Finally pulling the trigger on parts!

#546

Thread Starter

Super Hulk Smash

iTrader: (7)

Joined: Aug 2004

Posts: 11,255

Likes: 141

From: Pace, FL

I paid about $2k and that included new 243s.

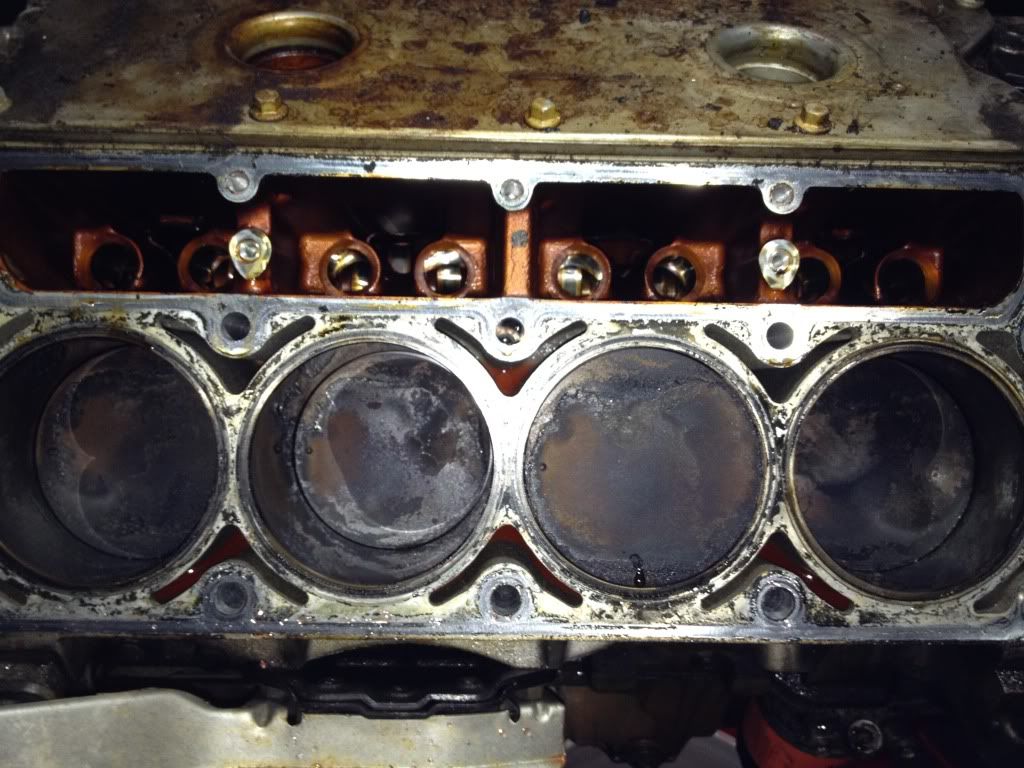

Also, I finally began work again on the motor tonight. I removed the rockers, pushrods, heads, lifters, lifter trays, and head gaskets. There's definitely some crude that fell in there and just a lot of gunky carbon buildup around the lifter bore and all over the pistons.

I plan to take tomorrow and thoroughly clean the motor, cylinders, and lifter bores, and then get down into the head bolt holes and chase those clean and then run some compressed air in there.

I'll make sure I take detailed pictures as I progress through the build process.

Also, I finally began work again on the motor tonight. I removed the rockers, pushrods, heads, lifters, lifter trays, and head gaskets. There's definitely some crude that fell in there and just a lot of gunky carbon buildup around the lifter bore and all over the pistons.

I plan to take tomorrow and thoroughly clean the motor, cylinders, and lifter bores, and then get down into the head bolt holes and chase those clean and then run some compressed air in there.

I'll make sure I take detailed pictures as I progress through the build process.

#550

Thread Starter

Super Hulk Smash

iTrader: (7)

Joined: Aug 2004

Posts: 11,255

Likes: 141

From: Pace, FL

So here's my question since I started on the valve covers as a test. Wire brush and brake cleaner seems to do the trick there. Is that the best way to go after the pistons?

I know I've heard of 3M roloc discs as well, but if the brake cleaner and wire brush works, is there a downside to using brake (or carb cleaner) in the internal engine?

I know I've heard of 3M roloc discs as well, but if the brake cleaner and wire brush works, is there a downside to using brake (or carb cleaner) in the internal engine?

#552

So here's my question since I started on the valve covers as a test. Wire brush and brake cleaner seems to do the trick there. Is that the best way to go after the pistons?

I know I've heard of 3M roloc discs as well, but if the brake cleaner and wire brush works, is there a downside to using brake (or carb cleaner) in the internal engine?

I know I've heard of 3M roloc discs as well, but if the brake cleaner and wire brush works, is there a downside to using brake (or carb cleaner) in the internal engine?

#555

When I did my H&C swap I used Permatex Gasket Remover (foam) to remove the crud from the pistons. Just let it sit on there for a couple of hours, wipe it off, any remaining use a little bit of acetone on a Kimberly Clark Solvent Resistant Blue Shop Towell and a razor blade. Barely any mess to it.

#557

Thread Starter

Super Hulk Smash

iTrader: (7)

Joined: Aug 2004

Posts: 11,255

Likes: 141

From: Pace, FL

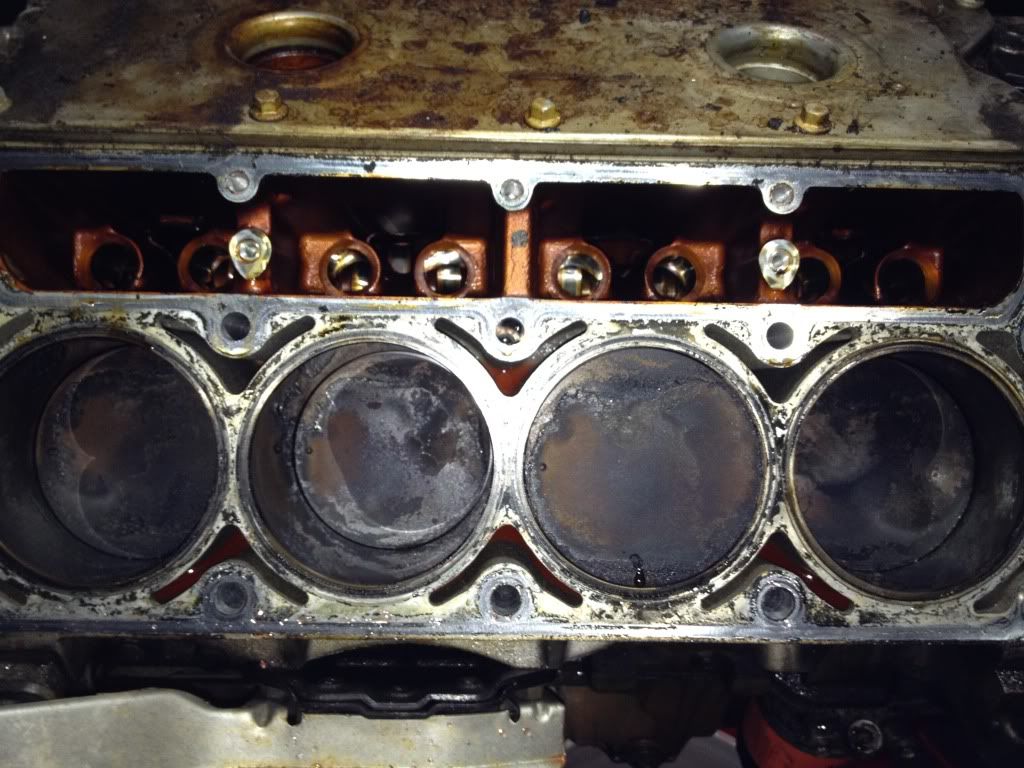

Time to get the Roloc. I wanted to avoid getting debris in the engine and into the bearings, but I can't get the pistons clean using carb cleaner/wire brush and even soaking the pistons with seafoam. The seafoam actually worked better than the carb cleaner.

Ugh.

I wouldn't worry with it, but since I'm measuring thousandths of an inch for flycutting, the carbon buildup is throwing off my measurements.

Ugh.

I wouldn't worry with it, but since I'm measuring thousandths of an inch for flycutting, the carbon buildup is throwing off my measurements.

#558

leave the valley on, tape up the lifter area and spin the deck surface down facing the floor, at least 90degrees if not further. Use the roloc edge so its spinning debris towards the floor.

Its not 100%, but helps with keeping stuff flying into your motor.

Its not 100%, but helps with keeping stuff flying into your motor.

#560

Thread Starter

Super Hulk Smash

iTrader: (7)

Joined: Aug 2004

Posts: 11,255

Likes: 141

From: Pace, FL

So, I'm busy with work these days and haven't really spent any time on the car (that's okay, it's f'ing hot).

But, I sat down this evening to plan out my weekends and some free time I have over the next few weeks to attack this build in a phased approach. And yes, I'm a project manager by trade, so this is how I tackle an undertaking of this magnitude:

Phase 1

Clean carbon buildup off of Pistons (still dealing with that)

Clear Cylinder Head Bolt Holes

Chase Threads Clean

Remove Harmonic Balancer (left it on - now I have to break it free on the engine stand)

Remove front cover and oil pump/timing chain

Remove old camshaft

Install new camshaft w/assembly lube

Install new oil pump/timing chain

Install New Cam plate torque to specs

Degree Camshaft w/degree wheel

Install front cover/new gasket

Disassemble Stock Heads

Tape off engine

Measure for Flycuts

Flycut .080" I and .060" E

Phase 2

Disassemble TEA Heads

Take TEA heads to machine shop for .020" mill for 58cc and my compression target

Remove one layer of stock head gasket (equiv .040")

Measure pushrod length with TEA heads + old gaskets

Order pushrods (all 16 may require different lengths with the short travel Johnsons)

Reassemble TEA heads

Install torque converter + fill with trans fluid

Remove stock flexplate

Install new flexplate

Install Temp Sender unit into Trans oil pan

Bolt Transmission to engine (outside of car - easier)

Phase 3

Install pushrods w/assembly lube

Install new Cometic gaskets w/copper spray

Install TEA heads

Install ARP Bolts + torque to spec w/Moly lube

Install Lunati Rockers w/assembly lube

Clean valve covers

Reinstall valve covers w/new GM gaskets

Install NGK spark plugs

Install ATI Balancer

Install new waterpump + 160 degree thermostat

Remove old engine mounts

Install new prothane engine mounts (outside of car still)

Install new LS6 PCV cover valley

Install new Engine Oil Sender (previous was destroyed)

Install new Knock Sensors (look rough)

Phase 4

Remove old catback exhaust (cut to remove if I can't get the axle to drop enough)

Remove LCAs and PHB

Remove gas tank

Remove old fuel pump

Install Racetronix fuel pump

Install Racetronix wiring harness upgrade

Reinstall gas tank

Install new LCAs and PHB and PHB Relo Kit

Phase 5

Install longblock + trans back into car

Reinstall trans dipstick and oil dipstick

Reinstall driveshaft

Reinstall Torque Arm and mount

Install fuel rails and injectors to FAST intake manifold

Install FAST intake manifold assembly

Install stock ignition coils + plug wires

Reinstall all electical connectors

Reinstall all vacuum lines inc brake booster

Reconnect fuel line

Reinstall starter

Install Kooks headers

Phase 6

Install Kooks True Dual Exhaust

Reinstall Alternator

Reinstall A/C compressor

Reinstall PS Pump + refill with fluid

Reinstall PS cooler

Reinstall TCS lines and throttle cable

Install new Goodyear belts

Install new BeCool radiator + top off with fluid

Reinstall GM radiator lines

Install new B&M trans cooler

Connect flex lines to transmission

Run Temp line from trans to inside of car

Install new FAST Throttle-Body

Install coolant TB bypass (yeah, never did - car was bone stock when I gutted it)

Install PCV Catch Can

Reinstall engine PCM

Phase 7

Doublecheck everything

Remove all tools from car

Put break in oil into the car w/new filter

Top off transmission fluid

Put on stock airbridge + MAF + cut inlet for 102 TB

(New lid + MAF will be installed after Geoff dynotunes)

Prime oil by disconnecting fuel/spark and turning over for several seconds

Reconnect fuel/spark

Start car

Top off Coolant

Add R134a to A/C

Drive around the block to get to operating temp

Check for vacuum leaks

Check for trouble codes

Call Geoff and schedule dyno tune

Hope to have done by November 1. And I will document each phase.

But, I sat down this evening to plan out my weekends and some free time I have over the next few weeks to attack this build in a phased approach. And yes, I'm a project manager by trade, so this is how I tackle an undertaking of this magnitude:

Phase 1

Clean carbon buildup off of Pistons (still dealing with that)

Clear Cylinder Head Bolt Holes

Chase Threads Clean

Remove Harmonic Balancer (left it on - now I have to break it free on the engine stand)

Remove front cover and oil pump/timing chain

Remove old camshaft

Install new camshaft w/assembly lube

Install new oil pump/timing chain

Install New Cam plate torque to specs

Degree Camshaft w/degree wheel

Install front cover/new gasket

Disassemble Stock Heads

Tape off engine

Measure for Flycuts

Flycut .080" I and .060" E

Phase 2

Disassemble TEA Heads

Take TEA heads to machine shop for .020" mill for 58cc and my compression target

Remove one layer of stock head gasket (equiv .040")

Measure pushrod length with TEA heads + old gaskets

Order pushrods (all 16 may require different lengths with the short travel Johnsons)

Reassemble TEA heads

Install torque converter + fill with trans fluid

Remove stock flexplate

Install new flexplate

Install Temp Sender unit into Trans oil pan

Bolt Transmission to engine (outside of car - easier)

Phase 3

Install pushrods w/assembly lube

Install new Cometic gaskets w/copper spray

Install TEA heads

Install ARP Bolts + torque to spec w/Moly lube

Install Lunati Rockers w/assembly lube

Clean valve covers

Reinstall valve covers w/new GM gaskets

Install NGK spark plugs

Install ATI Balancer

Install new waterpump + 160 degree thermostat

Remove old engine mounts

Install new prothane engine mounts (outside of car still)

Install new LS6 PCV cover valley

Install new Engine Oil Sender (previous was destroyed)

Install new Knock Sensors (look rough)

Phase 4

Remove old catback exhaust (cut to remove if I can't get the axle to drop enough)

Remove LCAs and PHB

Remove gas tank

Remove old fuel pump

Install Racetronix fuel pump

Install Racetronix wiring harness upgrade

Reinstall gas tank

Install new LCAs and PHB and PHB Relo Kit

Phase 5

Install longblock + trans back into car

Reinstall trans dipstick and oil dipstick

Reinstall driveshaft

Reinstall Torque Arm and mount

Install fuel rails and injectors to FAST intake manifold

Install FAST intake manifold assembly

Install stock ignition coils + plug wires

Reinstall all electical connectors

Reinstall all vacuum lines inc brake booster

Reconnect fuel line

Reinstall starter

Install Kooks headers

Phase 6

Install Kooks True Dual Exhaust

Reinstall Alternator

Reinstall A/C compressor

Reinstall PS Pump + refill with fluid

Reinstall PS cooler

Reinstall TCS lines and throttle cable

Install new Goodyear belts

Install new BeCool radiator + top off with fluid

Reinstall GM radiator lines

Install new B&M trans cooler

Connect flex lines to transmission

Run Temp line from trans to inside of car

Install new FAST Throttle-Body

Install coolant TB bypass (yeah, never did - car was bone stock when I gutted it)

Install PCV Catch Can

Reinstall engine PCM

Phase 7

Doublecheck everything

Remove all tools from car

Put break in oil into the car w/new filter

Top off transmission fluid

Put on stock airbridge + MAF + cut inlet for 102 TB

(New lid + MAF will be installed after Geoff dynotunes)

Prime oil by disconnecting fuel/spark and turning over for several seconds

Reconnect fuel/spark

Start car

Top off Coolant

Add R134a to A/C

Drive around the block to get to operating temp

Check for vacuum leaks

Check for trouble codes

Call Geoff and schedule dyno tune

Hope to have done by November 1. And I will document each phase.