Achieving 22ft lbs with 140* turn on rocker bolt

#21

8 Second Club

iTrader: (16)

preload is still the same, it doesn't make a lick of difference if its achieved by a fixed rocker or an adjustable one...

.020~.070 is still the same.

that 1/4-3/4 turn is still within that range...difference is, you set it with a lock instead of with bottoming out the bolt to 22 ft lbs

Posted from LS1Tech.com App for Android

.020~.070 is still the same.

that 1/4-3/4 turn is still within that range...difference is, you set it with a lock instead of with bottoming out the bolt to 22 ft lbs

Posted from LS1Tech.com App for Android

#22

TECH Addict

iTrader: (2)

preload is still the same, it doesn't make a lick of difference if its achieved by a fixed rocker or an adjustable one...

.020~.070 is still the same.

that 1/4-3/4 turn is still within that range...difference is, you set it with a lock instead of with bottoming out the bolt to 22 ft lbs

Posted from LS1Tech.com App for Android

.020~.070 is still the same.

that 1/4-3/4 turn is still within that range...difference is, you set it with a lock instead of with bottoming out the bolt to 22 ft lbs

Posted from LS1Tech.com App for Android

#23

8 Second Club

iTrader: (16)

Originally Posted by Darkman

Quote:

Originally Posted by soundengineer

preload is still the same, it doesn't make a lick of difference if its achieved by a fixed rocker or an adjustable one...

.020~.070 is still the same.

that 1/4-3/4 turn is still within that range...difference is, you set it with a lock instead of with bottoming out the bolt to 22 ft lbs

Posted from LS1Tech.com App for Android

The difference is that the threads for which you counting turns are located in two different places - one in is directly over the pushrod and the other is at the fulcrum.

Originally Posted by soundengineer

preload is still the same, it doesn't make a lick of difference if its achieved by a fixed rocker or an adjustable one...

.020~.070 is still the same.

that 1/4-3/4 turn is still within that range...difference is, you set it with a lock instead of with bottoming out the bolt to 22 ft lbs

Posted from LS1Tech.com App for Android

The difference is that the threads for which you counting turns are located in two different places - one in is directly over the pushrod and the other is at the fulcrum.

double adjustable, a little different, but that is not what we are talking about here

Posted from LS1Tech.com App for Android

#24

TECH Addict

iTrader: (2)

And therefore, the Comp Cam material is talking about 1/4 to 3/4 turns at the pushrod - not at the fulcrum as is being discussed here for non-adjustable rockers.

#25

I know that we are not talking about adjustable rockers here, but the Comp Cam material that you referenced is talking about adjustable rockers.

And therefore, the Comp Cam material is talking about 1/4 to 3/4 turns at the pushrod - not at the fulcrum as is being discussed here for non-adjustable rockers.

And therefore, the Comp Cam material is talking about 1/4 to 3/4 turns at the pushrod - not at the fulcrum as is being discussed here for non-adjustable rockers.

Your the only person who has ever said to use pre-load that low on stock lifters.

#27

8 Second Club

iTrader: (16)

I dont know where the hell you think the adjustment is on the rockers on an adjustable rocker....

but its in the exact same place it is on a non adjustable rocker...

the bolt that holds the rocker down is also your adjustment point on the adjustable rocker

the preload is still the same... it doesnt matter what type of rocker you use... the spec is .020~.070 from comp cams...

hell.. call them and ask already

and engine builders who only build engines, will tell you the same thing...

#28

Oh yeah...I quoted the wrong guy...I was referring to "soundengineer"

#29

8 Second Club

iTrader: (16)

I am definitely not the only person to ever say that....

there are just a whole lot of other posts by people who read it somewhere else on the internet....posts from people just quoting somebody else..

you cant just quote other people and expect it to be correct just because the first few things in a google search come up saying the same thing...

its a #'s game, and and seacrh engines dont look for facts, they only look for what is spouted out the most, truth or a lie, it does not care about it..

#30

I am definitely not the only person to ever say that....

there are just a whole lot of other posts by people who read it somewhere else on the internet....posts from people just quoting somebody else..

you cant just quote other people and expect it to be correct just because the first few things in a google search come up saying the same thing...

its a #'s game, and and seacrh engines dont look for facts, they only look for what is spouted out the most, truth or a lie, it does not care about it..

there are just a whole lot of other posts by people who read it somewhere else on the internet....posts from people just quoting somebody else..

you cant just quote other people and expect it to be correct just because the first few things in a google search come up saying the same thing...

its a #'s game, and and seacrh engines dont look for facts, they only look for what is spouted out the most, truth or a lie, it does not care about it..

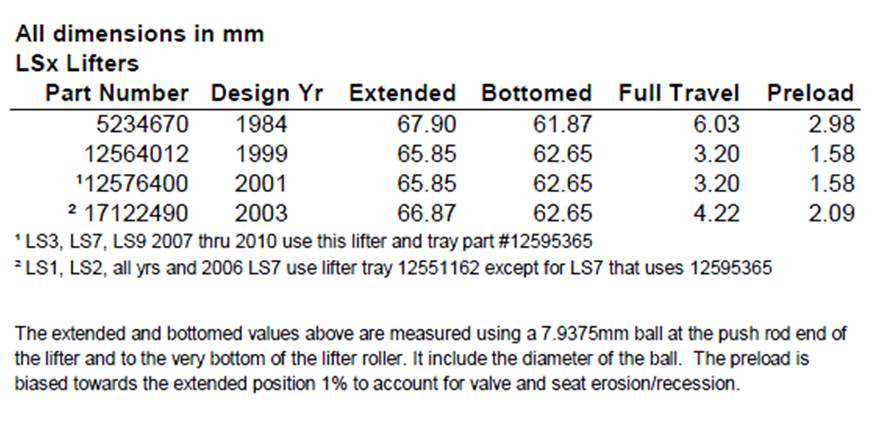

Notice the .082" of pre-load

#31

It seems like these posts pop up all too often and they cheap out on getting a 20 dollar tool to make sure they are getting a correct accurate measurement.

just for kicks I took my dial indicator and did count the turns for lash as mentioned in almost every one of these posts and found it very difficult to produce accurate results. (this was trying a pushrod that was too long)

Now my point is its very easy to push the plunger down before the rocker is really centered and the bolt head touches the rocker. now what you end up with is undetected plunger travel even easier if you try a few times and you create bleed down

maybe instead of figuring out how many licks it takes to get to the center of a tootsie pop just buy the length checker and do it right the first time

#32

It seems like these posts pop up all too often and they cheap out on getting a 20 dollar tool to make sure they are getting a correct accurate measurement.

just for kicks I took my dial indicator and did count the turns for lash as mentioned in almost every one of these posts and found it very difficult to produce accurate results. (this was trying a pushrod that was too long)

Now my point is its very easy to push the plunger down before the rocker is really centered and the bolt head touches the rocker. now what you end up with is undetected plunger travel even easier if you try a few times and you create bleed down

maybe instead of figuring out how many licks it takes to get to the center of a tootsie pop just buy the length checker and do it right the first time

#33

TECH Resident

iTrader: (5)

Here are four things I can add from experience:

1) even a comp pushrod length checker seems to have ~~.015 of slop. Best to measure flat to flat with calipers to confirm.

2). A motor can have .020 or more variation in preload variation just on the motor, ie perfectly same length pr.

3). The differential thermal expansion between steel and aluminum will cause you to lose ~.007 of preload by just warming to temp.

4) even custom PRs are binned in +/-.005" bins. Mine used most of that range.

All the above are just plain fact. Draw your own conclusions.

1) even a comp pushrod length checker seems to have ~~.015 of slop. Best to measure flat to flat with calipers to confirm.

2). A motor can have .020 or more variation in preload variation just on the motor, ie perfectly same length pr.

3). The differential thermal expansion between steel and aluminum will cause you to lose ~.007 of preload by just warming to temp.

4) even custom PRs are binned in +/-.005" bins. Mine used most of that range.

All the above are just plain fact. Draw your own conclusions.

#34

Here are four things I can add from experience:

1) even a comp pushrod length checker seems to have ~~.015 of slop. Best to measure flat to flat with calipers to confirm.

2). A motor can have .020 or more variation in preload variation just on the motor, ie perfectly same length pr.

3). The differential thermal expansion between steel and aluminum will cause you to lose ~.007 of preload by just warming to temp.

4) even custom PRs are binned in +/-.005" bins. Mine used most of that range.

All the above are just plain fact. Draw your own conclusions.

1) even a comp pushrod length checker seems to have ~~.015 of slop. Best to measure flat to flat with calipers to confirm.

2). A motor can have .020 or more variation in preload variation just on the motor, ie perfectly same length pr.

3). The differential thermal expansion between steel and aluminum will cause you to lose ~.007 of preload by just warming to temp.

4) even custom PRs are binned in +/-.005" bins. Mine used most of that range.

All the above are just plain fact. Draw your own conclusions.

I don't think anyone here is talking about "exact" measurements, thats why there is a range for pre-load (.050-.080), Room for error/expanison etc. I have used the E-tech Comp Cam tool for measuring, there is no "slop", there is a dotted line on it for accurate a repeatable measurements. Also .020" variance seems like a lot to me. When I measured, I had 2 pistons measured at .012" more than the other 6 and I thought that was alot.

BLUF, there is no reason to "guess" when there is a proven tool. You can just guess and will probably be fine, but you can say the same thing about really anything...Like why use a torque wrench? There is just a right and a wrong way of doing things. Doesnt always mean it will fail doing the latter of the two. Its just how you want to approach it. Honeslty I'm sick of people asking us to guess their measurements for them. Especially when 2000 post prior all say to buy the tool and measure.

Based on your comment, It does seem to me that your saying just throw what ever in and go because its all inaccurate anyways, which isnt entirely true

#35

12 Second Club

iTrader: (49)

I have found the easiest way to measure your valve train is to use a solid lifter and checker springs. I understand this is not viable for in car cam swaps as you cannot get to the lifters. However a checker spring is light enough it will tremendously aid in keeping the lifter from compressing while finding zero lash.

#36

TECH Resident

iTrader: (5)

I was definitely * NOT *saying throw in whatever ans go. My point was with 20 thou preload it would be real easy to run with no preload at all if the tolerances stacked against you.

As far as motor variations go and the 20 thou range, I know of three motors that varied this much. Mamo told me it was a typical range.

As far as length checkers go, mine also had a line and even if you accounted for the screw backlash it wad still not accurate to better than 10 thou. I have two checkers, this was true for both.

As far as motor variations go and the 20 thou range, I know of three motors that varied this much. Mamo told me it was a typical range.

As far as length checkers go, mine also had a line and even if you accounted for the screw backlash it wad still not accurate to better than 10 thou. I have two checkers, this was true for both.

#37

I have found the easiest way to measure your valve train is to use a solid lifter and checker springs. I understand this is not viable for in car cam swaps as you cannot get to the lifters. However a checker spring is light enough it will tremendously aid in keeping the lifter from compressing while finding zero lash.

#38

I was definitely * NOT *saying throw in whatever ans go. My point was with 20 thou preload it would be real easy to run with no preload at all if the tolerances stacked against you.

As far as motor variations go and the 20 thou range, I know of three motors that varied this much. Mamo told me it was a typical range.

As far as length checkers go, mine also had a line and even if you accounted for the screw backlash it wad still not accurate to better than 10 thou. I have two checkers, this was true for both.

As far as motor variations go and the 20 thou range, I know of three motors that varied this much. Mamo told me it was a typical range.

As far as length checkers go, mine also had a line and even if you accounted for the screw backlash it wad still not accurate to better than 10 thou. I have two checkers, this was true for both.