Money we'll spent build?

#21

TECH Veteran

iTrader: (14)

Forgive me op but I'm just not sure I understand the logic here. Spinning any of these engines to 7k is going to require a little bit of bottom end work. I get you want a fun high revving engine but theres no reason you cant do that with an lq9. In fact the lq9 shares the same stroke as the 5.3 so revving the 2 engines shouldnt be all that different.

I'd be shocked if a 4.8 got better mpg than the lq9. The lq9 will be working much less to drive the vehicle and not only that but to make your 400 hp the 4.8/5.3 is gonna need a cam and head work which will suck more fuel. An lq9 with an ls6 cam and an ls6 intake with bolt ons will easily top 400hp, will sound stock, deliver excellent fuel economy, be 100k reliable and will carry power to 6600. You could even mill the heads a tad to get 11:1, make more power and get a little better mpg.

Also keep in mind you say stock lq9's will tear up a 4l60, but if you cam and do work to get a 4.8 to that power level you're going to be knocking on the same door. In this case you could run a stock 4l60 till it pops which may be never or just save for a built one. Either route you will need it eventually.

I just think we're having a hard time understanding why you would build a 4.8 when the 6.0 is cheaper in the long run and will make more streetable reliable power.

I'd be shocked if a 4.8 got better mpg than the lq9. The lq9 will be working much less to drive the vehicle and not only that but to make your 400 hp the 4.8/5.3 is gonna need a cam and head work which will suck more fuel. An lq9 with an ls6 cam and an ls6 intake with bolt ons will easily top 400hp, will sound stock, deliver excellent fuel economy, be 100k reliable and will carry power to 6600. You could even mill the heads a tad to get 11:1, make more power and get a little better mpg.

Also keep in mind you say stock lq9's will tear up a 4l60, but if you cam and do work to get a 4.8 to that power level you're going to be knocking on the same door. In this case you could run a stock 4l60 till it pops which may be never or just save for a built one. Either route you will need it eventually.

I just think we're having a hard time understanding why you would build a 4.8 when the 6.0 is cheaper in the long run and will make more streetable reliable power.

#22

400 wheel horsepower in a 5.3 is going to take great heads and a big cam

400 fwhp is a midsize cam, and decent heads.

You need to have a realistic expectation on what you want out of it. A 5.3 with a big *** cam probably won't drive as well as you want it.

A 6.0 would be a mild build, still have good street manners, and.should get the mpg you want

400 fwhp is a midsize cam, and decent heads.

You need to have a realistic expectation on what you want out of it. A 5.3 with a big *** cam probably won't drive as well as you want it.

A 6.0 would be a mild build, still have good street manners, and.should get the mpg you want

#23

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

400 crank is a ball park, 385 is acceptable, 405 a bonus! I've read 4l60 crap out at about 450ftlbs a smaller bore engine is going to keep torque down. I don't want to cam the ever living crap out of it, and you can keep you mother thumpers there a pos IMO.

But why do a lot of people run a Chevy spec cam? Are there profiles just that good or does it have to do with the e.f.i. Thing?

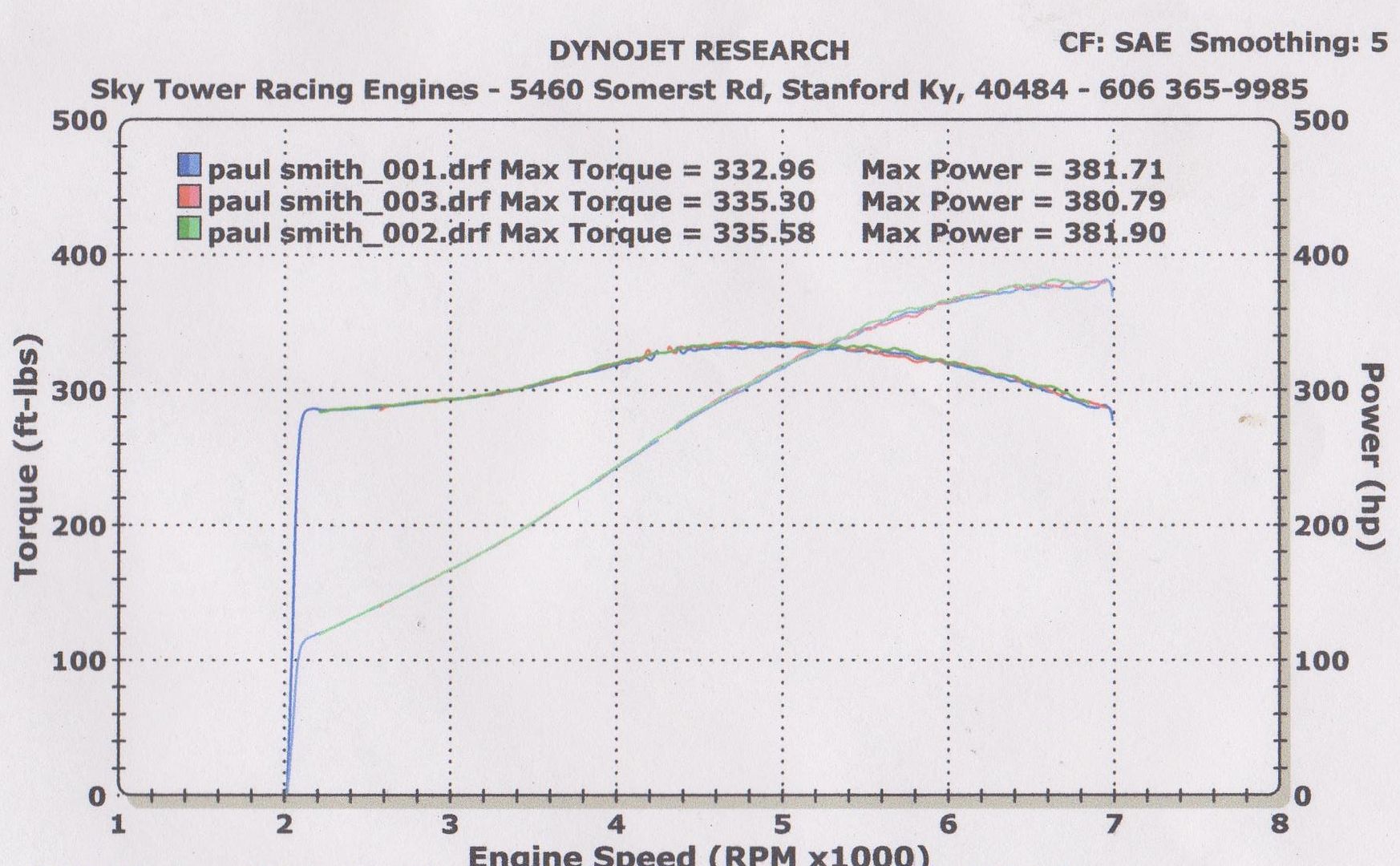

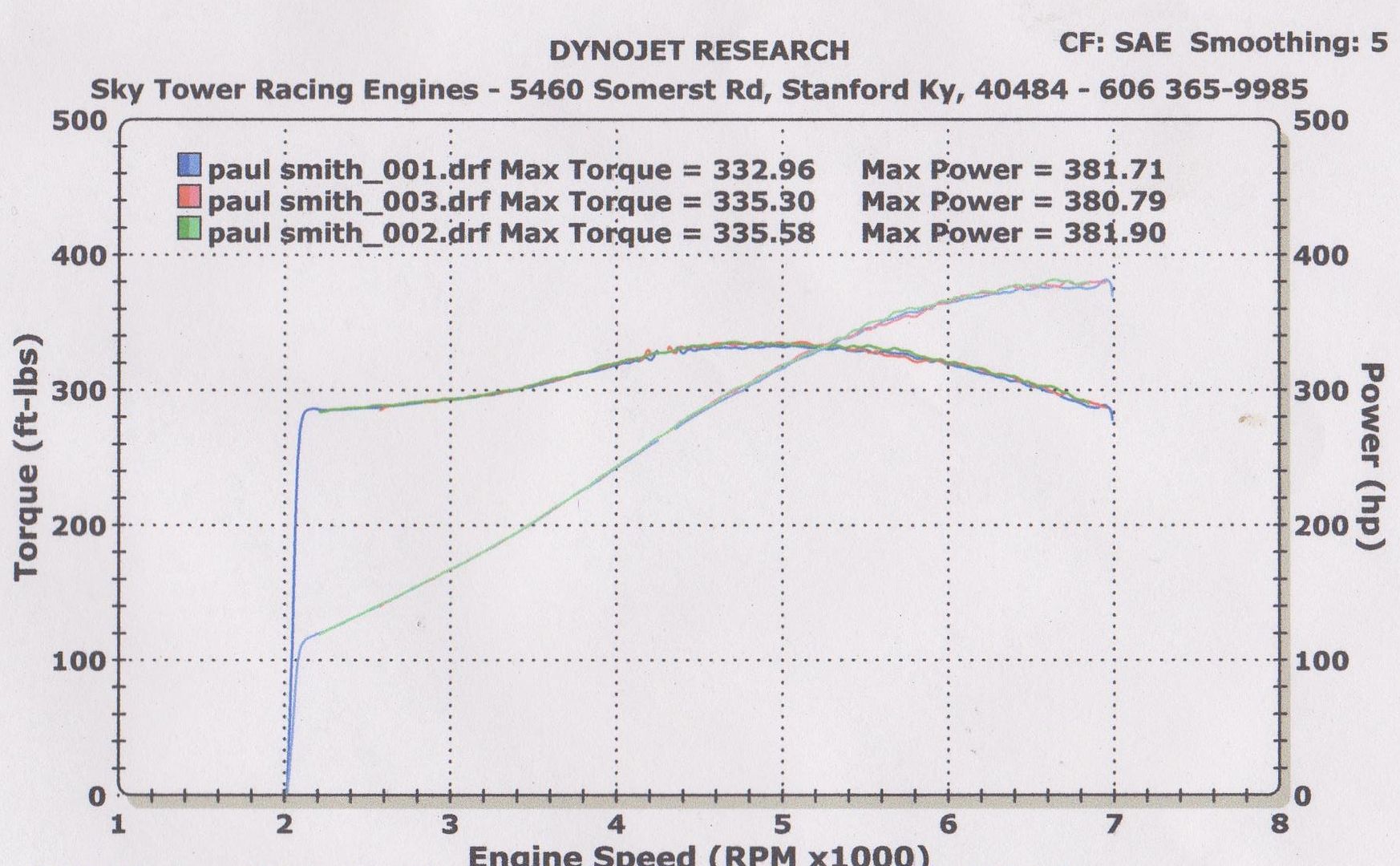

Here is a Dyno graph I found that fieroguru did with his l33. Quite amazing 382 ground horsepower(running through a 6spd) but yet impressive

You can find the build here https://ls1tech.com/forums/conversio...ed-swap-8.html

And for 7000, is it that much on these motors to achieve they factory spin 6000, with some hard push rods nice lifters good valves and rockers why not? It's not going to live there just make the occasional trip.

And seriously if I'm not happy with it, through a hair dryer at it and be done

But why do a lot of people run a Chevy spec cam? Are there profiles just that good or does it have to do with the e.f.i. Thing?

Here is a Dyno graph I found that fieroguru did with his l33. Quite amazing 382 ground horsepower(running through a 6spd) but yet impressive

You can find the build here https://ls1tech.com/forums/conversio...ed-swap-8.html

And for 7000, is it that much on these motors to achieve they factory spin 6000, with some hard push rods nice lifters good valves and rockers why not? It's not going to live there just make the occasional trip.

And seriously if I'm not happy with it, through a hair dryer at it and be done

#24

TECH Veteran

iTrader: (14)

That graph seems to be a little happy imo. 380whp is a tad high most 5.3's I've seen with cams are right around 340-350. A 224/232 is a pretty healthy cam on a 5.3 and would be even bigger in a 4.8.

The reason 7k is an issue is because of the rod bolts. An upgraded valvetrain can hold 7k but the rod bolts are sketchy past 6800 particularly 00-down. A set of katechs would fix that or Arp's but rods should be re-sized when replacing the bolts.

The whole point is that a 6.0 would make that same graph with another 20 ft lbs of torque (so not that much more) but would do it with a stock gm ls6 cam and a stock valvetrain.

Not really sure by what you mean on stock cam chevy specs? No one uses stock cams when making big power. I just suggested the ls6 cam in an lq9 as t would easily get you to your power goal with oem reliability and it would sound stock.

The reason 7k is an issue is because of the rod bolts. An upgraded valvetrain can hold 7k but the rod bolts are sketchy past 6800 particularly 00-down. A set of katechs would fix that or Arp's but rods should be re-sized when replacing the bolts.

The whole point is that a 6.0 would make that same graph with another 20 ft lbs of torque (so not that much more) but would do it with a stock gm ls6 cam and a stock valvetrain.

Not really sure by what you mean on stock cam chevy specs? No one uses stock cams when making big power. I just suggested the ls6 cam in an lq9 as t would easily get you to your power goal with oem reliability and it would sound stock.

#25

TECH Senior Member

iTrader: (35)

400 crank is a ball park, 385 is acceptable, 405 a bonus! I've read 4l60 crap out at about 450ftlbs a smaller bore engine is going to keep torque down. I don't want to cam the ever living crap out of it, and you can keep you mother thumpers there a pos IMO.

And for 7000, is it that much on these motors to achieve they factory spin 6000, with some hard push rods nice lifters good valves and rockers why not? It's not going to live there just make the occasional trip.

And seriously if I'm not happy with it, through a hair dryer at it and be done

And for 7000, is it that much on these motors to achieve they factory spin 6000, with some hard push rods nice lifters good valves and rockers why not? It's not going to live there just make the occasional trip.

And seriously if I'm not happy with it, through a hair dryer at it and be done

http://www.ws6project.com/user_stor/...-lift-212-218/

#26

TECH Veteran

iTrader: (14)

I agree for the most part especially about the 7k thing. However I think the op is going to need a hotter cam than that to get his 340whp or 400 at the crank. The displacement and small valve heads on it will hold him back. I think something in the mid 220's duration would get him there

#27

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

Okay, if I bought the right parts and paired them together, put 10-12 into this and made it happen it would be cool... A new truck will cost me 20k if I build this for ten money we'll spent.... Every thing blows up. Has some one pushed one hard made it last? If so where's the build thread.

#28

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

I'm in the planning stages of a project, I do not want to waste money and buy the best, I want something cool, the goals I've set are really kinda reasonable, 400 hp 20+mpg and a 100k. It needs to be a driver, hand the keys to grandma. That's what a driver is.

Every thing starts with a plan not a, "well now what do I do"

I don't know everything but I'm trying to find reading material on, but every one raps off the conclusion I'm on a "budget"

The budgets not 500 or $100,000 it's money well spent, I could have bought a custom 9 inch rear for some coin, or cut up a 8.8. Worth the money to save, I could have made my own fuel tank but hey, people make money doing that and I don't want to die. Money well spent.

Every thing starts with a plan not a, "well now what do I do"

I don't know everything but I'm trying to find reading material on, but every one raps off the conclusion I'm on a "budget"

The budgets not 500 or $100,000 it's money well spent, I could have bought a custom 9 inch rear for some coin, or cut up a 8.8. Worth the money to save, I could have made my own fuel tank but hey, people make money doing that and I don't want to die. Money well spent.

#29

TECH Veteran

iTrader: (14)

Ok then if I wa building this and I had to use a 5.3 block my build would be the following.. You can go with an iron or aluminum 5.3 personally i'd go aluminum to keep weight down but the block are a tad more expensive.

First thing is a set of decent heads. I would Give AI a call and have them port the 5.3 heads to 218cc which would not only give a solid compression boost but will net you a solid 40hp more

Next I would call up katech and order a set of their rod bolts and replace the stockers on the 5.3. This will allow you to spin to 7k without a rod letting go. I would also order a set of 11/32 pushrods necked to 5/16 at the ends. Hardened pushrods will still flex SOMEWHAT at high rpm so this is why I'd go with the 11/32 over standard 5/16.

Finally I would give one of our cam sponsors on here a call and tell them what your goals are and have them spec you a cam with a good valve spring to match. For your goals I would expect something in the 218/220 range on .580 lift with a 114ish lsa to keep the power carrying at 7k.

That should get you about 400 or a tad more fwhp from the 5.3. Will you get your mpg? Most likely. Will it be 100k reliable? With proper maintenance and no 7k redline dancing everyday, maybe yes.

Now is it the most cost effective easy way to get that power? No sorry man cubes will always make more power cheaper and will do it while getting the same or better mpg as this build here, simply because you wont need ported heads and a cam to get you there...

First thing is a set of decent heads. I would Give AI a call and have them port the 5.3 heads to 218cc which would not only give a solid compression boost but will net you a solid 40hp more

Next I would call up katech and order a set of their rod bolts and replace the stockers on the 5.3. This will allow you to spin to 7k without a rod letting go. I would also order a set of 11/32 pushrods necked to 5/16 at the ends. Hardened pushrods will still flex SOMEWHAT at high rpm so this is why I'd go with the 11/32 over standard 5/16.

Finally I would give one of our cam sponsors on here a call and tell them what your goals are and have them spec you a cam with a good valve spring to match. For your goals I would expect something in the 218/220 range on .580 lift with a 114ish lsa to keep the power carrying at 7k.

That should get you about 400 or a tad more fwhp from the 5.3. Will you get your mpg? Most likely. Will it be 100k reliable? With proper maintenance and no 7k redline dancing everyday, maybe yes.

Now is it the most cost effective easy way to get that power? No sorry man cubes will always make more power cheaper and will do it while getting the same or better mpg as this build here, simply because you wont need ported heads and a cam to get you there...

#30

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

I enjoy the build of a "hot rod" but I'm no idiot all of my goals are reasonable individually. And I think with the right combo and research it can be done within reason, and how cool would it be to do it with as little displacement as possible. It might be to taxing for a 4.8 so I'm open to 5.3's

But when I see these 100k turbo cars testing bottom ends running 9 with a minimum budget makes me wonder what can I do with a motor you think is useless unless boosted.

But when I see these 100k turbo cars testing bottom ends running 9 with a minimum budget makes me wonder what can I do with a motor you think is useless unless boosted.

#31

http://www.hotrod.com/techarticles/h...g_bang_theory/

I'm sure everyone on here has read this by now. But just read the 3rd paragraph. Tea did a 1.5 port job, fast 102 setup, comp 228/230 cam, comp lifters =451 hp. Minus a little for a diy job truck head, minus a little hp for your truck intake, and use that cam (or close). Keep stock truck injectors, you won't max them out. Maybe close but they're easy to change on down the road if needed. Use ls7 lifters, save some money. They'll do great for what you want. That cam isn't that big of a cam. Throw keys to Gammy and have her go get some bread and milk. I bet she brings your truck back with a smile and 1/4" less treads on the back

I'm sure everyone on here has read this by now. But just read the 3rd paragraph. Tea did a 1.5 port job, fast 102 setup, comp 228/230 cam, comp lifters =451 hp. Minus a little for a diy job truck head, minus a little hp for your truck intake, and use that cam (or close). Keep stock truck injectors, you won't max them out. Maybe close but they're easy to change on down the road if needed. Use ls7 lifters, save some money. They'll do great for what you want. That cam isn't that big of a cam. Throw keys to Gammy and have her go get some bread and milk. I bet she brings your truck back with a smile and 1/4" less treads on the back

#32

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

http://www.hotrod.com/techarticles/h...g_bang_theory/

I'm sure everyone on here has read this by now. But just read the 3rd paragraph. Tea did a 1.5 port job, fast 102 setup, comp 228/230 cam, comp lifters =451 hp. Minus a little for a diy job truck head, minus a little hp for your truck intake, and use that cam (or close). Keep stock truck injectors, you won't max them out. Maybe close but they're easy to change on down the road if needed. Use ls7 lifters, save some money. They'll do great for what you want. That cam isn't that big of a cam. Throw keys to Gammy and have her go get some bread and milk. I bet she brings your truck back with a smile and 1/4" less treads on the back

I'm sure everyone on here has read this by now. But just read the 3rd paragraph. Tea did a 1.5 port job, fast 102 setup, comp 228/230 cam, comp lifters =451 hp. Minus a little for a diy job truck head, minus a little hp for your truck intake, and use that cam (or close). Keep stock truck injectors, you won't max them out. Maybe close but they're easy to change on down the road if needed. Use ls7 lifters, save some money. They'll do great for what you want. That cam isn't that big of a cam. Throw keys to Gammy and have her go get some bread and milk. I bet she brings your truck back with a smile and 1/4" less treads on the back

I like how your on board for my idea, take the time and effort you as if your building a high horse motor and scale down, make it efficient project "modern mouse" squeezed 644 out of a 5.3. I have been looking for the threshold. Every article I've read trying to kill these motors have been relatively unsuccessful. Even under stupid boost.

Although not being any thing impressive number wise it will be impressive for sure.

Has any one blew one up?

#34

Exactly.. a 4.8 with a medium cam, port work/ls1 intake valves installed, good intake and headers. Your goals accomplished.

Youtube showed a guy blowing a 5.3 up on a dyno around 1,000rwhp. I never found out what exactly happened.

Youtube showed a guy blowing a 5.3 up on a dyno around 1,000rwhp. I never found out what exactly happened.

#35

11 Second Club

iTrader: (1)

I enjoy the build of a "hot rod" but I'm no idiot all of my goals are reasonable individually. And I think with the right combo and research it can be done within reason, and how cool would it be to do it with as little displacement as possible. It might be to taxing for a 4.8 so I'm open to 5.3's

But when I see these 100k turbo cars testing bottom ends running 9 with a minimum budget makes me wonder what can I do with a motor you think is useless unless boosted.

But when I see these 100k turbo cars testing bottom ends running 9 with a minimum budget makes me wonder what can I do with a motor you think is useless unless boosted.

One of the most stressful things that happens to an engine is the piston coming to TDC on the exhaust stroke then getting yanked back down pulling vacuum on the intake stroke. Instead of that solid mass of a connecting rod to push on you are relying on the connecting rod bolts which endure tremendous tension at that moment. I saw a writeup where someone did the math for an LT1 and I think it was at 6500rpm with a stock rotating assembly the rod bolts were subject to 2500lbs of tension without accounting for any vacuum above the piston. Rod bolts can allow the cap to wiggle when stressed and that starts to deform the bearing which gets eaten even if the rodbolt doesn't actually break. Smaller displacement engines are happier to rev because liston weight and stroke length are the factors that determine how much stress is on the rodbolts.

Boost HP properly tuned is easier to live with the biggest risk in boost HP is tuning issues causing detonation or in extreme cases butting the ring gap.

I believe HotRod also specifically states that while that held up surprisingly well they don't expect it to live truly long term like that.

#36

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

If the video was of a camero at a Dyno compition I be alive they state that that engine was a nitrous ran for two years and then boosted, I think he tried to be a little aggressive on timing and a rod went.

#37

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

Turbos can be used to keep rpm down.

One of the most stressful things that happens to an engine is the piston coming to TDC on the exhaust stroke then getting yanked back down pulling vacuum on the intake stroke. Instead of that solid mass of a connecting rod to push on you are relying on the connecting rod bolts which endure tremendous tension at that moment. I saw a writeup where someone did the math for an LT1 and I think it was at 6500rpm with a stock rotating assembly the rod bolts were subject to 2500lbs of tension without accounting for any vacuum above the piston. Rod bolts can allow the cap to wiggle when stressed and that starts to deform the bearing which gets eaten even if the rodbolt doesn't actually break. Smaller displacement engines are happier to rev because liston weight and stroke length are the factors that determine how much stress is on the rodbolts.

Boost HP properly tuned is easier to live with the biggest risk in boost HP is tuning issues causing detonation or in extreme cases butting the ring gap.

I believe HotRod also specifically states that while that held up surprisingly well they don't expect it to live truly long term like that.

One of the most stressful things that happens to an engine is the piston coming to TDC on the exhaust stroke then getting yanked back down pulling vacuum on the intake stroke. Instead of that solid mass of a connecting rod to push on you are relying on the connecting rod bolts which endure tremendous tension at that moment. I saw a writeup where someone did the math for an LT1 and I think it was at 6500rpm with a stock rotating assembly the rod bolts were subject to 2500lbs of tension without accounting for any vacuum above the piston. Rod bolts can allow the cap to wiggle when stressed and that starts to deform the bearing which gets eaten even if the rodbolt doesn't actually break. Smaller displacement engines are happier to rev because liston weight and stroke length are the factors that determine how much stress is on the rodbolts.

Boost HP properly tuned is easier to live with the biggest risk in boost HP is tuning issues causing detonation or in extreme cases butting the ring gap.

I believe HotRod also specifically states that while that held up surprisingly well they don't expect it to live truly long term like that.

It's because of slower piston speeds they are safe with boost allows you to control timing better and not get det.

#39

Teching In

Thread Starter

Join Date: Dec 2013

Location: Everett wa

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

for any one who cares got a new truck different project routehttps://ls1tech.com/forums/generation-iii-internal-engine/1721521-got-new-truck-now-what.html#post18166496