408 Build Thread (New numbers)

#21

I'm going with a 408 as well but I'm going with a -20 dish wiseco piston, k1 rods w/ARP 2000 rods bolts and a k1 crankshaft. I intend to run a GT91 turbo but have no clue of what cam and heads to use. I have some 243 heads and an ls2 intake but am not sure if they would be good for the 408. Any suggestions? I'm gonna run a 4l80 and a PTC 3500 converter. I also have an l92 vic Jr EFI intake and a carb intake.

This will be going into a 92 Mustang coupe with a 12 point cage that's been mini tubbed...

I should be a nice project....

Manny

This will be going into a 92 Mustang coupe with a 12 point cage that's been mini tubbed...

I should be a nice project....

Manny

#24

TECH Regular

iTrader: (7)

If you dont mind saying, how much did all the machine work cost you? Because i am trying to plan out a 408 build myself and cost comparing between buying a junkyard lq motor or just go ahead and get a short block from TSP or Livernois. Machine shop costs could be the deciding factor and like you i will probably run l92 heads and stay NA. Interested to see your numbers.

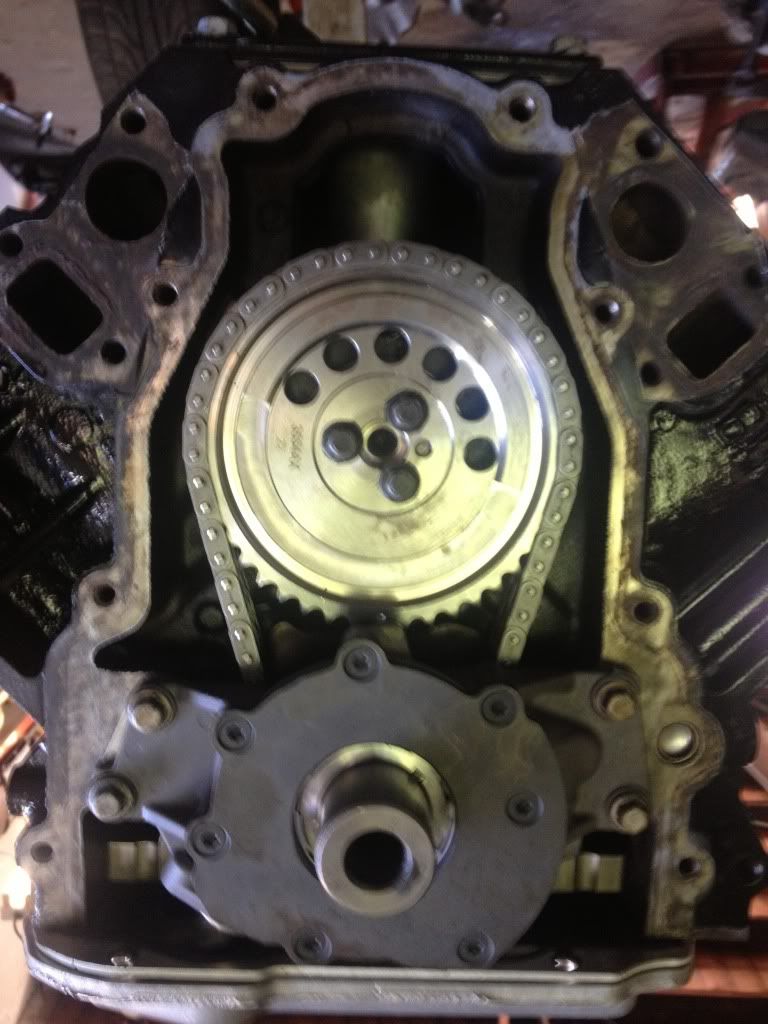

Boring The Block

Decking The Block

Balancing The Rotating Assembly

Line Bore the Main Journals

Instal Cam Bearins

Complete Engine Assembly

Degree The Cam

From my research it is about a wash between the two. Plus I was able to buy my parts as I was able too. It seemed everytime I started saving hoping to by the new wngine something else would come up. This way i was able to buy my parts as the funds were available.

#28

#30

So i have FLP 1.6" stepped headers that came with the car and a 2.5" TD exhaust. I was gonna reuse it and change it out later. But now im thinking i should just shell out the extra $1,000 now and get TSP 1 7/8" headers and the Rumbler X pipe. What do you guys think?

#34

I put my engine back in the cradle for the rest of the assembly. I then put the clutch on, and the trans soon followed. Heres a picture of the Monster Stage 2 clutch:

Also i recieved all my exhaust system except for the mufflers. It is TSP 1 7/8" headers:

And ebay stainless steel 3" true duals:

Shooting to get this bad boy running by friday, and have it dyno tuned saturday. If all goes well ill have the numbers posted sunday.

Also i recieved all my exhaust system except for the mufflers. It is TSP 1 7/8" headers:

And ebay stainless steel 3" true duals:

Shooting to get this bad boy running by friday, and have it dyno tuned saturday. If all goes well ill have the numbers posted sunday.

#35

TECH Apprentice

iTrader: (5)

Join Date: Nov 2004

Location: Metro Detroit

Posts: 309

Likes: 0

Received 0 Likes

on

0 Posts

Awesome man, really coming together. Im running the same clutch and headers as you. It will be interesting to see how our builds compair on the dyno. We are both running a custom cam pretty close in lift and duration, I stuck with the cathedral port and you went rectangular. Good luck this weekend.

#36

Well, I think i just hit a major roadblock. My machinist gave me a head to measure pushrods with, and i was turning the crank over to get the cam on the base circle. And at this one spot it got incredibly hard to turn, and it felt like something was hitting and scraping. Did some research and im pretty sure its the #1 rod bolt hitting the oil pan. My engine is currently in the cradle with the trans attached. So now i have to figure out how to get that pan off. Then clearance it, and ill probably have to weld a plate on the other side, idk it feels like it hits pretty hard.

#37

Teching In

iTrader: (1)

Join Date: Aug 2012

Location: >>>Texas Boy thru and thru<<<

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Well, I think i just hit a major roadblock. My machinist gave me a head to measure pushrods with, and i was turning the crank over to get the cam on the base circle. And at this one spot it got incredibly hard to turn, and it felt like something was hitting and scraping. Did some research and im pretty sure its the #1 rod bolt hitting the oil pan. My engine is currently in the cradle with the trans attached. So now i have to figure out how to get that pan off. Then clearance it, and ill probably have to weld a plate on the other side, idk it feels like it hits pretty hard.

#38

Hey man. Been following your build and a few others... Contemplating my own 408 build for my 1500HD. Just read your little issue with the windage tray... Did you know that SLP makes a cool spacer kit for this? SLP Part #12510. I have also seen others just use some hex nuts from Home Depot. This is why its always a good idea to mock it up first!.. Anyway, great build you got going there bud!

#39

Also just measured for pushrods. I got that 7.29 pushrods will give me about .045" of preload on the lunati link bar lifters without the head gasket. The head gasket is .06" compressed so i got 7.35" 3/8" pushrods from summit. Should be here in a couple days.

#40

Teching In

iTrader: (1)

Join Date: Aug 2012

Location: >>>Texas Boy thru and thru<<<

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

Well crap... figured it would hit the oil deflection tray long before the pan... Just one more thing to think about before I do my build... Ill step back into the shadows.. mouth shut and eyes wide open. If you get a chance would you mind posting a pic where it is hitting?