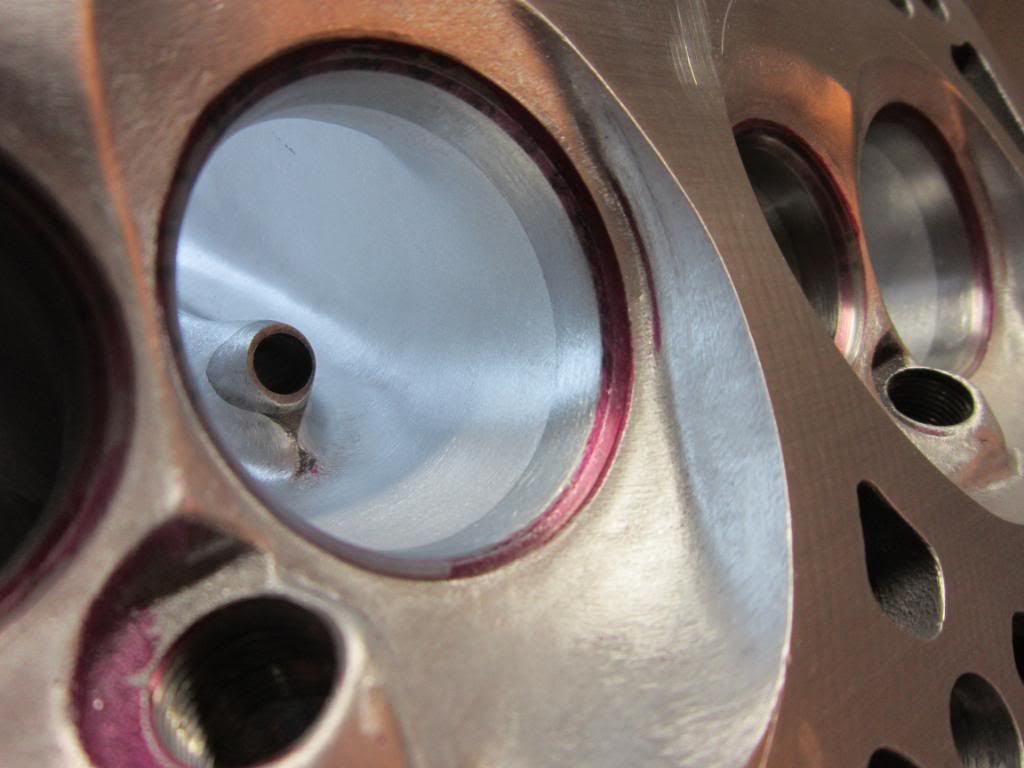

Pics of my DIY ported heads

#29

you think I used my feet or something

[IMG]http://i2.photobucket.com/albums/y11/studderin/stevenburke%20junk

Not that anyone is going to do anything with a flow number, 280, 330?? Shockwave can post what they make on the dyno if he wants.

junk 799s, not sure the miles? They were used, had carbon, on oil on them, my favorite

but guilds were tight.

but guilds were tight.stock valve with some back cuts, 45 seats nothing trick

tight VJ, big throats 1.815/1.4, kinda big top SSR normal 3+sq kept spring seat meat/rocker boss. inlet csa for a fast.

#33

TECH Fanatic

iTrader: (5)

also maybe i missed it but can you please post what tools you used to do this. i have ported 4 sets of LS heads now with alum cutters, cartridge rollers and cross buffs. mine look nothing like this. to be honest they make me feel like **** about my port work. whats the old saying the good make it look easy. nicely done. please share some your recipe with the rest of us (tools used, tips, ect...)

#35

Ya, I used it at BTR racing not a little Bport. Its a older cincinnati VMC. Got a big table, holds lots of tools (20+ I think). Check out the fixture in the back, holds blocks along the main center with a big ground bar in the mains and cam bores. So all the bores are 90* and 45* off the block center. And decked after holding the block in one setup, shows how off alot of bores are.

#38

also maybe i missed it but can you please post what tools you used to do this. i have ported 4 sets of LS heads now with alum cutters, cartridge rollers and cross buffs. mine look nothing like this. to be honest they make me feel like **** about my port work. whats the old saying the good make it look easy. nicely done. please share some your recipe with the rest of us (tools used, tips, ect...)

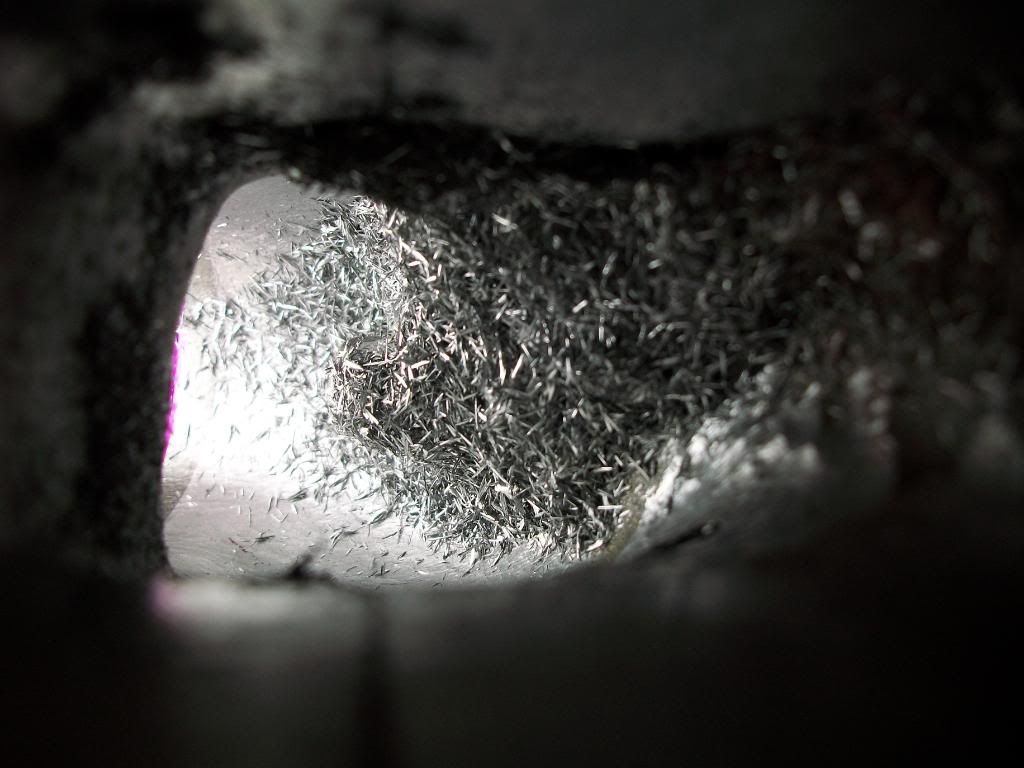

I only use good aluma and single cut carbide not, no double or light duty stuff but you need to have a lot of hours in to control them with the tq of ele. I get them Long 6inch and cut them down. get them for carbide selcet.com

http://www.carbideselect.com/burshpescuts.php

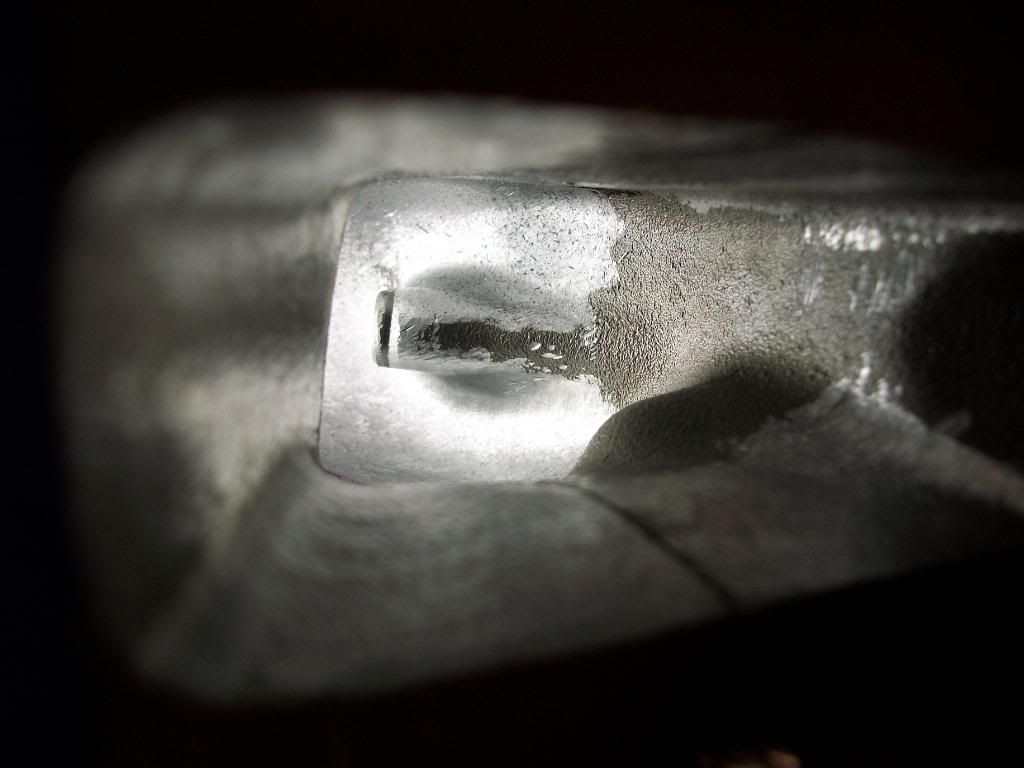

They really thows chips, and you can rough out a port to shape and size fast. No time getting there, Its ALL measuring it, and going to that size (cheap telescope gauge kit for HF) making tools to check other spots. But rolls just for fishish, pass oerv quick. (the orange 3M ones) not really removing anything or shaping at all. Just the strait wall really. Use them more as flap rolls to make it look all nice.

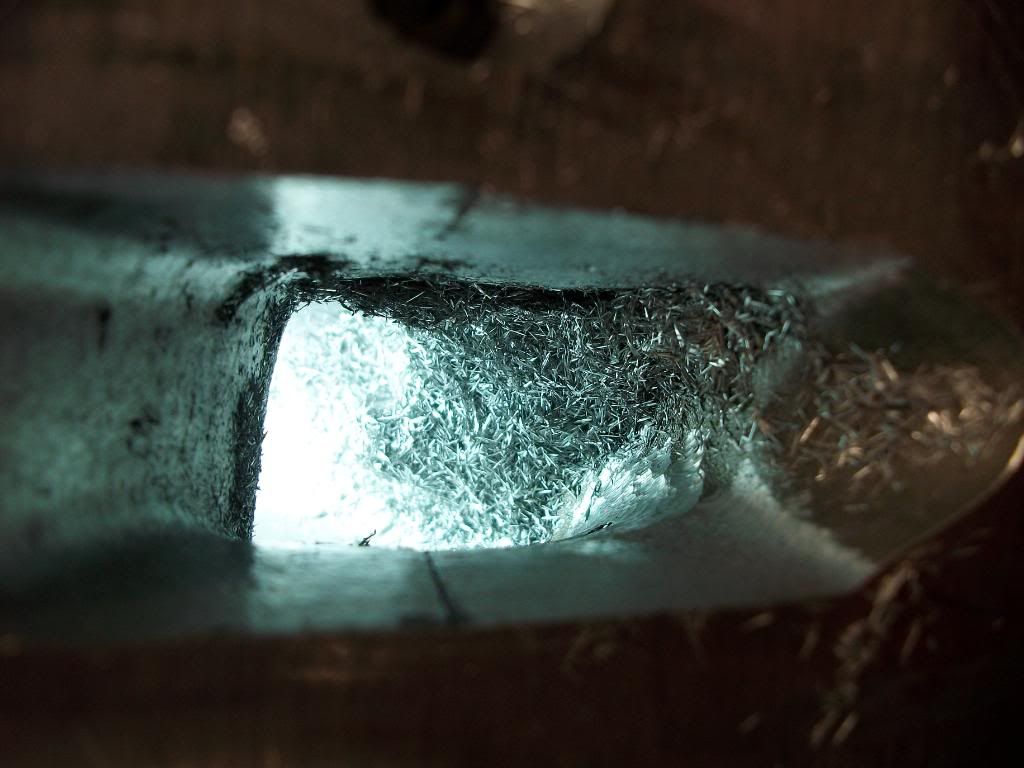

and a little 3/8 roll to get above the low side of the SSR, that was hard to do at 1st. I made a long roll manderal welding 2 of the SA ones together. But you can get them form MSC I htink 8-10-12, I think 14" long to get there. Just tune them slow. No cross buffs, might buzz it thu the ext port. quick but they don't last. I have some that are the small worn down size. I used to use flap sticks, but didnt at all on them. Takes to long setting them up with paper, I did this whole set with 2 rolls only. Could have used one but wanted a fresh one, went back and did the ssr after had it all sized and didnt like how it fit the final vj.

and a little 3/8 roll to get above the low side of the SSR, that was hard to do at 1st. I made a long roll manderal welding 2 of the SA ones together. But you can get them form MSC I htink 8-10-12, I think 14" long to get there. Just tune them slow. No cross buffs, might buzz it thu the ext port. quick but they don't last. I have some that are the small worn down size. I used to use flap sticks, but didnt at all on them. Takes to long setting them up with paper, I did this whole set with 2 rolls only. Could have used one but wanted a fresh one, went back and did the ssr after had it all sized and didnt like how it fit the final vj.

#39

Old School Heavy

iTrader: (16)

That is a pretty good pile of material laying there.

I have always used die grinders. I find them to be more maneuverable and less fatigue from the weight. Also, those big electric tend to create resistance to certain strokes because they have so much mass spinning inside.

Your work looks very uniform and all your walls look nice and straight. Did you measure the cross sectional area all the way to the short side radius?

I have always used die grinders. I find them to be more maneuverable and less fatigue from the weight. Also, those big electric tend to create resistance to certain strokes because they have so much mass spinning inside.

Your work looks very uniform and all your walls look nice and straight. Did you measure the cross sectional area all the way to the short side radius?

got touched after alot of milling

got touched after alot of milling