5.3 sonic testing results - attempting a 4" bore

#1

I'm in the middle of the new build for the Gto, and were building a completely new engine. I originally was planing a 5.3 turbo build, but have since decided on a max effort N/A setup 6.0.

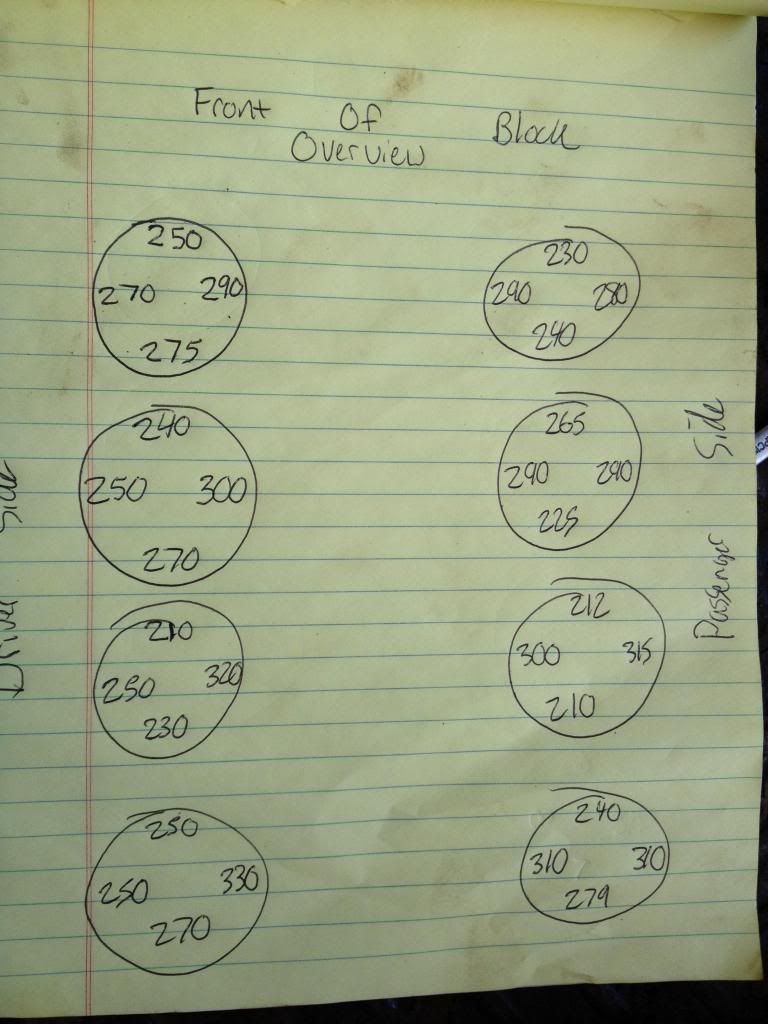

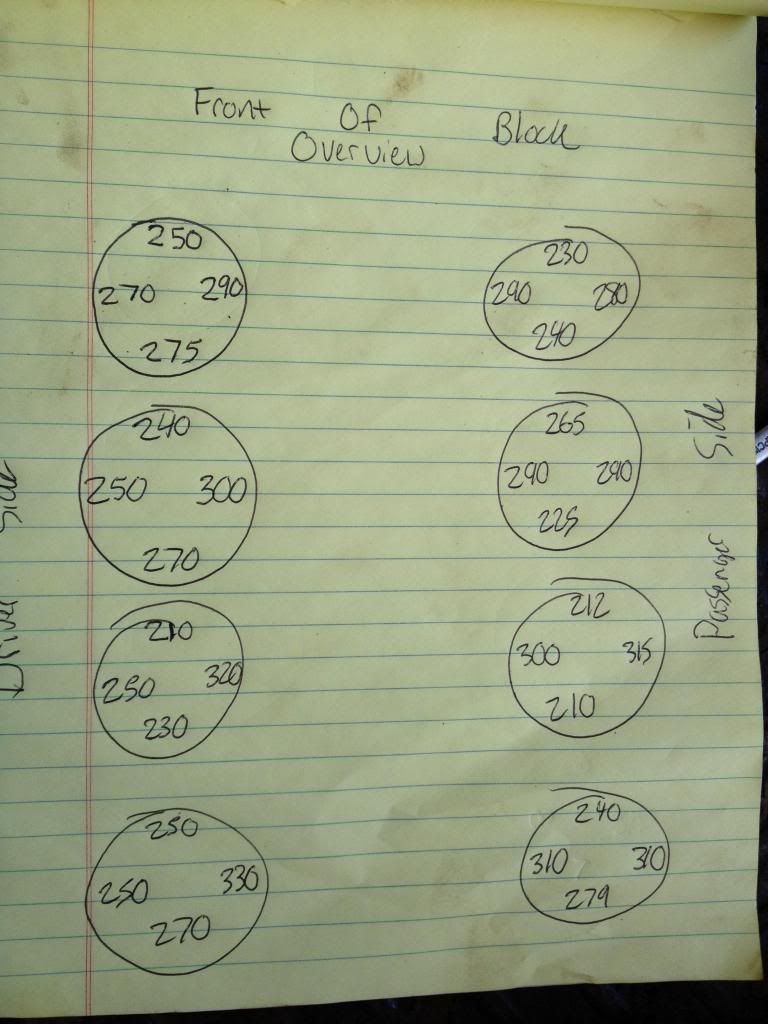

I work at a well drilling company and we have precision instruments to measure well casings thickness. I used the cast calibration, and tested all 8 cylinders, ran the instrument over every inch of that cylinder and recorded the thinnest # for each "side"

In a week I will be having the block professionally sonic tested to compare with my results. As a test method I checked a few places on the block with both the calipers and this wall thickness tester. The calipers showed .010 THICKER than the tester did, so take that for what it's worth.

These are my results, please excuse my poorly drawn paper. Ill be attempting a bore from 3.780 to 4.00.

I work at a well drilling company and we have precision instruments to measure well casings thickness. I used the cast calibration, and tested all 8 cylinders, ran the instrument over every inch of that cylinder and recorded the thinnest # for each "side"

In a week I will be having the block professionally sonic tested to compare with my results. As a test method I checked a few places on the block with both the calipers and this wall thickness tester. The calipers showed .010 THICKER than the tester did, so take that for what it's worth.

These are my results, please excuse my poorly drawn paper. Ill be attempting a bore from 3.780 to 4.00.

#4

I'm excited to get this underway. I splurged on this new build.

Level2 Tick trans rebuild

McLeod rst twin disk

Vic jr single plane

New king bearings

Ported 243's

Max effort FTI cam

I'm debating between Childs & Albert steel rings with Napier seconds or the same total seals

Arp rod bolts

All fresh machine work etc

Level2 Tick trans rebuild

McLeod rst twin disk

Vic jr single plane

New king bearings

Ported 243's

Max effort FTI cam

I'm debating between Childs & Albert steel rings with Napier seconds or the same total seals

Arp rod bolts

All fresh machine work etc

#7

Based on my above findings, the thinnest point of the thinnest cylinder is .140 wall thickness. Little thin, but for nA I think it will live....

Anyone out there attempted this yet? I want first hand experience, not hearsay.

Trending Topics

#9

TECH Junkie

iTrader: (18)

Ed has my unwavering business. My last cam was an absolute powerhouse from 2,000 all the way to 7,000 and I will be sending all my business his way! Couldn't be happier.

Based on my above findings, the thinnest point of the thinnest cylinder is .140 wall thickness. Little thin, but for nA I think it will live....

Anyone out there attempted this yet? I want first hand experience, not hearsay.

Based on my above findings, the thinnest point of the thinnest cylinder is .140 wall thickness. Little thin, but for nA I think it will live....

Anyone out there attempted this yet? I want first hand experience, not hearsay.

#10

TECH Junkie

iTrader: (5)

Based on my above findings, the thinnest point of the thinnest cylinder is .140 wall thickness. Little thin, but for nA I think it will live....

My figures came out at .100 wall thickness in some places. That seems too thin.

#14

8 Second Club

iTrader: (3)

For all the trouble, and uncertainty after boring, I think it would be cheaper to just get an LQ4/9 block and be done with it. Or just stop at the LS1 bore size.

Even though you have measured the thickness, what happens if you find a casting flaw and end up with a pin hole? That either you can't see, or find on the last hole. You still get to pay for the bore job.

If it were totally safe to do this, I would think it's being done all the time, and we don't seem to hear that.

My dollar six eighty worth of thoughts.

Ron

Even though you have measured the thickness, what happens if you find a casting flaw and end up with a pin hole? That either you can't see, or find on the last hole. You still get to pay for the bore job.

If it were totally safe to do this, I would think it's being done all the time, and we don't seem to hear that.

My dollar six eighty worth of thoughts.

Ron

#17

11 Second Club

iTrader: (2)

I would definitely stop at 3.908 and be happy with a reliable 347 as opposed

to trying to squeeze it out to a 364. If you were just doing a stock like idle to

5000 type towing motor it would live but lets face it you probably have 7000

rpm nasty on the mind and those thin *** cylinder walls WILL be deflecting !!

Even if ls2/3 liners are only .080" thick they are still supported by aluminum

on the backside to reduce/diminish bore deflection. Not too long ago I read

an article where Joe Sherman (father of the GEN I 383) found that an after

market block (dart or world) was worth nearly 20 horsepower over a well

machined 35 year old 010 GM block. Obviously the old block with 3 decades

worth of coolant porosity and rot thinned out the cylinders in addition to the

.030" bore. He atributed the power increase to the thickness and casting

rigidity of the aftermarket block which holds the cylinder barrels from defl-

ection as the piston travels the bore. Not only is ring seal improved (less

flutter) but oil control is improved (less consumption)

to trying to squeeze it out to a 364. If you were just doing a stock like idle to

5000 type towing motor it would live but lets face it you probably have 7000

rpm nasty on the mind and those thin *** cylinder walls WILL be deflecting !!

Even if ls2/3 liners are only .080" thick they are still supported by aluminum

on the backside to reduce/diminish bore deflection. Not too long ago I read

an article where Joe Sherman (father of the GEN I 383) found that an after

market block (dart or world) was worth nearly 20 horsepower over a well

machined 35 year old 010 GM block. Obviously the old block with 3 decades

worth of coolant porosity and rot thinned out the cylinders in addition to the

.030" bore. He atributed the power increase to the thickness and casting

rigidity of the aftermarket block which holds the cylinder barrels from defl-

ection as the piston travels the bore. Not only is ring seal improved (less

flutter) but oil control is improved (less consumption)